Products

-

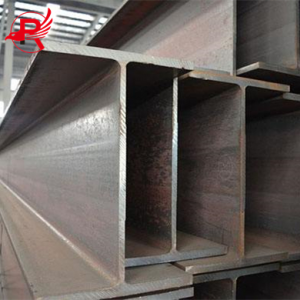

ASTM H-Shaped Steel Structural Engineering and Steel Pile Construction

ASTM H-Shaped Steel have revolutionized the construction industry by offering unmatched strength, load-bearing capabilities, and cost-effectiveness. Their unique design and material composition ensure structural stability in buildings, bridges, and industrial applications. Moreover, their versatility transcends beyond construction, empowering other industries with durable structural components. As the world continues to seek innovative solutions for architectural marvels and resilient infrastructure, carbon steel H-beams will remain a cornerstone in the realm of structural engineering.

-

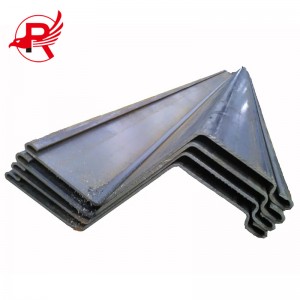

U Type Profile Hot Rolled Steel Sheet Pile

A U-shaped steel sheet pile is a type of steel piling that has a cross-sectional shape resembling the letter “U”. It is commonly used in civil engineering and construction projects for various applications, such as retaining walls, cofferdams, foundation support, and waterfront structures.

The detail of a U-shaped steel sheet pile typically includes the following specifications:

Dimensions: The size and dimensions of the steel sheet pile, such as the length, width, and thickness, are specified according to the project requirements.

Cross-sectional properties: Key properties of the U-shaped steel sheet pile include the area, moment of inertia, section modulus, and weight per unit length. These properties are crucial for calculating the structural design and stability of the pile.

-

Construction Can Be 41*41 Pillar Channel/C Channel/Seismic Support

Strut Channel is composed of U-shaped steel or C-shaped steel made of zinc-aluminum-magnesium and supporting connection accessories. It can not only be easily transported and assembled, but also has the advantages of easy maintenance, long service life and low economic cost. It is indispensable for photovoltaic power stations. One of the missing material accessories.

-

JIS Standard SY295 Type 2 U Hot Rolled Steel Sheet Piles

A U-shaped steel sheet pile is a type of steel piling that has a cross-sectional shape resembling the letter “U”. It is commonly used in civil engineering and construction projects for various applications, such as retaining walls, cofferdams, foundation support, and waterfront structures.

The detail of a U-shaped steel sheet pile typically includes the following specifications:

Dimensions: The size and dimensions of the steel sheet pile, such as the length, width, and thickness, are specified according to the project requirements.

Cross-sectional properties: Key properties of the U-shaped steel sheet pile include the area, moment of inertia, section modulus, and weight per unit length. These properties are crucial for calculating the structural design and stability of the pile.

-

Горячекатаная стальная шпунтовая свая Z-образной формы с гидроизоляцией

Z-образные стальные шпунтовые сваи, строительные материалы, замки Z-образных стальных шпунтовых свай симметрично распределены по обе стороны от нейтральной оси, а непрерывность стенки в значительной степени увеличивает момент сопротивления стальных шпунтовых свай, Таким образом, это гарантирует, что механические свойства секции будут полностью проявлены.

Детали двутавровой балки обычно включают в себя следующие характеристики:

Диапазон производства стальных шпунтовых свай типа Z:

Толщина: 4-16 мм.

Длина: неограниченно или по желанию клиента.

Другое: Доступны нестандартные размеры и конструкции, доступна защита от коррозии.

Материал: Q235B, Q345B, S235, S240, SY295, S355, S430, S460, A690, ASTM A572, класс 50, ASTM A572, класс 60 и все материалы национальных стандартов, материалы европейских стандартов и материалы американского стандарта, подходящие для производства Z-образных изделий. стальные шпунтовые сваи.

Стандарты производственного контроля продукции: национальный стандарт GB/T29654-2013, европейский стандарт EN10249-1/EN10249-2. -

Hot Rolled Water-Stop U-Shaped Steel Sheet Pile

A U-shaped steel sheet pile is a type of steel piling that has a cross-sectional shape resembling the letter “U”. It is commonly used in civil engineering and construction projects for various applications, such as retaining walls, cofferdams, foundation support, and waterfront structures.

The detail of a U-shaped steel sheet pile typically includes the following specifications:

Dimensions: The size and dimensions of the steel sheet pile, such as the length, width, and thickness, are specified according to the project requirements.

Cross-sectional properties: Key properties of the U-shaped steel sheet pile include the area, moment of inertia, section modulus, and weight per unit length. These properties are crucial for calculating the structural design and stability of the pile.

-

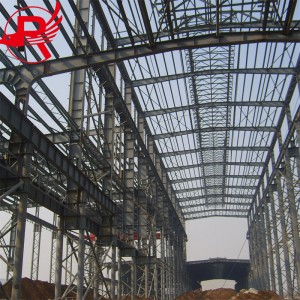

Steel Structure Space With Steel Structure Building Residential Is Applicable

Steel structure is a structure composed of steel materials and is one of the main building structure types. The structure is mainly composed of steel beams, steel columns, steel trusses and other components made of section steel and steel plates, and adopts silanization, pure manganese phosphating, washing and drying, galvanizing and other rust prevention processes.

*Depending on your application, we can design the most economical and durable steel frame system to help you create maximum value for your project.

-

Prefab Warehouse Steel Structure Workshop Industrial Steel Structure Warehouse

industrial steel structure is a structure composed of steel materials and is one of the main building structure types. The structure is mainly composed of steel beams, steel columns, steel trusses and other components made of section steel and steel plates, and adopts silanization, pure manganese phosphating, washing and drying, galvanizing and other rust prevention processes.

*Depending on your application, we can design the most economical and durable steel frame system to help you create maximum value for your project.

-

Prefabricated Construction Industrial Metal Materials Hangar Shed Warehouse Workshop Plant Steel Structure Building

steel structures, high-strength steels should be studied to greatly increase their yield point strength. In addition, new types of steels, such as H-shaped steel (also known as wide-flange steel) and T-shaped steel, as well as profiled steel plates, are rolled to adapt to large-span structures and The need for super high-rise buildings.In addition, there is a heat-resistant bridge light steel structure system. The building itself is not energy-efficient. This technology uses clever special connectors to solve the problem of cold and hot bridges in the building. The small truss structure allows cables and water pipes to pass through the wall for construction. Decoration is convenient.

-

Prefabricated Metal Space Frame Storage Warehouse Steel Structure Construction

Practice has shown that the greater the force, the greater the deformation of the steel member. However, when the force is too large, the steel members will fracture or severe and significant plastic deformation, which will affect the normal work of the engineering structure. Steel structure is a structure composed of steel materials and is one of the main building structure types. The structure is mainly composed of steel beams, steel columns, steel trusses and other components made of section steel and steel plates, and adopts silanization, pure manganese phosphating, washing and drying, galvanizing and other rust prevention processes.

*Depending on your application, we can design the most economical and durable steel frame system to help you create maximum value for your project.

-

Prefabricated Workshop Prefabricated Industrial Building Steel Space Frame Warehouse Factory Workshop

Steel structure is Practice has shown that the greater the force, the greater the deformation of the steel member. However, when the force is too large, the steel members will fracture or severe and significant plastic deformation, which will affect the normal work of the engineering structure. In order to ensure the normal working of engineering materials and structures under load, it is required that each steel member should have sufficient load-bearing capacity, also known as bearing capacity. The bearing capacity is mainly measured by the sufficient strength, stiffness and stability of the steel member.

-

Prefabricated Steel Structure Warehouse Building / Steel Structure Workshop

Steel structure In addition, there is a heat-resistant bridge light steel structure system. The building itself is not energy-efficient. This technology uses clever special connectors to solve the problem of cold and hot bridges in the building. The small truss structure allows cables and water pipes to pass through the wall for construction. Decoration is convenient.