In the brilliant starry sky of metal materials, Copper Coilare widely used in many fields with their unique charm, from ancient architectural decoration to cutting-edge industrial manufacturing. Today, let's take a deep look at copper coils and unveil their mysterious veil.

1. What is Copper Coil?

Copper, also known as red copper, is named after the purple oxide film formed after oxidation on its surface. The main component is copper, with a content of more than 99.5% and very few impurities. Copper coils are made of copper as raw material and processed through a series of processes. Because copper has good electrical conductivity, thermal conductivity and ductility, copper coils inherit these excellent properties and have become the "darling" of many industries.

Characteristics of copper coils

1. Excellent electrical conductivity

The electrical conductivity of copper coils is second only to silver, ranking second among all metals. This feature makes it an ideal material for wire and cable manufacturing. In the field of power transmission, cables made of copper coils can effectively reduce resistance, reduce the loss of electric energy during transmission, and ensure stable and efficient power transmission.

2. Good thermal conductivity

Copper coils have excellent thermal conductivity and can quickly absorb and transfer heat. In the manufacture of equipment such as heat exchangers and radiators, copper coils are the preferred material. For example, the radiator of a car engine is made of copper coil, which can quickly dissipate the heat generated by the engine, ensure that the engine works at a suitable temperature, and extend its service life.

3. Excellent corrosion resistance

A dense oxide film can be formed on the surface of copper. This oxide film is like a "protective film" to prevent the copper from further oxidation and corrosion. In a humid or corrosive gas environment, pipes, containers, etc. made of copper coils can still maintain good performance and will not be easily corroded and damaged.

4. Excellent processing performance

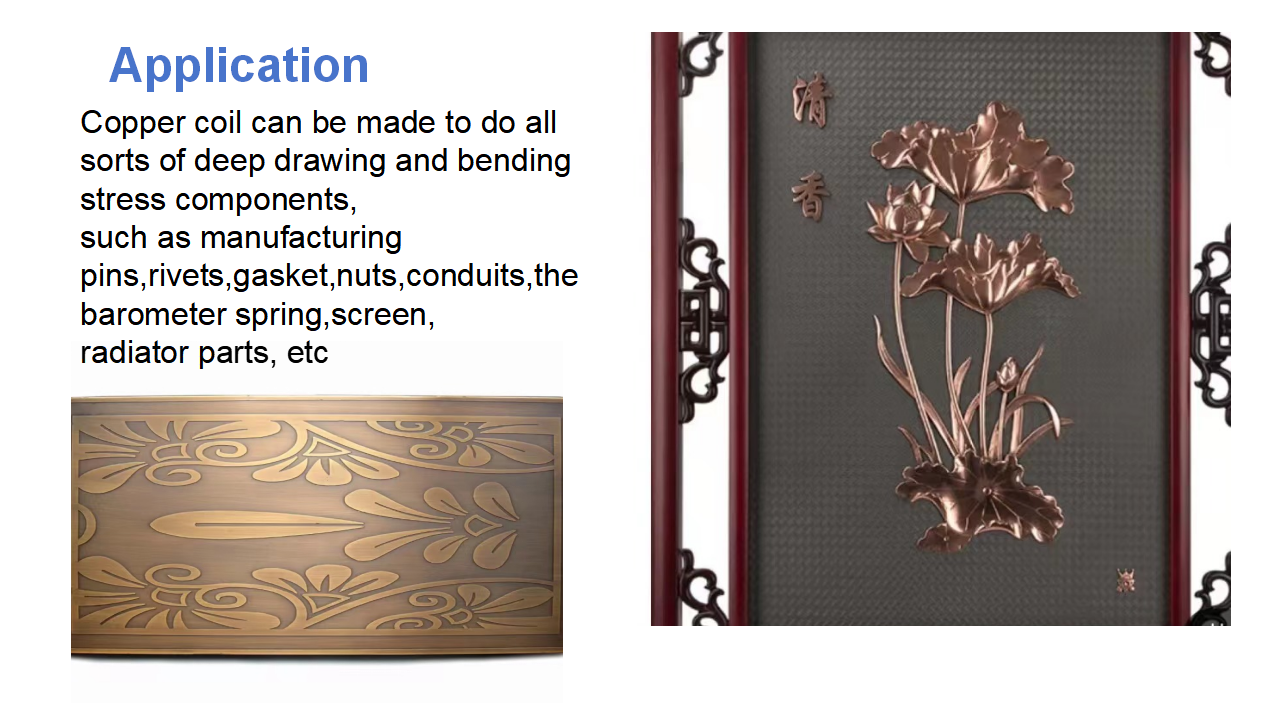

Copper has good ductility and plasticity and is easy to process. Copper coils can be made into various parts of complex shapes through various processing methods such as stamping, stretching, and bending to meet the diverse needs of different industries

Application Fields of Copper Coils

1. Power industry

In the power industry, copper coils are widely used in the manufacture of equipment such as wires and cables, transformers, and switch cabinets. High-quality copper cables can ensure the stability and reliability of power transmission, and the copper windings in transformers can improve the efficiency and performance of transformers.

2. Construction industry

In the construction field, copper coils are often used in the production of roofs, walls, decorative lines, etc. The unique color and luster of copper can add a unique artistic atmosphere to the building and enhance the beauty and value of the building. In addition, pipes made of copper coils are corrosion-resistant and have a long service life, and are widely used in building water supply and drainage systems.

3. Electronics industry

Copper coils are widely used in the electronics industry and are an important material for manufacturing printed circuit boards and electronic components. The good electrical conductivity and thermal conductivity of copper can meet the needs of electronic products for high-performance materials and ensure the stable operation of electronic products.

4. Machinery manufacturing industry

In the machinery manufacturing field, copper coils are often used to manufacture various parts, such as bearings, gears, seals, etc. The wear resistance and self-lubricating properties of copper can reduce friction and wear between parts and improve the service life and operating efficiency of mechanical equipment.

Copper coils play an important role in many industries due to their excellent electrical conductivity, thermal conductivity, corrosion resistance and processing performance. With the continuous advancement of science and technology, the application areas of copper coils will continue to expand. I believe that in the future, copper coils will continue to contribute to the development of human society and write a new glorious chapter.

If you are interested in copper coils, please leave a message in the comment area to share your views and experiences!

Address

Bl20, Shanghecheng, Shuangjie Street, Beichen District, Tianjin, China

Phone

+86 15320016383

Post time: Mar-24-2025