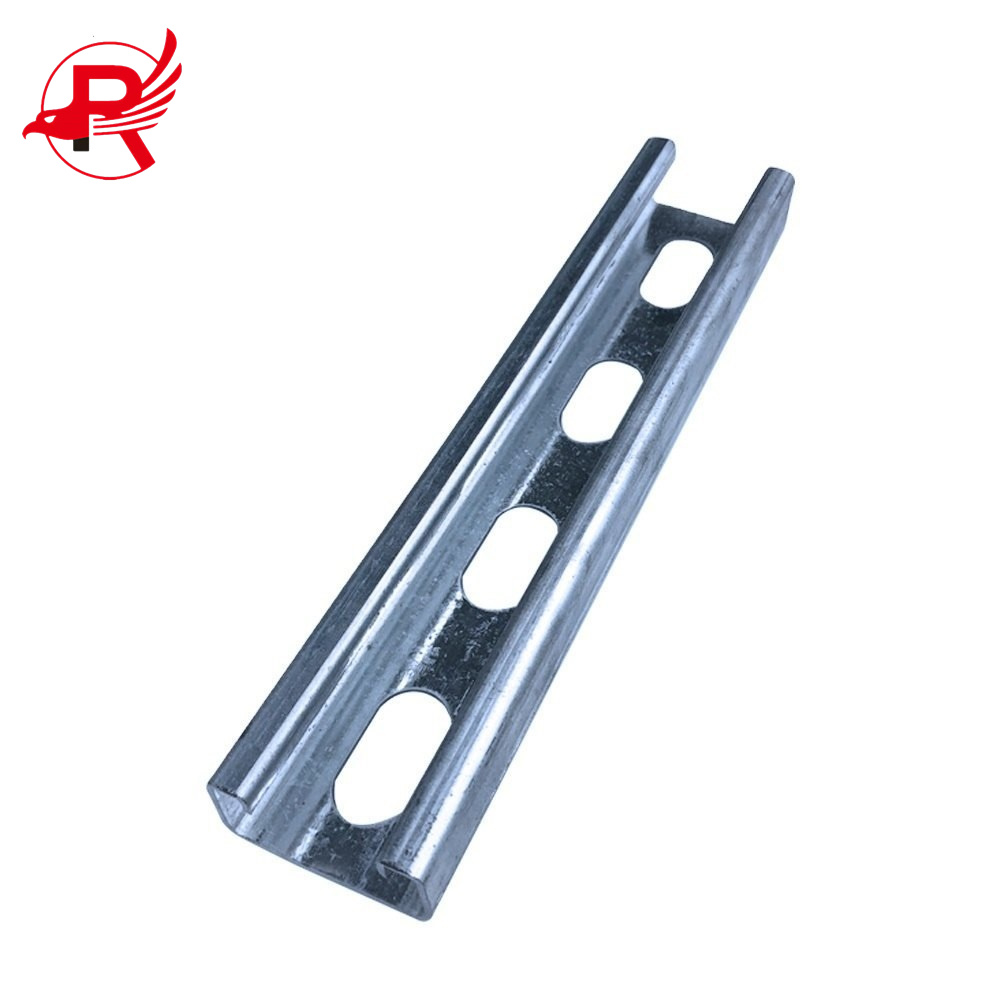

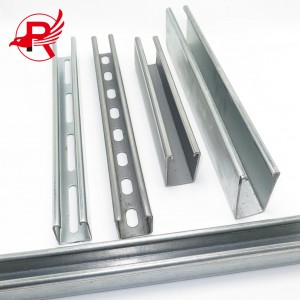

Mounting Profile 41*41 Strut Channel / C Channel/ Seismic Bracket

The characteristics of 2x4 C Channel Steel 2x6 Steel Channel mainly include the following points:

High stability: the fixed photovoltaic bracket can resist changes in various climatic conditions to ensure the reliability of the photovoltaic module support.

Low maintenance cost: Due to its simple construction, easy installation and maintenance, the overall operating cost is reduced.

Wide applicability: suitable for a variety of sites, such as roof, ground, hillside, etc., suitable for various scales of solar power station system.

Long life: the design life of the fixed photovoltaic bracket can reach more than 30 years.

Advantages and disadvantages: Although the maintenance cost is low, due to the inability to actively adjust the optimal light Angle, it may affect the power generation efficiency when the lighting conditions are not good. For high wind or cold areas of photovoltaic brackets may need additional reinforcement.

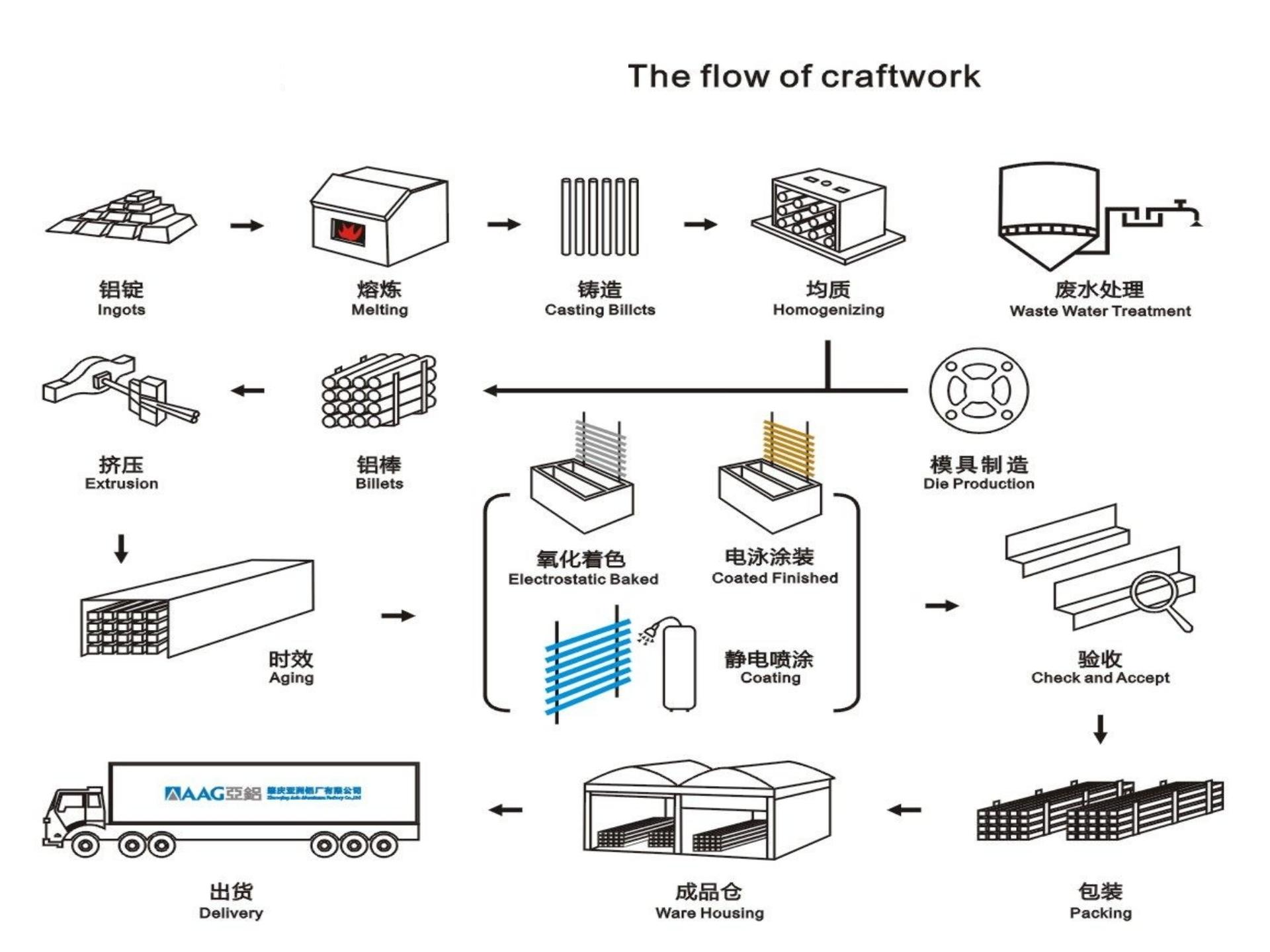

PRODUCT PRODUCTION PROCESS

PRODUCT SIZE

|

Product Size

|

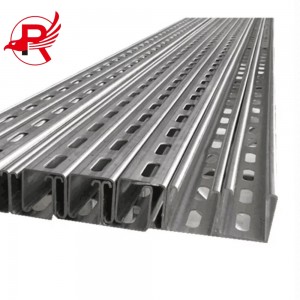

41*21,/41*41 /41*62/41*82mm with slotted or plain1-5/8'' x 1-5/8'' 1-5/8'' x 13/16''/or customized size

length is cut according to customer's requirements U or C shape with standard AISI, ASTM, GB,BS,EN,JIS,DIN or customer's drawings |

|

Product Material and Surface

|

· Material: carbon steel

· Surface coating: o Galvanized o Hot Dipped Galvanizing o Electrolytic Galvanizing o Powder coating o Neomagnal |

|

Corrosion Rating of Hot Dipped Galvanized

|

For example

Indoor:Production premises with high humidity levels and some impurities in the air, such as food industry facilities.

Outdoor:Urban and industrial atmosphere with medium sulphur dioxide levels. Coastal areas with low salinity levels.

Galvanization wear:0,7 μm - 2,1 μm in a year

Indoor:Chemical industry production plants, coastal shipyards and boatyards.

Outdoor:Industrial areas and coastal areas with medium salinity levels.

Galvanization wear:2,1 μm - 4,2 μm in a year

|

| No. | Size | Thickness | Type | Surface

Treatment |

||

| mm | inch | mm | Gauge | |||

| A | 41x21 | 1-5/8x13/16" | 1.0,1.2,1.5,2.0,2.5 | 20,19,17,14,13 | Slotted, Solid | GI,HDG,PC |

| B | 41x25 | 1-5/8x1" | 1.0,1.2,1.5,2.0,2.5 | 20,19,17,14,13 | Slotted, Solid | GI,HDG,PC |

| C | 41x41 | 1-5/8x1-5/8" | 1.0,1.2,1.5,2.0,2.5 | 20,19,17,14,13 | Slotted, Solid | GI,HDG,PC |

| D | 41x62 | 1-5/8x2-7/16" | 1.0,1.2,1.5,2.0,2.5 | 20,19,17,14,13 | Slotted, Solid | GI,HDG,PC |

| E | 41x82 | 1-5/8x3-1/4" | 1.0,1.2,1.5,2.0,2.5 | 20,19,17,14,13 | Slotted, Solid | GI,HDG,PC |

ADVANTAGE

C Channel Structural Steel has the advantages of light weight, corrosion resistance, easy installation and reusable, and is widely used in the construction of photovoltaic power generation system

In specific photovoltaic power station projects, photovoltaic brackets have the following characteristics:

Photovoltaic brackets need to be used for a long time in a specific environment. It has strong mechanical properties such as wind pressure resistance, snow pressure resistance, earthquake resistance, and corrosion resistance, ensuring normal operation in various harsh environments such as sandstorm, rain, snow, earthquake, etc., and its service life is generally required to be more than 25 years.

Photovoltaic brackets need to meet various standards of the project site. The core of photovoltaic power station design is structural design. The entire photovoltaic power station structural design is mainly realized through photovoltaic brackets. Photovoltaic brackets play an important role in the construction of photovoltaic power stations. The product quality, design and installation of photovoltaic brackets need to comply with the climate environment, building standards, power design and other standards of the project site. Choosing appropriate photovoltaic brackets and scientific and reasonable design and installation can not only reduce project costs and improve power generation efficiency, but also reduce later operation and maintenance costs.

PRODUCT INSPECTION

Photovoltaic brackets are structures used to support and install solar photovoltaic modules. They are usually composed of connectors, columns, keels, beams, auxiliary parts and other parts. Photovoltaic brackets come in many forms, such as welded type and assembled type according to the connection method, fixed type and sun-mounted type according to the installation structure, ground type and roof type according to the installation location.

The testing items of photovoltaic brackets include the following aspects:

Overall appearance inspection: Visual inspection of the photovoltaic power station’s support structure, welding quality, fasteners and anchors to determine whether it is damaged or severely deformed.

Stability inspection of the bracket: including inspection of the inclination, levelness, offset performance, etc. of the bracket to ensure that the bracket can maintain a stable working condition even in natural disasters and other abnormal situations.

Bearing capacity inspection: Evaluate the bearing capacity of the bracket by measuring the actual load and design bearing capacity of the bracket to ensure reasonable distribution of the load and prevent bracket collapse and accidents caused by excessive load.

Fastener status inspection: Check fasteners such as plates and bolts to ensure that the connection heads are not loose or flashing, and replace fasteners that need maintenance or replacement in a timely manner.

Corrosion and aging inspection: Inspect the bracket parts for corrosion, aging, compression deformation, etc. to prevent damage and component failure due to long-term use.

Related facility inspections: Includes inspections of related facilities such as solar panels, trackers, arrays, and inverters to ensure that all elements of the system are operating within system specifications.

APPLICATION

C Purlin Galvanized adapted to climate and terrain

Under different climate and terrain conditions, it is necessary to choose photovoltaic bracket varieties that are suitable for the local area. In extreme climate conditions, such as earthquakes, heavy rains, storms, sandstorms, etc., photovoltaic racks need to have sufficient stability and wind pressure resistance to avoid accidents.

It can be seen that photovoltaic brackets can be installed not only on roofs, but also on the ground and water. The selection of photovoltaic brackets requires comprehensive consideration of factors such as load-bearing capacity, environmental conditions, stability, construction and operation and maintenance costs. Photovoltaic supports that are stable and strong enough can ensure the long-term stable operation of photovoltaic power stations and make important contributions to the development of renewable energy.

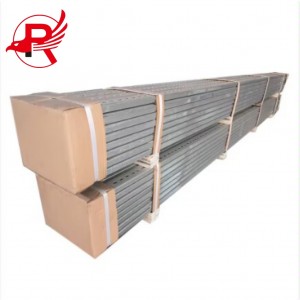

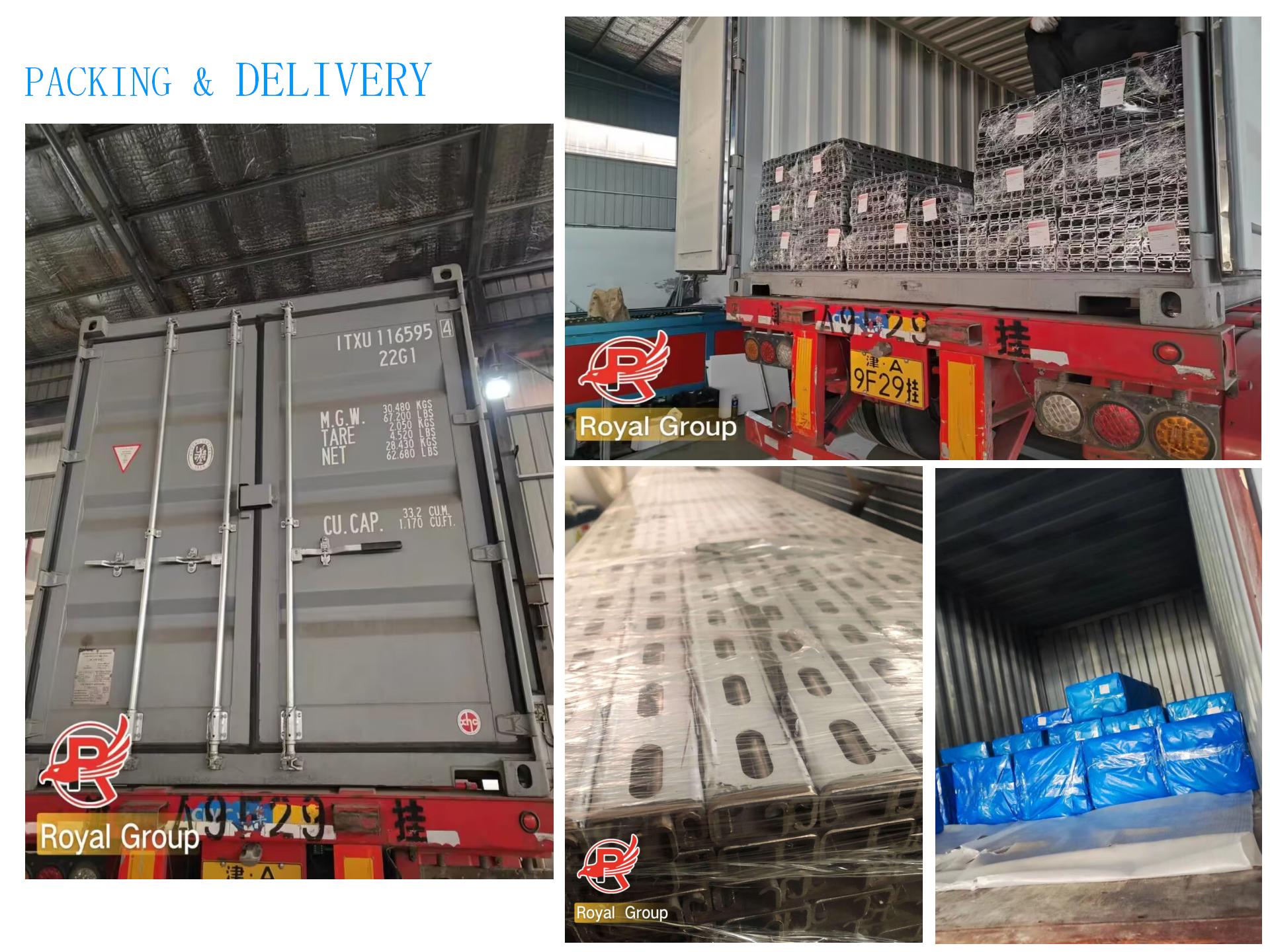

PACKAGING AND SHIPPING

What are the transportation packaging of Cold Rolled C Channel:

1. Iron frame packing

2. Wooden frame packing

3. Carton pallet packaging

|

Package

|

Standard export seaworthy package,suit for all kinds of transport, or as required.

Water-proof Paper + Edge protection + Wooden Pallets

|

|

Loading Port

|

Tianjin, Xingang Port, Qingdao,Shanghai, Ningbo, or any China Seaport

|

|

Container

|

1*20ft container load Max. 25 Ton, Max. length 5.8m

1*40ft container load Max. 25 Ton, Max. Length 11.8m

|

|

Delivery Time

|

7-15 days or according to the order's quantity

|

COMPANY STRENGTH

Made in China, first-class service, cutting-edge quality, world-renowned

1. Scale effect: Our company has a large supply chain and a large steel factory, achieving scale effects in transportation and procurement, and becoming a steel company that integrates production and services

2. Product diversity: Product diversity, any steel you want can be purchased from us, mainly engaged in steel structures, steel rails, steel sheet piles, photovoltaic brackets, channel steel, silicon steel coils and other products, which makes it more flexible Choose the desired product type to meet different needs.

3. Stable supply: Having a more stable production line and supply chain can provide more reliable supply. This is especially important for buyers who require large quantities of steel.

4. Brand influence: Have higher brand influence and larger market

5. Service: A large steel company that integrates customization, transportation and production

6. Price competitiveness: reasonable price

*Send the email to chinaroyalsteel@163.com to get a quotation for your projects

CUSTOMERS VISIT

FAQ

1. Why choose your company?

Because we are factory directly, So the price is lower. Delivery time can be ensured.

2.Where is your factory located? How can I visit there?

Our factory is located in the center of Tianjin, China, About 1 hours bus ride from Tianjin port. So it's really convenient for you to come to our company. We are here warmly welcome you.

3.What type of payment do you have available?

TT and L/C, As to sample order West union will be also acceptable.

4.How can I get some samples?

We are honored to offer you samples.

5.How does your factory do regarding quality control?

Each products need be inspected before into the wherehouse. Our boss and all SAIYANG staff had pay highly attention of the quality.

6. How can I get a quotation?

Because all our products are OEM products. This means customized products. In order to send you an accurate quotation, the following information will be needed: Materials and thickness, Size, Surface treatment, order quantity, Drawings will be highly appreciated. Then I will send you an accurate quotation.