When it comes to steel rail safety and maintenance, taking precautions is crucial. Here are some precautions regarding rail to ensure its safety and reliability.

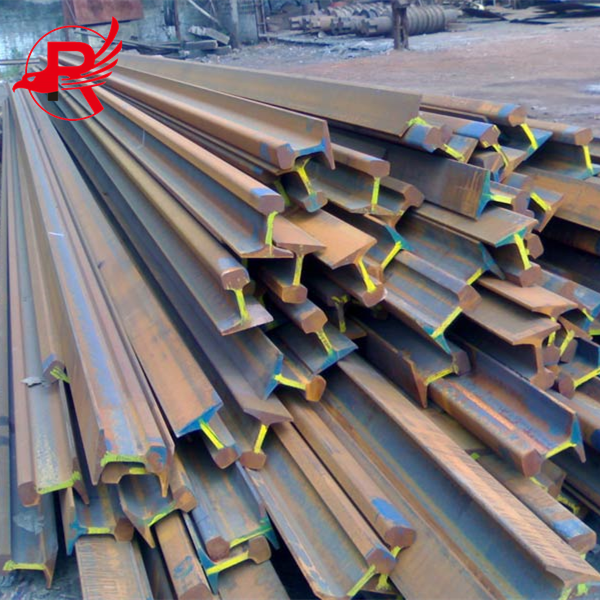

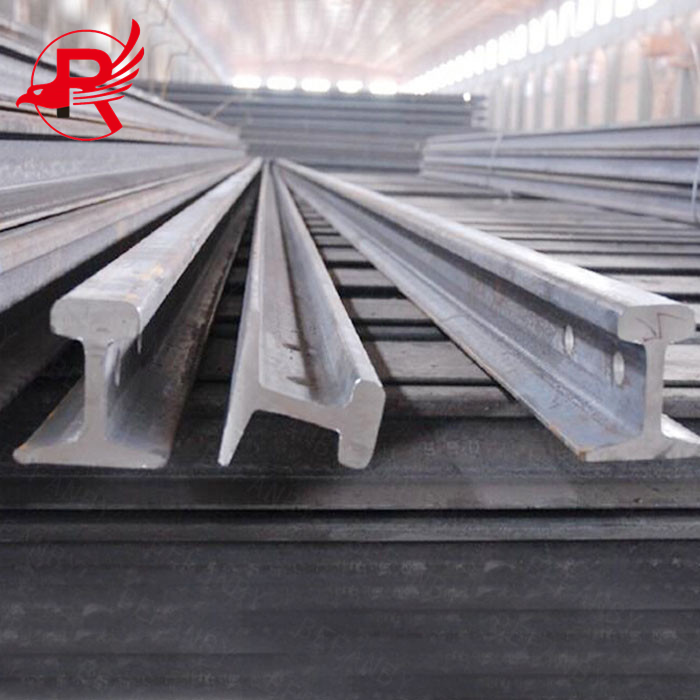

- Regular inspection: Carbon Steel Rails should be inspected regularly for signs of wear, cracks or damage. This can help identify potential issues before they become safety hazards.Proper maintenance: Maintenance such as lubrication and cleaning should be performed regularly to ensure that the rails remain in good condition and free from corrosion.Load limit monitoring: Ensure that the load carried by the rail does not exceed its specified load-bearing capacity. Overloading can lead to premature wear and potential failure.

Control of environmental factors: Protect rails from harsh environmental conditions, such as extreme temperatures, moisture and chemicals, which can accelerate corrosion and deterioration.

Proper installation: Custom Steel Railroad Rails should be installed according to manufacturer guidelines and industry standards to ensure proper alignment and stability.

Training and Awareness: Rail workers should be trained in proper operation and safety procedures to prevent accidents and injuries.

Reporting and Repair: Any signs of damage or wear should be reported immediately and any necessary repairs made by qualified personnel.

Use of protective equipment: Appropriate personal protective equipment should be used when working on rails to prevent injury.

Comply with regulations: Ensure compliance with all safety regulations and standards related to the use of rails to maintain a safe working environment.

Emergency plan: Develop an emergency plan for rail accidents or failures. This should include evacuation, containment and reporting procedures.

Address

Bl20, Shanghecheng, Shuangjie Street, Beichen District, Tianjin, China

Phone

+86 13652091506

Post time: Oct-12-2023