GB Standard Non Oriented Electrical Silicon Steel Cold Rolled Silicon Steel Coil

Product Detail

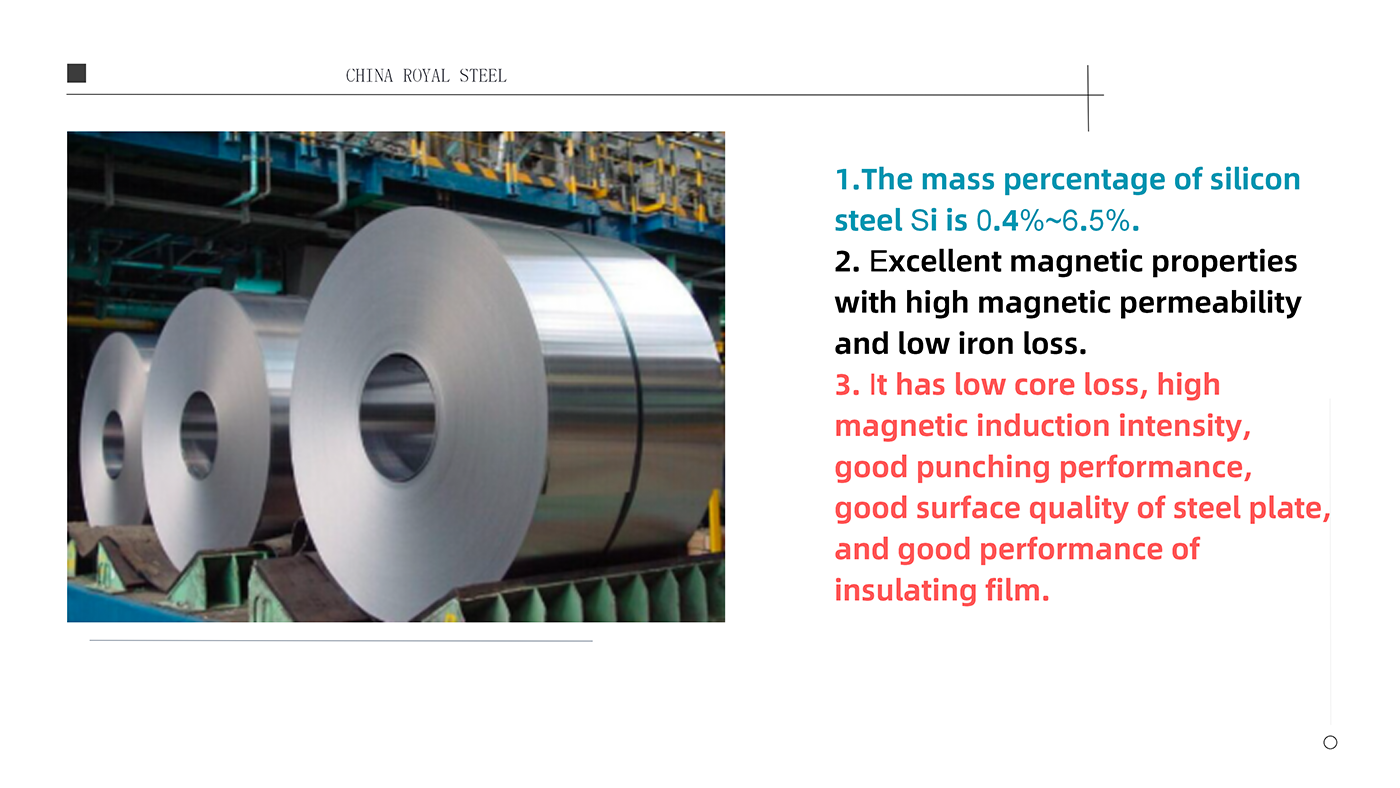

Silicon alloy steel containing 1.0 to 4.5% silicon and less than 0.08% carbon is called silicon steel. It has the characteristics of high magnetic permeability, low coercivity, and large resistivity, so the hysteresis loss and eddy current loss are small. Mainly used as magnetic materials in motors, transformers, electrical appliances and electrical instruments. In order to meet the needs of punching and shearing when manufacturing electrical appliances, a certain degree of plasticity is also required. In order to improve the magnetic induction performance and reduce hysteresis loss, the content of harmful impurities is required to be as low as possible, and the plate shape is required to be smooth and the surface quality is good.

Features

Silicon steel uses core loss (iron loss for short) and magnetic induction intensity (magnetic induction for short) as the guaranteed magnetic value of the product. The low loss of silicon steel can save a lot of electrical energy, extend the operating time of motors and transformers, and simplify the cooling system. The power loss caused by the loss of silicon steel accounts for 2.5% to 4.5% of the annual power generation, of which the iron loss of the transformer accounts for about 50%, the small motor of 1 to 100kW accounts for about 30%, and the fluorescent lamp ballast accounts for about 15%.

| Trademark | Nominal thickness(mm) | 密度(kg/dm³) | Density(kg/dm³)) | Minimum magnetic induction B50(T) | Minimum stacking coefficient (%) |

| B35AH230 | 0.35 | 7.65 | 2.30 | 1.66 | 95.0 |

| B35AH250 | 7.65 | 2.50 | 1.67 | 95.0 | |

| B35AH300 | 7.70 | 3.00 | 1.69 | 95.0 | |

| B50AH300 | 0.50 | 7.65 | 3.00 | 1.67 | 96.0 |

| B50AH350 | 7.70 | 3.50 | 1.70 | 96.0 | |

| B50AH470 | 7.75 | 4.70 | 1.72 | 96.0 | |

| B50AH600 | 7.75 | 6.00 | 1.72 | 96.0 | |

| B50AH800 | 7.80 | 8.00 | 1.74 | 96.0 | |

| B50AH1000 | 7.85 | 10.00 | 1.75 | 96.0 | |

| B35AR300 | 0.35 | 7.80 | 2.30 | 1.66 | 95.0 |

| B50AR300 | 0.50 | 7.75 | 2.50 | 1.67 | 95.0 |

| B50AR350 | 7.80 | 3.00 | 1.69 | 95.0 |

Application

Silicon steel has high magnetic induction, which reduces the excitation current of the iron core and saves electric energy. The high magnetic induction of silicon steel enables the design of a high maximum magnetic induction (Bm), small size and light weight of the core, saving silicon steel, wires, insulation materials and structural materials, etc., which not only reduces the losses and manufacturing costs of motors and transformers, but also facilitates assembly and transportation.

Packaging & Shipping

silicon steel products needs to pay attention to moisture-proof and shock-proof during transportation. First of all, the packaging material should have a certain moisture-proof performance, such as the use of moisture-proof cardboard or the addition of moisture absorption agents; Secondly, in the process of packaging, the product should try to avoid direct contact with the ground and other hard objects, in order to prevent damage caused by vibration or extrusion during transportation.

FAQ

Q1. Where is your factory ?

A1: Our company’s processing center is located in Tianjin, China.Which is well equipped with kinds of machines, such as laser cutting machine,mirror polishing machine and so on. We can provide a wide range of personalized services according to the customers’ needs.

Q2. What are your company's main products ?

A2: Our main products are stainless steel plate/sheet, coil, round/square pipe, bar, channel, steel sheet pile, steel strut,etc.

Q3. How do you control quality ?

A3: Mill Test Certification is supplied with shipment, Third Party Inspection is available.

Q4. What are the advantages of your company ?

A4: We have many professionals, technical personnel, more competitive prices and

best after-dales service than other stainless steel companies.

Q5. How many coutries you already exported ?

A5: Exported to more than 50 countries mainly from America, Russia, UK, Kuwait,

Egypt, Turkey, Jordan, India, etc.

Q6. Can you provide sample ?

A6: Small samples in store and can provide the samples for free. Customized samples will take about 5-7days.