Construction Can Be 41*41 Pillar Channel/C Channel/Seismic Support

Definition: Strut C channel, also known as C-Channel, is a type of metal framing channel that is commonly used in construction, electrical, and industrial applications. It has a C-shaped cross-section with a flat back and two perpendicular flanges.

Material: Strut C channels are typically made from galvanized steel or stainless steel. The galvanized steel channels are coated with zinc to protect against corrosion, while stainless steel channels offer greater resistance to corrosion.

Sizes: Strut C channels are available in various sizes, including different lengths, widths, and gauges. Common sizes range from small profiles like 1-5/8" x 1-5/8" to larger profiles like 3" x 1-1/2" or 4" x 2".

Applications: C channels are primarily used in building construction for structural support, as well as in electrical and mechanical installations for routing and securing cables, pipes, and other components. They are also used in shelving, framework, and various industrial applications.

Installation: Strut C channels can be easily installed and connected using specialized fittings, brackets, and clamps. They can be attached to walls, ceilings, or other surfaces using screws, bolts, or welds.

Load Capacity: The load-bearing capacity of a strut C channel depends on its size and material. Manufacturers provide load tables that specify the maximum recommended loads for different channel dimensions and installation methods.

Accessories and Attachments: Various accessories and attachments are available for strut C channels, including spring nuts, beam clamps, threaded rods, hangers, brackets, and pipe supports. These accessories enhance their versatility and enable customization for specific applications.

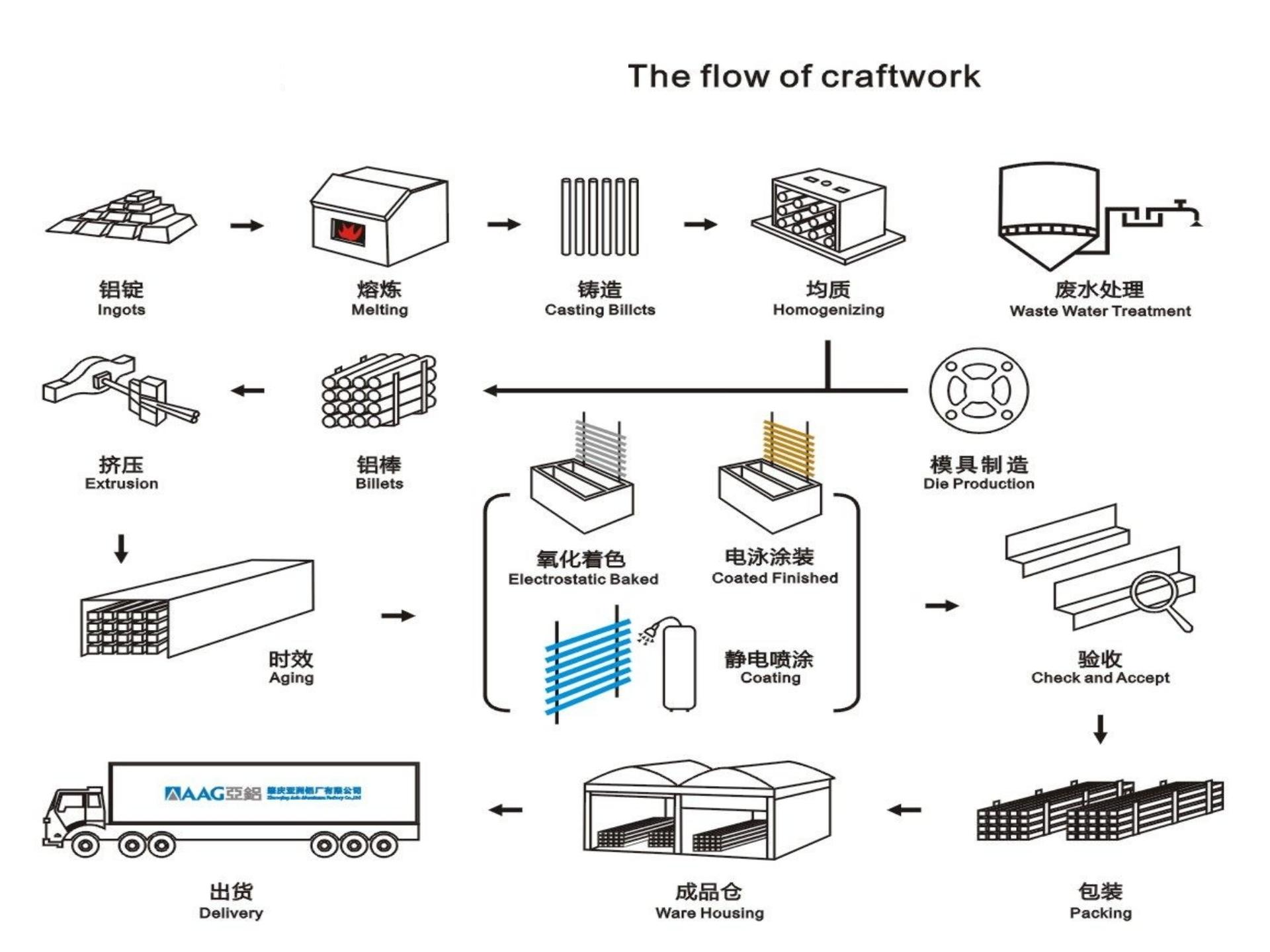

PRODUCT PRODUCTION PROCESS

PRODUCT SIZE

|

SPECIFICATIONS FOR H-BEAM |

|

| 1. Size | 1) 41x41x2.5x3000mm |

| 2)Wall Thickness:2mm,2.5mm,2.6MM | |

| 3)Strut Channel | |

| 2. Standard: | GB |

| 3.Material | Q235 |

| 4. Location of our factory | Tianjin,China |

| 5. Usage: | 1)rolling stock |

| 2)Building steel structure | |

| 3Cable tray | |

| 6. Coating: | 1) galvanized2) Galvalume

3) hot dip galvanized |

| 7. Technique: | hot rolled |

| 8. Type: | Strut Channel |

| 9. Section Shape: | c |

| 10. Inspection: | Client inspection or inspection by 3rd party. |

| 11. Delivery: | Container, Bulk Vessel. |

| 12. About Our Quality: | 1) No damage, no bent2) Free for oiled&marking

3) All goods can be checked by third party inspection before shipment |

| No. | Size | Thickness | Type | Surface

Treatment |

||

| mm | inch | mm | Gauge | |||

| A | 41x21 | 1-5/8x13/16" | 1.0,1.2,1.5,2.0,2.5 | 20,19,17,14,13 | Slotted, Solid | GI,HDG,PC |

| B | 41x25 | 1-5/8x1" | 1.0,1.2,1.5,2.0,2.5 | 20,19,17,14,13 | Slotted, Solid | GI,HDG,PC |

| C | 41x41 | 1-5/8x1-5/8" | 1.0,1.2,1.5,2.0,2.5 | 20,19,17,14,13 | Slotted, Solid | GI,HDG,PC |

| D | 41x62 | 1-5/8x2-7/16" | 1.0,1.2,1.5,2.0,2.5 | 20,19,17,14,13 | Slotted, Solid | GI,HDG,PC |

| E | 41x82 | 1-5/8x3-1/4" | 1.0,1.2,1.5,2.0,2.5 | 20,19,17,14,13 | Slotted, Solid | GI,HDG,PC |

ADVANTAGE

Versatility: Strut C channels can be used in a wide range of applications, making them versatile for various industries such as construction, electrical, and industrial. They offer flexibility for mounting and supporting different components and infrastructure.

High Strength: The design of the C-shaped profile provides excellent strength and rigidity, allowing the channels to support heavy loads and resist bending or deformation. They are able to withstand the weight of cable trays, pipes, and other equipment.

Easy Installation: Strut C channels are designed for easy installation, thanks to their standardized dimensions and pre-punched holes along the length of the channel. This allows for quick and straightforward attachment to walls, ceilings, or other surfaces using appropriate fasteners.

Adjustability: The pre-punched holes in the channels allow for adjustable positioning of accessories and attachments, such as brackets and clamps. This makes it convenient to modify the layout or add/remove components as needed during installation or future modifications.

Corrosion Resistance: Strut C channels made from galvanized steel or stainless steel are highly resistant to corrosion. This ensures long-lasting performance, even in harsh environmental conditions or corrosive environments.

Compatibility with Accessories: Strut C channels are compatible with a wide range of accessories and attachments designed specifically for this type of channel. These accessories include nuts, bolts, clamps, and fittings, which makes it easier to customize the channel system to meet specific requirements.

Cost-effective: Strut C channels offer a cost-effective solution for structural support and mounting applications. They are relatively inexpensive compared to alternative methods, such as custom metal fabrication, while still providing the necessary strength and durability.

PRODUCT INSPECTION

The testing items of photovoltaic brackets include the following aspects:

Overall appearance inspection: Visual inspection of the C Channel Structural Steel station’s support structure, welding quality, fasteners and anchors to determine whether it is damaged or severely deformed.

Stability inspection of the bracket: including inspection of the inclination, levelness, offset performance, etc. of the bracket to ensure that the bracket can maintain a stable working condition even in natural disasters and other abnormal situations.

Bearing capacity inspection: Evaluate the bearing capacity of the bracket by measuring the actual load and design bearing capacity of the bracket to ensure reasonable distribution of the load and prevent bracket collapse and accidents caused by excessive load.

Fastener status inspection: Check fasteners such as plates and bolts to ensure that the connection heads are not loose or flashing, and replace fasteners that need maintenance or replacement in a timely manner.

Corrosion and aging inspection: Inspect the bracket parts for corrosion, aging, compression deformation, etc. to prevent damage and component failure due to long-term use.

Related facility inspections: Includes inspections of related facilities such as solar panels, trackers, arrays, and inverters to ensure that all elements of the system are operating within system specifications.

PROJECT

Our company has participated in the largest solar energy development project in South America, providing brackets and solution design. We provided 15,000 tons of photovoltaic brackets for this project. The photovoltaic brackets adopted domestic emerging technologies to help the development of the photovoltaic industry in South America and improve local residents. Life. The photovoltaic support project includes a photovoltaic power station with an installed capacity of approximately 6MW and a battery energy storage power station of 5MW/2.5h. It can generate approximately 1,200 kilowatt hours per year. The system has good photoelectric conversion capabilities.

APPLICATION

Strut Channel have a wide range of applications in various industries and construction projects. Some of the common applications include:

Roof Photovoltaic Power Generation System:Installing Strut Channel and photovoltaic modules on the roof of a building is a distributed photovoltaic power station. Power generation through photovoltaic modules is common in urban buildings or places with tight land use, which can greatly reduce the requirements for the site.

Ground photovoltaic power station:The ground photovoltaic power station is usually built on the ground and is a centralized photovoltaic power station. It is composed of photovoltaic modules, support structures and electrical equipment, which can convert solar energy into electrical energy and transmit it to the grid. It is a clean, renewable and increasingly common Construction method of photovoltaic power station.

Agricultural Photovoltaic System:Install the photovoltaic support next to the farmland or on the top or side of some greenhouses to provide crops with dual functions of shading and power generation, which can reduce the economic cost of the agricultural system.

other special scenes:For example, offshore wind power generation, road lighting and other fields can also use photovoltaic brackets to set up power stations, and can also carry out general contracting of photovoltaic power station projects in the whole county to help energy conservation and environmental protection.

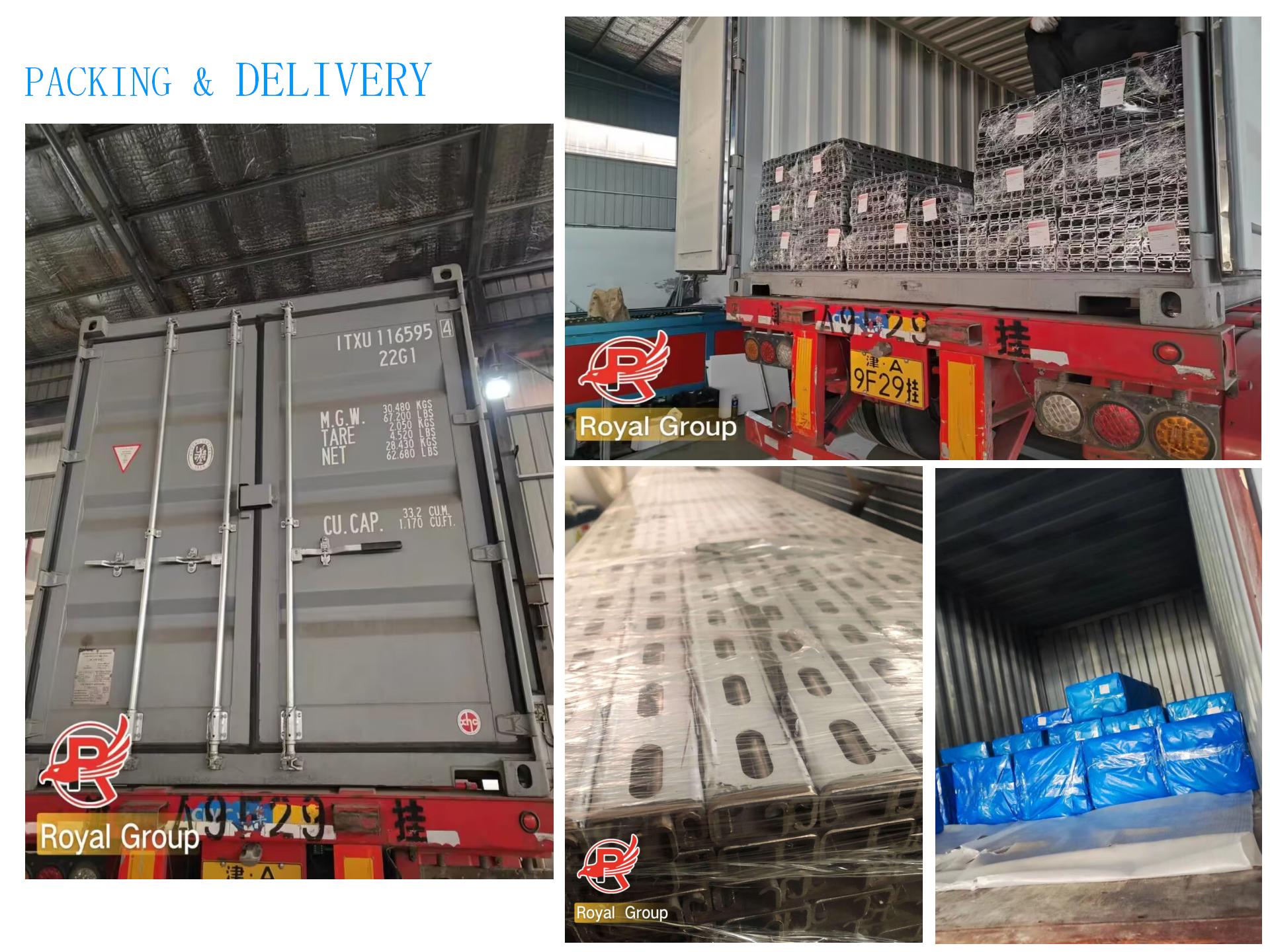

PACKAGING AND SHIPPING

Packaging:

We pack the products in bundles. A bundle of 500-600kg. A small cabinet weighs 19 tons.The outer layer will be wrapped with plastic film.

Shipping:

Choose a suitable mode of transportation: Depending on the quantity and weight of the Strut Channel, select the appropriate mode of transportation, such as flatbed trucks, containers, or ships. Consider factors like distance, time, cost, and any regulatory requirements for transportation.

Use appropriate lifting equipment: To load and unload the Strut Channel, use suitable lifting equipment such as cranes, forklifts, or loaders. Ensure that the equipment used has sufficient capacity to handle the weight of the sheet piles safely.

Secure the load: Properly secure the packaged stack of Strut Channel on the transportation vehicle using strapping, bracing, or other suitable means to prevent shifting, sliding, or falling during transit.

COMPANY STRENGTH

Made in China, first-class service, cutting-edge quality, world-renowned

1. Scale effect: Our company has a large supply chain and a large steel factory, achieving scale effects in transportation and procurement, and becoming a steel company that integrates production and services

2. Product diversity: Product diversity, any steel you want can be purchased from us, mainly engaged in steel structures, steel rails, steel sheet piles, photovoltaic brackets, channel steel, silicon steel coils and other products, which makes it more flexible Choose the desired product type to meet different needs.

3. Stable supply: Having a more stable production line and supply chain can provide more reliable supply. This is especially important for buyers who require large quantities of steel.

4. Brand influence: Have higher brand influence and larger market

5. Service: A large steel company that integrates customization, transportation and production

6. Price competitiveness: reasonable price

*Send the email to chinaroyalsteel@163.com to get a quotation for your projects

CUSTOMERS VISIT

FAQ

1.How can I get a quotation from you ?

You can leave us message, and we will reply every message in time.

2.Will you delivery the goods on time?

Yes,we promise to provide best quality products and delivery on time. Honesty is our company's tenet.

3.Can I get samples before order ?

Yes, of course. Usually our samples are free,we can produce by your samples or technical drawings.

4.What is your payment terms?

Our usual payment term is 30% deposit, and rest against B/L. EXW, FOB,CFR, CIF.

5.Do you accept the third party inspection?

Yes absolutely we accept.

6.How do we trust your company?

We specialise in steel business for years as golden supplier, headquarter locates in Tianjin province, welcome to investigate in any ways, by all means.