Wholesale Discount Hongtai Metal 400 500 600 U Z Type Larsen Hot Roll Steel Sheet Pile Price Per Kg

Innovation, good quality and reliability are the core values of our enterprise. These principles today extra than ever form the basis of our success as an internationally active mid-size organization for Wholesale Discount Hongtai Metal 400 500 600 U Z Type Larsen Hot Roll Steel Sheet Pile Price Per Kg, If possible, make sure you send your necessities with a detailed list including the style/item and quantity you require. We’ll then mail our greatest selling prices to you.

Innovation, good quality and reliability are the core values of our enterprise. These principles today extra than ever form the basis of our success as an internationally active mid-size organization for China Sheet Pile and Steel Sheet Pile, The credibility is the priority, and the service is the vitality. We promise we now have the ability to supply excellent quality and reasonable price products and solutions for customers. With us, your safety is guaranteed.

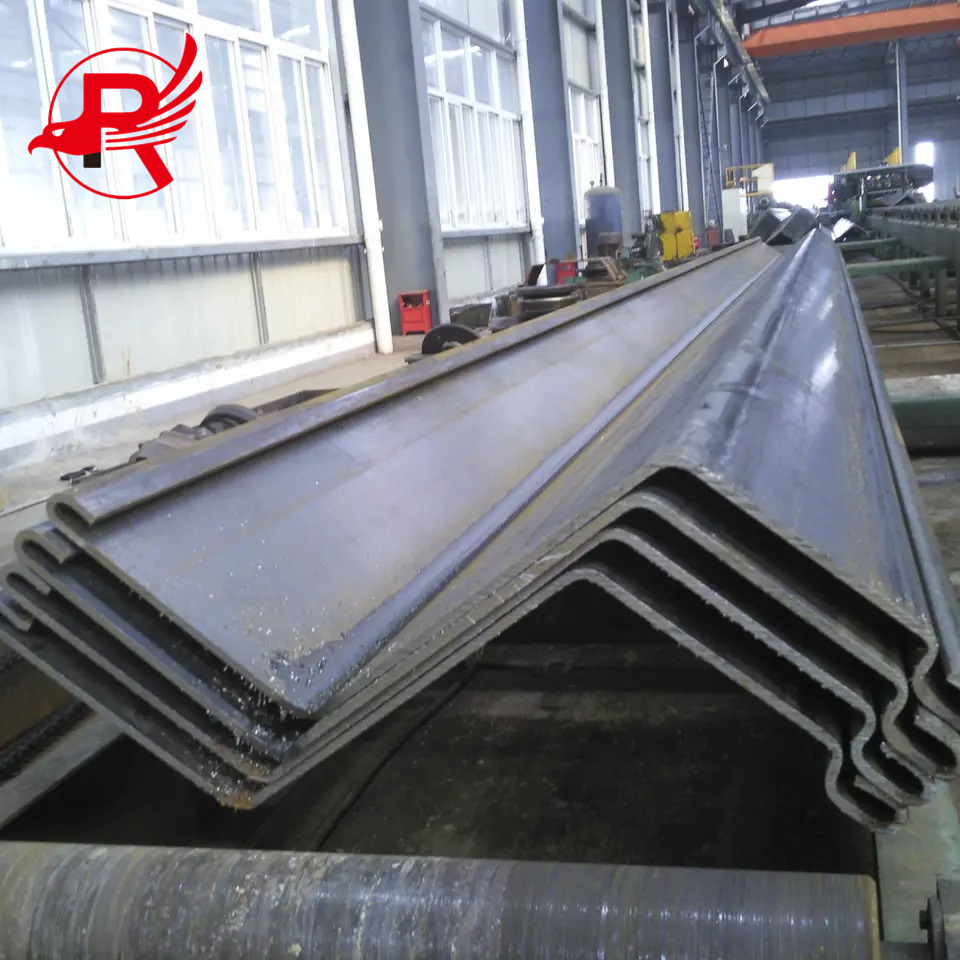

PRODUCT PRODUCTION PROCESS

The production process of cold-formed Z-shaped steel sheet piles usually includes the following steps:

Material preparation: Select steel plate materials that meet the requirements, usually hot-rolled or cold-rolled steel plates, and select materials according to design requirements and standards.

Cutting: Cut the steel plate according to the design requirements to obtain a steel plate blank that meets the length requirements.

Cold bending: The cut steel plate blank is sent to the cold bending forming machine for forming processing. The steel plate is cold-bent into a Z-shaped cross-section through processes such as rolling and bending.

Welding: Weld the cold-formed Z-shaped steel sheet piles to ensure that their connections are firm and defect-free.

Surface treatment: Surface treatment is performed on the welded Z-shaped steel sheet piles, such as rust removal, painting, etc., to improve its anti-corrosion performance.

Inspection: Conduct quality inspection on the produced cold-formed Z-shaped steel sheet piles, including inspection of appearance quality, dimensional deviation, welding quality, etc.

Packaging and leaving the factory: The qualified cold-formed Z-shaped steel sheet piles are packaged, marked with product information, and shipped out of the factory for storage.

*Send the email to chinaroyalsteel@163.com to get a quotation for your projects

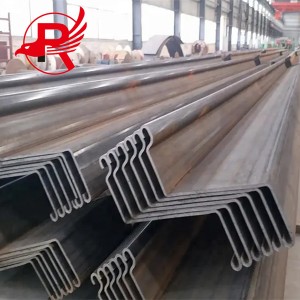

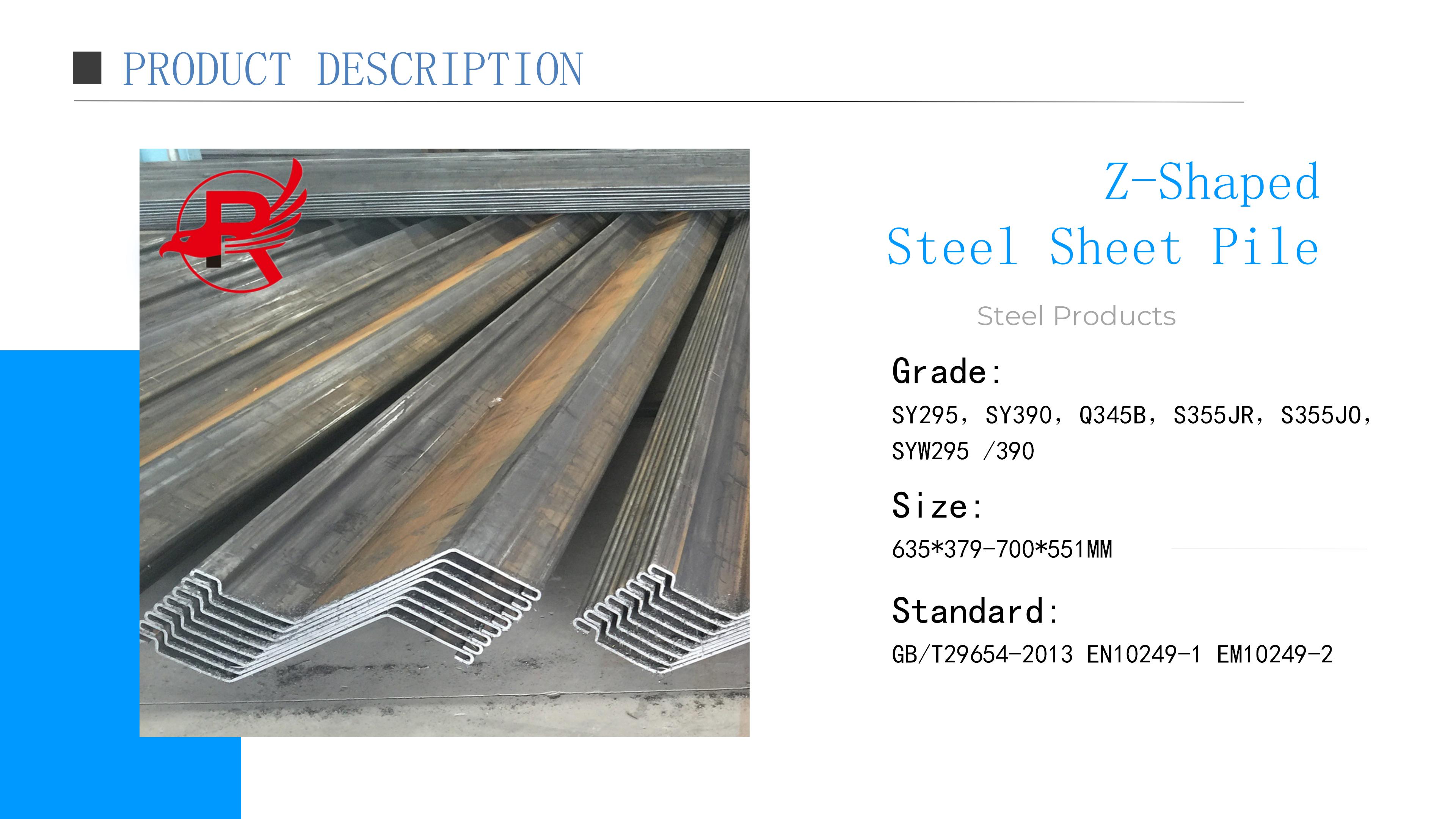

PRODUCT SIZE

*Send the email to chinaroyalsteel@163.com to get a quotation for your projects

|

SPECIFICATIONS FOR Z SHEET PILE |

|

| 1. Size | 1) 635*379—700*551mm |

| 2)Wall Thickness:4—16MM | |

| 3)Z type sheet pile | |

| 2. Standard: | GB/T29654-2013 EN10249-1 |

| 3.Material | Q235B Q345B S235 S240 SY295 S355 S340 |

| 4. Location of our factory | Tianjin,China |

| 5. Usage: | 1)rolling stock |

| 2)Building steel structure | |

| 3Cable tray | |

| 6. Coating: | 1) Bared2) Black Painted (varnish coating)3) galvanized |

| 7. Technique: | hot rolled |

| 8. Type: | Z type sheet pile |

| 9. Section Shape: | Z |

| 10. Inspection: | Client inspection or inspection by 3rd party. |

| 11. Delivery: | Container, Bulk Vessel. |

| 12. About Our Quality: | 1) No damage, no bent2) Free for oiled&marking3) All goods can be checked by third party inspection before shipment |

FEATURES

some key features of hot-rolled cold formed Z sheet pile:

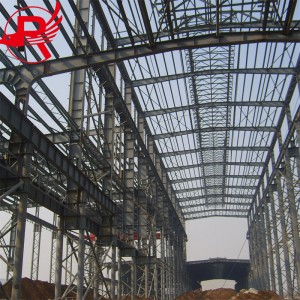

Versatility: Z Type steel piles are suitable for a wide range of applications, including foundation construction for buildings, bridges, ports, harbors, and offshore structures. They can also be used in temporary shoring and retaining walls.

High load-bearing capacity: nz26 sheet pile are designed to support heavy vertical loads and resist lateral forces. The Z shape provides excellent strength and stiffness, allowing the piles to effectively transfer loads to the underlying soil or rock.

Interlocking system: Z Type steel piles feature interlocking edges on each side, enabling easy and secure connections between individual piles. The interlock mechanism provides stability, prevents water infiltration, and allows for quick installation.

Durable construction: Hot-rolled Z Type steel piles are manufactured from high-quality steel, ensuring durability and long-term performance. The steel undergoes a hot-rolling process, which enhances its structural integrity and resistance to deformation.

Efficient installation: Z Type steel piles can be installed quickly and efficiently due to their interlocking system. Their modular design allows for easy handling, transportation, and assembly on-site. This results in cost savings and faster project completion.

Corrosion resistance: To enhance the durability of Z Type steel piles, they can be treated with protective coatings like hot-dip galvanization or epoxy paint. These coatings provide a barrier against corrosion, especially in corrosive environments such as marine or industrial settings.

Customization options: Z Type steel piles can be customized to specific project requirements in terms of length, size, and strength. Special configurations can also be designed to accommodate variations in soil conditions and design loads.

APPLICATION

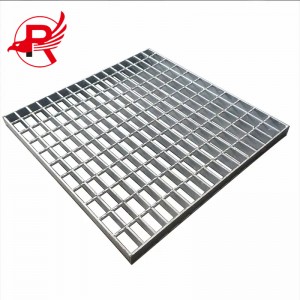

PACKAGING AND SHIPPING

The packaging and shipping of Hot Rolled Z Type Steel Piles typically involves the following steps:

Packaging: The steel piles are bundled together using steel straps or wires to keep them securely packed. The bundles are usually compactly arranged to optimize space and minimize any movement during transportation. Additionally, protective materials, such as plastic or wooden end-caps, can be applied to prevent damage to the ends of the piles.

Securing the bundles: Once the steel piles are bundled, they are loaded onto pallets or skids for easier handling and transportation. The bundles may be further secured with additional strapping or wrapping materials to ensure they remain intact throughout transit.

Labeling: Each bundle is labeled with essential information such as product specifications, dimensions, weight, and handling instructions. This helps to identify and track the piles during the shipping process.

Loading: The packaged and labeled bundles are loaded onto trucks, shipping containers, or flatbed trailers depending on the mode of transportation. Loading procedures should be carried out carefully with the use of appropriate lifting equipment and proper distribution of weight to maintain balance and prevent damage to the piles.

Transport: The loaded shipments are then transported to their destination using various modes of transportation – road, rail, or sea, depending on the distance and logistics involved. It is crucial to choose reliable transportation services and ensure that the vehicles or vessels are suitable for handling heavy and bulky cargo.

Unloading at the destination: Upon arrival, the bundles are carefully unloaded using appropriate equipment and precautions. Forklifts or cranes may be utilized to safely offload the steel piles from the container or vehicle.

Storage: If the steel piles are not immediately required for construction, they should be stored in a suitable location. The storage area should be flat, dry, and free from any chemicals that may cause corrosion. The piles should be stacked in a way that promotes proper ventilation and avoids any excessive stress on the bundles.

FAQ

Q1: What type of work does your company do?

A1: We mainly produce steel sheet piles/rails/silicon steel/shaped steel, etc.

Q2: How long is your delivery time?

A2: Generally it is 5-10 days if the goods are in stock. Or if the goods are not in stock, 15-20 days depending on

quantity.

Q3: What are the advantages of your company?

A3: Our company has a professional team and professional production lines.

Q4: Are you a trading company or a manufacturer?

A4: We are factory.

Q5: What are your payment terms?

A5: Payment <=1000USD, 100% in advance. Payment >= 1000 USD, 30% T/T in advance,

If you have any other questions, please contact us through the following methods.

Innovation, good quality and reliability are the core values of our enterprise. These principles today extra than ever form the basis of our success as an internationally active mid-size organization for Wholesale Discount Hongtai Metal 400 500 600 U Z Type Larsen Hot Roll Steel Sheet Pile Price Per Kg, If possible, make sure you send your necessities with a detailed list including the style/item and quantity you require. We’ll then mail our greatest selling prices to you.

Wholesale Discount China Sheet Pile and Steel Sheet Pile, The credibility is the priority, and the service is the vitality. We promise we now have the ability to supply excellent quality and reasonable price products and solutions for customers. With us, your safety is guaranteed.