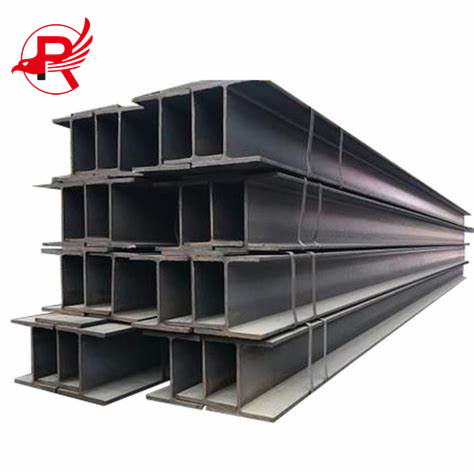

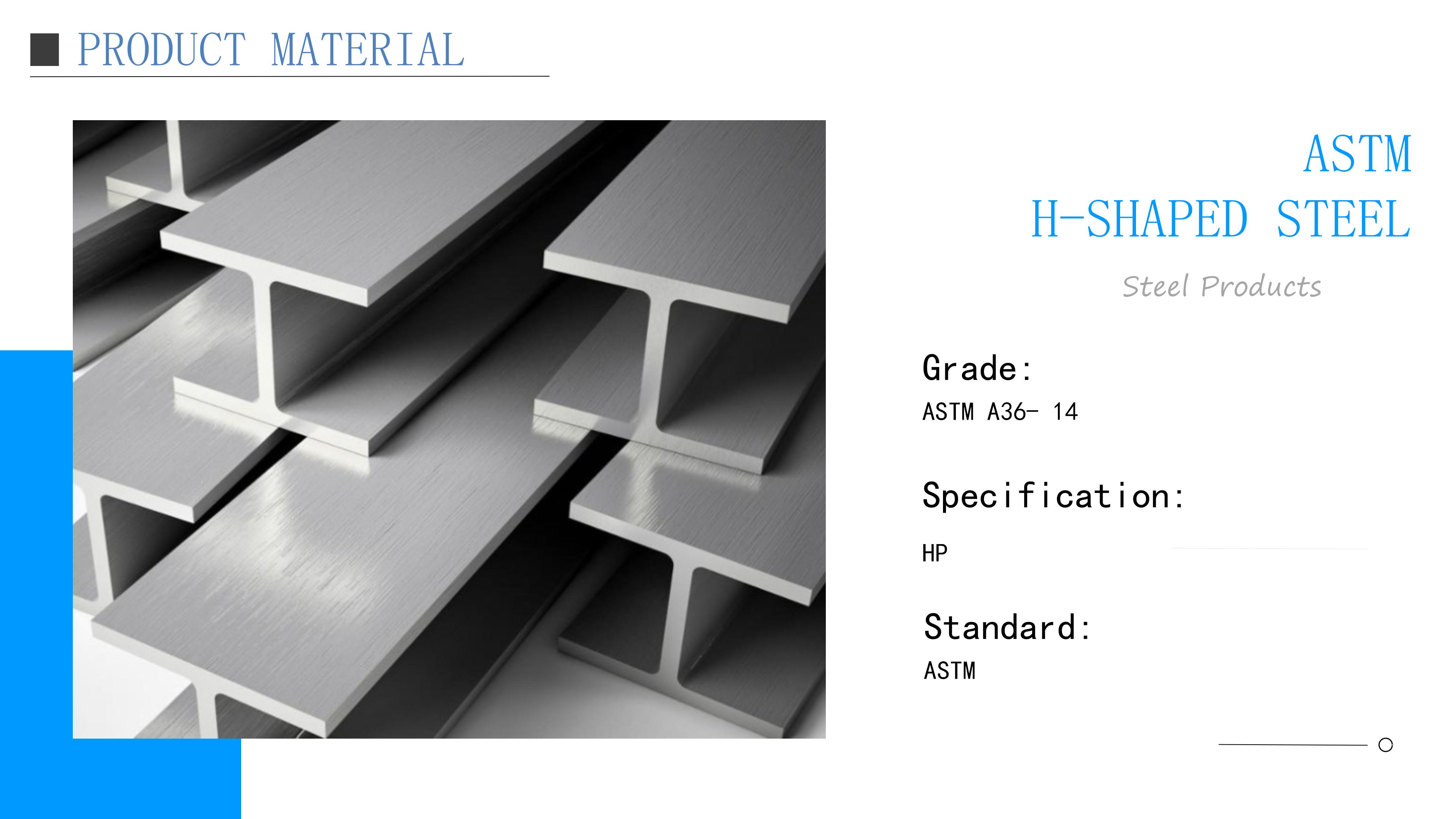

ASTM H-Shaped Steel W4x13, W30x132, W14x82 | A36 Steel H Beam

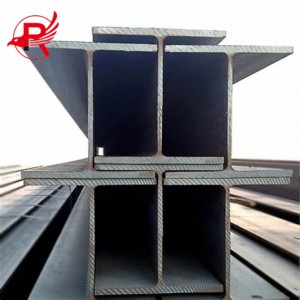

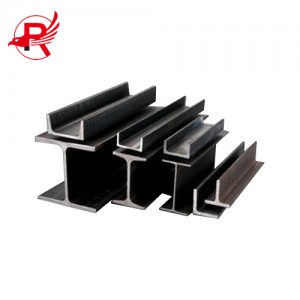

Wide Flange Beams, also known as an I-beam or H-beam, is a structural steel beam with a wide, balanced flange and a parallel web. This shape allows the beam to support heavy loads and resist bending and twisting forces. Wide flange beams are commonly used in construction, industrial, and residential applications to support building structures, bridges, and large equipment. They are available in various sizes and can be customized to meet specific project requirements. Wide flange beams are manufactured according to industry standards and specifications to ensure high strength, durability, and stability in various building and infrastructure projects.

PRODUCT PRODUCTION PROCESS

Preliminary Preparation:

Smelting:

Continuous Casting Billet:

Hot Rolling:

Finish Rolling:

Cooling:

Quality Inspection and Packaging:

PRODUCT SIZE

ADVANTAGE

Wide Flange, are used in various structural applications to support heavy loads over long spans. The wide flange design offers excellent load-bearing capacity as well as resistance to bending and twisting. W beams are available in various sizes and are commonly used in construction, industrial plants, bridges, and infrastructure projects. Their design complies with industry standards and specifications to ensure structural integrity and safety. Common features include high strength, versatility, and the ability to be easily customized according to specific project requirements.

PROJECT

Our company has many years of experience in foreign trade of W4x13 beam. The total amount of H-beams exported to Canada this time is more than 8,000,000 tons. The customer will inspect the goods in the factory. Once the goods pass the inspection, payment will be made and shipped. Since the construction of this project started, our company has carefully arranged the production plan and compiled the process flow to ensure the timely delivery of the H-shaped steel project. Since it is used in large factory buildings, the performance requirements for H-shaped steel products are higher than the corrosion resistance of oil platform H-shaped steel. Therefore, our company starts from the source of production and increases the control of steelmaking, continuous casting and rolling related processes. Strengthen the quality of products of various specifications to be effectively controlled in all aspects, ensuring a 100% pass rate of finished products. In the end, the processing quality of H-shaped steel was unanimously recognized by customers, and long-term cooperation and mutual benefit were achieved on the basis of mutual trust.

PRODUCT INSPECTION

For ordinary W30x132 beam or H-Beam S275jr, if the carbon content is 0.4% to 0.7%, and the mechanical property requirements are not very high, normalizing can be used as the final heat treatment. First, cross-shaped steel columns need to be produced. After division of labor in the factory, they are then assembled, calibrated, and inspected to ensure that the products are qualified and then transported to the construction area for splicing. During the splicing process, the splicing must be carried out in strict accordance with the corresponding procedures. , Only in this way can the quality of the product be effectively guaranteed. After the assembly is completed, the final installation results must be inspected. After the inspection, ultrasonic waves must be used to conduct non-destructive inspection of the interior, so that defects caused during assembly can be effectively eliminated. In addition, cross pillar processing is also required. During the installation of the steel structure, you first need to select the standard annotation, close the net for control, and then conduct a vertical measurement of the column top elevation. After that, the displacement of the column top and the steel structure need to be processed for super-deflection, and then the super-flat results and the inspection results of the lower column are comprehensively processed. The processing of thick feet needs to be carried out after the position of the steel column is determined. Through the analysis of the processing data, the verticality of the steel column is corrected again. After the installation is completed, the measurement records need to be reviewed and the welding problems need to be inspected. In addition, the closure of the control points needs to be inspected again. Finally, the pre-control data diagram of the lower steel column needs to be drawn.

APPLICATION

Wide flange beams have a wide range of applications in construction and structural engineering. Some of the common uses include:

Building construction: Wide flange beams are used as primary load-bearing members in the construction of buildings, providing support for floors, roofs, and overall structural stability.

Bridges: Wide flange beams are frequently used in the construction of bridge structures, providing support for roadways, pedestrian walkways, and rail lines.

Industrial buildings: These beams are commonly used in the construction of industrial facilities, such as warehouses, manufacturing plants, and distribution centers, to support heavy equipment and machinery.

Infrastructure projects: Wide flange beams are essential in the construction of infrastructure projects such as tunnels, airports, and stadiums, providing structural support for large spans and heavy loads.

Support structures: Wide flange beams are used as support columns and beams in various structural applications, providing strength and stability to the overall structure.

Overall, wide flange beams are versatile structural elements that are used in a wide variety of construction projects where strength, stability, and load-bearing capacity are essential.

PACKAGING AND SHIPPING

Packaging:

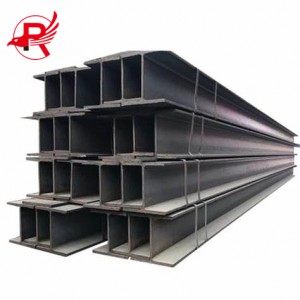

Stably Stacking Sheet Piles: Stack H-section steel neatly and stably, ensuring they are arranged in order to prevent instability. Use strapping or packing belts to secure the stacks and avoid displacement during transportation.

Using Protective Packaging Materials: Wrap the stacked sheet piles with moisture-proof materials such as plastic or waterproof paper to protect them from water, moisture and other environmental factors. This helps prevent rust and corrosion.

Transportation:

Selecting Appropriate Transportation Methods: Based on the quantity and weight of the sheet piles, choose suitable transportation methods such as flatbed trucks, containers or ships. Consider factors like distance, time, cost and any regulatory requirements for transportation.

Using Suitable Lifting Equipment: Use appropriate lifting equipment such as cranes, forklifts or loaders to load and unload U-type steel sheet piles. Ensure the equipment used has sufficient load-bearing capacity to safely lift the weight of the sheet piles.

Securing Goods: Use strapping, supports or other appropriate methods to firmly fix the packaged sheet pile stacks on the transport vehicles, preventing displacement, sliding or falling during transportation.

COMPANY STRENGTH

Made in China, first-class service, cutting-edge quality, world-renowned

1. Scale effect: Our company has a large supply chain and a large steel factory, achieving scale effects in transportation and procurement, and becoming a steel company that integrates production and services

2. Product diversity: Product diversity, any steel you want can be purchased from us, mainly engaged in steel structures, steel rails, steel sheet piles, photovoltaic brackets, channel steel, silicon steel coils and other products, which makes it more flexible Choose the desired product type to meet different needs.

3. Stable supply: Having a more stable production line and supply chain can provide more reliable supply. This is especially important for buyers who require large quantities of steel.

4. Brand influence: Have higher brand influence and larger market

5. Service: A large steel company that integrates customization, transportation and production

6. Price competitiveness: reasonable price

*Send the email to [email protected] to get a quotation for your projects