Products

-

Factory Wholesale Tensile Strength ASTM Equal Angle Steel Price Good 50*5 60*5 63*6 Mild Angle Bar

ASTM Equal Angle Steel commonly known as angle iron, is a long steel with two sides perpendicular to each other. There are equal angle steel and unequal angle steel.The width of two sides of an equal angle steel is equal. The specification is expressed in mm of side width × side width × side thickness.

-

Galvalume/Aluzinc Steel Coil

aluminum zinc plated steel coil is a product made of cold-rolled low-carbon steel coil as the base material and hot-dip aluminum-zinc alloy coating. This coating is mainly composed of aluminum, zinc and silicon, forming a dense oxide layer that effectively blocks oxygen, water and carbon dioxide in the atmosphere and provides good anti-corrosion protection. Galvalume coil has excellent corrosion resistance, weather resistance and heat reflection properties, and is suitable for use in a variety of environmental conditions. It also has high strength and plasticity and is easy to be processed into various shapes, so it is widely used in construction, home appliances, transportation and other fields. In short, galvalume coil has become an important metal material with its excellent anti-corrosion performance and diversified application fields.

-

Factory Price L Profile ASTM Equal Angle Steel Galvanized Equal Unequal Angle Steel Mild Steel Angle Bar

ASTM Equal Angle Steel commonly known as angle iron, is a long steel with two sides perpendicular to each other. There are equal angle steel and unequal angle steel.The width of two sides of an equal angle steel is equal. The specification is expressed in mm of side width × side width × side thickness. Such as “∟ 30 × 30 × 3″, that is to say, equal angle steel with side width of 30mm and side thickness of 3mm. It can also be expressed by model. The model is the centimeter of the side width, such as ∟ 3 × 3. The model does not represent the dimensions of different edge thicknesses in the same model, so the edge width and edge thickness dimensions of angle steel shall be filled in completely in the contract and other documents to avoid using the model alone. The specification of hot rolled equal leg angle steel is 2 × 3-20 × 3.

-

Structural Galvanized Slotted Steel C Channel bracket Solar Panel Profile With Holes

Every construction project requires robust and reliable materials to ensure its durability and longevity. Among the various options available, C Channel Structural Steel and Galvanized C Purlins steel stand out as popular choices for their exceptional strength and versatility.Our company has participated in the largest solar energy development project in South America, providing brackets and solution design. We provided 15,000 tons of photovoltaic brackets for this project. The photovoltaic brackets adopted domestic emerging technologies to help the development of the photovoltaic industry in South America and improve local residents. Life. The photovoltaic support project includes a photovoltaic power station with an installed capacity of approximately 6MW and a battery energy storage power station of 5MW/2.5h. It can generate approximately 1,200 kilowatt hours per year. The system has good photoelectric conversion capabilities.

-

Price discount 0.6mm hot rolled pre-coated PPGI color coated galvanized steel coil for sale

Color coated coil is a color steel product formed by coating organic coatings on galvanized steel coil or cold rolled steel coil as substrate. Its main features include: good corrosion resistance, strong weather resistance; Rich color, smooth and beautiful surface, to meet different design needs; Good processability, easy to form and weld; At the same time, it has a light weight and is suitable for construction, home appliances, automobiles and other industries. Because of its excellent performance and beautiful appearance, color coated rolls are widely used in roofs, walls, doors and Windows and various decorative occasions.

-

High Quality 4.8 Galvanized Carbon Mild Steel U Channel Slotted Metal Strut Channel

In the realm of architecture and construction, creating sturdy and reliable structures is of utmost importance. It is essential to choose the right materials and components that not only provide strength but also offer versatility in design.The main function of the c channel steel bracket is to fix the c channel steel modules in various c channel steel power station application scenarios such as roofs, ground, and water surfaces, to ensure that the solar panels can be fixed in place and can withstand gravity and wind pressure. It can also help adjust the angle of solar panels to adapt to different solar radiation and improve solar power generation efficiency.

-

Galvanized Prepainted CGCC Steel Color Coated Corrugated Iron Roofing Sheets Roof Board

Galvanized corrugated board is a common building material, and the selection and application of its size and specifications are very important. In practical applications, reasonable selection plans can be formulated according to actual needs in order to achieve optimal results.

-

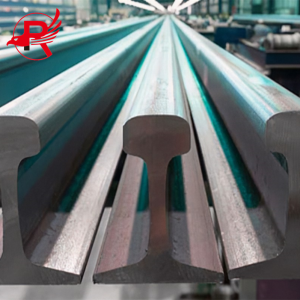

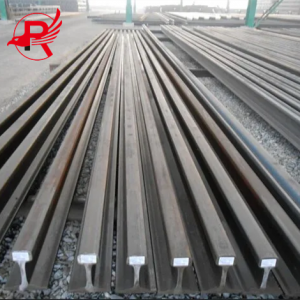

GB Standard Is Used For Rail Carbon Steel Rail Price Concessions

Steel rail is an important part of the track structure. It is responsible for guiding the wheels and transmitting loads. It needs to have sufficient strength, stability and wear resistance. The section shape of the rail is I-shaped, so that the rail has the best bending resistance. The rail is composed of a rail head, a rail waist and a rail bottom.

-

High quality price discount factory direct galvanized steel wire

Galvanized steel wire is a type of steel wire that has been galvanized and is widely used in many industries due to its excellent corrosion resistance and strength. The process of galvanizing is to immerse the steel wire in molten zinc to form a protective film. This film can effectively prevent the steel wire from rusting in humid or corrosive environments, thereby extending its service life. This characteristic makes galvanized steel wire widely used in construction, agriculture, transportation and other fields.

-

High Grade Q345B 200*150mm Carbon Steel Welded Galvanized Steel H Beam for Construction

H – beam steel is a new economic construction. The section shape of H beam is economical and reasonable, and the mechanical properties are good. When rolling, each point on the section extends more evenly and the internal stress is small. Compared with ordinary I-beam, H beam has the advantages of large section modulus, light weight and metal saving, which can reduce the building structure by 30-40%. And because its legs are parallel inside and outside, the leg end is a right Angle, assembly and combination into components, can save welding, riveting work up to 25%.

H section steel is an economic section steel with better mechanical properties, which is optimized and developed from I-section steel. Especially, the section is the same as the letter “H”

-

Manufacture Q345 Cold Rolled Galvanized C Channel Steel

Galvanized C-shaped steel is a new type of steel made of high-strength steel plate, then cold-bent and roll-formed. Compared with traditional hot-rolled steel, the same strength can save 30% of the material. When making it, the given C-shaped steel size is used. C-shaped steel The forming machine automatically processes and forms. Compared with ordinary U-shaped steel, galvanized C-shaped steel can not only be preserved for a long time without changing its material, but also has relatively strong corrosion resistance, but its weight is also slightly heavier than the accompanying C-shaped steel. It also has a uniform zinc layer, smooth surface, strong adhesion, and high dimensional accuracy. All surfaces are covered by a zinc layer, and the zinc content on the surface is usually 120-275g/㎡, which can be said to be a super protective one.

-

GB Standard Steel Rail Railway Rail Heavy Duty Factory Price Steel Rail Strong And Durable Suitable For Construction And So On

Steel rail is an important part of the track structure. It is responsible for guiding the wheels and transmitting loads. It needs to have sufficient strength, stability and wear resistance. The section shape of the rail is I-shaped, so that the rail has the best bending resistance. The rail is composed of a rail head, a rail waist and a rail bottom.