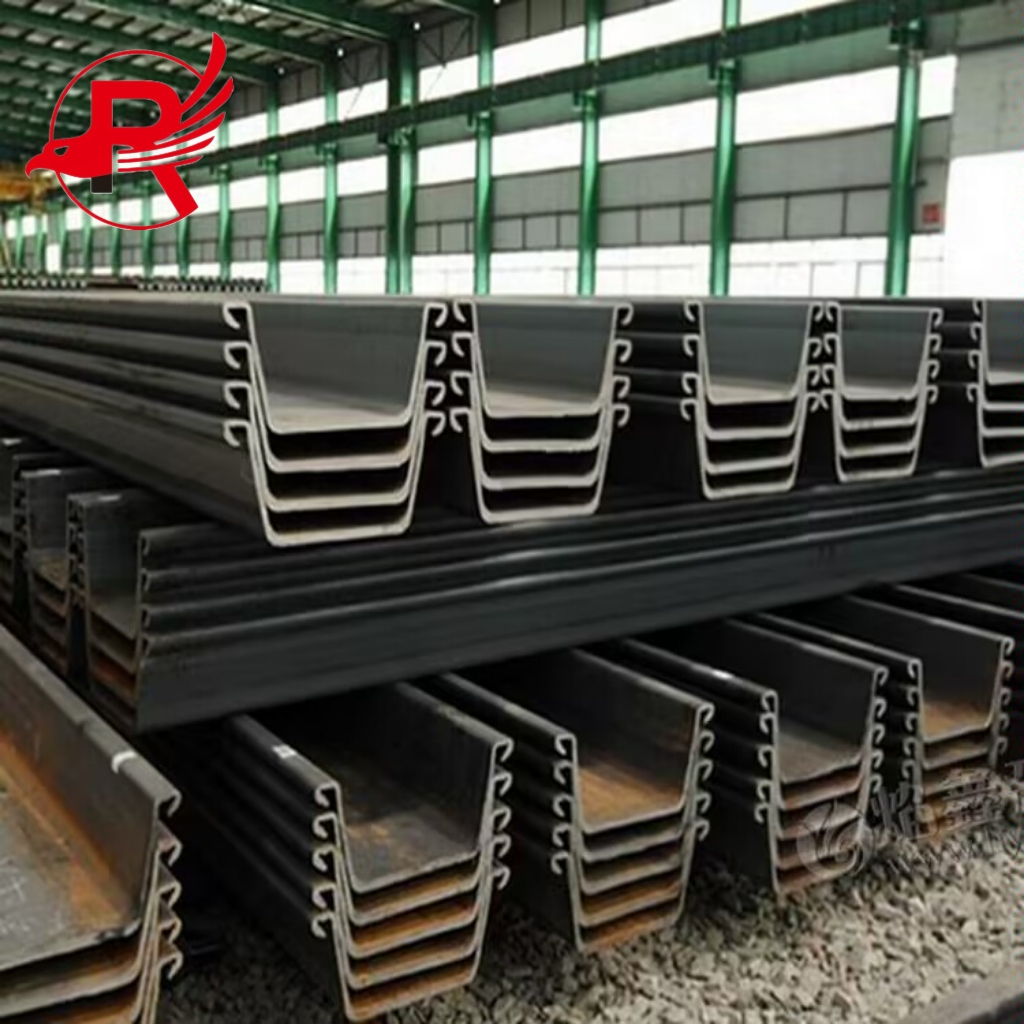

Steel sheet pile is a steel structure with linkage devices on the edges, and the linkage devices can be freely combined to form a continuous and tight retaining soil or water retaining wall.

Steel sheet piles are driven (pressed) into the foundation with a pile driver and connected to each other to form a steel sheet pile wall to retain soil and water. Commonly used cross-section types include: U-shaped, Z-shaped and straight web type.

Steel sheet piles are suitable for supporting soft foundations and deep foundation pits with high groundwater levels. They are easy to construct and have the advantage of good water-stopping performance and can be reused. The delivery status of steel sheet piles. The delivery lengths of cold-formed steel sheet piles are 6m, 9m, 12m, and 15m. They can also be processed to cut-to-length according to user requirements, with a maximum length of 24m.

Pile driver, commonly known as "manipulator", is a machine for driving steel sheet piles. When driving and pulling out piles, the speed and vibration frequency can be adjusted to meet the requirements of different working environments.

Construction Process

(1) Construction preparations: Before driving the pile, the groove at the pile tip should be closed to prevent soil from squeezing in, and the lock should be coated with butter or other grease. Steel sheet piles that are in disrepair, have deformed locks, and are severely rusted should be repaired and corrected. Bent and deformed piles can be corrected by hydraulic jack pressure or fire baking.

(2) Division of piling flow sections.

(3) During the piling process. To ensure the verticality of steel sheet piles. Use two theodolite to control in two directions.

(4) The position and direction of the first and second steel sheet piles that are started to be driven should be ensured to be accurate in order to serve as a guide model. Therefore, they should be measured every 1m driven. After driving to the predetermined depth, immediately use steel bars or steel plates to surround the piles. The bracket is welded for temporary fixation.

Effect:

1. Handle and solve a series of problems that arise during the excavation process;

2. The construction is simple and the construction period is shortened.

3. For construction tasks, it can reduce the space requirements;

4. The use of steel sheet piles can provide necessary safety and is highly timely (for disaster relief and rescue operations);

5. The use of steel sheet piles is not restricted by weather conditions;

6. In the process of using steel sheet piles, the complex procedures for checking the performance of materials or systems can be simplified;

7. Ensure its adaptability, good interchangeability and reuse.

8. It can be recycled and reused, saving money.

Its advantages are: high strength, easy to drive into hard soil; it can be constructed in deep water, and if necessary, diagonal supports can be added to form a cage. It has good waterproof performance; it can form cofferdams of various shapes as needed and can be reused many times. Therefore, it has a wide range of uses.

1. It has strong bearing capacity and light structure. The continuous wall composed of steel sheet piles has high strength and rigidity.

2. It has good water tightness and the locks at the joints of the steel sheet piles are tightly combined to naturally prevent seepage.

3. The construction is simple, can adapt to different geological conditions and soil quality, can reduce the amount of earthwork excavated in the foundation pit, and the operation takes up less space. 4. Good durability. Depending on the use environment, the service life can be as long as 50 years.

5. The construction is environmentally friendly, the amount of soil taken and the amount of concrete are greatly reduced, which can effectively protect land resources.

6. The operation is efficient and is extremely suitable for rapid implementation of disaster relief and prevention such as flood control, collapse, quicksand, and earthquakes. 7. The material can be recycled and used repeatedly. In temporary projects, it can be reused 20 to 30 times.

8. Compared with other single structures, the wall is lighter and has greater adaptability to deformation, making it suitable for the prevention and treatment of various geological disasters.

Contact Us for More Information

Email: [email protected]

Tel / WhatsApp: +86 13652091506

Post time: Mar-22-2024