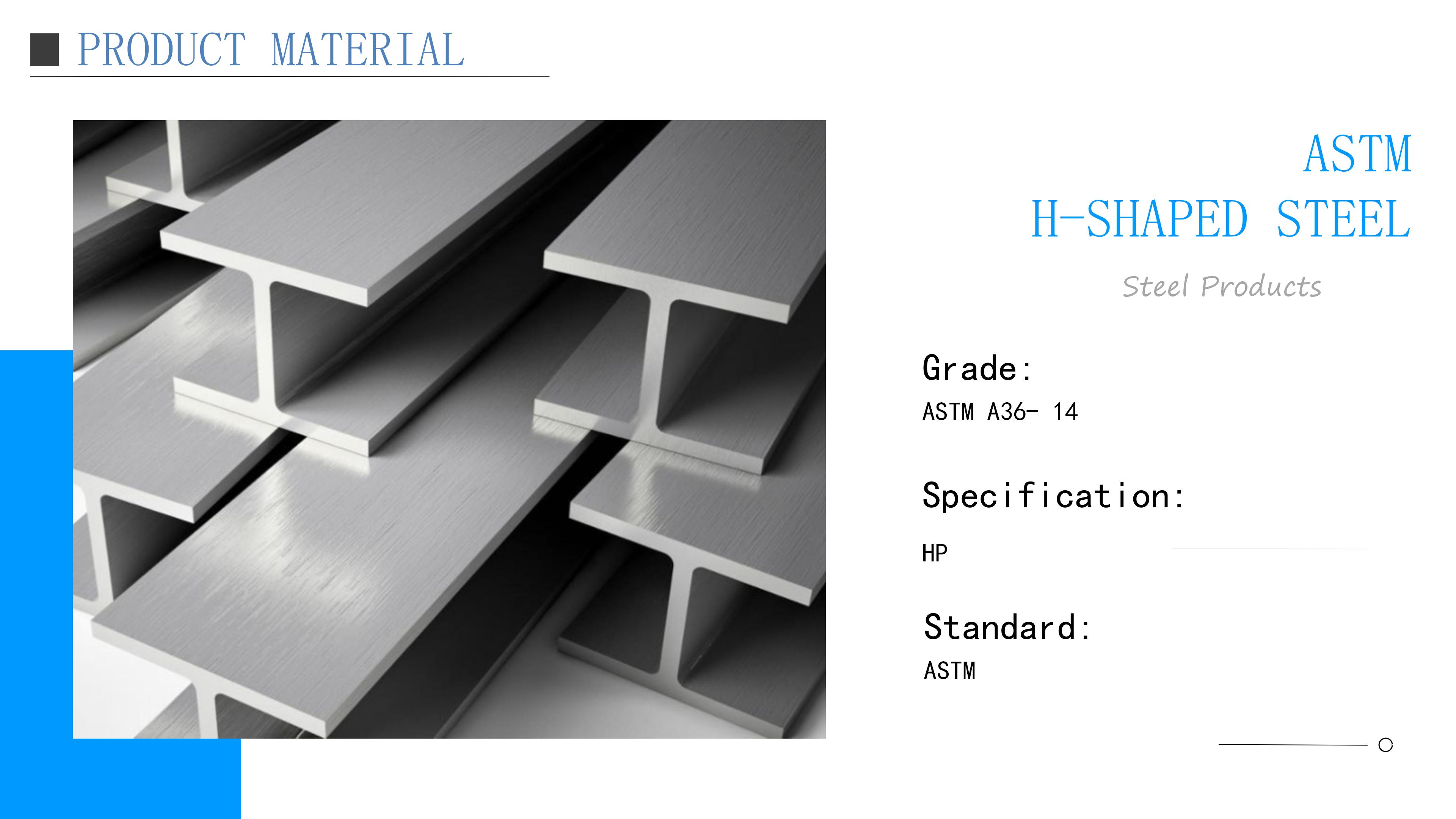

ASTM H-Shaped Steel Structural Engineering and Steel Pile Construction

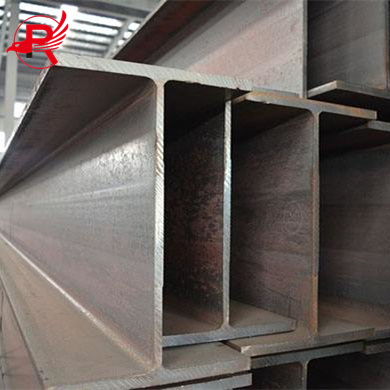

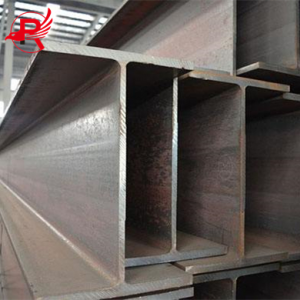

In the ever-evolving world of construction and engineering, the demand for reliable and durable structural steel solutions is at an all-time high. Among the many options available, the H Beam Pile, also known as the H Section Beam or H Shaped Steel, has emerged as a go-to choice for professionals worldwide. This blog aims to shed light on the various aspects of this remarkable product, including its features, applications, and benefits within the industry.

PRODUCT PRODUCTION PROCESS

1. Preliminary preparation: including raw material procurement, quality inspection and material preparation. The raw material is usually molten iron produced from high-quality graphitization furnace steelmaking or electric furnace steelmaking, which is put into production after quality inspection.

2. Smelting: Pour the molten iron into the converter and add appropriate returned steel or pig iron for steelmaking. During the steelmaking process, the carbon content and temperature of the molten steel are controlled by adjusting the dosage of graphitizing agent and blowing oxygen in the furnace.

3. Continuous casting billet: The steelmaking billet is poured into the continuous casting machine, and the flowing water from the continuous casting machine is injected into the crystallizer, allowing the molten steel to gradually solidify to form a billet.

4. Hot rolling: The continuous casting billet is hot rolled through the hot rolling unit to make it reach the specified size and geometric shape.

5. Finish rolling: The hot-rolled billet is finished rolled, and the size and shape of the billet are made more accurate by adjusting the rolling mill parameters and controlling the rolling force.

6. Cooling: The finished steel is cooled to reduce the temperature and fix the dimensions and properties.

7. Quality inspection and packaging: Quality inspection of finished products and packaging according to size and quantity requirements.

PRODUCT SIZE

| Divis ibn (depth x idth |

Unit Weight kg/m) |

Sandard Sectional Dimension (mm) |

Secional Area cm² |

||||

| W | H | B | 1 | 2 | r | A | |

| HP8x8 | 53.5 | 203.7 | 207.1 | 11.3 | 11.3 | 10.2 | 68.16 |

| HP10x10 | 62.6 | 246.4 | 255.9 | 10.5 | 10.7 | t2.7 | 70.77 |

| 85.3 | 253.7 | 259.7 | 14.4 | 14.4 | 127 | 108.6 | |

| HP12x12 | 78.3 | 2992 | 305.9 | 11.0 | 11.0 | 15.2 | 99.77 |

| 93.4 | 303.3 | 308.0 | 13.1 | 13.1 | 15.2 | 119.0 | |

| 111 | 308.1 | 310.3 | 15.4 | 15.5 | 15.2 | 140.8 | |

| 125 | 311.9 | 312.3 | 17.4 | 17.4 | 15.2 | 158.9 | |

| HP14x14% | 108.0 | 345.7 | 370.5 | 12.8 | t2.8 | 15.2 | 137.8 |

| 132.0 | 351.3 | 373.3 | 15.6 | 15.6 | 15.2 | 168.4 | |

| 152.0 | 355.9 | 375.5 | 17.9 | 17.9 | 15.2 | 193.7 | |

| 174.0 | 360.9 | 378.1 | 20.4 | 20.4 | 15.2 | 221.5 | |

|

SPECIFICATIONS FOR H-BEAM |

|

| 1. Size | 1) Thickness:5-34mm or customized |

| 2)Length:6-12m | |

| 3)Web Thickness:6mm-16mm | |

| 2. Standard: | JIS ASTM DIN EN GB |

| 3.Material | Q195 Q235 Q345 A36 S235JR S335JR |

| 4. Location of our factory | Tianjin,China |

| 5. Usage: | 1)industrial high-rise building |

| 2)Buildings in Earthquake Prone Areas | |

| 3)large bridges with long spans | |

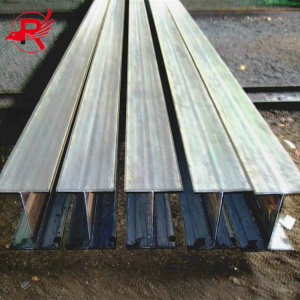

| 6. Coating: | 1) Bared

2) Black Painted (varnish coating) 3) galvanized |

| 7. Technique: | hot rolled |

| 8. Type: | H type sheet pile |

| 9. Section Shape: | H |

| 10. Inspection: | Client inspection or inspection by 3rd party. |

| 11. Delivery: | Container, Bulk Vessel. |

| 12. About Our Quality: | 1) No damage, no bent

2) Free for oiled&marking 3) All goods can be checked by third party inspection before shipment |

ADVANTAGE

Versatility in Applications:

One of the significant advantages of Beam H is its remarkable versatility, making it suitable for a wide range of applications in the construction industry. Due to its excellent load-bearing capacity, these beams are extensively used in the construction of bridges, buildings, warehouses, and various other large structures. The unique shape of H beams allows for effective distribution of weight, minimizing the risk of sagging or deformation under heavy loads.

Strength and Durability:

When it comes to supporting heavy loads, H Beam 100x100 undoubtedly stands out in the competition. The structural steel H beam exhibits remarkable strength properties, making it an ideal choice for projects where load-bearing capacity is of utmost importance. Additionally, the use of hot rolled steel in the manufacturing process enhances the overall durability and resilience of these beams, making them highly resistant to warping, twisting, and corrosion.

Design Flexibility:

Another noteworthy aspect of H Beam 200x200 is its inherent design flexibility, allowing architects and engineers to create innovative and aesthetically pleasing structures. The H-shaped profile enables easy connection to other structural elements, including columns, beams, and braces, providing endless design possibilities. Moreover, the availability of various sizes and weights ensures that the H beams can be tailored to suit specific project requirements.

Cost-Effective Solution:

In addition to their exceptional strength and design flexibility, H Beam Pile also offers cost-effectiveness, making them an attractive solution for construction projects. These beams can be procured at competitive prices due to the standardized manufacturing process and widespread availability. Furthermore, the durability and longevity of H beams translate into cost savings in terms of maintenance and replacements over the life span of a structure.

PROJECT

Our company has many years of experience in foreign trade of H-beams. The total amount of H-beams exported to Canada this time is more than 8,000,000 tons. The customer will inspect the goods in the factory. Once the goods pass the inspection, payment will be made and shipped. Since the construction of this project started, our company has carefully arranged the production plan and compiled the process flow to ensure the timely delivery of the H-shaped steel project. Since it is used in large factory buildings, the performance requirements for H-shaped steel products are higher than the corrosion resistance of oil platform H-shaped steel. Therefore, our company starts from the source of production and increases the control of steelmaking, continuous casting and rolling related processes. Strengthen the quality of products of various specifications to be effectively controlled in all aspects, ensuring a 100% pass rate of finished products. In the end, the processing quality of H-shaped steel was unanimously recognized by customers, and long-term cooperation and mutual benefit were achieved on the basis of mutual trust.

APPLICATION

Applications of H Section Beams:

The versatility of H section beams makes them indispensable in a multitude of construction projects. H section beams serve as primary structural elements in the construction of bridges, providing the backbone for strong and durable spans. Their ability to withstand heavy loads and resist lateral forces makes them ideal for high-rise buildings, ensuring stability and accommodating large floor openings. Additionally, H section beams find applications in industrial settings, supporting heavy machinery and providing ample raised storage space.

H section beams are also widely used in the shipbuilding industry, where their superior load-bearing capacity and resistance to corrosion make them ideal for constructing various marine structures. Moreover, modern architectural designs often employ H section beams as aesthetically pleasing design elements, adding an industrial touch to contemporary structures.

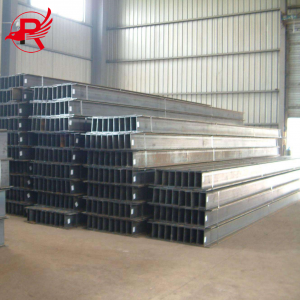

PACKAGING AND SHIPPING

Packaging:

Stack the sheet piles securely: Arrange the H-Beam in a neat and stable stack, ensuring that they are aligned properly to prevent any instability. Use strapping or banding to secure the stack and prevent shifting during transportation.

Use protective packaging materials: Wrap the stack of sheet piles with a moisture-resistant material, such as plastic or waterproof paper, to protect them from exposure to water, humidity, and other environmental elements. This will help prevent rust and corrosion.

Shipping:

Choose a suitable mode of transportation: Depending on the quantity and weight of the sheet piles, select the appropriate mode of transportation, such as flatbed trucks, containers, or ships. Consider factors like distance, time, cost, and any regulatory requirements for transportation.

Use appropriate lifting equipment: To load and unload the U-shaped steel sheet piles, use suitable lifting equipment such as cranes, forklifts, or loaders. Ensure that the equipment used has sufficient capacity to handle the weight of the sheet piles safely.

Secure the load: Properly secure the packaged stack of sheet piles on the transportation vehicle using strapping, bracing, or other suitable means to prevent shifting, sliding, or falling during transit.

COMPANY STRENGTH

Made in China, first-class service, cutting-edge quality, world-renowned

1. Scale effect: Our company has a large supply chain and a large steel factory, achieving scale effects in transportation and procurement, and becoming a steel company that integrates production and services

2. Product diversity: Product diversity, any steel you want can be purchased from us, mainly engaged in steel structures, steel rails, steel sheet piles, photovoltaic brackets, channel steel, silicon steel coils and other products, which makes it more flexible Choose the desired product type to meet different needs.

3. Stable supply: Having a more stable production line and supply chain can provide more reliable supply. This is especially important for buyers who require large quantities of steel.

4. Brand influence: Have higher brand influence and larger market

5. Service: A large steel company that integrates customization, transportation and production

6. Price competitiveness: reasonable price

*Send the email to chinaroyalsteel@163.com to get a quotation for your projects

FAQ

1.How can I get a quotation from you ?

You can leave us message, and we will reply every message in time.

2.Will you delivery the goods on time?

Yes,we promise to provide best quality products and delivery on time. Honesty is our company's tenet.

3.Can I get samples before order ?

Yes, of course. Usually our samples are free,we can produce by your samples or technical drawings.

4.What is your payment terms?

Our usual payment term is 30% deposit, and rest against B/L. EXW, FOB,CFR, CIF.

5.Do you accept the third party inspection?

Yes absolutely we accept.

6.How do we trust your company?

We specialise in steel business for years as golden supplier, headquarter locates in Tianjin province, welcome to investigate in any ways, by all means.