Products

-

Building Materials Slotted Unistrut Stainless Steel Channel Bar Gi Steel C Channel

Water body photovoltaic racks are photovoltaic panels set up on the water surface, which can generate photovoltaic power for lakes, reservoirs, ponds and other water bodies. Water photovoltaic systems can avoid construction impacts and land occupation, have stable power generation and good environmental benefits, and also have certain landscape effects.

-

China Manufactory C Channel Unistrut Channel Support System Anti-Seismic Cable Tray Support

Photovoltaic brackets are support structures for installing photovoltaic modules and are mainly used for the construction and installation of photovoltaic power generation systems. Its application scope includes but is not limited to the following aspects:

-

Construction Material Unistrut Channel Price Cold Rolled C Channel

From a performance perspective, flexible photovoltaic brackets have a higher acceptance rate in the current market, and they are more suitable for difficult operating environments such as ordinary mountains and barren slopes.Increase the effective use area of the structure. Compared with the concrete structure, the cross-sectional area of the steel structure column is small, which can increase the effective use area of the building. Depending on the different forms of the building, the effective use area can be increased by 4-6%.

-

Q235B Q345b C Beam H Steel Structure Steel Unistrut Channel

Because it is an important part of the solar photovoltaic power generation system, its role is to support and fix the photovoltaic modules. With the continuous expansion of the solar energy market and the continuous advancement of technology, the photovoltaic bracket industry has also achieved considerable development.

-

Factory Price Hot Dipped Galvanized Unistrut Channel Galvanizing Plant

Agricultural greenhouses can provide an excellent solar resource. Agricultural greenhouses must be covered with sunshade protection, and photovoltaic modules need to avoid exposure to strong sunlight and harsh weather conditions. Agricultural greenhouses can provide appropriate shade protection for photovoltaic modules, which extends the life of photovoltaic modules.

-

Products Price 904L 347 347H 317 317L 316ti Unistrut Channel

The connection and assembly between brackets must be assembled with nuts and connectors. Some companies directly use welding assembly, which is easy to break and collapse over time. Brackets assembled with nuts and connectors are easy to disassemble and assemble, while those assembled by welding must be cut to be removed, which affects the interests of users. Let’s talk about counterweights. The most commonly used ones on the market now are cement piers, steel structures, chemical anchor bolts, etc.

-

Hot Rolled Steel Profile Unistrut C Channel Steel Price

Generally speaking, solar zinc-aluminum-magnesium photovoltaic brackets are special brackets specially designed and developed to be able to place, install and fix the required solar panels in many solar photovoltaic power generation systems.The steel structure, mainly hot-rolled C-shaped steel, has a scientific and reasonable structure, good plasticity and flexibility, and high structural stability. It is suitable for building structures that bear large vibration and impact loads. It has strong resistance to natural disasters and is especially suitable for Some building structures in earthquake-prone zones.

-

Stainless Steel 41X41 41X21mm Unistrut Channel

The photovoltaic bracket is one of the important components in the photovoltaic power generation system; its main function is to support the entire system so that the angle between the photovoltaic panels in the power generation system and the sun is more vertical.

-

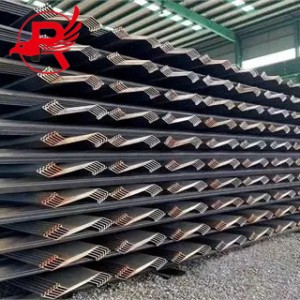

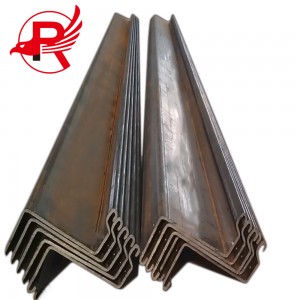

Cold Z Type Steel Sheet Piles for Cofferdam Retaining Wall Shoreline Protection

Steel sheet pile is a steel structure with linkage devices on the edges, and the linkage devices can be freely combined to form a continuous and tight retaining soil or water retaining wall.

-

Steel Profile Hot Z Shape Sheet Pile Sheet Pile with Manufacture Price

As a widely used foundation engineering construction material, steel sheet piles have the characteristics of convenient construction, green environmental protection, strong adaptability and high strength. They have very broad application prospects in foundation engineering construction under various geological conditions.

-

Cold Formed and Hot Rolled Larsen Q235 Q345 Q345b Sy295 Sy390 Metal Sheet Piling Z Type Steel Sheet Pile 6m 12m

Steel sheet piles can be used as one of the construction technologies for foundation engineering construction, and are suitable for basic parts of various construction projects, such as basements, frame structures, house exteriors, etc.

-

Steel Sheet Pile Factory Az12/Au20/Au750/Az580/Za680 Hot Rolled Sale Types of Steel Sheet Pile

Larsen steel sheet pile support structures are commonly used in foundation pit enclosure construction methods, commonly known as fenders. Due to the different specifications of Larsen steel sheet piles and their wide use areas, Larsen steel sheet piles need to be transported to the construction site before actual use. , generally choose to transport Larsen steel sheet piles by car. If the distance is long and the demand is large, it will be more economical and faster to ship Larsen steel sheet piles. Jiaohang Shipping Center has just undertaken the port-to-door transportation of tens of thousands of tons of Larsen steel sheet piles. This Among them is the issue of how to safely load and unload Larsen steel sheet piles.