Modern Prefab Steel Structure Building Prefabricated Warehouse/Workshop/Aircraft Hangar/Office Construction Material

Steel structure is suitable for high-rise buildings, which can improve the height and stability of the building

Steel structure can manufacture various types of Bridges, such as suspension Bridges, arch Bridges, cable-stayed Bridges, etc., which can achieve large span and high strength.

*Send the email to chinaroyalsteel@163.com to get a quotation for your projects

| Product name: | Steel Building Metal Structure |

| Material : | Q235B ,Q345B |

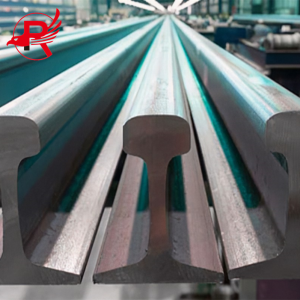

| Main frame : | H-shape steel beam |

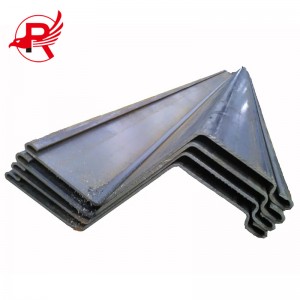

| Purlin : | C,Z - shape steel purlin |

| Roof and wall : | 1.corrugated steel sheet ;

2.rock wool sandwich panels ;

3.EPS sandwich panels ; 4.glass wool sandwich panels |

| Door: | 1.Rolling gate

2.Sliding door

|

| Window: | PVC steel or aluminum alloy |

| Down spout : | Round pvc pipe |

| Application : | All kinds of industrial workshop ,warehouse ,high-rise building |

PRODUCT PRODUCTION PROCESS

ADVANTAGE

Steel structures have the advantages of light weight, high structural reliability, high degree of mechanization of manufacturing and installation, good sealing performance, heat and fire resistance, low carbon, energy saving, green and environmental protection.

Steel structure is a structure composed of steel materials and is one of the main types of building structures. The structure is mainly composed of steel beams, steel columns, steel trusses and other components made of shaped steel and steel plates, and adopts rust removal and anti-rust processes such as silanization, pure manganese phosphating, washing and drying, and galvanizing. Each component or component is usually connected by welds, bolts or rivets. Because of its light weight and easy construction, it is widely used in large factories, venues, super high-rises and other fields. Steel structures are prone to rust. Generally, steel structures need to be derusted, galvanized or painted, and must be maintained regularly.

High strength and light weight. Compared with concrete and wood, the density and yield strength are lower. Therefore, under the same stress conditions, steel structure members have small cross-sections, light weight, easy transportation and installation, and are suitable for large-span, high-height, heavy-load structures. Steel tools have good toughness and plasticity, uniform materials, high structural reliability, are suitable for withstanding impact and dynamic loads, and have good seismic resistance. The internal structure of the steel is uniform and close to isotropic homogeneous body. The workability of the steel structure fully complies with the calculation theory, so it has high safety and reliability.

High strength and light weight. Compared with concrete and wood, the density and yield strength are lower. Therefore, under the same stress conditions, steel structure members have small cross-sections, light weight, easy transportation and installation, and are suitable for large-span, high-height, heavy-load structures. 2. Steel tools have good toughness and plasticity, uniform materials, high structural reliability, are suitable for withstanding impact and dynamic loads, and have good seismic resistance. The internal structure of the steel is uniform and close to isotropic homogeneous body. The workability of the steel structure fully complies with the calculation theory, so it has high safety and reliability.

DEPOSIT

The construction of Building Steel Structure is mainly composed of four parts: foundation embedded parts, steel columns and steel beams, walls and roofs, and steel roofs. The following is the general function of these components:

1. Foundation embedded parts are generally buried underground. Their main purpose is to fix steel beams, which can stabilize the main structure of the steel structure factory.

2. Steel columns and steel beams are the main load-bearing components of the factory building. They mainly bear the longitudinal load of the entire steel structure. Their function is to bear the load of the steel structure factory building from the outside world and the workshop traffic, ensuring that the longitudinal direction of the steel structure factory building frame remains unchanged and withstands the longitudinal pressure. .

3. Walls and roofs. Mainly bear the lateral load outside the factory building. On the one hand, it forms a longitudinal structure with steel columns and steel beams to provide horizontal traction; on the other hand, it connects independent planar structures into an overall spatial structure, providing the necessary longitudinal stiffness, integrity and stability for the factory building. The roof structure of the factory building plays a vital role in the stability of the entire structure.

4. The steel roof mainly bears the longitudinal load from the outside of the factory building. In addition to shielding the factory from wind and rain, its main function is to bear and transmit horizontal loads to ensure the overall spatial effect of the structure.

PRODUCT INSPECTION

The quality inspection of Metal Steel Building projects includes all specified test and inspection contents of raw materials, welding materials, weldments, fasteners, welds, bolt ball joints, coatings and other materials and projects of steel structures. Sampling testing, steel chemical composition analysis, paint and fire retardant coating testing. Shaanxi Best Inspection Technology Co., Ltd. carries out steel structure welding inspection, bolt fastener inspection, metal material inspection, advertising facility inspection, iron tower inspection, pressure vessel inspection, house safety appraisal, coal shed safety inspection, etc. across the country.

PROJECT

Our company often exports Building Steel Design products to the Americas and Southeast Asian countries. We participated in one of the projects in the Americas with a total area of approximately 543,000 square meters and a total use of approximately 20,000 tons of steel. After the project is completed, it will become a steel structure complex integrating production, living, office, education and tourism.

APPLICATION

Industrial buildings and facilities. Steel Building are suitable for manufacturing plants, warehouses, logistics centers, airports, railways, bridges, etc. These buildings need to withstand large loads and impacts, while also requiring efficient and economical construction and operation.

Commercial buildings and public facilities. Including shopping malls, hotels, hospitals, schools, cultural centers and sports venues, etc. Steel structures provide modern appearance, high durability, high safety and efficient operation features in these buildings.

Residential buildings. High-rise residences, villas, apartments, nursing homes, etc. Steel structures provide seismic, fire-resistant and environmentally friendly performance in residential buildings while providing a comfortable living environment.

Municipal engineering and agricultural construction. Such as sewage treatment plants, water plants, agricultural greenhouses, etc. Steel structures provide reliable, durable solutions in these areas.

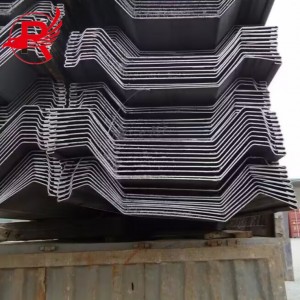

PACKAGING AND SHIPPING

Packaging Steel Beam Building needs to be strong, can not let the steel sheet pile shake back and forth, in order to avoid the appearance of the steel sheet pile is not damaged, the general transport steel sheet pile will take containers, bulk cargo, LCL and so on Factors such as weight, size and shape of steel components need to be taken into consideration when packaging them to reduce the risk of damage during transportation and handling. The following are the principles and methods of steel component packaging:

1. Select appropriate packaging materials: The selection of packaging materials should take into account the nature of the goods and the transportation distance. Commonly used packaging materials include wooden boxes, wooden pallets, cartons, films, etc.

2. Add cushioning materials: If the goods need to withstand vibration and impact during transportation, cushioning materials such as foam plastics and air cushion films can be used to cushion the impact.

3. Reinforcement and strapping: The goods need to be reinforced and strapped when packaging to ensure that they will not move or be damaged during transportation.

4. Clear markings: Use clear identification and markings as well as relevant documentation to indicate the type, quantity, weight, volume and other information of the goods.

COMPANY STRENGTH

Made in China, first-class service, cutting-edge quality, world-renowned

1. Scale effect: Our company has a large supply chain and a large steel factory, achieving scale effects in transportation and procurement, and becoming a steel company that integrates production and services

2. Product diversity: Product diversity, any steel you want can be purchased from us, mainly engaged in steel structures, steel rails, steel sheet piles, photovoltaic brackets, channel steel, silicon steel coils and other products, which makes it more flexible Choose the desired product type to meet different needs.

3. Stable supply: Having a more stable production line and supply chain can provide more reliable supply. This is especially important for buyers who require large quantities of steel.

4. Brand influence: Have higher brand influence and larger market

5. Service: A large steel company that integrates customization, transportation and production

6. Price competitiveness: reasonable price

*Send the email to chinaroyalsteel@163.com to get a quotation for your projects

CUSTOMERS VISIT