In the United States, the steel Metal Processing parts market has always been prosperous, and demand continues to remain strong. From construction sites to advanced automobile manufacturing workshops to precision machinery manufacturing factories, various types of steel processing parts have become an indispensable key element in the operation of many industries with their excellent performance.

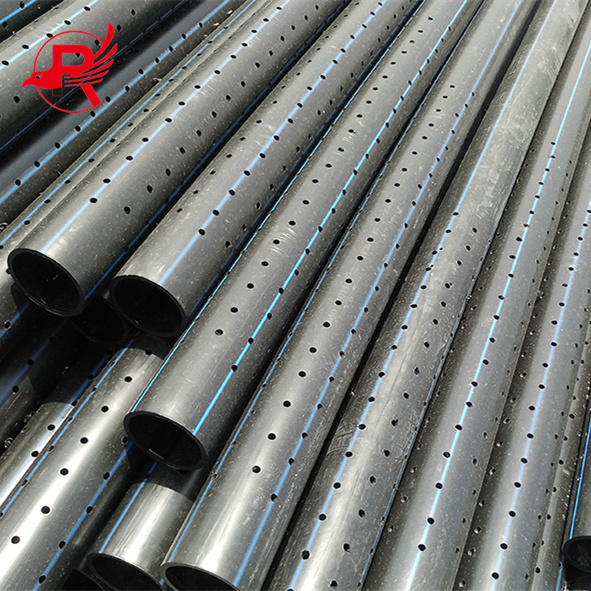

As far as steel pipe processing parts are concerned, Punching Processing, Cutting Processing, Welding Processing and bending processes have given steel pipes a new value. In the field of pipeline connection, Hot Rolled Steel Pipe punching technology is crucial. Through high-precision punching equipment, precise apertures can be drilled on steel pipes to ensure that pipeline connectors are tightly engaged, effectively avoid medium leakage, greatly improve the sealing and stability of pipeline systems, and are widely used in large-scale pipeline network projects such as oil and gas transportation, urban water supply and heating. The cutting process is like a skilled tailor, who accurately cuts steel pipes into the required length according to the different needs of industries such as construction and machinery manufacturing. Whether it is scaffolding steel pipes for building high-rise buildings or pipes for manufacturing precision machinery parts, accurate cutting length is the basis for ensuring the smooth progress of the project.

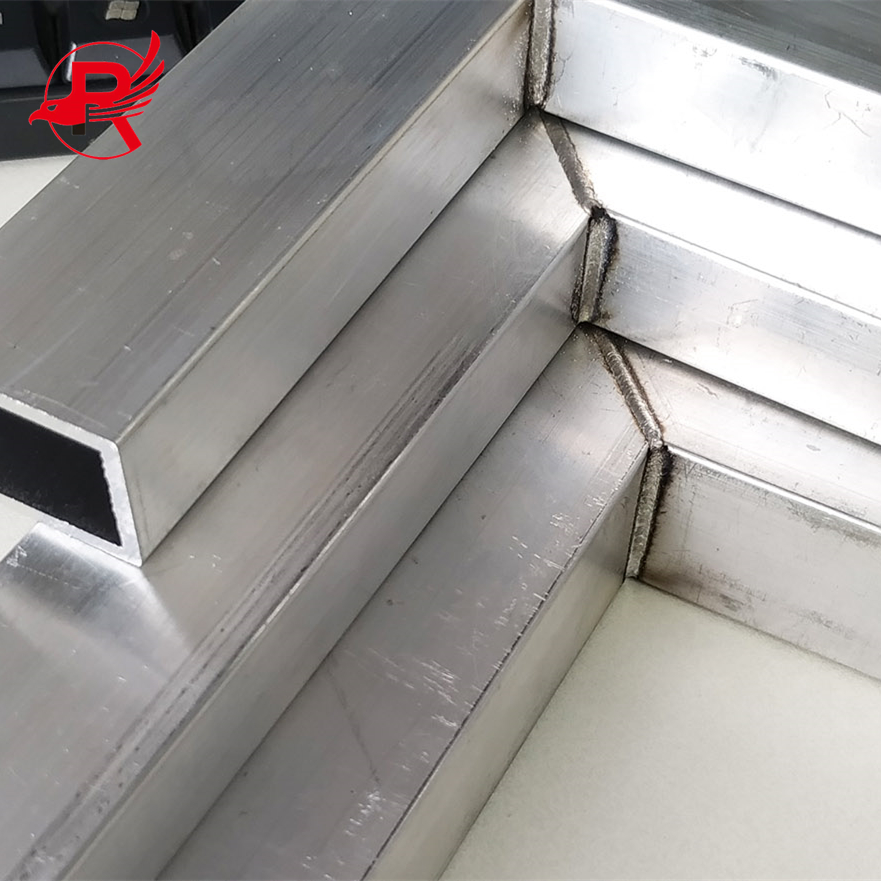

The welding process has infinitely expanded the application boundaries of GI Steel Pipe. It can cleverly combine multiple sections of steel pipes to build complex and stable structures. In the construction industry, skyscrapers that reach into the sky rely on scaffolding built with welded steel pipes to ensure construction safety; in bridge construction, the sturdy welded steel pipe support structure bears the weight of vehicles coming and going, becoming an important link connecting traffic arteries. The application scenarios of steel pipes that have been bent are also extremely wide. In the field of furniture manufacturing, bent steel pipes can create stylish and comfortable furniture frames, adding modern beauty to the home environment; on the production line of automotive parts, the car seat frame uses bent steel pipes, which not only ensures the strength of the seat, but also takes into account the ergonomic design and improves driving comfort.

Steel plate processed parts also shine in various industries, and punching and bending are the most widely used processes. In the manufacture of electrical equipment, the steel plate punching process provides convenience for line installation and equipment heat dissipation. The shell of the electrical control cabinet is usually made of perforated Ms Steel Plate. The reasonably distributed holes not only facilitate the entry and exit of wires and cables, but also promote air circulation, dissipate the heat generated by the operation of the equipment in time, and ensure the stable operation of electrical equipment. In the field of construction, bent steel plates can be seen everywhere. The building exterior wall decorative panels can be bent to create unique shapes and lines, adding artistic charm to the appearance of the building; as structural support parts, bent steel plates can effectively bear the weight of the building with their enhanced mechanical properties to ensure the stability and safety of the building structure. In the manufacturing industry, bent steel plates are made into various mechanical shells to provide reliable protection for internal precision parts; pallet products are made of bent steel plates, which have good load-bearing capacity and durability, and are widely used in logistics and transportation to improve cargo handling efficiency.

As the US construction industry continues to move towards high altitude and intelligence, the automotive industry is developing towards new energy and lightweight, and the manufacturing industry continues to pursue high precision and high efficiency, the demand for steel processing parts is increasing day by day. With their excellent strength, durability and adaptability, these processed parts are deeply integrated into many engineering projects and product production processes, playing an irreplaceable key role in various application scenarios. Therefore, they firmly occupy an important position in the best-selling products in the United States and become an important force in promoting the development of American industry.

Address

Bl20, Shanghecheng, Shuangjie Street, Beichen District, Tianjin, China

Phone

+86 13652091506

Post time: Mar-10-2025