Steel Channel Sizes 150X90 35355 Galvanized Steel Furring Channel 41X41 Unistrut Channel Steel

Choose appropriate materials: Strut Channel should be made of corrosion-resistant, anti-aging, high-strength materials, such as aluminum alloy, stainless steel, etc. At the same time, considering environmental protection requirements, recyclable materials can also be used.

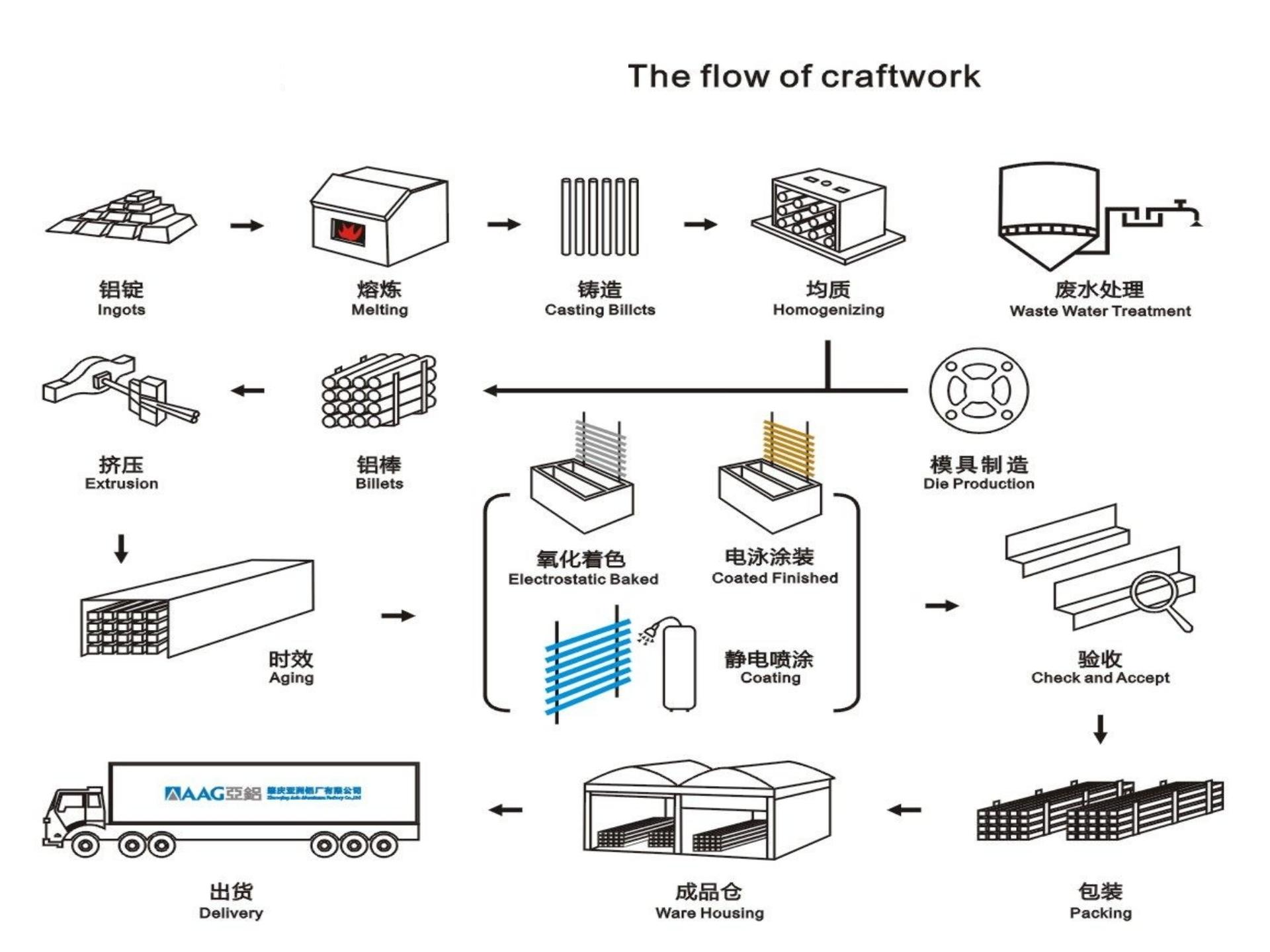

PRODUCT PRODUCTION PROCESS

For use to support conduits, fixtures and ventilation systems from beams and other strutctural systems.

|

Product Name

|

Made in China Hot Dip Galvanized Steel Slotted Strut Channel ( C Channel, Unistrut, Uni Strut Channel)

|

|

Material

|

Q195/Q235/SS304/SS316/Aluminum

|

|

Thickness

|

1.5mm/2.0mm/2.5mm

|

|

Type

|

41*21,/41*41 /41*62/41*82mm with slotted or plain

|

|

Length

|

3m/3.048m/6m

|

|

Finished

|

Pre-galvanized/HDG/power coated

|

| No. | Size | Thickness | Type | Surface

Treatment |

||

| mm | inch | mm | Gauge | |||

| A | 41x21 | 1-5/8x13/16" | 1.0,1.2,1.5,2.0,2.5 | 20,19,17,14,13 | Slotted, Solid | GI,HDG,PC |

| B | 41x25 | 1-5/8x1" | 1.0,1.2,1.5,2.0,2.5 | 20,19,17,14,13 | Slotted, Solid | GI,HDG,PC |

| C | 41x41 | 1-5/8x1-5/8" | 1.0,1.2,1.5,2.0,2.5 | 20,19,17,14,13 | Slotted, Solid | GI,HDG,PC |

| D | 41x62 | 1-5/8x2-7/16" | 1.0,1.2,1.5,2.0,2.5 | 20,19,17,14,13 | Slotted, Solid | GI,HDG,PC |

| E | 41x82 | 1-5/8x3-1/4" | 1.0,1.2,1.5,2.0,2.5 | 20,19,17,14,13 | Slotted, Solid | GI,HDG,PC |

ADVANTAGE

Steel Strut has excellent mechanical properties and usability. So what are the advantages of C-shaped steel? Let’s introduce it to you.

1. The structure is light in weight. Compared with the concrete structure, which is lighter in weight, the reduction of the structure's weight reduces the internal force of the structure design, which can reduce the need for basic treatment of the building structure, simplify the construction, and reduce the cost.

2. Steel Strut design has flexible and rich features. When the beam height is the same, the bays of the steel structure can be 50% larger than the bays of the concrete structure, thus making the building installation more flexible.

3. The steel structure, mainly hot-rolled C-shaped steel, has a scientific and reasonable structure, good steel channel and flexibility, and high structural stability. It is suitable for building structures that bear large vibration and impact loads. It has strong resistance to natural disasters and is especially suitable for Some building structures in earthquake-prone zones.

4. Increase the effective use area of the structure. Compared with the concrete structure, the cross-sectional area of the steel structure column is small, which can increase the effective use area of the building. Depending on the different forms of the building, the effective use area can be increased by 4-6%.

5. Compared with welded C-shaped steel, it can significantly save labor and materials, reduce the consumption of raw materials, energy and labor, has low residual stress, and has good appearance and surface quality.

6. It is convenient for machining, structural connection and installation, and is also easy to dismantle and reuse.

In addition, the use of C-shaped steel can effectively protect the environment, which is reflected in three aspects: first, compared with concrete, dry construction can be used, which produces less noise and less dust; second, due to the reduced weight, less soil is required for basic construction , causing little damage to land resources and conducive to the protection of the ecological environment; third, after the service life of the building structure expires, after the structure is dismantled, the amount of solid waste generated is small, and the recycling value of scrap steel resources is high.

PRODUCT INSPECTION

1. Inspection of the size and geometry of photovoltaic supports, including inspection of verticality, horizontality, symmetry, distance tolerance, etc.

2. Inspection of photovoltaic bracket connectors and welding quality, including inspection of specifications and strength of fasteners, quality and reliability of welds, etc.

3. Inspection of the surface quality and coating of photovoltaic supports, including inspection of surface finish, oxide film thickness, coating adhesion, etc.

4. Inspection of the load-bearing capacity and stability of photovoltaic supports, including inspection of maximum load, deflection and inclination.

PROJECT

Our company has participated in the largest solar energy development project in South America, providing brackets and solution design. We provided 15,000 tons of photovoltaic brackets for this project. The photovoltaic brackets adopted domestic emerging technologies to help the development of the photovoltaic industry in South America and improve local residents. Life. The photovoltaic support project includes a photovoltaic power station with an installed capacity of approximately 6MW and a battery energy storage power station of 5MW/2.5h. It can generate approximately 1,200 kilowatt hours per year. The system has good photoelectric conversion capabilities.

APPLICATION

Under different climate and terrain conditions, it is necessary to choose Galvanized C Channel varieties that are suitable for the local area. In extreme climate conditions, such as earthquakes, heavy rains, storms, sandstorms, etc., photovoltaic racks need to have sufficient stability and wind pressure resistance to avoid accidents. It can be seen that photovoltaic brackets can be installed not only on roofs, but also on the ground and water. The selection of photovoltaic brackets requires comprehensive consideration of factors such as load-bearing capacity, environmental conditions, stability, construction and operation and maintenance costs. Photovoltaic supports that are stable and strong enough can ensure the long-term stable operation of photovoltaic power stations and make important contributions to the development of renewable energy.

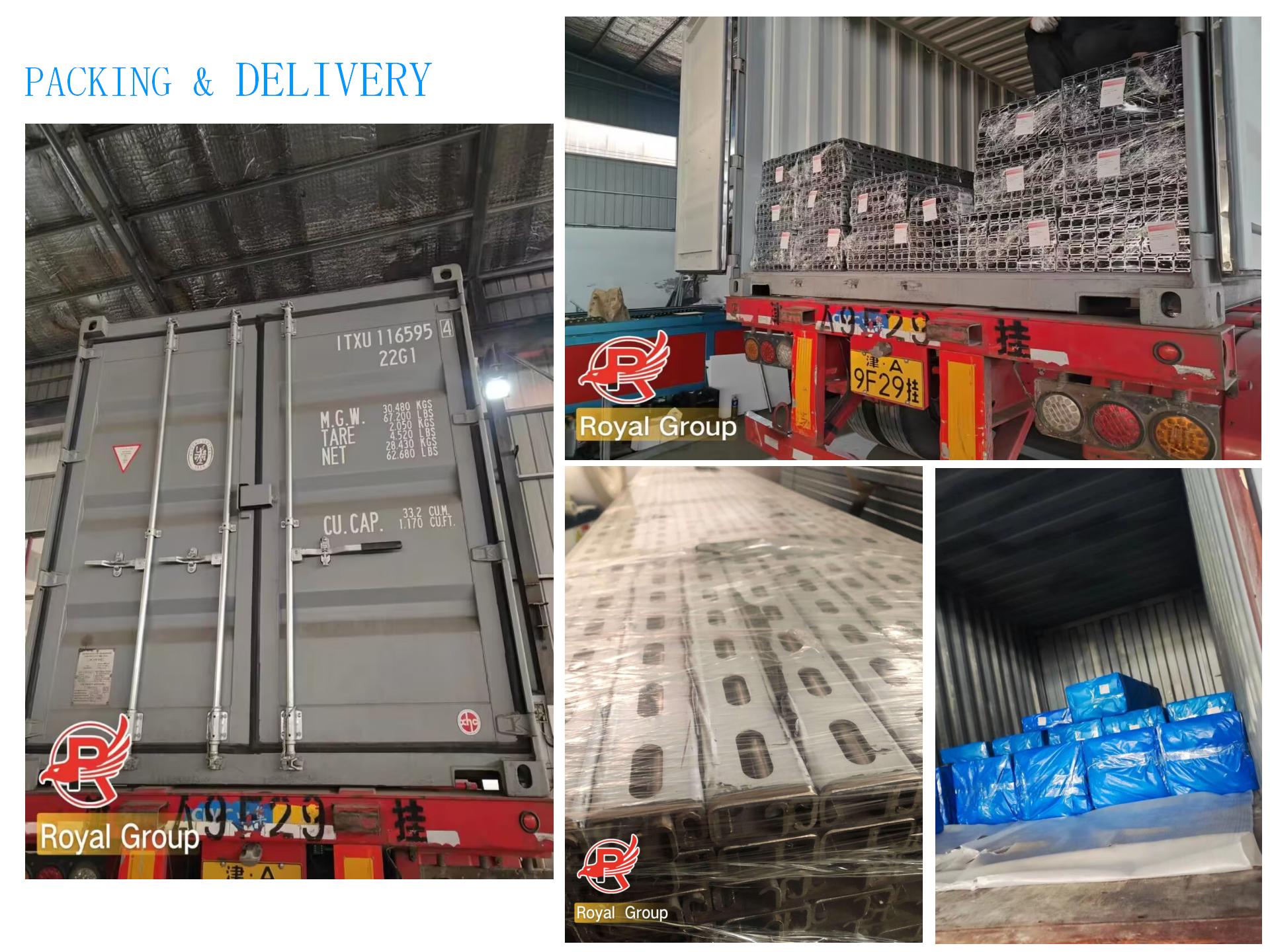

PACKAGING AND SHIPPING

1. Photovoltaic module packaging

The packaging of photovoltaic modules is mainly to protect their glass surfaces and bracket systems and to prevent collision and damage during transportation. Therefore, in the packaging of photovoltaic modules, the following packaging materials are commonly used:

1. Foam box: Use rigid foam box for packaging. The box is made of high-strength cardboard or wooden box, which can effectively protect the photovoltaic modules and is more convenient for transportation and handling operations.

2. Wooden boxes: Fully consider that heavy objects may be collided, squeezed, etc. during transportation, so using ordinary wooden boxes will be stronger. However, this packaging method takes up a certain amount of space and is not conducive to environmental protection.

3. Pallet: It is packaged in a special pallet and placed on corrugated cardboard, which can hold up the photovoltaic panels stably and is firm and easy to transport.

4. Plywood: Plywood is used to fix the photovoltaic modules to ensure that they are not subject to collision and extrusion to avoid damage or deformation during transportation.

2. Transportation of photovoltaic modules

There are three main modes of transportation for photovoltaic modules: land transportation, sea transportation, and air transportation. Each method has its own characteristics.

1. Land transportation: Applicable to transportation within the same city or province, with a single transportation distance not exceeding 1,000 kilometers. General transportation companies and logistics companies can transport photovoltaic modules to their destinations via land transportation. During transportation, pay attention to avoid collisions and extrusions, and choose a professional transportation company to cooperate as much as possible.

2. Sea transportation: suitable for inter-provincial, cross-border and long-distance transportation. Pay attention to packaging, protection and moisture-proof treatment, and try to choose a large logistics company or a professional shipping company as a partner.

3. Air transportation: suitable for cross-border or long-distance transportation, which can greatly shorten transportation time. However, air freight costs are relatively high and appropriate protection measures are required.

COMPANY STRENGTH

Made in China, first-class service, cutting-edge quality, world-renowned

1. Scale effect: Our company has a large supply chain and a large steel factory, achieving scale effects in transportation and procurement, and becoming a steel company that integrates production and services

2. Product diversity: Product diversity, any steel you want can be purchased from us, mainly engaged in steel structures, steel rails, steel sheet piles, photovoltaic brackets, channel steel, silicon steel coils and other products, which makes it more flexible Choose the desired product type to meet different needs.

3. Stable supply: Having a more stable production line and supply chain can provide more reliable supply. This is especially important for buyers who require large quantities of steel.

4. Brand influence: Have higher brand influence and larger market

5. Service: A large steel company that integrates customization, transportation and production

6. Price competitiveness: reasonable price

*Send the email to chinaroyalsteel@163.com to get a quotation for your projects

CUSTOMERS VISIT

FAQ

1.How can I get a quotation from you ?

You can leave us message, and we will reply every message in time.

2.Will you delivery the goods on time?

Yes,we promise to provide best quality products and delivery on time. Honesty is our company's tenet.

3.Can I get samples before order ?

Yes, of course. Usually our samples are free,we can produce by your samples or technical drawings.

4.What is your payment terms?

Our usual payment term is 30% deposit, and rest against B/L. EXW, FOB,CFR, CIF.

5.Do you accept the third party inspection?

Yes absolutely we accept.

6.How do we trust your company?

We specialise in steel business for years as golden supplier, headquarter locates in Tianjin province, welcome to investigate in any ways, by all means.