Products

-

Laser Die Cutting Machine Fiber Laser Cutting Machine Sheet Metal

laser cut metal is a high-precision, high-efficiency cutting processing method that is widely used in the processing of metals, plastics, wood and other materials. Laser cutting uses a high-energy, dense laser beam to melt or vaporize materials, allowing for fast, precise cuts. This processing method has the following characteristics:

First of all, laser cutting has extremely high precision and fineness, enabling fine cutting and engraving of materials, and is suitable for making parts with complex shapes and precise structures.

Secondly, laser cutting is fast and has high production efficiency. Laser cutting equipment can move and cut quickly, making it suitable for high-volume production and efficient processing.

In addition, laser cutting has less impact on the material and the heat affected zone is small. Compared with traditional cutting methods, laser cutting can reduce deformation and thermal effects and maintain the original properties of the material.

Laser cutting is suitable for a variety of materials, including metals, plastics, glass, ceramics, etc., and is therefore widely used in aerospace, automobile manufacturing, electronic equipment and other industries.

In short, laser cutting, as a high-precision and high-efficiency cutting processing method, provides precision processing solutions for all walks of life and has become one of the indispensable and important processes in modern manufacturing.

-

Non-Abrasive Waterjet Cutting OEM Custom Precision Metal Cutting Parts Carbon Steel Stainless Steel 3/4/5 Axis CNC Machining

Waterjet cutting is an advanced technology that uses high-pressure water flow and an abrasive mixture to cut materials. By mixing water and abrasives and then pressurizing them, a high-speed jet is formed, and the jet is used to impact the workpiece at high speed, thereby achieving cutting and processing of various materials.

Water jet cutting is widely used in aerospace, automobile manufacturing, building materials and other fields. In the aerospace field, water jet cutting can be used to cut aircraft parts, such as fuselage, wings, etc., ensuring the accuracy and quality of parts. In automobile manufacturing, waterjet cutting can be used to cut body panels, chassis parts, etc., ensuring the accuracy and appearance quality of the parts. In the field of building materials, water jet cutting can be used to cut marble, granite and other materials to achieve fine carving and cutting.

-

Welding Station, Laser and Plasma Cutting

Plasma cutting is an advanced processing technology that uses high temperature and high energy generated by plasma to cut materials. In the plasma cutting process, a gas or gas mixture is heated to a high temperature to generate a plasma, and then the high energy of the plasma is used to cut the material.

Plasma cutting has the following characteristics: First, it has a wide range of applications and can efficiently cut various materials such as metals, alloys, stainless steel, and aluminum alloys. Secondly, the cutting speed is fast and the efficiency is high, and it can achieve precise cutting of materials with various complex shapes. In addition, the heat-affected zone generated during plasma cutting is small, the cutting surface is smooth, and no secondary processing is required, making it suitable for high-precision processing requirements.

Plasma cutting is widely used in metal processing, machinery manufacturing, aerospace and other fields. In the field of metal processing, plasma cutting can be used to cut various metal parts, such as steel plates, aluminum alloy parts, etc., ensuring the accuracy and quality of the parts. In the aerospace field, plasma cutting can be used to cut aircraft parts, such as engine parts, fuselage structures, etc., ensuring the accuracy and lightweight of the parts.

In short, plasma cutting, as an efficient and high-precision cutting processing technology, has broad application prospects and market demand, and will play an important role in the future manufacturing industry.

-

Custom Steel Production Metal Cut Bending Processing Fabrication Parts Steel Sheet Process Metal Parts

Waterjet cutting is an advanced technology that uses high-pressure water flow and an abrasive mixture to cut materials. By mixing water and abrasives and then pressurizing them, a high-speed jet is formed, and the jet is used to impact the workpiece at high speed, thereby achieving cutting and processing of various materials.

Water jet cutting is widely used in aerospace, automobile manufacturing, building materials and other fields. In the aerospace field, water jet cutting can be used to cut aircraft parts, such as fuselage, wings, etc., ensuring the accuracy and quality of parts. In automobile manufacturing, waterjet cutting can be used to cut body panels, chassis parts, etc., ensuring the accuracy and appearance quality of the parts. In the field of building materials, water jet cutting can be used to cut marble, granite and other materials to achieve fine carving and cutting.

-

State-of-the-art Facility Offering Precision Sheet Metal and Steel Profile Cutting Services

Waterjet cutting is an advanced technology that uses high-pressure water flow and an abrasive mixture to cut materials. By mixing water and abrasives and then pressurizing them, a high-speed jet is formed, and the jet is used to impact the workpiece at high speed, thereby achieving cutting and processing of various materials.

Water jet cutting is widely used in aerospace, automobile manufacturing, building materials and other fields. In the aerospace field, water jet cutting can be used to cut aircraft parts, such as fuselage, wings, etc., ensuring the accuracy and quality of parts. In automobile manufacturing, waterjet cutting can be used to cut body panels, chassis parts, etc., ensuring the accuracy and appearance quality of the parts. In the field of building materials, water jet cutting can be used to cut marble, granite and other materials to achieve fine carving and cutting.

-

Custom Precision Sheet Metal Steel Processing Welding Bend Laser Cut Service Metal Stamping Sheet Metal Fabrication

Laser cutting is a technology that uses a high-powered laser to cut materials such as metal, wood, plastic, and glass. The laser beam is focused and directed by a computer-controlled system to precisely cut and shape the material. This process is commonly used in manufacturing, prototyping, and artistic applications due to its high level of precision and versatility. Laser cutting is known for its ability to produce intricate designs and complex shapes with minimal material waste.

-

Oem High Demand Laser Cutting Parts Products Stamping Processing Sheet Metal Fabrication

Laser cutting is a technology that uses a high-powered laser to cut materials such as metal, wood, plastic, and glass. The laser beam is focused and directed by a computer-controlled system to precisely cut and shape the material. This process is commonly used in manufacturing, prototyping, and artistic applications due to its high level of precision and versatility. Laser cutting is known for its ability to produce intricate designs and complex shapes with minimal material waste.

-

Hot Selling 20ft 40ft CSC Certified Side Open Shipping Container from China to USA Canada

A container is a standardized cargo packaging unit used to transport goods. It is usually made of metal, steel or aluminum and has a standard size and structure to facilitate transfer between different modes of transportation, such as cargo ships, trains and trucks. The standard size of a container is 20 feet and 40 feet long and 8 feet by 6 feet high.

-

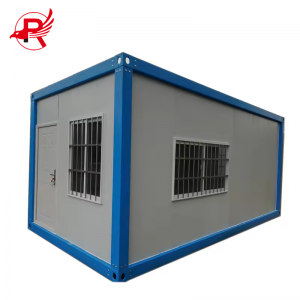

Quick Installation Foldable 20-foot Container House

A container home is a type of residence that is built using modified shipping containers. These containers are modified and assembled to create a functional and livable space. They are often used as affordable housing solutions, vacation homes, and even commercial spaces.

-

Quick Installation Foldable 40-foot Container House

A container home is a type of residence that is built using modified shipping containers. These containers are modified and assembled to create a functional and livable space. They are often used as affordable housing solutions, vacation homes, and even commercial spaces.

-

Good Quality Hot Selling 20ft 40ft 40HQ New and Used Shipping Container with Certificate

A container is a standardized cargo packaging unit used to transport goods. It is usually made of metal, steel or aluminum and has a standard size and structure to facilitate transfer between different modes of transportation, such as cargo ships, trains and trucks. The standard size of a container is 20 feet and 40 feet long and 8 feet by 6 feet high.

-

Manufacturers Provide Steel Structure Custom Logo Open Side 20ft 40ft Shipping Container

A container is a standardized cargo packaging unit used to transport goods. It is usually made of metal, steel or aluminum and has a standard size and structure to facilitate transfer between different modes of transportation, such as cargo ships, trains and trucks. The standard size of a container is 20 feet and 40 feet long and 8 feet by 6 feet high.