Hot-rolled steel sheet piles are widely used in many fields such as foundation pit support, bank reinforcement, seawall protection, wharf construction and underground engineering. Due to its excellent carrying capacity, it can effectively cope with soil pressure and water pressure. The manufacturing cost of hot-rolled steel sheet pile is relatively low, and it can be reused, and has good economy. At the same time, the steel can be recycled, in line with the concept of sustainable development. Although the hot-rolled steel sheet pile itself has a certain durability, in some corrosive environments, anti-corrosion treatment such as coating and hot-dip galvanizing is often used to further extend the service life.

Steel sheet piles have a number of significant advantages in the construction industry. First, it is made of high-strength steel, which can withstand large soil and water pressures, ensuring the stability of the structure. In terms of construction, steel sheet piles are quickly driven into the earth by piling equipment, which significantly shorens the construction period and reduces the construction cost. It is suitable for a variety of soil conditions and can work effectively in weak, wet or complex geological environments. In addition, steel sheet piles can be customized in shape and size according to specific needs, providing design flexibility. In terms of maintenance, its corrosion resistance treatment reduces the cost of later maintenance, usually only needs regular inspection, and the workload is less. Finally, the construction process of steel sheet piles has less noise and vibration, and less impact on the surrounding environment. In summary, steel sheet pile has become an important support and enclosure material in the construction industry by virtue of its high efficiency, economy and environmental adaptability.

Hot-rolled steel sheet pile is a kind of basic material widely used in civil engineering and building construction, mainly used to prevent soil leakage, support soil, and as a retaining wall of DAMS and wharfs.

Hot-rolled steel sheet piles are usually made of high-strength carbon steel or alloy steel, which has good mechanical properties and durability. Through the hot rolling process, the grain of the steel plate is refined, and its strength and toughness are enhanced.

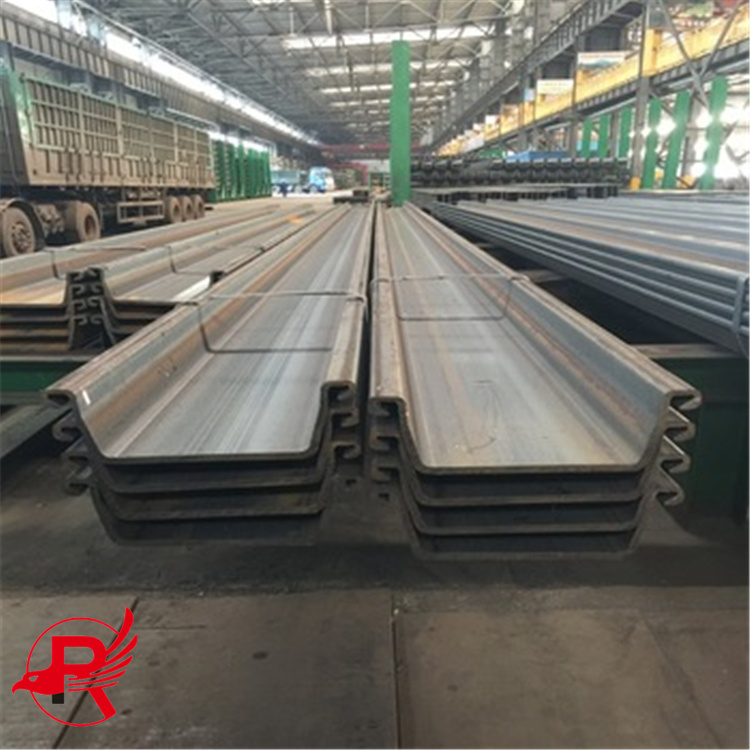

The section of steel sheet piles is generally "U" shape or "Z" shape, which is convenient for mutual occlusion and connection. Common thickness and width specifications are varied and can be customized according to engineering needs. Hot rolled steel sheet piles are driven into the soil by pile driver or hydraulic pile hammer and other equipment to form a stable protective structure. The piling process is rapid, reducing construction time and impact on the surrounding environment.

Post time: Sep-19-2024