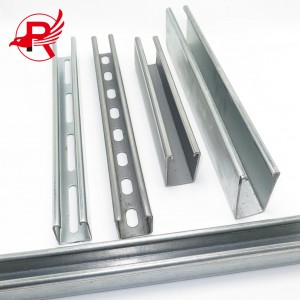

Steel Struts Galvanized Slotted C Channel Metal Strut Channel

C Channel Structural Steel, specifically galvanized C Purlins, offer an array of advantages in the construction industry. Their strength, cost-effectiveness, and ease of installation make them an ideal choice for various applications. Furthermore, the galvanized coating enhances their durability and safeguards them against corrosion. With such versatile features, galvanized C Purlins have rightfully earned their place as reliable building solutions in modern construction practices.

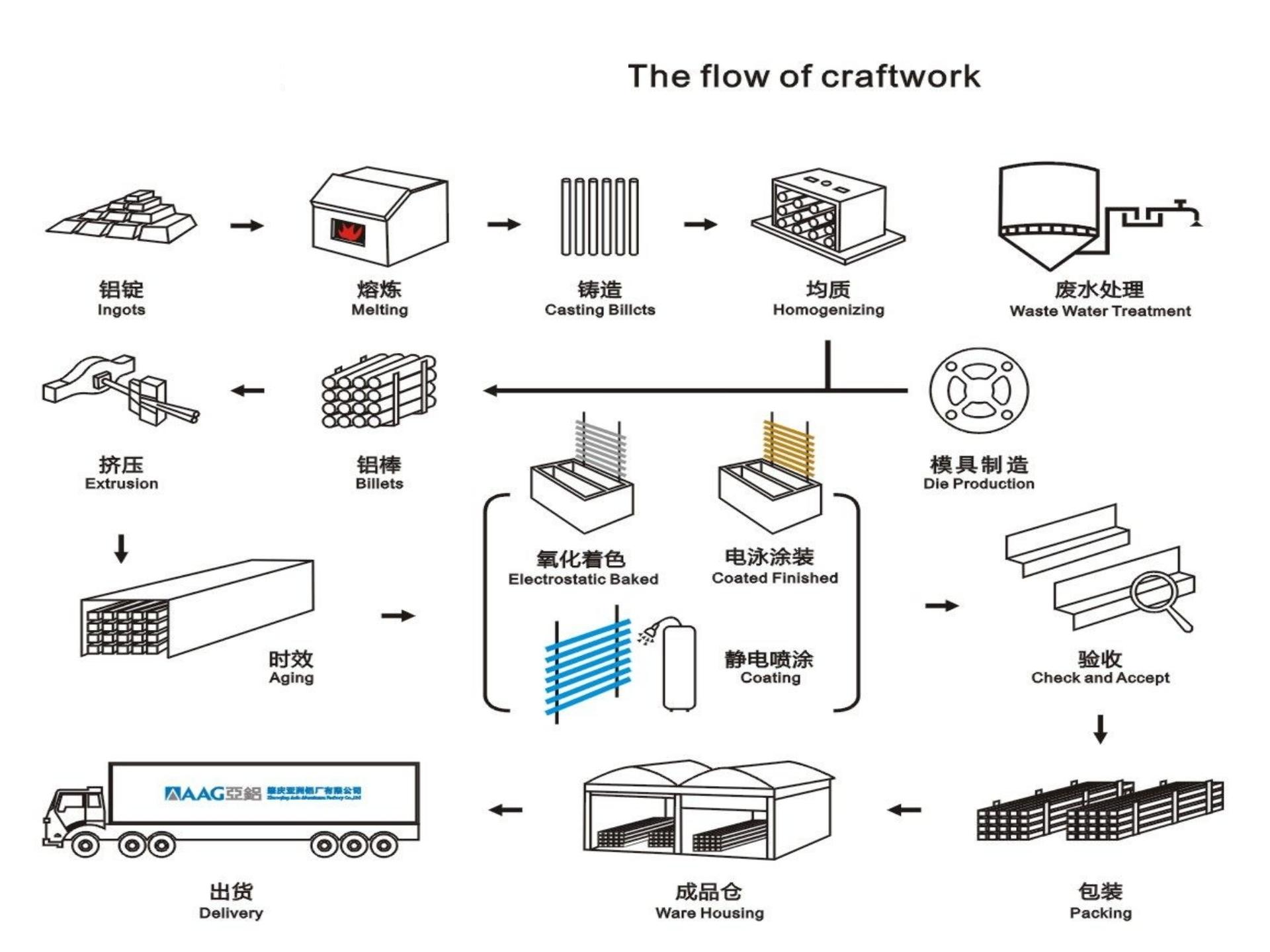

PRODUCT PRODUCTION PROCESS

|

Material

|

Q195/Q235/SS304/SS316

|

|

Thickness

|

1.5mm/1.9mm/2.0mm/2.5mm/2.7mm12GA/14GA/16GA/0.079''/0.098''

|

|

Cross Section

|

41*21,/41*41 /41*62/41*82mm with slotted or plain1-5/8'' x 1-5/8'' 1-5/8'' x 13/16''

|

|

Standard

|

GB/DIN/ANSI/JIS/ISO

|

|

Length

|

2m/3m/6m/customized10ft/19ft/customized

|

|

Packing

|

50~100pcs wapped by plastic bag

|

|

Finished

|

1. Pre-galvanized steel

2. HDG(Hot dip galvanized)

3. Stainless steel SS304 4. Stainless steel SS316 5. Aluminium 6. Powder Coated |

| No. | Size | Thickness | Type | Surface

Treatment |

||

| mm | inch | mm | Gauge | |||

| A | 41x21 | 1-5/8x13/16" | 1.0,1.2,1.5,2.0,2.5 | 20,19,17,14,13 | Slotted, Solid | GI,HDG,PC |

| B | 41x25 | 1-5/8x1" | 1.0,1.2,1.5,2.0,2.5 | 20,19,17,14,13 | Slotted, Solid | GI,HDG,PC |

| C | 41x41 | 1-5/8x1-5/8" | 1.0,1.2,1.5,2.0,2.5 | 20,19,17,14,13 | Slotted, Solid | GI,HDG,PC |

| D | 41x62 | 1-5/8x2-7/16" | 1.0,1.2,1.5,2.0,2.5 | 20,19,17,14,13 | Slotted, Solid | GI,HDG,PC |

| E | 41x82 | 1-5/8x3-1/4" | 1.0,1.2,1.5,2.0,2.5 | 20,19,17,14,13 | Slotted, Solid | GI,HDG,PC |

ADVANTAGE

1).Extensiveness:

Sunlight irradiates the earth's surface, regardless of region, and can be developed and utilized regardless of land, ocean, mountains or flat land. Although the irradiation time and intensity are different, it is widely distributed and will not be inaccessible due to geographical or weather reasons. 2).Infinity and sustainability:

Based on current estimates of the rate of nuclear energy produced by the sun, hydrogen storage is sufficient to last for tens of billions of years. Today, when ecological pollution is becoming more and more severe, solar energy resources are inexhaustible and are a truly renewable and clean energy source.

3).Flexible installation location:

The roof of the building is open, which has the advantages of not being affected by the orientation of the building, receiving sunlight for a long time, and avoiding shadow interference to the greatest extent. Photovoltaic power generation can be installed not only on the roofs of residential facilities, but also in industrial-scale facilities, using solar power to obtain electrical energy to meet the electricity needs within the building. In the field of rural revitalization, the development of rooftop distributed photovoltaic technology can also effectively solve the power consumption problem in county areas.

4).Green and environmentally friendly:

C Purlins Steel generation itself does not consume fuel, does not emit any substances including greenhouse gases and other waste gases, does not pollute the air, and does not produce noise.

5). Improve national energy stability:

Through photovoltaic power generation, people can reduce their dependence on fossil fuel power generation, effectively avoid the impact caused by energy crises or fuel market instability, thereby improving national energy security.

6). Low operation and maintenance costs:

C Purlins Steel generation has no mechanical transmission components and operates stably and reliably. A photovoltaic power generation system can generate electricity as long as it has solar cell components. Coupled with the widespread use of automatic control technology, it can basically be unattended and has low maintenance costs. The installation methods used in actual solar photovoltaic bracket projects mainly include: fixed installation (fixed, fixed and manually adjustable), single-axis tracking (flat axis, oblique axis), and dual-axis tracking. Each installation method has its own characteristics. During the production process of solar photovoltaic brackets, corrugated panels may be scrapped, which not only increases production costs, but also causes waste of raw materials, which needs to be analyzed and controlled.

PRODUCT INSPECTION

1. Inspection of the size and geometry of u channel steel supports, including inspection of verticality, horizontality, symmetry, distance tolerance, etc.

2. Inspection of steel channel bracket connectors and welding quality, including inspection of specifications and strength of fasteners, quality and reliability of welds, etc.

3. Inspection of the surface quality and coating of c channel steel supports, including inspection of surface finish, oxide film thickness, coating adhesion, etc.

4. Inspection of the load-bearing capacity and stability of c channel steel supports, including inspection of maximum load, deflection and inclination.

PROJECT

Our company has C-Shaped Steel Purlins in the largest solar energy development project in South America, providing brackets and solution design. We provided 15,000 tons of photovoltaic brackets for this project. The photovoltaic brackets adopted domestic emerging technologies to help the development of the photovoltaic industry in South America and improve local residents. Life. The photovoltaic support project includes a photovoltaic power station with an installed capacity of approximately 6MW and a battery energy storage power station of 5MW/2.5h. It can generate approximately 1,200 kilowatt hours per year. The system has good C-Shaped Steel Purlins conversion capabilities.

APPLICATION

Applications of Galvanized C Purlins:

1. Industrial Buildings: Galvanized C Purlins are extensively used in the construction of industrial buildings, such as factories, warehouses, and manufacturing units. Their robustness and dimensional stability ensure the structural integrity required in such demanding environments.

2. Agricultural Structures: The agricultural sector also benefits from the use of galvanized C Purlins. They provide ample support for roofing systems in barns, storage sheds, and livestock shelters. The corrosion resistance of the galvanized coating ensures that these structures can withstand harsh weather conditions.

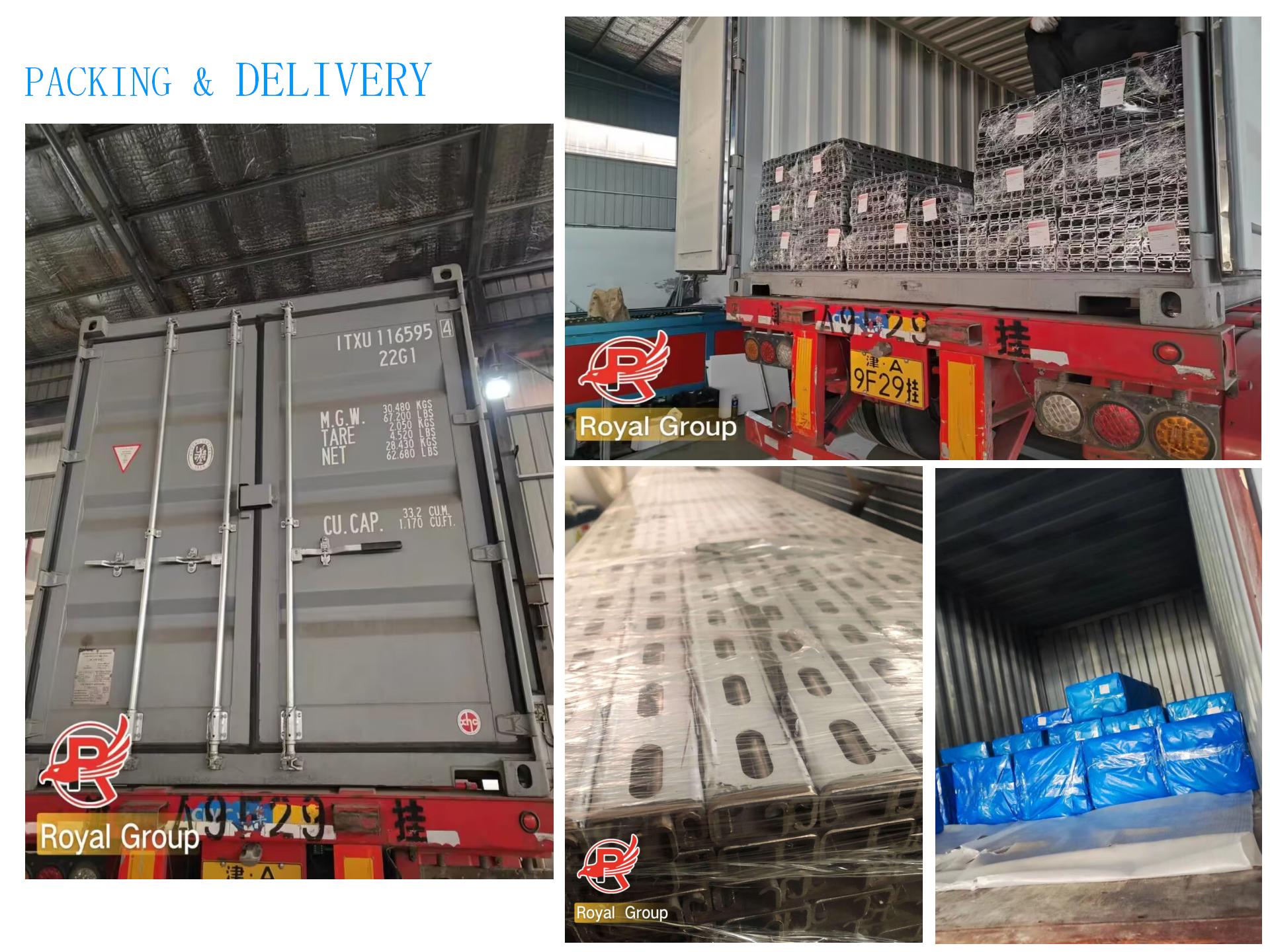

PACKAGING AND SHIPPING

Packaging:

We pack the products in bundles. A bundle of 500-600kg. A small cabinet weighs 19 tons.The outer layer will be wrapped with plastic film.

Shipping:

Choose a suitable mode of transportation: Depending on the quantity and weight of the Strut Channel, select the appropriate mode of transportation, such as flatbed trucks, containers, or ships. Consider factors like distance, time, cost, and any regulatory requirements for transportation.

Use appropriate lifting equipment: To load and unload the Strut Channel, use suitable lifting equipment such as cranes, forklifts, or loaders. Ensure that the equipment used has sufficient capacity to handle the weight of the sheet piles safely.

Secure the load: Properly secure the packaged stack of Strut Channel on the transportation vehicle using strapping, bracing, or other suitable means to prevent shifting, sliding, or falling during transit.

COMPANY STRENGTH

Made in China, first-class service, cutting-edge quality, world-renowned

1. Scale effect: Our company has a large supply chain and a large steel factory, achieving scale effects in transportation and procurement, and becoming a steel company that integrates production and services

2. Product diversity: Product diversity, any steel you want can be purchased from us, mainly engaged in steel structures, steel rails, steel sheet piles, photovoltaic brackets, channel steel, silicon steel coils and other products, which makes it more flexible Choose the desired product type to meet different needs.

3. Stable supply: Having a more stable production line and supply chain can provide more reliable supply. This is especially important for buyers who require large quantities of steel.

4. Brand influence: Have higher brand influence and larger market

5. Service: A large steel company that integrates customization, transportation and production

6. Price competitiveness: reasonable price

*Send the email to chinaroyalsteel@163.com to get a quotation for your projects

CUSTOMERS VISIT

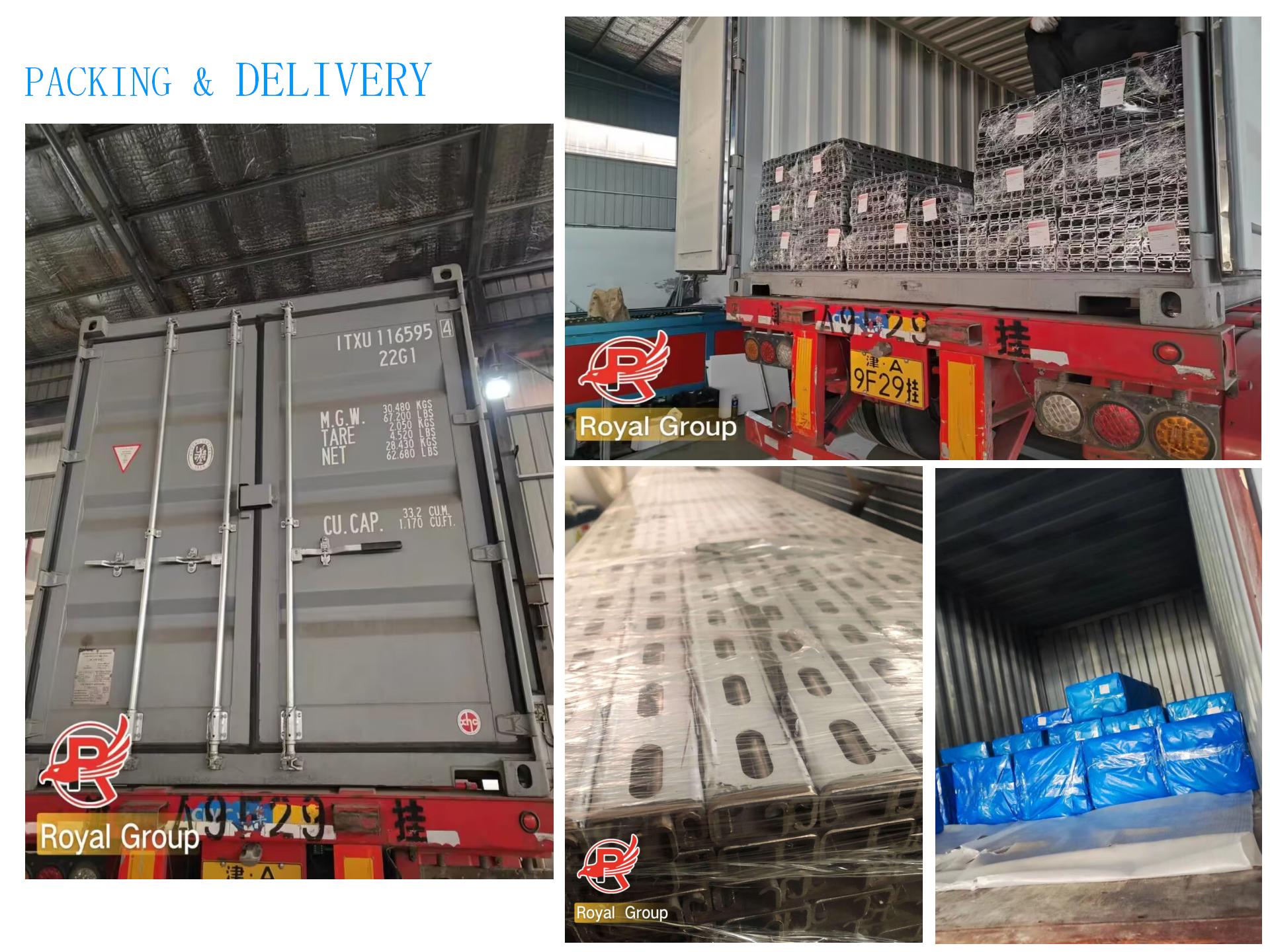

Packaging:

We pack the products in bundles. A bundle of 500-600kg. A small cabinet weighs 19 tons.The outer layer will be wrapped with plastic film.

Shipping:

Choose a suitable mode of transportation: Depending on the quantity and weight of the Strut Channel, select the appropriate mode of transportation, such as flatbed trucks, containers, or ships. Consider factors like distance, time, cost, and any regulatory requirements for transportation.

Use appropriate lifting equipment: To load and unload the Strut Channel, use suitable lifting equipment such as cranes, forklifts, or loaders. Ensure that the equipment used has sufficient capacity to handle the weight of the sheet piles safely.

Secure the load: Properly secure the packaged stack of Strut Channel on the transportation vehicle using strapping, bracing, or other suitable means to prevent shifting, sliding, or falling during transit.

COMPANY STRENGTH

CUSTOMERS VISIT

FAQ

1. who are we?

We are based in Tianjin, China, start from 2012,sell to Southeast Asia(20.00%),South Asia(20.00%),Southern Europe(10.00%),Western Europe(10.00%),Africa(10.00%),North America(25.00%),South America(5.00%). There are total about 51-100 people in our office.

2. how can we guarantee quality?

Always a pre-production sample before mass production;

Always final Inspection before shipment;

3.what can you buy from us?

Steel Pipes,Iron Angles,Iron Beams,Welded Steel Structures,Perforated Steel Products

4. why should you buy from us not from other suppliers?

High quality; Competitive price; Short delivery time; Satisfied service; Manufactured according to different standards

5. what services can we provide?

Accepted Delivery Terms: FOB,CFR,CIF;

Accepted Payment Currency:USD,CNY;

Accepted Payment Type: T/T,L/C;

Language Spoken:English,Chinese