Steel Structure Building Structure Steel Industrial Warehouse Building Prefabricated Warehouse

Used in hotels, restaurants, apartments and other multi-story and high-rise buildings. There are now more and more high-rise buildings using steel structures

Steel Structure System that require mobility or frequent assembly and disassembly, etc., if it is currently difficult or uneconomical to use other building materials, steel structures may be considered.

*Send the email to [email protected] to get a quotation for your projects

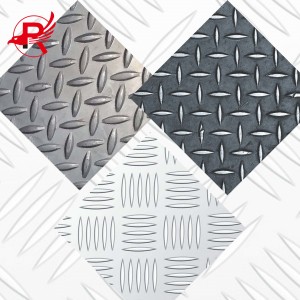

| Product name: | Steel Building Metal Structure |

| Material : | Q235B ,Q345B |

| Main frame : | H-shape steel beam |

| Purlin : | C,Z - shape steel purlin |

| Roof and wall : | 1.corrugated steel sheet ;

2.rock wool sandwich panels ;

3.EPS sandwich panels ; 4.glass wool sandwich panels |

| Door: | 1.Rolling gate

2.Sliding door

|

| Window: | PVC steel or aluminum alloy |

| Down spout : | Round pvc pipe |

| Application : | All kinds of industrial workshop ,warehouse ,high-rise building |

PRODUCT PRODUCTION PROCESS

ADVANTAGE

What should you pay attention to when making a Steel Structure House?

1. Pay attention to the reasonable structure

When arranging the rafters of a steel structure house, it is necessary to combine the design and decoration methods of the attic building. During the production process, it is necessary to avoid secondary damage to the steel and avoid possible safety hazards.

2. Pay attention to steel selection

There are many types of steel on the market today, but not all materials are suitable for building houses. In order to ensure the stability of the structure, it is recommended not to choose hollow steel pipes, and the interior cannot be directly painted, as it is easy to rust.

3. Pay attention to the clear structural layout

When the steel structure is stressed, it will produce obvious vibrations. Therefore, when building a house, we must conduct precise analysis and calculations to avoid vibrations and ensure visual beauty and solidity.

4. Pay attention to painting

After the steel frame is fully welded, the surface should be painted with anti-rust paint to prevent rust due to external factors. Rust will not only affect the decoration of the walls and ceilings, but even endanger safety.

DEPOSIT

Steel Structure Design are generally used as load-bearing frameworks in heavy-duty workshops, such as open-hearth workshops, blooming mills, and mixing furnace workshops in metallurgical plants; steel casting workshops, hydraulic press workshops, and forging workshops in heavy machine plants; slipway workshops in shipyards; and aircraft manufacturing plants. assembly workshops, as well as roof trusses, crane beams, etc. in workshops with larger spans in other factories.

PROJECT

Our company often exports steel structure products to the Americas and Southeast Asian countries. We participated in one of the projects in the Americas with a total area of approximately 543,000 square meters and a total use of approximately 20,000 tons of steel. After the project is completed, it will become a steel structure complex integrating production, living, office, education and tourism.

PRODUCT INSPECTION

Connection inspection is steel structure factory building to ensure the stability and safety of steel structures. The main inspection contents include welding quality, bolt connection quality, rivet connection quality, etc. For the detection of welding quality, non-destructive testing and other methods can be used for detection; for the detection of bolted connections and rivet connections, tools such as torque wrenches need to be used for measurement and testing.

APPLICATION

Used for larger radio masts, microwave towers, television towers, high-voltage transmission line towers, chemical exhaust towers, oil drilling rigs, atmospheric monitoring towers, tourist observation towers, transmission towers, etc.

PACKAGING AND SHIPPING

Steel structures are easily affected by the external environment during transportation and installation, so they must be packaged. The following are several commonly used packaging methods:

1. Plastic film packaging: Wrap a layer of plastic film with a thickness of not less than 0.05mm on the surface of the steel structure to ensure that the goods are protected from moisture, dust and pollution, and to avoid scratching the surface during loading and unloading.

2. Cardboard packaging: Use three-layer or five-layer cardboard to make a box or box, and place it on the surface of the steel structure to ensure that there is no friction and wear between the panels.

3. Wooden packaging: Cover the baffle on the surface of the steel structure and fix it on the steel structure. Simple steel structures can be wrapped with wooden frames.

4. Metal coil packaging: Pack the steel structure in steel coils to fully protect it during transportation and installation.

COMPANY STRENGTH

Made in China, first-class service, cutting-edge quality, world-renowned

1. Scale effect: Our company has a large supply chain and a large steel factory, achieving scale effects in transportation and procurement, and becoming a steel company that integrates production and services

2. Product diversity: Product diversity, any steel you want can be purchased from us, mainly engaged in steel structures, steel rails, steel sheet piles, photovoltaic brackets, channel steel, silicon steel coils and other products, which makes it more flexible Choose the desired product type to meet different needs.

3. Stable supply: Having a more stable production line and supply chain can provide more reliable supply. This is especially important for buyers who require large quantities of steel.

4. Brand influence: Have higher brand influence and larger market

5. Service: A large steel company that integrates customization, transportation and production

6. Price competitiveness: reasonable price

*Send the email to [email protected] to get a quotation for your projects

CUSTOMERS VISIT