Advantages:

-

High section modulus-to-weight ratio for efficiency

-

Increased stiffness minimizes deflection

-

Wide design allows easy installation

-

Superior corrosion resistance, with extra thickness at critical points

The C-shaped support channel is made of high-quality steel and can withstand heavy loads and harsh environmental conditions. Its unique shape and design provide excellent load-bearing capacity, making it perfect for use in construction, infrastructure and industrial projects. Whether you need to support beams, columns or other structural elements, our C-shaped steel channels will do the job.

Whether working on commercial buildings, residential projects or industrial facilities, our C-shaped support channels are the ultimate choice for ensuring structural stability and integrity.

C-channel steel struts are typically made of high-quality carbon steel with high strength and load carrying capacity. The single-pillar structure is simple in design and easy to install for a variety of construction and mechanical support applications. Its cross section form makes the pillar have good stability in both longitudinal and transverse, suitable for bearing large loads. In addition, C-channel steel has good corrosion resistance and can maintain a long service life in harsh environments, making it ideal for use in places such as industrial plants and warehouses.

Z-shaped steel sheet piles, a highly effective and widely used retaining material, are named for their resemblance to the letter “Z” in their cross-section.U-type (Larsen) steel sheet piles The two types together make the backbone of modern steel sheet pile engineering with significantly different features in structural performance and field of application.

Advantages:

High section modulus-to-weight ratio for efficiency

Increased stiffness minimizes deflection

Wide design allows easy installation

Superior corrosion resistance, with extra thickness at critical points

Hot Rolled Au Pu 6m-18m U-Shaped Steel Sheet Pile is a durable, high-strength steel piling solution designed for retaining walls, waterfront structures, and earth retention projects.

Steel sheet pile has a wide range of applications and can be used in various anchoring systems. It has good adaptability in both soil and water, and can be applied to construction projects, shipyards and wharves where both may exist, and can also be used to support deep foundation pits and metal storage tanks.

The practicality of steel sheet piles is reflected in the innovative construction of many new products, such as special welding buildings; Hydraulic vibration pile driver to make metal plate; Seal combination sluice and factory paint treatment. A number of factors ensure that sheet pile remains one of the more useful manufacturing components: it not only facilitates the progressive improvement of steel quality, but also facilitates the research and development of sheet pile market; It helps to optimize the design of product features and better meet the needs of users

Steel sheet piles are long structural sections with interlocking connections, commonly used as retaining walls in waterfront structures, cofferdams, and other soil- or water-retaining applications. Made of steel for strength and durability, their interlocking design enables continuous walls, providing efficient support for excavations and structural projects.

Disc scaffolding is the most widely used type today, consisting of uprights, crossbars, and diagonal bars assembled with fittings. Most tubes are hot-dip galvanized, preventing rust and breakage over long-term storage. It offers economy, convenience, speed, and safety, making it suitable for vertical work, peripheral safety nets, overhead installation, and indoor decoration at various floor heights.

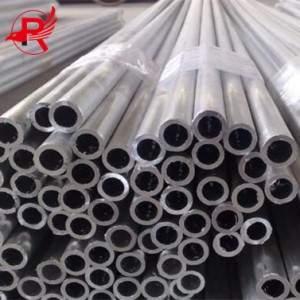

Aluminum Pipe and Tube are Light Weight, Corrosion Free, High Conductivity and Excellent Machinability, these properties make Aluminum Pipe/Tube the Best Choice for all Industrial Uses.

Aluminum pipes are lightweight, corrosion-resistant, and highly conductive, making them ideal for diverse industrial applications.

Cold-formed U-shaped steel sheet piles in S235, S275, or S355 steel, 6–18 m long, ideal for retaining walls, cofferdams, and foundations.

These U-shape Steel Sheet Piles are cold formed based on GB standard and can be offered in high strength grades Q235b, Q345b, Q390 and Q420. They are used for retaining walls, foundations, cofferdams and many other civil engineering works and are supplied in lengths from 6m to 18m. The Cold Formed U Pile design provides consistent thickness and interlock mechanism, high durability in soil and water condition.