Industrial Building Customized Prefabricated Steel Structure Building Warehouse/Workshop

Steel Structures S235jr is currently the most widely used structural system in construction projects, and it is widely used in buildings, bridges, towers and other fields. This article will introduce the relevant knowledge of steel structure engineering in detail from two aspects: its uses and advantages.

The steel structure system has the comprehensive advantages of light weight, factory manufacturing, fast installation, short construction period, good seismic performance, fast investment recovery, and less environmental pollution.

*Send the email to chinaroyalsteel@163.com to get a quotation for your projects

| Product name: | Steel Building Metal Structure |

| Material : | Q235B ,Q345B |

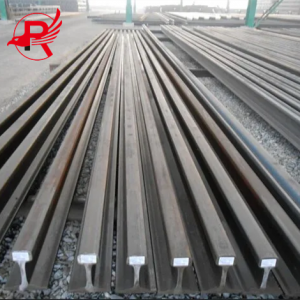

| Main frame : | H-shape steel beam |

| Purlin : | C,Z - shape steel purlin |

| Roof and wall : | 1.corrugated steel sheet ;

2.rock wool sandwich panels ;

3.EPS sandwich panels ; 4.glass wool sandwich panels |

| Door: | 1.Rolling gate

2.Sliding door

|

| Window: | PVC steel or aluminum alloy |

| Down spout : | Round pvc pipe |

| Application : | All kinds of industrial workshop ,warehouse ,high-rise building |

PRODUCT PRODUCTION PROCESS

ADVANTAGE

Steel Structure Metal Building is a structure composed of steel materials, which is one of the main types of building structures. The structure is mainly composed of beams, steel columns, steel trusses and other components made of profiled steel and steel plates. It adopts silanization, pure manganese phosphating, washing and drying, galvanizing and other rust removal and rust prevention processes. Components or parts are usually connected by welding, bolts or rivets. Because of its light weight and easy construction, it is widely used in large-scale factory buildings, stadiums, and super high-rise areas. Steel structures are susceptible to corrosion. Generally, steel structures need to be derusted, galvanized or painted, and regularly maintained.

Steel is characterized by high strength, light weight, good overall rigidity, and strong resistance to deformation. Therefore, it is particularly suitable for the construction of large-span, ultra-high, and super-heavy buildings; the material has good homogeneity and isotropy, which is ideal elasticity Material, which best meets the basic assumptions of general engineering mechanics; the material has good plasticity and toughness, can have large deformation, and can withstand dynamic loads well; the construction period is short; it has a high degree of industrialization, and can be specialized in production with a high degree of mechanization.

For steel structures, high-strength steels should be studied to greatly increase their yield point strength. In addition, new types of steels, such as H-shaped steel (also known as wide-flange steel) and T-shaped steel, as well as profiled steel plates, are rolled to adapt to large-span structures and The need for super high-rise buildings.

In addition, there is a heat-resistant bridge light steel structure system. The building itself is not energy-efficient. This technology uses clever special connectors to solve the problem of cold and hot bridges in the building. The small truss structure allows cables and water pipes to pass through the wall for construction. Decoration is convenient.

DEPOSIT

The main structural part of a Steel Structure Warehouse also includes other components, such as steel plates, bridges, stairs, etc. These components not only bear structural loads, but also play a role in aesthetics, ventilation, drainage and other functions. When designing, you need to select and apply according to actual needs.

In short, the main structural part of a steel structure house includes steel columns, steel beams, steel frames and other components. These components work together to bear the load and external effects of the building, thereby ensuring the safety, stability and aesthetics of the house.

PROJECT

Our company often exports Steel Structures products to the Americas and Southeast Asian countries. We participated in one of the projects in the Americas with a total area of approximately 543,000 square meters and a total use of approximately 20,000 tons of steel. After the project is completed, it will become a steel structure complex integrating production, living, office, education and tourism.

PRODUCT INSPECTION

Steel structure engineering testing includes all specified testing and testing contents for materials and projects such as raw materials, welding materials, weldments, fasteners, welds, bolt ball joints, coatings, etc. for steel structures and special equipment. Main structure engineering testing, sampling testing, steel chemical composition analysis, coating testing, construction engineering materials, waterproof material testing, etc., energy-saving testing and other complete testing technologies.

APPLICATION

In the field of construction, steel structure engineering is widely used in the structural systems of high-rise buildings, long-span buildings, sports venues, exhibition halls and other buildings. The advantages of steel structures such as high strength, lightweight, and fast construction speed make them widely used in the construction field.

PACKAGING AND SHIPPING

Packaging Steel Structures Warehouse needs to be strong, can not let the steel sheet pile shake back and forth, in order to avoid the appearance of the steel sheet pile is not damaged, the general transport steel sheet pile will take containers, bulk cargo, LCL and so on

COMPANY STRENGTH

Made in China, first-class service, cutting-edge quality, world-renowned

1. Scale effect: Our company has a large supply chain and a large steel factory, achieving scale effects in transportation and procurement, and becoming a steel company that integrates production and services

2. Product diversity: Product diversity, any steel you want can be purchased from us, mainly engaged in steel structures, steel rails, steel sheet piles, photovoltaic brackets, channel steel, silicon steel coils and other products, which makes it more flexible Choose the desired product type to meet different needs.

3. Stable supply: Having a more stable production line and supply chain can provide more reliable supply. This is especially important for buyers who require large quantities of steel.

4. Brand influence: Have higher brand influence and larger market

5. Service: A large steel company that integrates customization, transportation and production

6. Price competitiveness: reasonable price

*Send the email to chinaroyalsteel@163.com to get a quotation for your projects

CUSTOMERS VISIT