Professional Custom GB Standard Steel Rail Standard Grade Heavy Type Railway Steel Railing Rail

The strength, wear resistance and impact resistance of Railroad Track for sale depend to a large extent on the material of the rail, that is, on the chemical composition, metallographic organization, production process and heat treatment quality of the steel. The chemical composition of the rail, in addition to iron, also contains carbon, manganese, silicon, sulfur and phosphorus. High carbon content can increase the strength of the rail, but too high carbon content will reduce its plastic and impact toughness. Increasing the content of manganese and silicon can increase the strength, hardness and toughness of the rail. Sulfur and phosphorus are harmful impurities and should not be allowed to exceed the prescribed limits. In addition, adding an appropriate amount of chromium, nickel, molybdenum, vanadium, titanium or copper to the rail to make alloy rail, can improve the quality of the rail. Since the 1970s, China has produced low-alloy steel rails containing rare earth, low manganese, medium silicon, titanium and copper. In order to improve the anti-wear energy of the rail end part, prevent crushing and ensure the uniform wear of the rail, the rail surface quenching is usually carried out at both ends of the rail to improve its hardness; Full length quenching, better rail use effect.

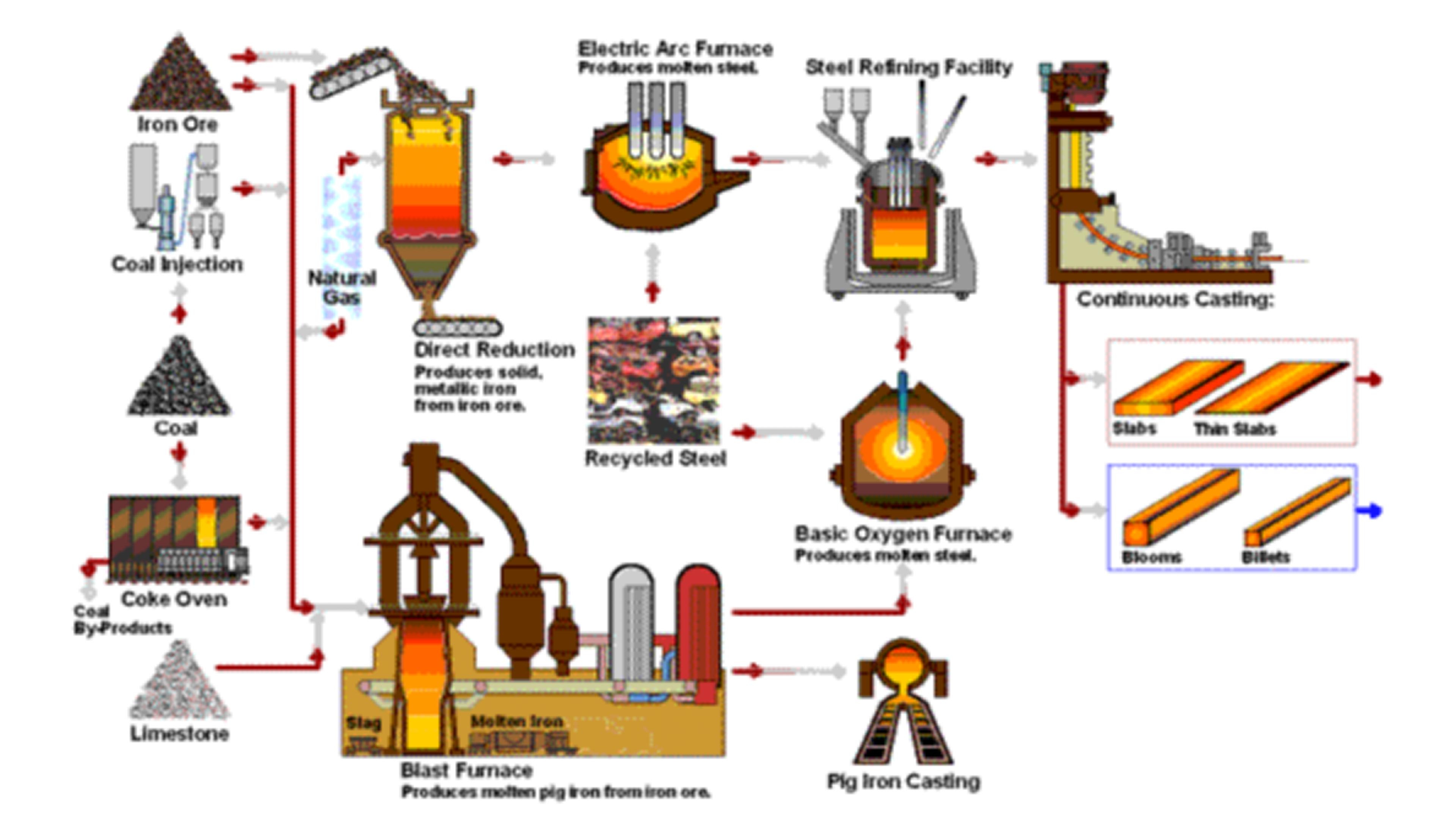

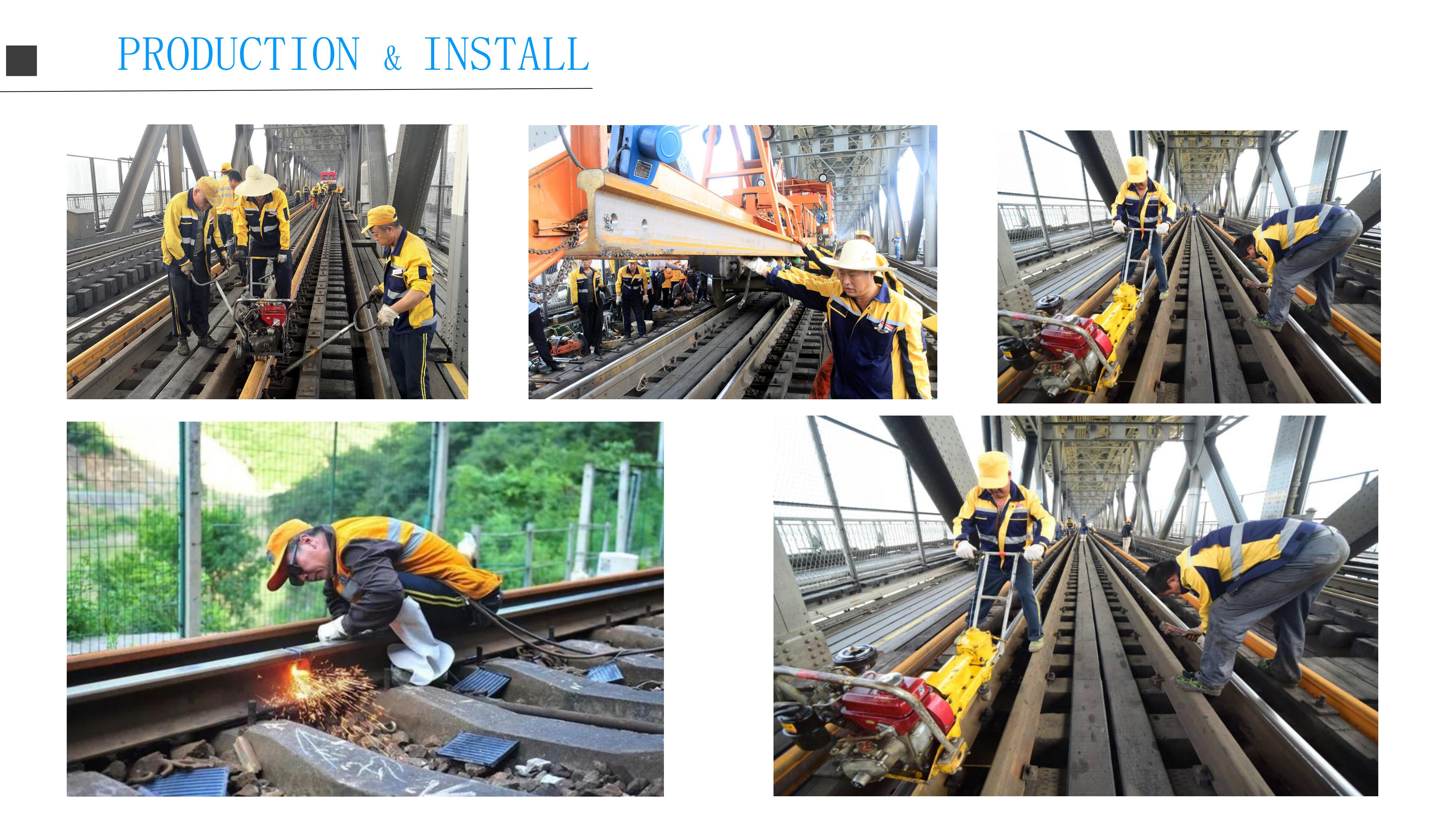

PRODUCT PRODUCTION PROCESS

Technology and Construction Process

The process of constructing train track steel tracks involves precision engineering and careful consideration of various factors. It begins with designing the track layout, taking into account the intended usage, train speeds, and terrain. Once the design is finalized, the construction process commences with the following key steps:

1. Excavation and Foundation: The construction crew prepares the ground by excavating the area and creating a sturdy foundation to support the weight and stress imposed by trains.

2. Ballast Installation: A layer of crushed stone, known as ballast, is laid on the prepared surface. This serves as a shock-absorbing layer, providing stability, and helping to distribute the load evenly.

3. Ties and Fastening: Wooden or concrete ties are then installed on top of the ballast, imitating a frame-like structure. These ties offer a secure base for the steel railroad tracks. They are fastened using specific spikes or clips, ensuring they remain firmly in place.

4. Rail Installation: The steel railroad rails 10m, often referred to as standard rails, are meticulously laid on top of the ties. Being made of high-quality steel, these tracks possess remarkable strength and durability.

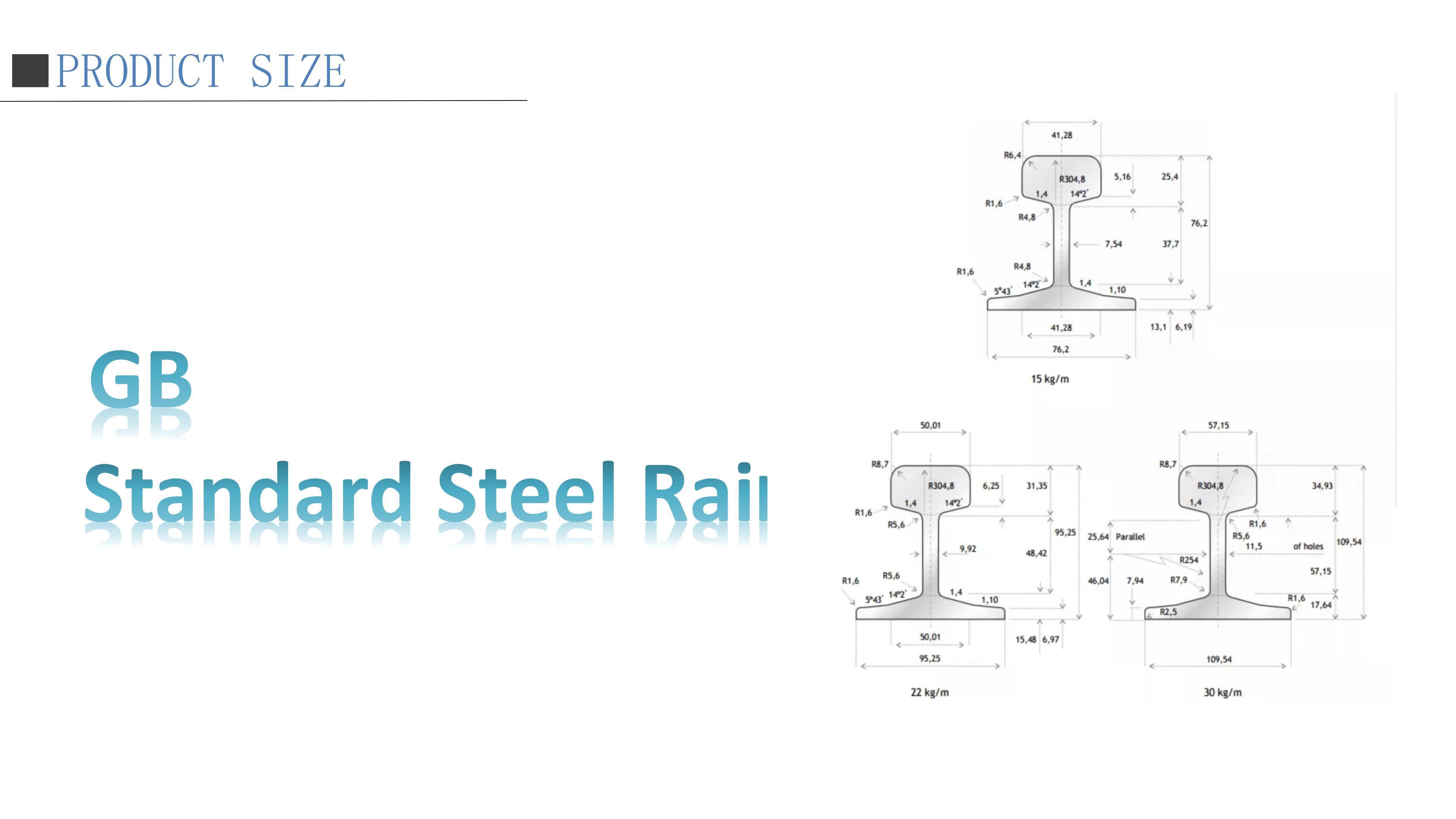

PRODUCT SIZE

|

Product Name:

|

GB Standard Steel Rail | |||

| Type: | Heavy Rail, Crane Rail,Light Rail | |||

| Material/Specification: | ||||

| Light Rail: | Model/Material: | Q235,55Q ; | Specification: | 30kg/m,24kg/m,22kg/m,18kg/m,15kg/m,12 kg/m,8 kg/m. |

| Heavy Rail : | Model/Material: | 45MN,71MN; | Specification: | 50kg/m,43kg/m,38kg/m,33kg/m. |

| Crane Rail: | Model/Material: | U71MN; | Specification: | QU70 kg /m ,QU80 kg /m,QU100kg /m,QU120 kg /m. |

| Commodity | Grade | Section Size(mm) | ||||

| Rail Height | Base Width | Head Width | Thickness | Weight(kgs) | ||

| Light Rail | 8KG/M | 65.00 | 54.00 | 25.00 | 7.00 | 8.42 |

| 12KG/M | 69.85 | 69.85 | 38.10 | 7.54 | 12.2 | |

| 15KG/M | 79.37 | 79.37 | 42.86 | 8.33 | 15.2 | |

| 18KG/M | 90.00 | 80.00 | 40.00 | 10.00 | 18.06 | |

| 22KG/M | 93.66 | 93.66 | 50.80 | 10.72 | 22.3 | |

| 24KG/M | 107.95 | 92.00 | 51.00 | 10.90 | 24.46 | |

| 30KG/M | 107.95 | 107.95 | 60.33 | 12.30 | 30.10 | |

| Heavy Rail | 38KG/M | 134.00 | 114.00 | 68.00 | 13.00 | 38.733 |

| 43KG/M | 140.00 | 114.00 | 70.00 | 14.50 | 44.653 | |

| 50KG/M | 152.00 | 132.00 | 70.00 | 15.50 | 51.514 | |

| 60KG/M | 176.00 | 150.00 | 75.00 | 20.00 | 74.64 | |

| 75KG/M | 192.00 | 150.00 | 75.00 | 20.00 | 74.64 | |

| UIC54 | 159.00 | 140.00 | 70.00 | 16.00 | 54.43 | |

| UIC60 | 172.00 | 150.00 | 74.30 | 16.50 | 60.21 | |

| Lifting Rail | QU70 | 120.00 | 120.00 | 70.00 | 28.00 | 52.80 |

| QU80 | 130.00 | 130.00 | 80.00 | 32.00 | 63.69 | |

| QU100 | 150.00 | 150.00 | 100.00 | 38.00 | 88.96 | |

| QU120 | 170.00 | 170.00 | 120.00 | 44.00 | 118.1 | |

ADVANTAGE

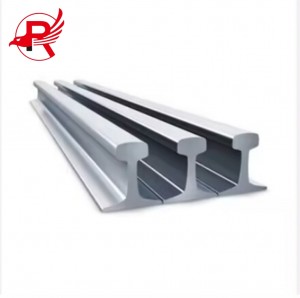

Sort by weight. The type of rail is usually differentiated according to the weight, for example, we often say 50 rail, which refers to the weight of 50kg/m rail, and so on, there are 38 rail, 43 rail, 50 rail, 60 rail, 75 rail, etc., of course, there are 24 rail, 18 rail, but that is the old age. Rails with 43 rails and above are generally called heavy rails.

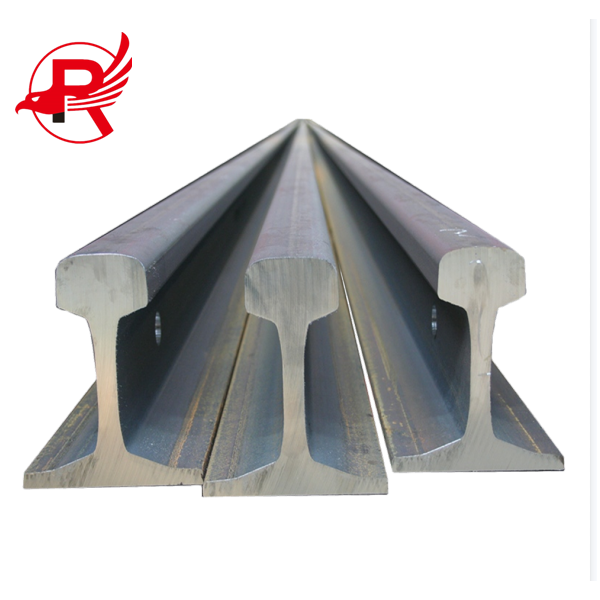

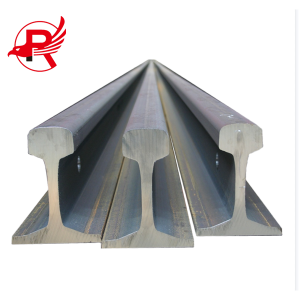

The cross-sectional shape of the rail consists of a bend-resistant I-shaped section and consists of a rail head, a rail waist and a rail bottom. In order for the rail guide to better withstand various forces and ensure the necessary strength conditions, the guide rail should have sufficient height, the head and bottom should have sufficient area and height, and the waist and bottom should not be too thin.

In order to facilitate statistical analysis and analysis of railway damage, railway damage needs to be classified. According to the damaged location of the rail track section, the occurrence of damage and the cause of the damage, it is divided into 9 types and 32 types of injuries, divided into two digits. A ten-digit number indicates the location and status of the damage, and a single number indicates the cause of the damage.

Side wear occurs on the outer links of small radius curves and is one of the main types of damage on curves. When the train runs on a curve, the friction and sliding of the rail wheel rails are the fundamental cause of side rail grinding. When a train passes through a small radius curve, there are usually two points of contact between the wheels and the track, and there is a lot of side grinding. The size of the side grind can be expressed by the product of the guiding force and the impact angle, that is, the wear coefficient. Improving the conditions for trains to pass curves, such as using worn wheel treads, using radial bogies, etc. will reduce the speed of side grinding.

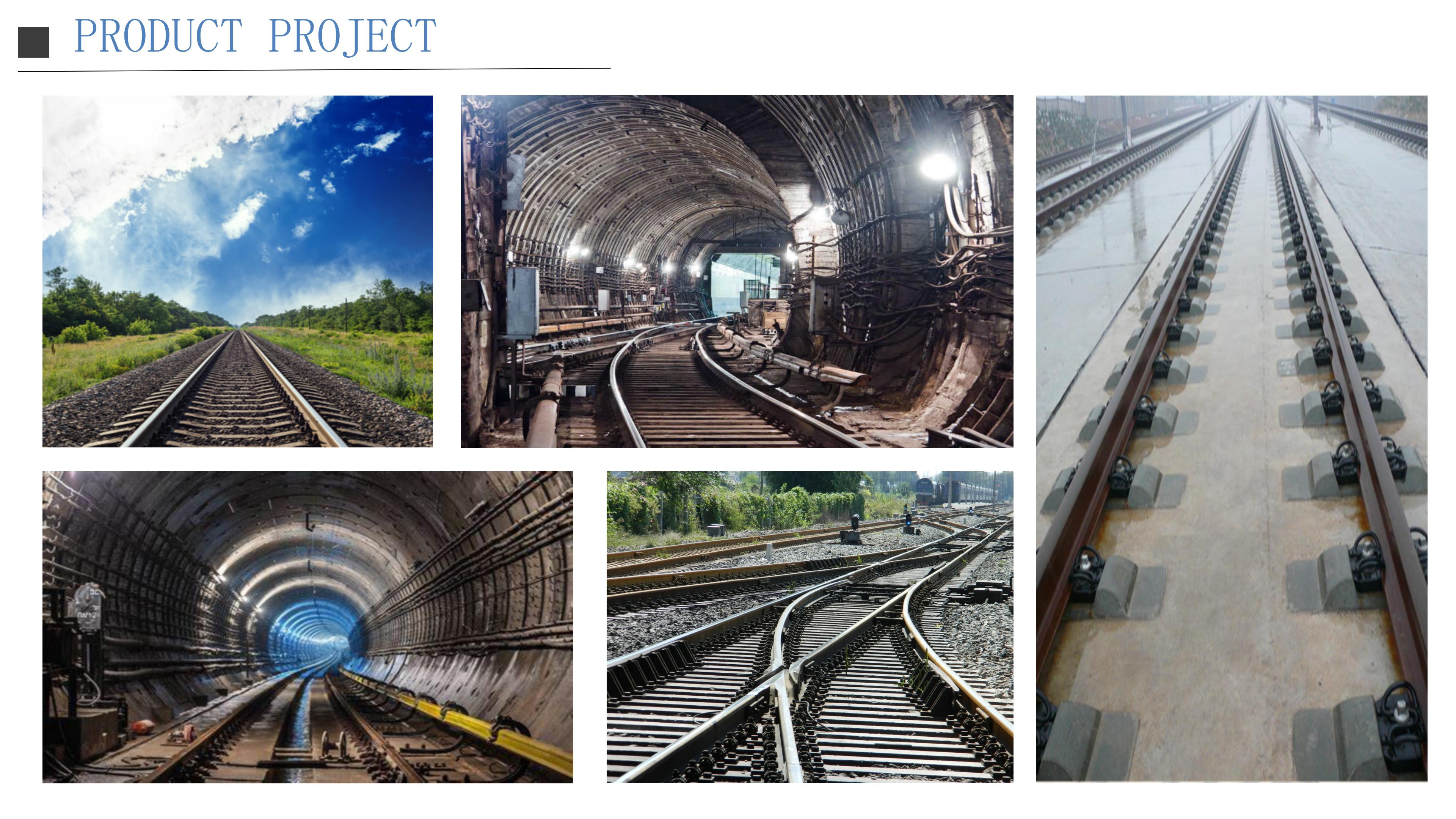

PROJECT

Our company’s china rail supplier 13,800 tons of steel rails exported to the United States were shipped at Tianjin Port at one time. The construction project was completed with the last rail being steadily laid on the railway line. These rails are all from the universal production line of our rail and steel beam factory, using global Produced to the highest and most rigorous technical standards.

For more information about rail products, please contact us!

WeChat: +86 13652091506

Tel: +86 13652091506

Email: [email protected]

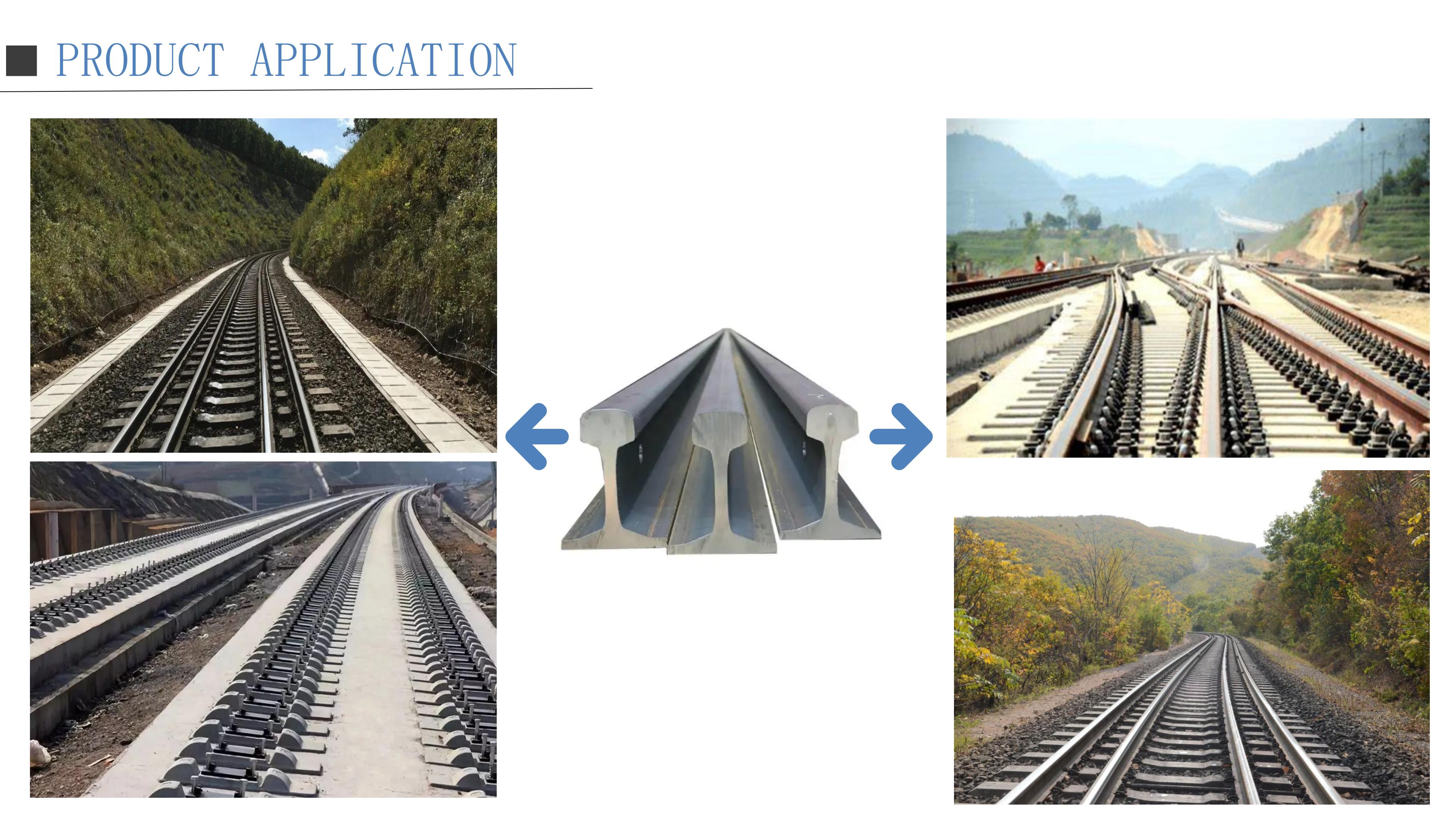

APPLICATION

Classified by manufacturing process. According to the classification of manufacturing process, rail can be mainly divided into hot rolled rail and heat treatment rail. In fact, the rail is produced by the hot rolling process, the heat treatment rail is in the hot rolling molding of the rail for heat treatment again, divided into online heat treatment and offline heat treatment of two kinds, online heat treatment is already the mainstream, more energy saving and more efficient.Railroad Track for sale

PACKAGING AND SHIPPING

3, Characteristics and Improvement Trends of Rail Sections:

Characteristics and Improvement Trends of Rail Sections

The continuous increase of railway speed and axle load requires rails to have greater rigidity and better wear resistance.

In order to make the rails have sufficient thickness, the height of the rails can be increased appropriately to ensure that the rails have a large horizontal moment of inertia. At the same time, in order to make the rail have sufficient stability, the width of the rail should be selected as wide as possible when designing the width of the rail. In order to best match the stiffness and stability, countries usually control the ratio of the rail height to the bottom width, is H/B, when designing the rail section. Generally, H/B is controlled between 1.15 and 1.248. The H/B values of rails in some countries are shown in the table.

COMPANY STRENGTH

Made in China, first-class service, cutting-edge quality, world-renowned

1. Scale effect: Our company has a large supply chain and a large steel factory, achieving scale effects in transportation and procurement, and becoming a steel company that integrates production and services

2. Product diversity: Product diversity, any steel you want can be purchased from us, mainly engaged in steel structures, steel rails, steel sheet piles, photovoltaic brackets, channel steel, silicon steel coils and other products, which makes it more flexible Choose the desired product type to meet different needs.

3. Stable supply: Having a more stable production line and supply chain can provide more reliable supply. This is especially important for buyers who require large quantities of steel.

4. Brand influence: Have higher brand influence and larger market

5. Service: A large steel company that integrates customization, transportation and production

6. Price competitiveness: reasonable price

*Send the email to [email protected] to get a quotation for your projects

CUSTOMERS VISIT

FAQ

1.How can I get a quotation from you ?

You can leave us message, and we will reply every message in time.

2.Will you delivery the goods on time?

Yes,we promise to provide best quality products and delivery on time. Honesty is our company's tenet.

3.Can I get samples before order ?

Yes, of course. Usually our samples are free,we can produce by your samples or technical drawings.

4.What is your payment terms?

Our usual payment term is 30% deposit, and rest against B/L. EXW, FOB,CFR, CIF.

5.Do you accept the third party inspection?

Yes absolutely we accept.

6.How do we trust your company?

We specialise in steel business for years as golden supplier, headquarter locates in Tianjin province, welcome to investigate in any ways, by all means.