GB Standard Is Used For Rail Carbon Steel Rail Price Concessions

china steel rail have been an integral part of transportation systems worldwide, providing a convenient and efficient means of commute and cargo transportation. At the heart of this vast network lies a crucial component: train rail steel. These steel tracks, which support the movement of trains, play a vital role in maintaining the safety and longevity of the railway system. In this blog, we will explore the significance of train rail steel and its importance in the production of durable and reliable railway tracks.

PRODUCT PRODUCTION PROCESS

Technology and Construction Process

The process of constructing china steel rail tracks involves precision engineering and careful consideration of various factors. It begins with designing the track layout, taking into account the intended usage, train speeds, and terrain. Once the design is finalized, the construction process commences with the following key steps:

1. Excavation and Foundation: The construction crew prepares the ground by excavating the area and creating a sturdy foundation to support the weight and stress imposed by trains.

2. Ballast Installation: A layer of crushed stone, known as ballast, is laid on the prepared surface. This serves as a shock-absorbing layer, providing stability, and helping to distribute the load evenly.

3. Ties and Fastening: Wooden or concrete ties are then installed on top of the ballast, imitating a frame-like structure. These ties offer a secure base for the steel railroad tracks. They are fastened using specific spikes or clips, ensuring they remain firmly in place.

4. Rail Installation: The steel railroad rails 10m, often referred to as standard rails, are meticulously laid on top of the ties. Being made of high-quality steel, these tracks possess remarkable strength and durability.

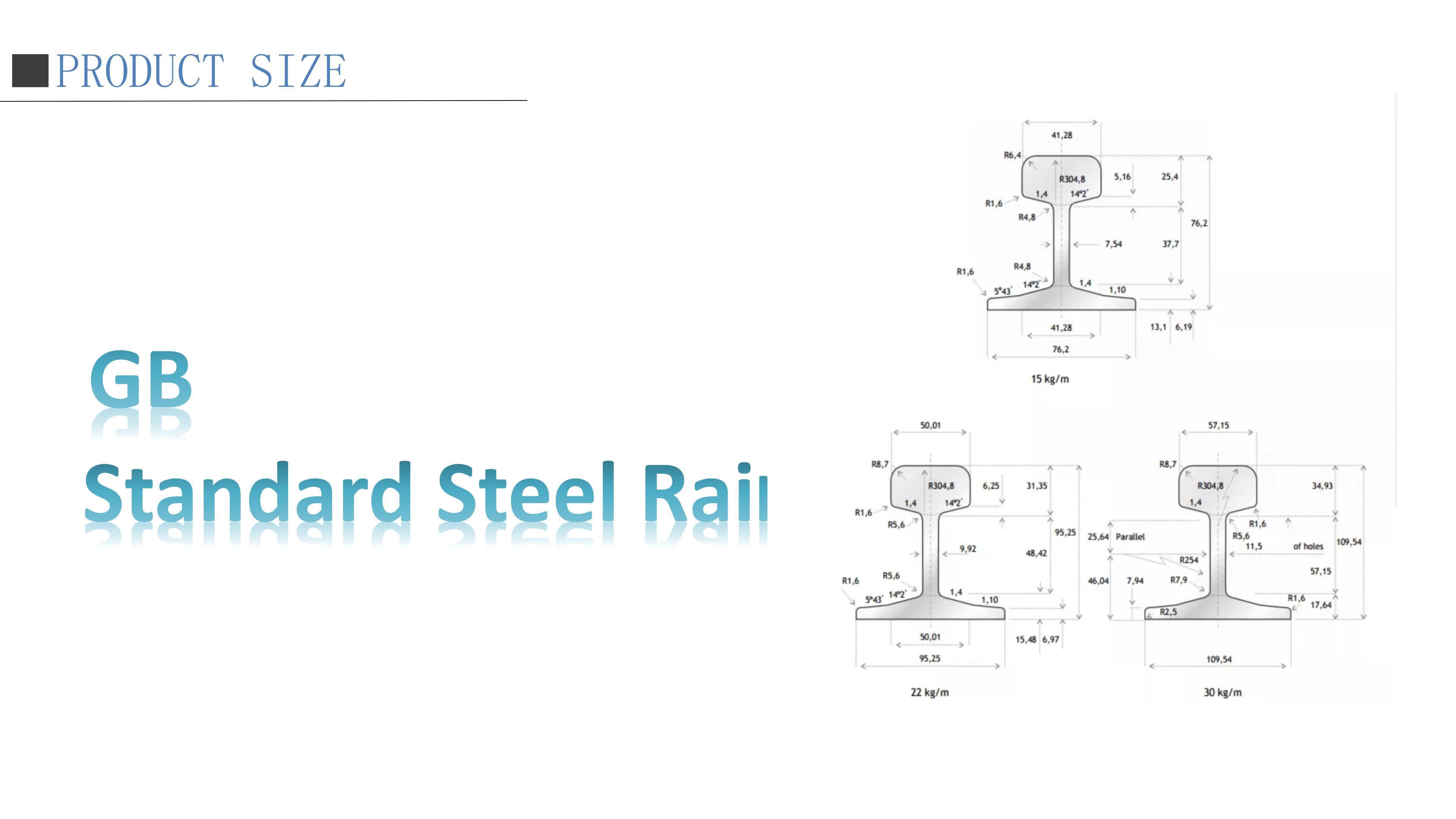

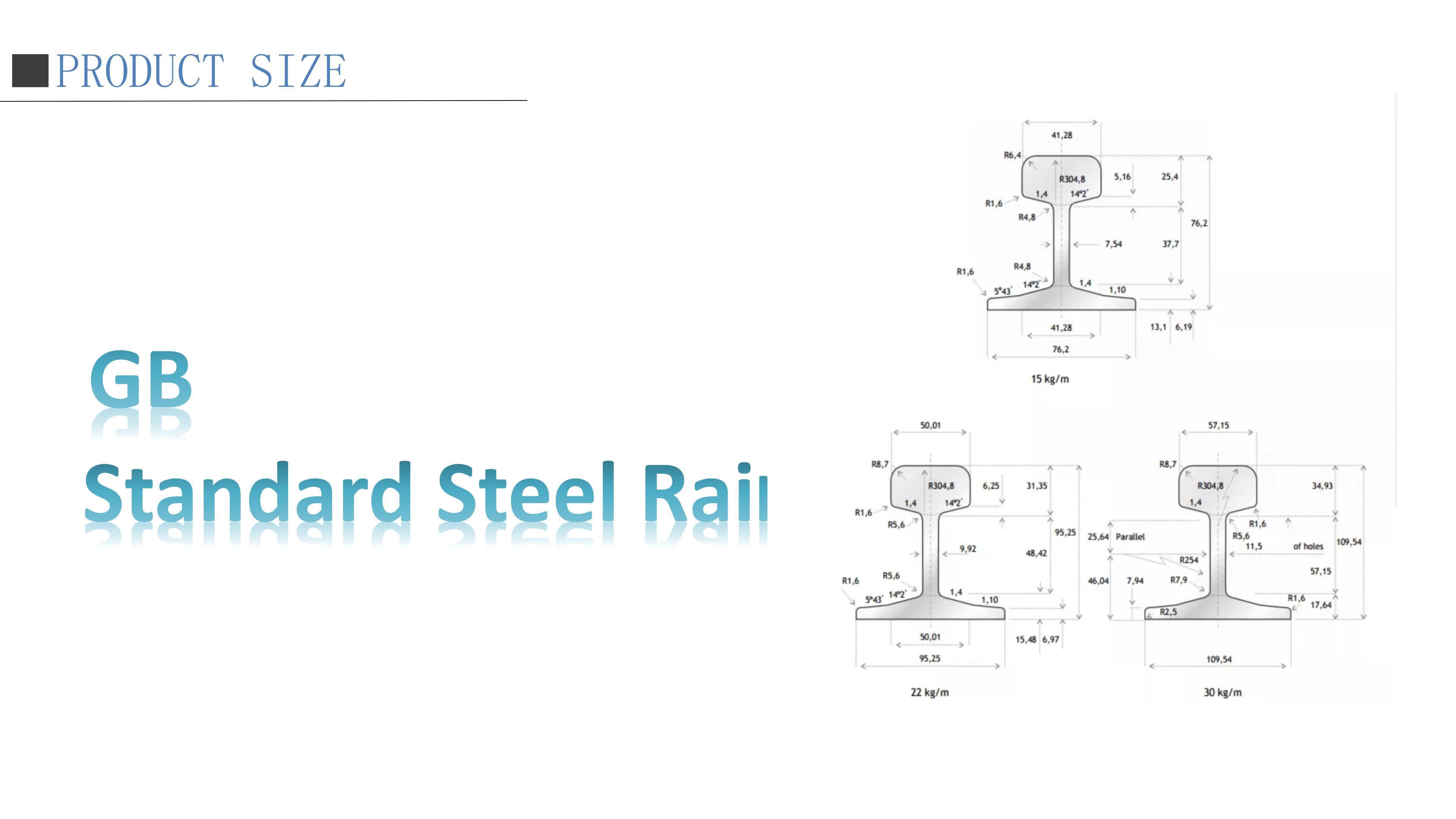

PRODUCT SIZE

|

Product Name:

|

Steel Rail | |||

|

Type:

|

Heavy Rail, Crane Rail,Light Rail

|

|||

|

Material/Specification:

|

||||

|

Light Rail:

|

Model/Material:

|

Q235,55Q ;

|

Specification:

|

30kg/m,24kg/m,22kg/m,18kg/m,15kg/m,12 kg/m,8 kg/m.

|

|

Heavy Rail :

|

Model/Material:

|

45MN,71MN;

|

Specification:

|

50kg/m,43kg/m,38kg/m,33kg/m.

|

|

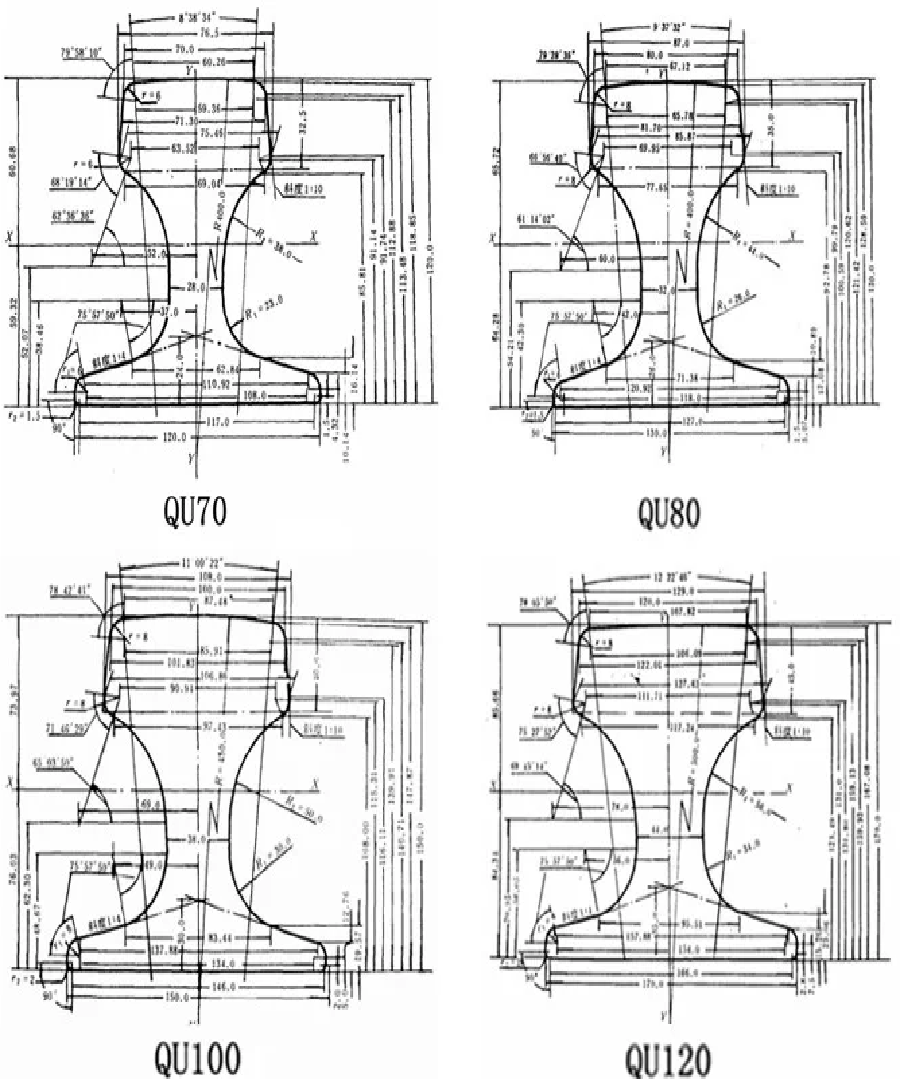

Crane Rail:

|

Model/Material:

|

U71MN;

|

Specification:

|

QU70 kg /m ,QU80 kg /m,QU100kg /m,QU120 kg /m.

|

National standard rail:

Specifications: GB6kg, 8kg, GB9kg, GB12, GB15kg, 18kg, GB22kg, 24kg, GB30, P38kg, P43kg, P50kg, P60kg, QU70, QU80, QU100, QU120

Standard: GB11264-89 GB2585-2007 YB/T5055-93

Material: U71Mn/50Mn

Length: 6m-12m 12.5m-25m

| Commodity | Grade | Section Size(mm) | ||||

| Rail Height | Base Width | Head Width | Thickness | Weight(kgs) | ||

| Light Rail | 8KG/M | 65.00 | 54.00 | 25.00 | 7.00 | 8.42 |

| 12KG/M | 69.85 | 69.85 | 38.10 | 7.54 | 12.2 | |

| 15KG/M | 79.37 | 79.37 | 42.86 | 8.33 | 15.2 | |

| 18KG/M | 90.00 | 80.00 | 40.00 | 10.00 | 18.06 | |

| 22KG/M | 93.66 | 93.66 | 50.80 | 10.72 | 22.3 | |

| 24KG/M | 107.95 | 92.00 | 51.00 | 10.90 | 24.46 | |

| 30KG/M | 107.95 | 107.95 | 60.33 | 12.30 | 30.10 | |

| Heavy Rail | 38KG/M | 134.00 | 114.00 | 68.00 | 13.00 | 38.733 |

| 43KG/M | 140.00 | 114.00 | 70.00 | 14.50 | 44.653 | |

| 50KG/M | 152.00 | 132.00 | 70.00 | 15.50 | 51.514 | |

| 60KG/M | 176.00 | 150.00 | 75.00 | 20.00 | 74.64 | |

| 75KG/M | 192.00 | 150.00 | 75.00 | 20.00 | 74.64 | |

| UIC54 | 159.00 | 140.00 | 70.00 | 16.00 | 54.43 | |

| UIC60 | 172.00 | 150.00 | 74.30 | 16.50 | 60.21 | |

| Lifting Rail | QU70 | 120.00 | 120.00 | 70.00 | 28.00 | 52.80 |

| QU80 | 130.00 | 130.00 | 80.00 | 32.00 | 63.69 | |

| QU100 | 150.00 | 150.00 | 100.00 | 38.00 | 88.96 | |

| QU120 | 170.00 | 170.00 | 120.00 | 44.00 | 118.1 | |

ADVANTAGE

GB Standard Steel Rail have the following advantages:

1. High strength, high hardness and good wear resistance, able to meet the needs of long-term high-intensity operation.

2. It has good fatigue resistance and can withstand repeated loads without being prone to fatigue failure.

3. Good corrosion resistance, able to resist corrosion from various chemical substances and extend service life.

4. High safety, which can ensure the safe operation of rail transit and reduce the probability of accidents.

5. It has a long service life and can meet the long-term use needs of rail transit.

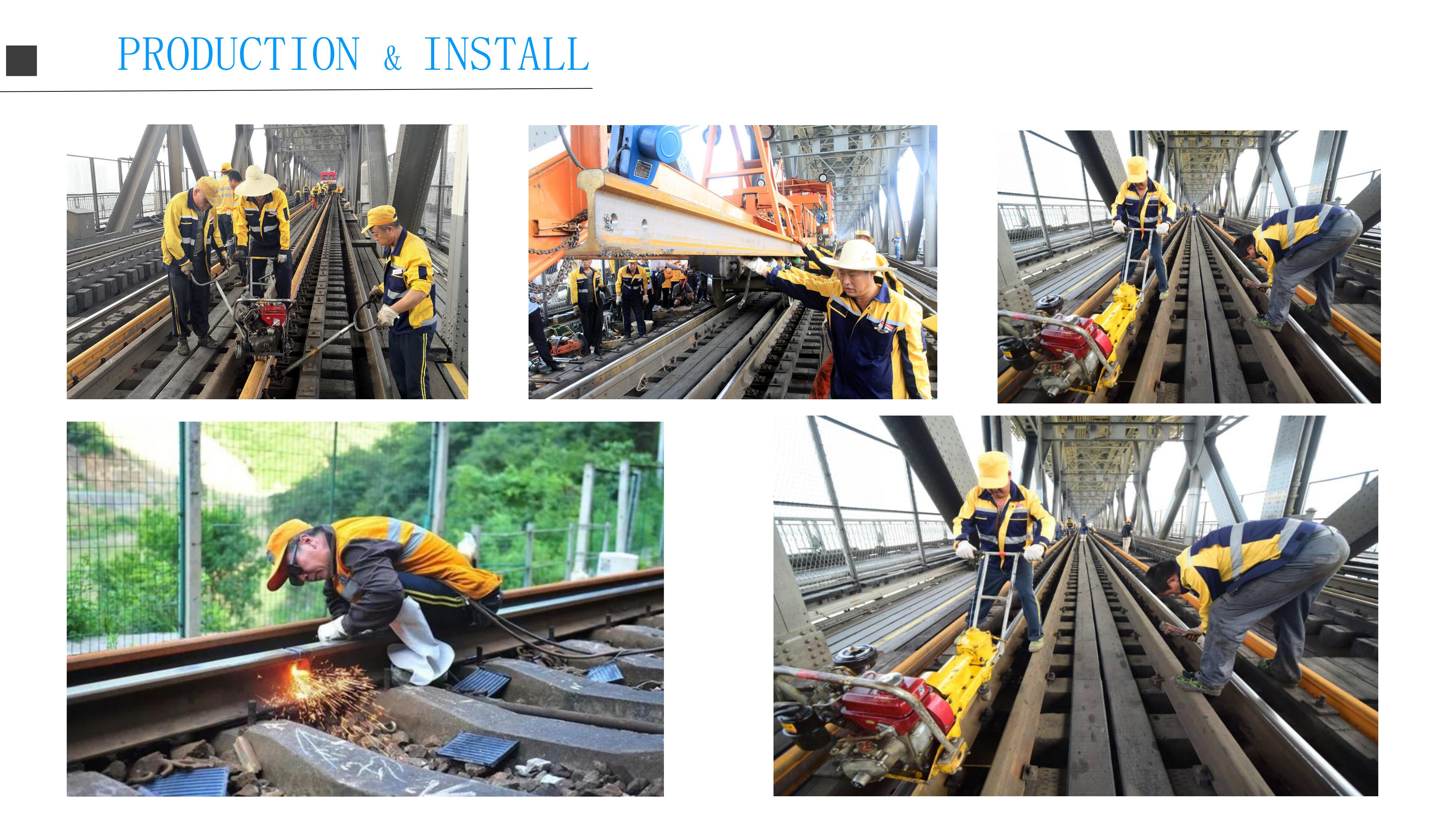

PROJECT

Our company’s china rail supplier 13,800 tons of steel rails exported to the United States were shipped at Tianjin Port at one time. The construction project was completed with the last rail being steadily laid on the railway line. These rails are all from the universal production line of our rail and steel beam factory, using global Produced to the highest and most rigorous technical standards.

For more information about rail products, please contact us!

WeChat: +86 13652091506

Tel: +86 13652091506

Email: chinaroyalsteel@163.com

china rail supplier,china steel rail,GB Standard Steel Rail

APPLICATION

1. rail of train transportation field

Rails are an essential and important component in railway construction and operation. In railway transportation, steel rails are responsible for supporting and carrying the entire weight of the train, and their quality and performance directly affect the safety and stability of the train. Therefore, rails must have excellent physical and chemical properties such as high strength, wear resistance, and corrosion resistance. At present, the rail standard used by most domestic railway lines is GB/T 699-1999 "High Carbon Structural Steel".

2. Construction engineering field

In addition to the railway field, steel rails are also widely used in construction engineering, such as in the construction of cranes, tower cranes, bridges and underground projects. In these projects, rails are used as footings and fixtures to support and carry weight. Their quality and stability have a vital impact on the safety and stability of the entire construction project.

3. Heavy machinery field

In the field of heavy machinery manufacturing, rails are also a common component, mainly used on runways composed of rails. For example, steelmaking workshops in steel plants, production lines in automobile factories, etc. all need to use runways composed of steel rails to support and carry heavy machines and equipment weighing tens of tons or more.

In short, the wide application of steel rails in transportation, construction engineering, heavy machinery and other fields has made important contributions to the development and progress of these industries. Today, with the continuous innovation and development of technology, rails are constantly updated and upgraded to adapt to the continuous improvement and pursuit of performance and quality in various fields.

Good corrosion resistance: The surface of channel steel can be treated with anti-corrosion to improve its corrosion resistance and extend its service life.

Wide range of applications: Channel steel can be used in building structures, machinery manufacturing, bridge construction, shipbuilding and other fields, and has a wide range of applications.

In general, channel steel has the characteristics of high strength, simple manufacturing process, regular shape, good corrosion resistance and wide application. It is a commonly used structural material.

PACKAGING AND SHIPPING

Methods to improve rail stiffness and wear resistance include:

Choose high-strength materials: Choosing suitable rail steel specification materials, such as alloy steel or high-strength steel with good wear resistance, can improve the rigidity and wear resistance of the rails.

Optimize the geometry of the rail: By changing the rail's cross-sectional shape, rail waist width, rail squat height and other parameters, the stiffness and wear resistance of the rail can be improved.

Strengthen the heat treatment of rails: Through appropriate heat treatment processes, such as normalizing, quenching, etc., the strength and hardness of rails can be improved, thereby improving stiffness and wear resistance.

Improve the surface hardness of the rail: Surface quenching, surface spraying of ceramic coatings and other methods can be used to increase the hardness of the rail surface and improve wear resistance.

Adding appropriate alloying elements: Adding appropriate alloying elements, such as chromium, titanium, etc., to the material can increase the hardness and wear resistance of the rail.

Strengthen the maintenance of rails: conduct regular inspection, repair and lubrication to keep the rails in good condition and extend their service life.

It should be noted that the above methods should be selected and applied according to specific conditions and needs to achieve the purpose of improving rail stiffness and wear resistance.

COMPANY STRENGTH

Made in China, first-class service, cutting-edge quality, world-renowned

1. Scale effect: Our company has a large supply chain and a large steel factory, achieving scale effects in transportation and procurement, and becoming a steel company that integrates production and services

2. Product diversity: Product diversity, any steel you want can be purchased from us, mainly engaged in steel structures, steel rails, steel sheet piles, photovoltaic brackets, channel steel, silicon steel coils and other products, which makes it more flexible Choose the desired product type to meet different needs.

3. Stable supply: Having a more stable production line and supply chain can provide more reliable supply. This is especially important for buyers who require large quantities of steel.

4. Brand influence: Have higher brand influence and larger market

5. Service: A large steel company that integrates customization, transportation and production

6. Price competitiveness: reasonable price

*Send the email to chinaroyalsteel@163.com to get a quotation for your projects

CUSTOMERS VISIT

FAQ

1.How can I get a quotation from you ?

You can leave us message, and we will reply every message in time.

2.Will you delivery the goods on time?

Yes,we promise to provide best quality products and delivery on time. Honesty is our company's tenet.

3.Can I get samples before order ?

Yes, of course. Usually our samples are free,we can produce by your samples or technical drawings.

4.What is your payment terms?

Our usual payment term is 30% deposit, and rest against B/L. EXW, FOB,CFR, CIF.

5.Do you accept the third party inspection?

Yes absolutely we accept.

6.How do we trust your company?

We specialise in steel business for years as golden supplier, headquarter locates in Tianjin province, welcome to investigate in any ways, by all means.