And We'll Help You Figure It Out

If you don't already have a professional designer to create professional part design files for you, then we can help you with this task.

You can tell me your inspirations and ideas or make sketches and we can turn them into real products.

We have a team of professional engineers who will analyze your design, recommend material selection, and final production and assembly.

One-stop technical support service makes your work easy and convenient.

Tell Us What You Need

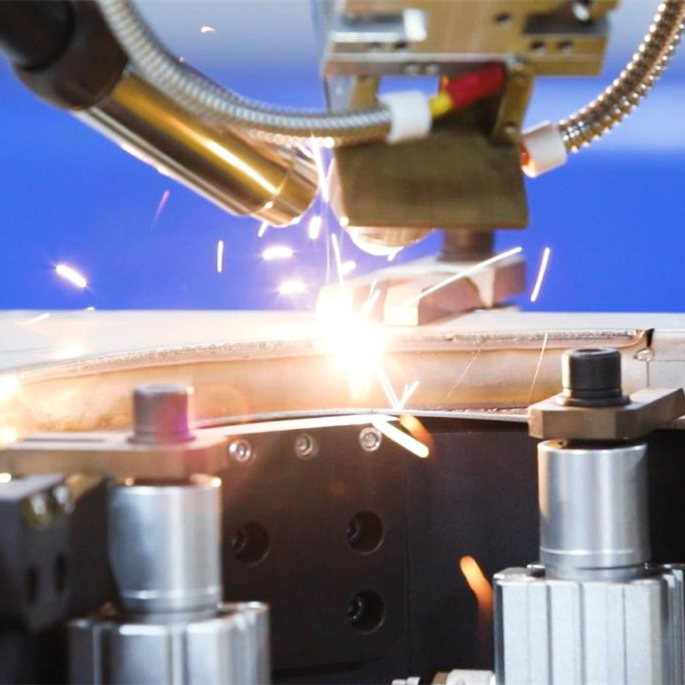

Welding processing is a common metalworking method that can be used to join different types of metal materials. When selecting materials that can be welded, factors such as the material’s chemical composition, melting point, and thermal conductivity need to be considered. Common materials that can be welded include carbon steel, galvanized steel, stainless steel, aluminum and copper.

Carbon steel is a common welding material with good weldability and strength, making it suitable for many industrial applications. Galvanized steel is often used for corrosion protection purposes and its weldability depends on the thickness and quality of the galvanized layer. Stainless steel has corrosion resistance and is suitable for environments that require corrosion resistance, but welding stainless steel requires special welding processes and materials. Aluminum is a lightweight metal with good thermal and electrical conductivity, but welding aluminum requires special welding methods and alloy materials. Copper has good electrical and thermal conductivity and is suitable for electrical and heat exchange fields, but welding copper requires consideration of oxidation issues.

When selecting welding materials, the characteristics of the material, application environment and welding process need to be considered to ensure the quality and performance of the welded connection. Welding is a complex process that requires comprehensive consideration of material selection, welding methods and operating techniques to ensure the quality and reliability of the final welded joint.

| Steel | Stainless Steel | Aluminum Alloy | Copper |

| Q235 - F | 201 | 1060 | H62 |

| Q255 | 303 | 6061-T6 / T5 | H65 |

| 16Mn | 304 | 6063 | H68 |

| 12CrMo | 316 | 5052-O | H90 |

| # 45 | 316L | 5083 | C10100 |

| 20 G | 420 | 5754 | C11000 |

| Q195 | 430 | 7075 | C12000 |

| Q345 | 440 | 2A12 | C51100 |

| S235JR | 630 | ||

| S275JR | 904 | ||

| S355JR | 904L | ||

| SPCC | 2205 | ||

| 2507 |

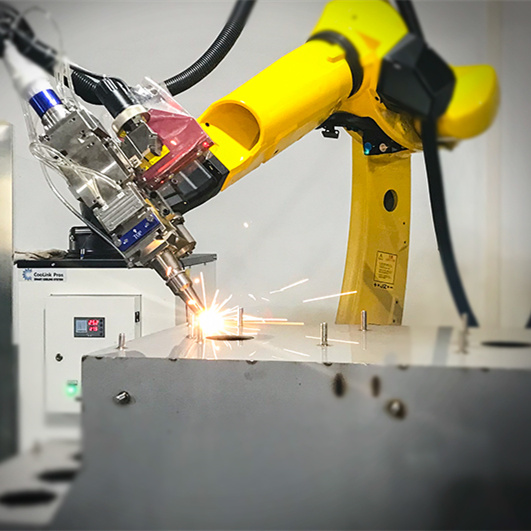

Metal Welding Service Applications

- Precision Metal Welding

- Thin Plate Welding

- Metal Cabinet Welding

- Steel Structure Welding

- Metal Frame Welding