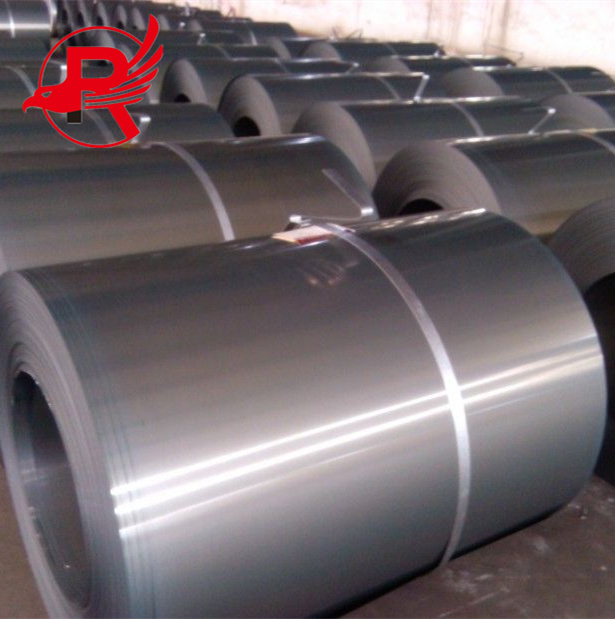

Silicon Steel Grain Oriented Electrical Steel Coil of Chinese Prime Factory

Product Detail

Adding silicon can increase the resistivity and reduce wear and porcelain effectiveness, but the production technology of silicon steel plates is relatively complicated.

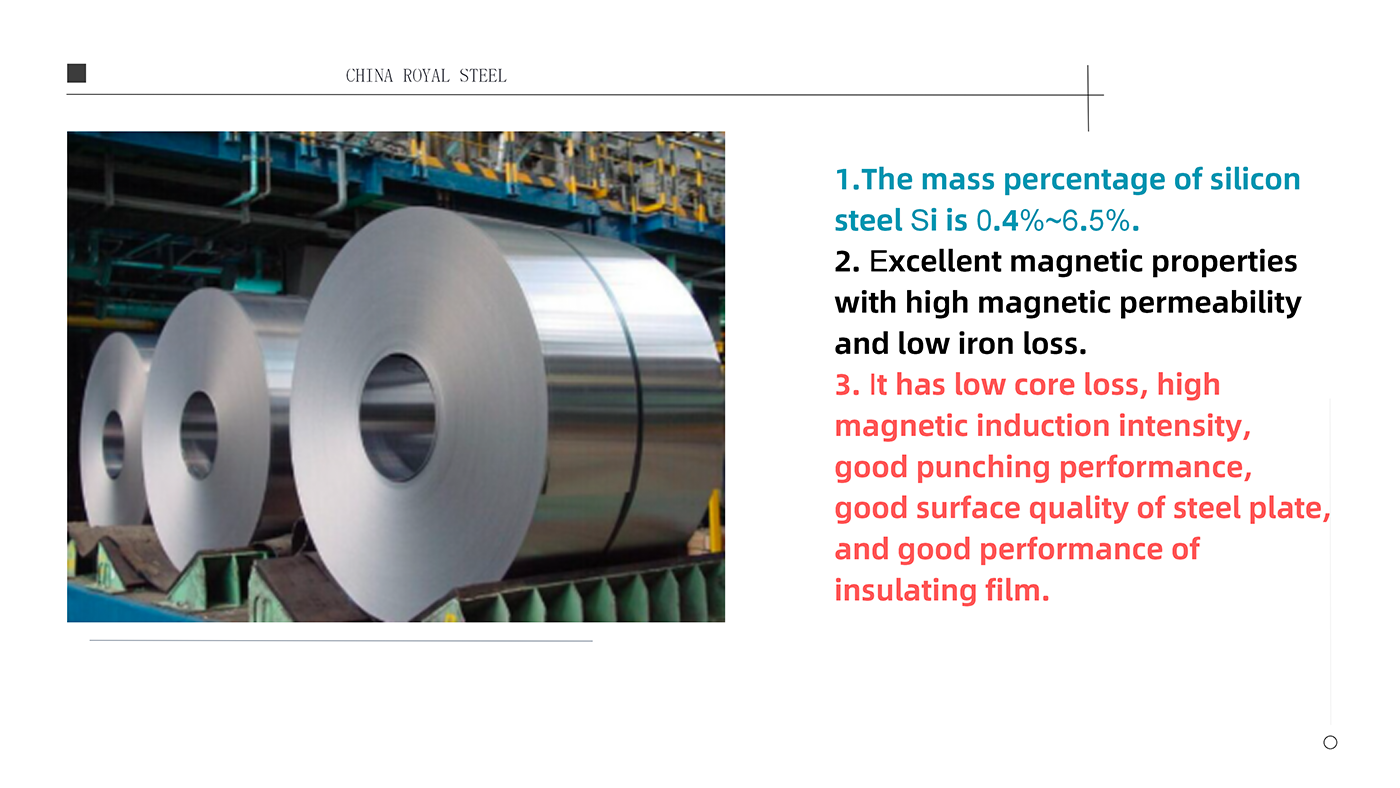

Features

The performance requirements for steel silicon plates are mainly to reduce iron loss, which is an important indicator. At the same time, it must be able to bring a relatively high intensity of magnetic induction under a strong magnetic field. The surface must be smooth and flat, and the thickness must be uniform to increase the filling factor. Mainly used to make iron cores for various transformers, motors and generators. The world's silicon steel sheet production accounts for about 1% of the total steel production.

Application

It's important to note that these are just a few examples of the many applications silicon steel coils can be used for. The specific application and design requirements will determine the specific type, grade, and characteristics of silicon steel to be used. Consulting with a professional in the field or referring to manufacturer specifications will help in selecting the right silicon steel coil for a particular application.

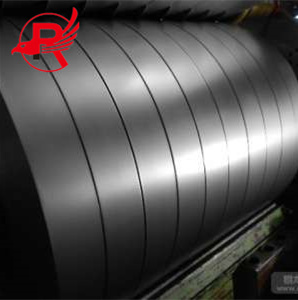

Packaging & Shipping

1. Before transportation, you should check whether the packaging of silicon steel sheets is intact to avoid damage during transportation.

2. During transportation, handle it with care and do not use excessive force to avoid deformation or damage of the silicon steel sheet.

3. Silicon steel sheets should be transported upright and not sideways or tilted. This will help protect the shape and performance of the silicon steel sheets.

4. During transportation, care should be taken to prevent the silicon steel sheet from rubbing against hard objects to avoid scratching or damaging the surface.

5. When transporting silicon steel sheets, the silicon steel sheets should be placed in a flat, dry, and dust-free place. This will help protect the quality of the silicon steel sheets and extend their service life.

6. When handling silicon steel sheets, vibration and collision should be avoided to avoid affecting the magnetic permeability and electrical properties of the silicon steel sheets.

FAQ

Q1. Where is your factory ?

A1: Our company’s processing center is located in Tianjin, China.Which is well equipped with kinds of machines, such as laser cutting machine,mirror polishing machine and so on. We can provide a wide range of personalized services according to the customers’ needs.

Q2. What are your company's main products ?

A2: Our main products are stainless steel plate/sheet, coil, round/square pipe, bar, channel, steel sheet pile, steel strut,etc.

Q3. How do you control quality ?

A3: Mill Test Certification is supplied with shipment, Third Party Inspection is available.

Q4. What are the advantages of your company ?

A4: We have many professionals, technical personnel, more competitive prices and

best after-dales service than other stainless steel companies.

Q5. How many coutries you already exported ?

A5: Exported to more than 50 countries mainly from America, Russia, UK, Kuwait,

Egypt, Turkey, Jordan, India, etc.

Q6. Can you provide sample ?

A6: Small samples in store and can provide the samples for free. Customized samples will take about 5-7days.