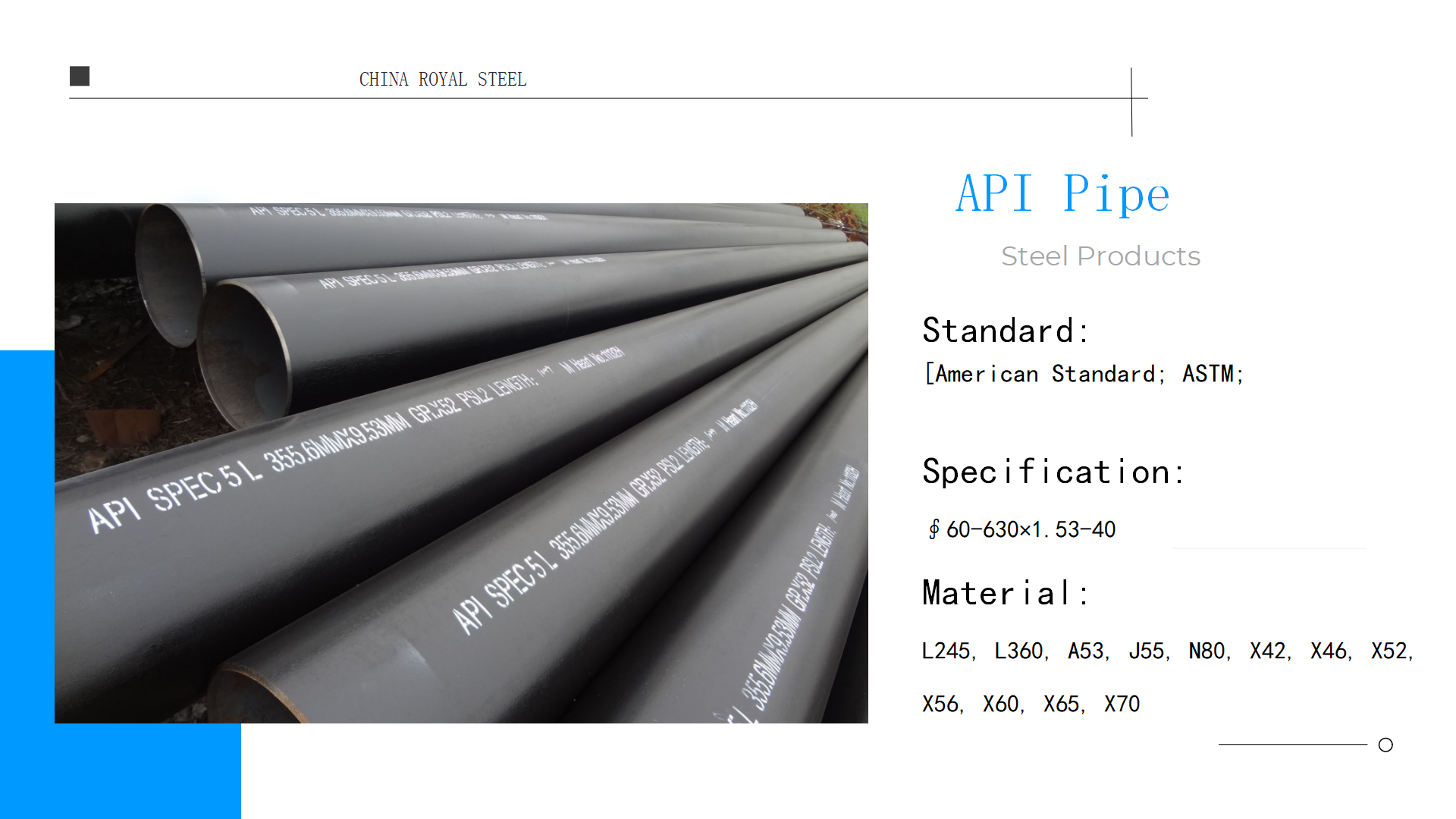

Oil Pipe Line API 5L ASTM A106 A53 Seamless Steel Pipe

Product Detail

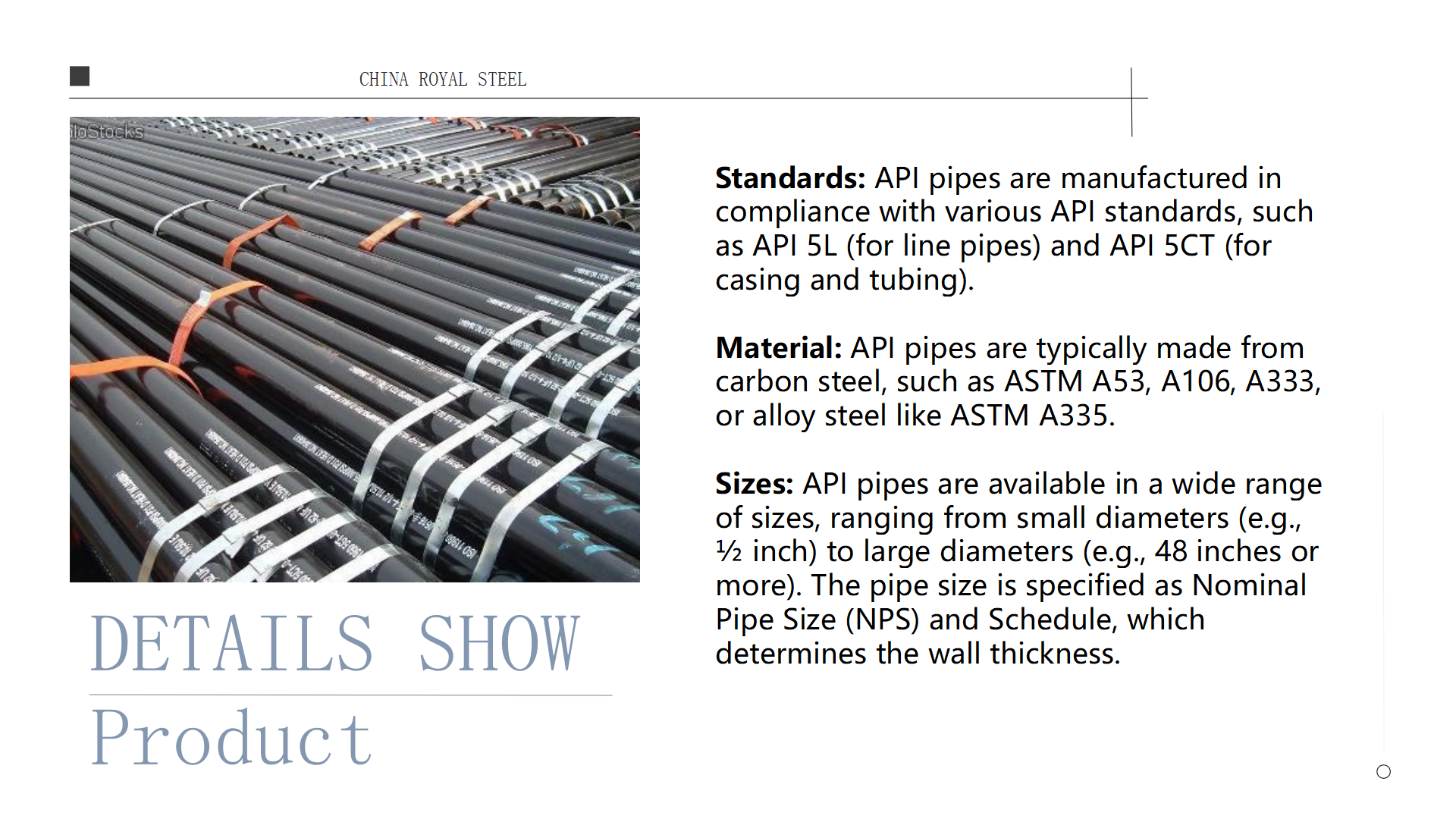

API steel pipe, or American Petroleum Institute steel pipe, is a type of steel pipe commonly used in the oil and gas industry. It is manufactured according to the API 5L and API 5CT standards set by the American Petroleum Institute.

API steel pipes are known for their high strength, durability, and resistance to corrosion. They are typically used for transporting oil, gas, and other fluids in various exploration, production, and transportation applications.

|

Product name

|

Material

|

Standard

|

Size(mm)

|

Application

|

|

Low temperature tube

|

16MnDG

10MnDG 09DG 09Mn2VDG 06Ni3MoDG ASTM A333 |

GB/T18984-

2003

ASTM A333

|

OD:8-1240*

WT:1-200 |

Apply to - 45 ℃ ~ 195 ℃ low temperature pressure vessel and low temperature heat exchanger pipe

|

|

High-pressure boiler tube

|

20G

ASTMA106B ASTMA210A ST45.8-III |

GB5310-1995

ASTM SA106 ASTM SA210 DIN17175-79 |

OD:8-1240*

WT:1-200 |

Suitable for manufacturing high pressure boiler tube, header, steam pipe, etc

|

|

Petroleum cracking tube

|

10

20 |

GB9948-2006

|

OD: 8-630*

WT:1-60 |

Used in oil refinery furnace tube, heat exchanger tube

|

|

Low medium pressure boiler tube

|

10#

20# 16Mn,Q345 |

GB3087-2008

|

OD:8-1240*

WT:1-200 |

Suitable for manufacturing various structure of low and medium pressure boiler and locomotive boiler

|

|

General structure

of the tube

|

10#,20#,45#,27SiMn

ASTM A53A,B 16Mn,Q345 |

GB/T8162-

2008 GB/T17396- 1998 ASTM A53 |

OD:8-1240*

WT:1-200 |

Apply to the general structure, engineering support, mechanical processing, etc

|

|

Oil casing

|

J55,K55,N80,L80

C90,C95,P110 |

API SPEC 5CT

ISO11960 |

OD:60-508*

WT:4.24-16.13 |

Used for extraction of oil or gas in oil Wells casing, used in oil and gas well sidewall

|

Features

API steel pipes have several notable features that make them highly suitable for the oil and gas industry. Here are some of the key features of API steel pipes:

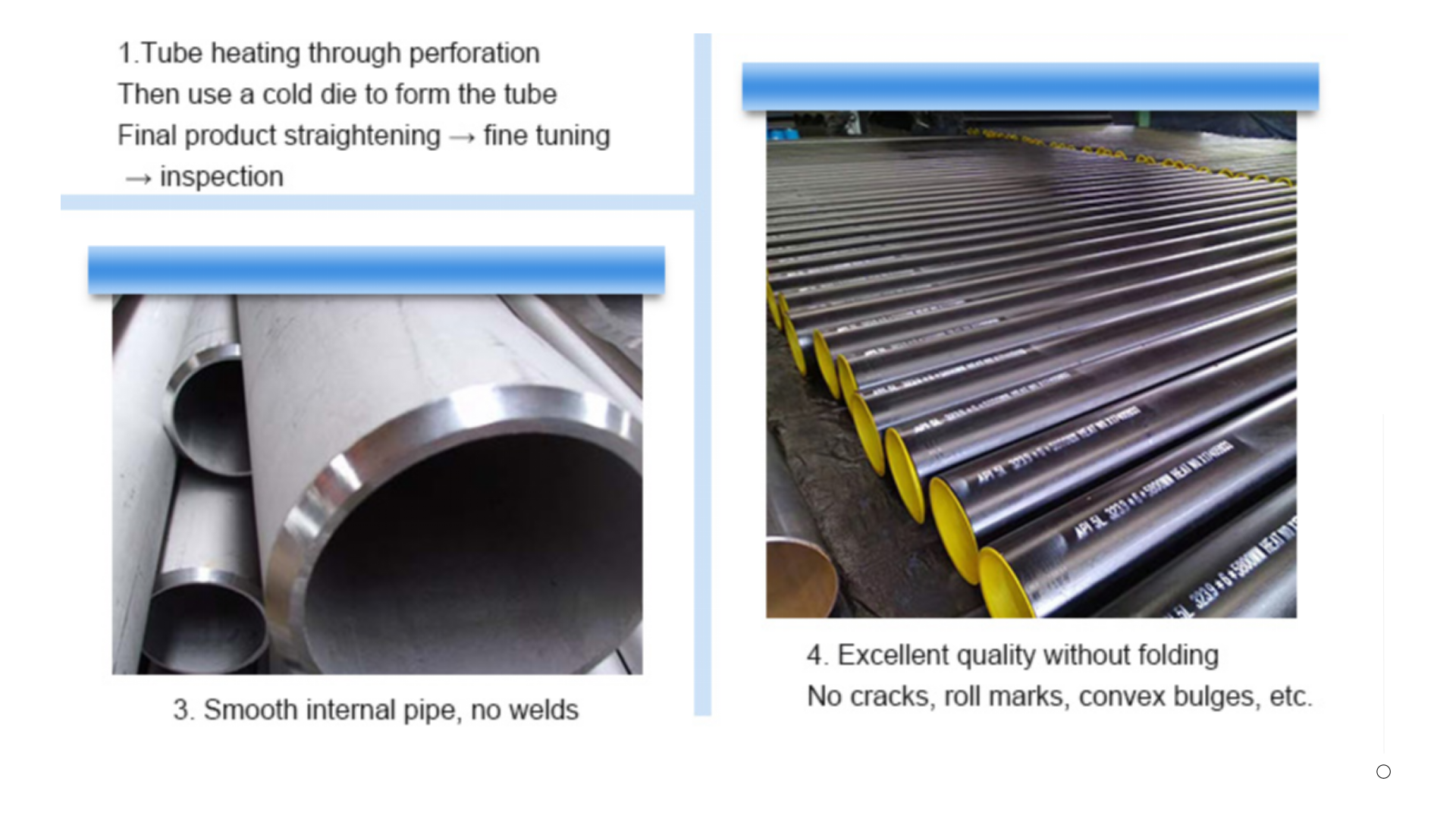

High Strength: API steel pipes are known for their high strength, which enables them to withstand the extreme pressure and weight associated with oil and gas transportation. This strength ensures the pipes can handle the demanding conditions encountered in exploration, production, and transportation processes.

Durability: API steel pipes are manufactured to be durable and resistant to wear and tear. They can withstand harsh environmental conditions, including exposure to corrosive substances and rough handling during installation and operation. This durability ensures the pipes have a long service life, reducing the need for frequent replacements.

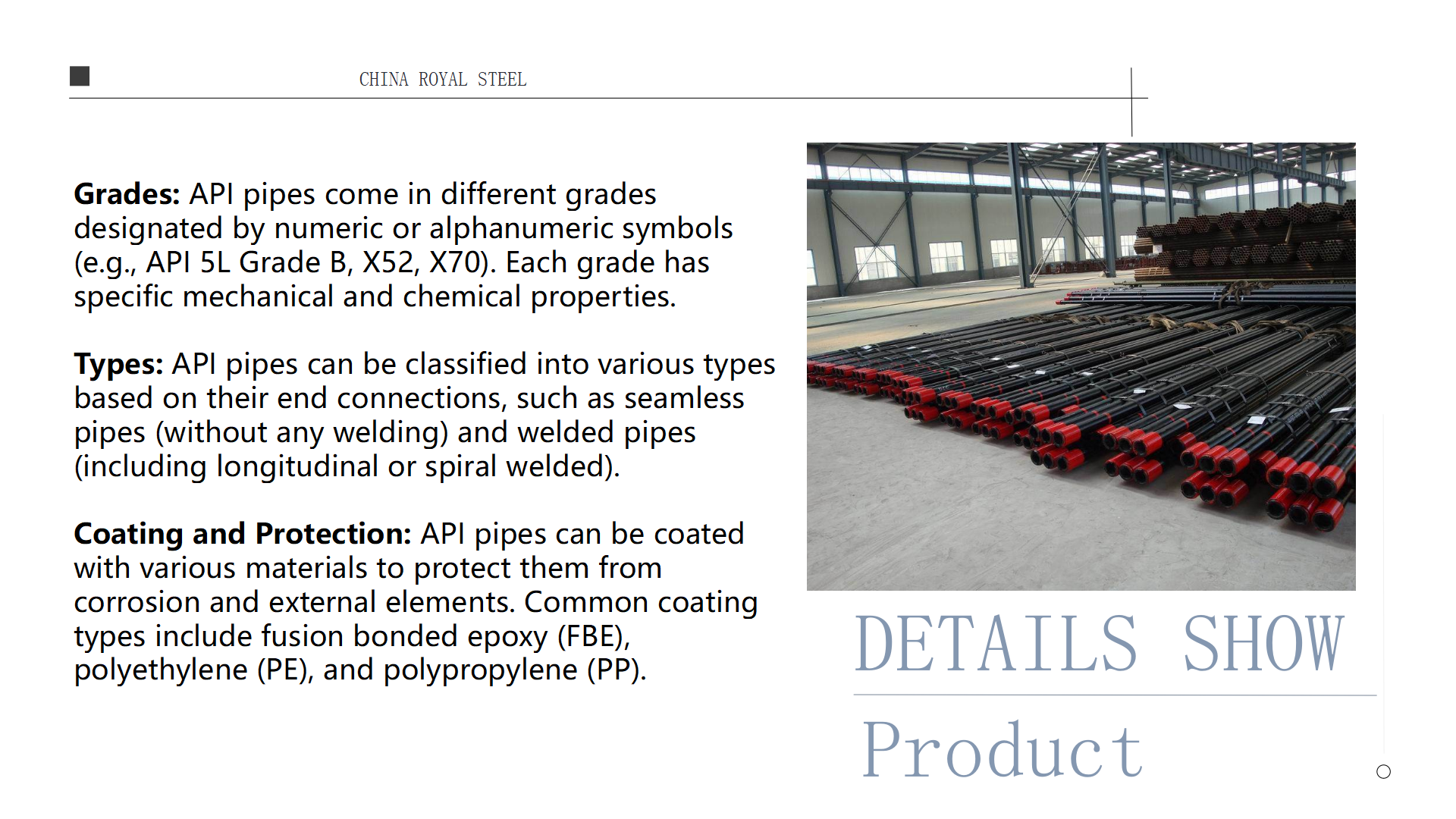

Corrosion Resistance: API steel pipes are designed to be resistant to corrosion. The steel used in their construction is often coated or treated with protective coatings to prevent rust and corrosion caused by contact with water, chemicals, and other corrosive substances commonly found in the oil and gas industry.

Standardized Specifications: API steel pipes adhere to standardized specifications set by the American Petroleum Institute. These specifications ensure uniformity in terms of dimensions, materials, manufacturing processes, and performance, allowing for easy interchangeability and compatibility with other API-compliant equipment and systems.

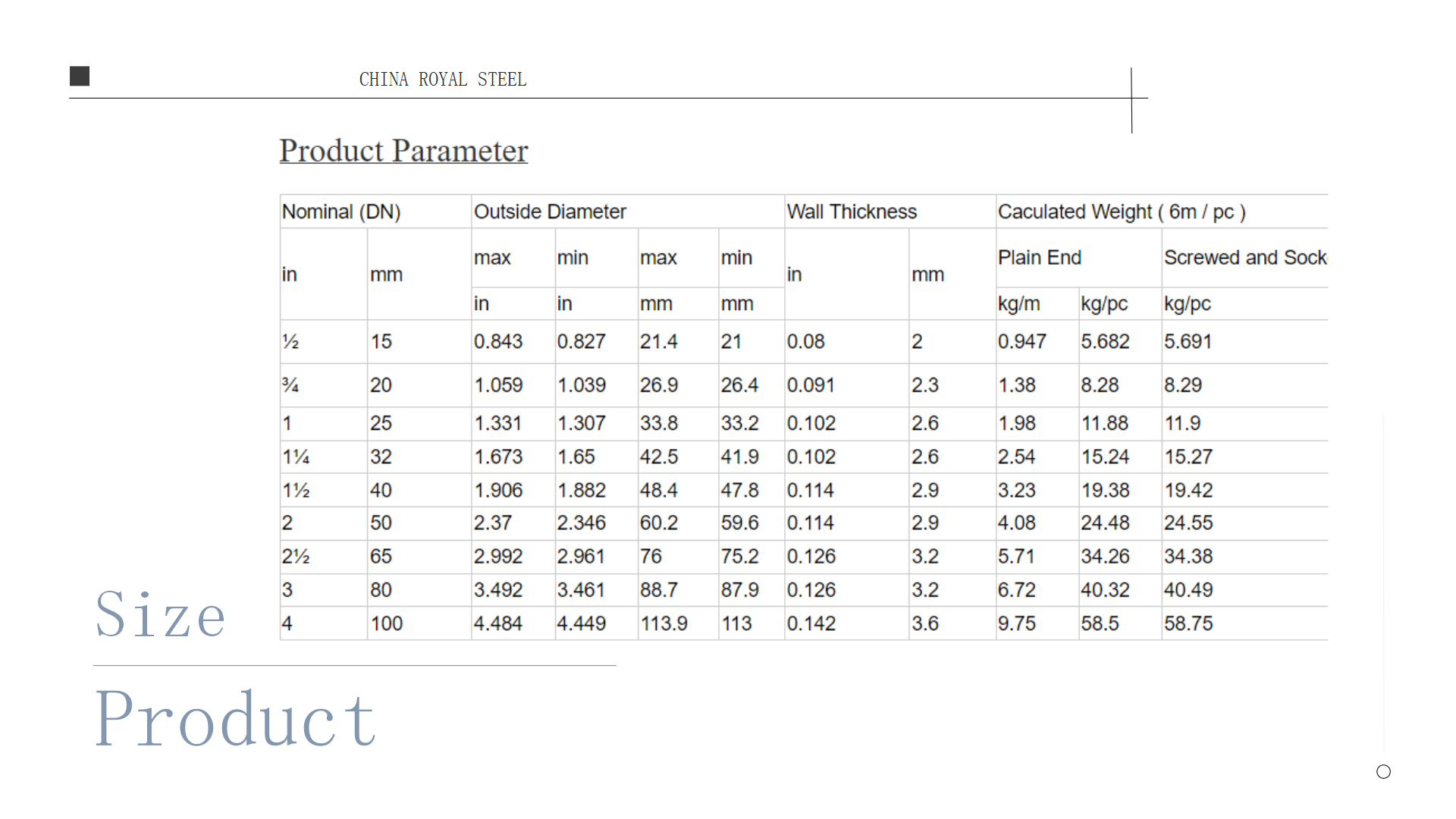

Variety of Sizes and Types: API steel pipes come in a range of sizes, from small diameters to larger ones, to cater to various applications in the oil and gas industry. They are available in both seamless and welded options, providing flexibility in choosing the most suitable pipe type for specific project requirements.

Rigorous Quality Control: API steel pipes undergo stringent quality control measures and testing during the manufacturing process. This ensures that the pipes meet the prescribed standards for materials, mechanical properties, and dimensional accuracy, guaranteeing their reliability, safety, and performance in oil and gas operations.

Application

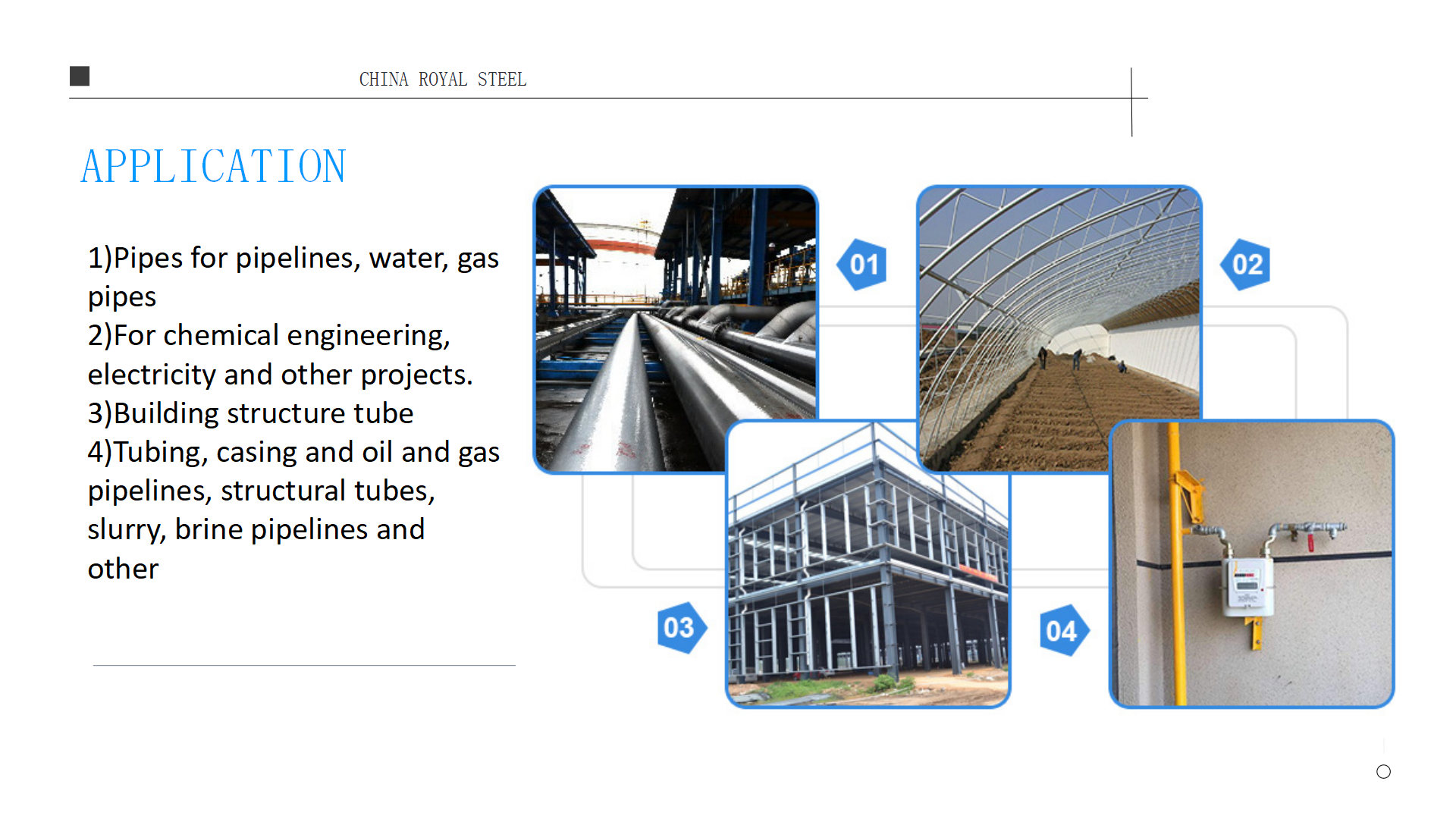

API 5L steel pipes are widely used in various applications within the oil and gas industry. Here are some of the key applications of API 5L steel pipes:

- Oil and Gas Transportation: API 5L steel pipes are primarily used for the transportation of oil and gas from production sites to refineries, storage facilities, and distribution points. They are designed to withstand high pressure and can handle the transportation of both crude oil and natural gas over long distances.

- Offshore and Subsea Projects: API 5L steel pipes are suitable for offshore drilling and production operations. They can be used for installing pipelines and flowlines on the seabed, connecting offshore platforms, and transporting oil and gas from offshore fields to onshore facilities.

- Pipeline Construction: API 5L steel pipes are commonly used in pipeline projects for various purposes, including gathering, transmission, and distribution of oil and gas. These pipes can be laid underground or aboveground, depending on the specific project requirements.

- Industrial Applications: API 5L steel pipes find applications in other industries beyond oil and gas. They are utilized in industries that require the transportation of fluids, such as water and chemicals. API 5L pipes are also used in construction projects for structural purposes, such as in the fabrication of support structures and framework.

- Oil and Gas Exploration: API 5L steel pipes are often employed in the exploration and drilling phase of oil and gas projects. They are used in the construction of drilling rigs, wellheads, and casing, as well as in the extraction of oil and gas from underground reservoirs.

- Refineries and Petrochemical Plants: API 5L steel pipes are crucial in refinery and petrochemical plant operations. They are used for the transportation of crude oil and various petroleum products within the facility. These pipes are also employed in the construction of process piping systems, heat exchangers, and other equipment.

- Natural Gas Distribution: API 5L steel pipes are used in the distribution of natural gas to industrial, commercial, and residential areas. They facilitate the safe and efficient transportation of natural gas from processing plants to end-users, such as power plants, businesses, and households.

Packaging & Shipping

FAQ

Q: Why choose us?

A: Our company have been in steel business for more than ten years, we are internationally experienced, professional, and we can provide variety of steel products with high quality to our clients

Q: Can provide OEM/ODM service?

A: Yes. Please feel free to contact us for more details discuss.

Q: How is your Payment Term?

A:One is 30% deposit by TT before production and 70% balance against copy of B/L; the other is Irrevocable L/C 100% at sight.

Q: Can we visit your factory?

A: Warmly welcome. Once we have your schedule, we will arrange the professional sales team to follow up your case.

Q: Can you provide sample?

A: Yes, for regular sizes sample is free but buyer need to pay freight cost.