Steel Rail

-

Building AREMA Standard Steel Rail Railway Crane Iron Rail

AREMA Standard Steel Rail are an important load-bearing structure when trains are running on railways. They can bear the weight of trains and transmit them to the roadbed. They also need to guide trains and reduce friction on sleepers. Therefore, the load-bearing capacity of rails is one of the important considerations.

-

AS 1085 Steel Rail Railway Light Steel Rails Track Crane Light_Rail Railroad Steel Rail

AS 1085 Steel Rail are the main components of railway tracks. Its function is to guide the wheels of rolling stock forward, bear the huge pressure of the wheels, and transmit it to the sleepers. Rails must provide a continuous, smooth and least-resistance rolling surface for the wheels. In electrified railways or automatic block sections, the rails can also double as track circuits.

-

Railroad Train BS Standard Steel Rail

The function of the BS Standard Steel Rail is to guide the wheels of rolling stock forward, bear the huge pressure of the wheels, and transmit it to the sleepers. Rails must provide a continuous, smooth and least-resistance rolling surface for the wheels. In electrified railways or automatic block sections, the rails can also double as track circuits.

-

High Quality Industry EN Standard Rail/UIC Standard Steel Rail Mining Rail Railroad Steel Rail

Improve railway operation efficiency: The use of steel rails can reduce the resistance and noise of trains, improve railway operation efficiency, speed up trains, shorten transportation time, and improve service quality.

-

Rail Track Heavy Steel Rail for DIN Standard Steel Rail

Steel rails are the main components of railway tracks. Its function is to guide the wheels of rolling stock forward, bear the huge pressure of the wheels, and transmit it to the sleepers. Rails must provide a continuous, smooth and least-resistance rolling surface for the wheels. In electrified railways or automatic block sections, the rails can also double as track circuits.

-

Railroad Rail Supplier Manufacturer JIS Standard Steel Rail

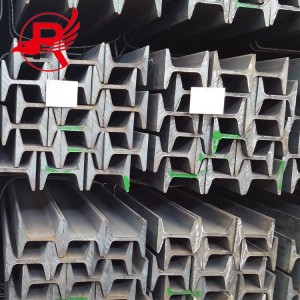

The cross-section shape of the rail is an I-shaped cross-section with the best bending resistance, which is composed of three parts: JIS Standard Steel Rail, rail waist and rail bottom. In order to enable the rail to better withstand forces from all aspects and ensure the necessary strength conditions, the rail should be of sufficient height, and its head and bottom should be of sufficient area and height. The waist and bottom should not be too thin.

-

Mining Use Train ISCOR Steel Rails Railway Crane Steel Rail Price

The main features of ISCOR steel rail include high strength, wear resistance and stability. They need to be able to withstand the weight of trains and constant use, and therefore play a vital role in rail transport. Rails need to be designed and manufactured to strict standards to ensure their quality and safety.

-

Chinese factory direct sales of high-precision rail price concessions

A rail is a long strip of steel used for railway tracks, mainly used to support and guide the wheels of a train. It is usually made of high-strength steel with good wear resistance and pressure resistance. The top of the rail is straight and the bottom is wide, which can evenly distribute the weight of the train and ensure the smooth running of the train on the track. Modern rail often uses seamless rail technology, which has higher strength and longer service life. The design and quality of rail directly affect the safety and comfort of railway transportation.