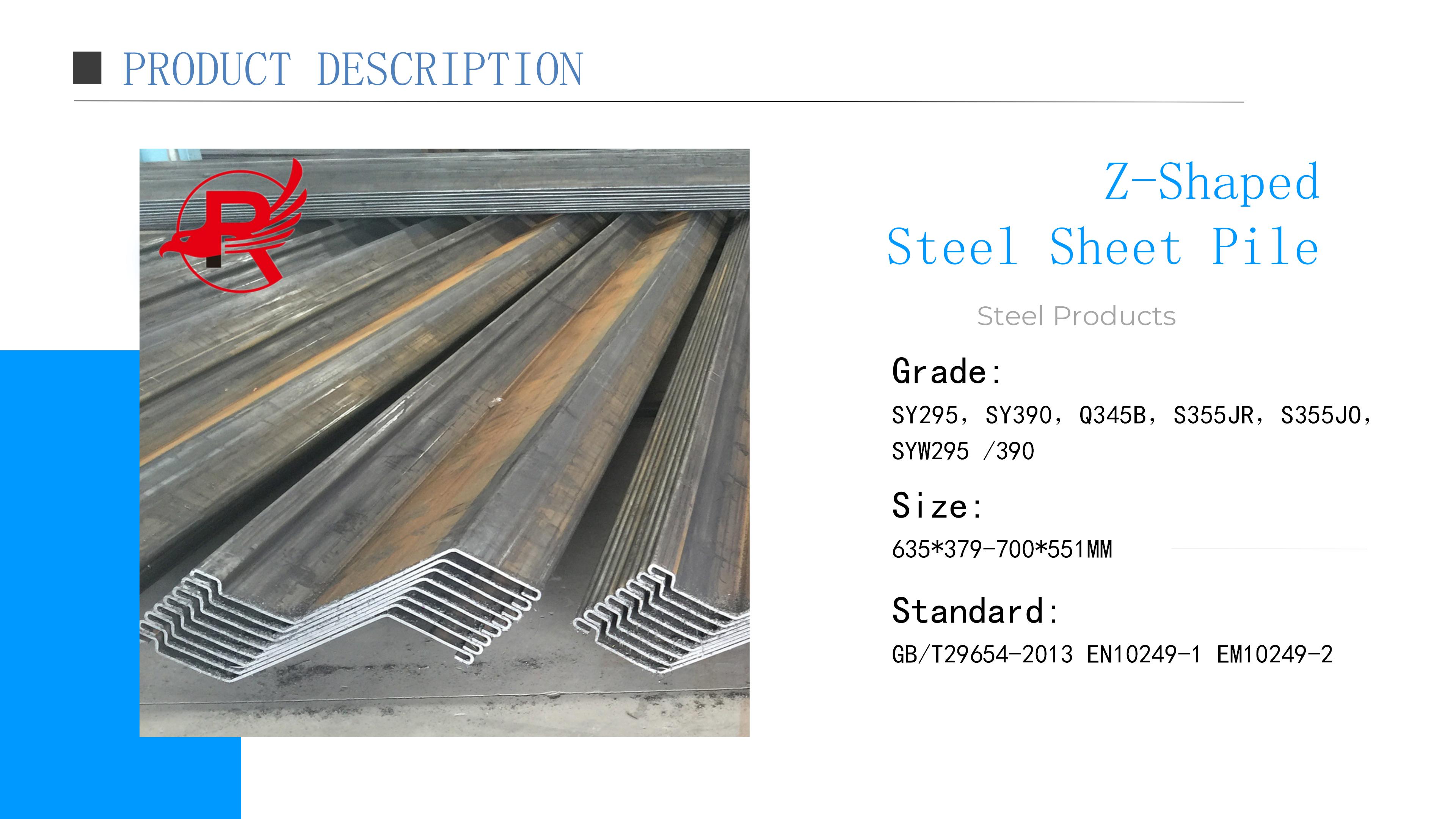

Cold Selling Sheet Pile Z Type SY295 SY390 Steel Sheet Piles

RODUCT PRODUCTION PROCESS

The production process of cold-formed z type steel sheet pile usually includes the following steps:

Material preparation: Select steel plate materials that meet the requirements, usually hot-rolled or cold-rolled steel plates, and select materials according to design requirements and standards.

Cutting: Cut the steel plate according to the design requirements to obtain a steel plate blank that meets the length requirements.

Cold bending: The cut steel plate blank is sent to the cold bending forming machine for forming processing. The steel plate is cold-bent into a Z-shaped cross-section through processes such as rolling and bending.

Welding: Weld the cold-formed Z-shaped steel sheet piles to ensure that their connections are firm and defect-free.

Surface treatment: Surface treatment is performed on the welded Z-shaped steel sheet piles, such as rust removal, painting, etc., to improve its anti-corrosion performance.

Inspection: Conduct quality inspection on the produced cold-formed Z-shaped steel sheet piles, including inspection of appearance quality, dimensional deviation, welding quality, etc.

Packaging and leaving the factory: The qualified cold-formed Z-shaped steel sheet piles are packaged, marked with product information, and shipped out of the factory for storage.

*Send the email to [email protected] to get a quotation for your projects

PRODUCT SIZE

The height (H) of z type sheet pile usually ranges from 200mm to 600mm.

The width (B) of Q235b Z-shaped steel sheet piles usually ranges from 60mm to 210mm.

The thickness (t) of Z-shaped steel sheet piles usually ranges from 6mm to 20mm.

| Section | Width | Height | Thickness | Cross Sectional Area | Weight | Elastic Section Modulus | Moment of Inertia | Coating Area (both sides per pile) | ||

|---|---|---|---|---|---|---|---|---|---|---|

| (w) | (h) | Flange (tf) | Web (tw) | Per Pile | Per Wall | |||||

| mm | mm | mm | mm | cm²/m | kg/m | kg/m² | cm³/m | cm4/m | m²/m | |

| CRZ12-700 | 700 | 440 | 6 | 6 | 89.9 | 49.52 | 70.6 | 1,187 | 26,124 | 2.11 |

| CRZ13-670 | 670 | 303 | 9.5 | 9.5 | 139 | 73.1 | 109.1 | 1,305 | 19,776 | 1.98 |

| CRZ13-770 | 770 | 344 | 8.5 | 8.5 | 120.4 | 72.75 | 94.5 | 1,311 | 22,747 | 2.2 |

| CRZ14-670 | 670 | 304 | 10.5 | 10.5 | 154.9 | 81.49 | 121.6 | 1,391 | 21,148 | 2 |

| CRZ14-650 | 650 | 320 | 8 | 8 | 125.7 | 64.11 | 98.6 | 1,402 | 22,431 | 2.06 |

| CRZ14-770 | 770 | 345 | 10 | 10 | 138.5 | 83.74 | 108.8 | 1,417 | 24,443 | 2.15 |

| CRZ15-750 | 750 | 470 | 7.75 | 7.75 | 112.5 | 66.25 | 88.34 | 1,523 | 35,753 | 2.19 |

| CRZ16-700 | 700 | 470 | 7 | 7 | 110.4 | 60.68 | 86.7 | 1,604 | 37,684 | 2.22 |

| CRZ17-700 | 700 | 420 | 8.5 | 8.5 | 132.1 | 72.57 | 103.7 | 1,729 | 36,439 | 2.19 |

| CRZ18-630 | 630 | 380 | 9.5 | 9.5 | 152.1 | 75.24 | 119.4 | 1,797 | 34,135 | 2.04 |

| CRZ18-700 | 700 | 420 | 9 | 9 | 139.3 | 76.55 | 109.4 | 1,822 | 38,480 | 2.19 |

| CRZ18-630N | 630 | 450 | 8 | 8 | 132.7 | 65.63 | 104.2 | 1,839 | 41,388 | 2.11 |

| CRZ18-800 | 800 | 500 | 8.5 | 8.5 | 127.2 | 79.9 | 99.8 | 1,858 | 46,474 | 2.39 |

| CRZ19-700 | 700 | 421 | 9.5 | 9.5 | 146.3 | 80.37 | 114.8 | 1,870 | 39,419 | 2.18 |

| CRZ20-700 | 700 | 421 | 10 | 10 | 153.6 | 84.41 | 120.6 | 1,946 | 40,954 | 2.17 |

| CRZ20-800 | 800 | 490 | 9.5 | 9.5 | 141.2 | 88.7 | 110.8 | 2,000 | 49,026 | 2.38 |

Section Modulus Range

1100-5000cm3/m

Width Range (single)

580-800mm

Thickness Range

5-16mm

Production Standards

BS EN 10249 Part 1 & 2

Steel Grades

S235JR, S275JR, S355JR, S355JO

ASTM A572 Gr42, Gr50, Gr60

Q235B, Q345B, Q345C, Q390B, Q420B

Others available on request

Length

35.0m maximum but any project specific length can be produced

Delivery Options

Single or Pairs

Pairs either loose, welded or crimped

Lifting Hole

Grip Plate

By container (11.8m or less) or Break Bulk

Corrosion Protection Coatings

|

Product Name

|

|

|

Steel Grade

|

S275,S355,S390,S430,SY295,SY390,Grade50,Grade55,Grade60,A690

|

|

Length

|

Up to over 100m

|

|

Dimensions

|

Any width x height x thickness

|

|

Standard

|

EN10249,EN10248,JIS A 5523 and JIS A 5528,ASTM A328 / ASTM A328M

|

|

Corner sections

|

Cold formed interlock or clutches

|

|

Installation by

|

Excavator hydraulic or diesel vibration hammers

|

|

Suppliers kind

|

U,Z,L,S,Pan,Flat,hat profiles

|

*Send the email to [email protected] to get a quotation for your projects

FEATURES

The main advantages of z sheet pile dimensions include their high strength, durability, and versatility. They can withstand high vertical and lateral loads, making them suitable for various applications. In addition, their interlocking design provides increased stability and resistance against water pressure.

Z type steel sheet piles are typically made from hot-rolled steel, ensuring their strength and integrity. They are available in different sizes, lengths, and thicknesses to suit different project requirements. Additionally, they can be driven into the ground using different methods, such as vibratory hammers or hydraulic presses.

In summary, Z type steel sheet piles are an essential component in many construction projects, providing reliable soil retention and excavation support. Their strength, durability, and versatility make them a popular choice for various applications in civil engineering and construction.

APPLICATION

Applications and Advantages

Both cold-formed Z sheet pile and z sheet piles have a wide range of applications and advantages in the construction industry. AZ sheet piles can be utilized for various tasks, including cofferdams, bridge abutments, temporary or permanent retaining walls, seawalls, and flood barriers. The benefits of steel sheet pile wall include quick installation, versatility, cost-effectiveness, durability, and environmentally-friendly characteristics.

![0$NU_O5TD8Y4}`E3UXEVP]2](http://www.chinaroyalsteel.com/uploads/0NU_O5TD8Y4E3UXEVP2.jpg)

PACKAGING AND SHIPPING

Packaging:

Stack the sheet piles securely: Arrange the Z-shaped sheet piles in a neat and stable stack, ensuring that they are aligned properly to prevent any instability. Use strapping or banding to secure the stack and prevent shifting during transportation.

Use protective packaging materials: Wrap the stack of sheet piles with a moisture-resistant material, such as plastic or waterproof paper, to protect them from exposure to water, humidity, and other environmental elements. This will help prevent rust and corrosion.

Shipping:

Choose a suitable mode of transportation: Depending on the quantity and weight of the sheet piles, select the appropriate mode of transportation, such as flatbed trucks, containers, or ships. Consider factors like distance, time, cost, and any regulatory requirements for transportation.

Use appropriate lifting equipment: To load and unload the U-shaped steel sheet piles, use suitable lifting equipment such as cranes, forklifts, or loaders. Ensure that the equipment used has sufficient capacity to handle the weight of the sheet piles safely.

Secure the load: Properly secure the packaged stack of sheet piles on the transportation vehicle using strapping, bracing, or other suitable means to prevent shifting, sliding, or falling during transit.

COMPANY STRENGTH

Made in China, first-class service, cutting-edge quality, world-renowned

1. Scale effect: Our company has a large supply chain and a large steel factory, achieving scale effects in transportation and procurement, and becoming a steel company that integrates production and services

2. Product diversity: Product diversity, any steel you want can be purchased from us, mainly engaged in steel structures, steel rails, steel sheet piles, photovoltaic brackets, channel steel, silicon steel coils and other products, which makes it more flexible Choose the desired product type to meet different needs.

3. Stable supply: Having a more stable production line and supply chain can provide more reliable supply. This is especially important for buyers who require large quantities of steel.

4. Brand influence: Have higher brand influence and larger market

5. Service: A large steel company that integrates customization, transportation and production

6. Price competitiveness: reasonable price

*Send the email to [email protected] to get a quotation for your projects

CUSTOMER VISIT PROCESS

When a customer wishes to visit a product, the following steps can usually be arranged:

Make an appointment to visit: Customers can contact the manufacturer or sales representative in advance to make an appointment for the time and place to visit the product.

Arrange a guided tour: Arrange professionals or sales representatives as tour guides to show customers the production process, technology and quality control process of the product.

Display products: During the visit, show products at different stages to customers so that customers can understand the production process and quality standards of the products.

Answer questions: During the visit, customers may have various questions, and the tour guide or sales representative should answer them patiently and provide relevant technical and quality information.

Provide samples: If possible, product samples can be provided to customers so that customers can more intuitively understand the quality and characteristics of the product.

Follow-up: After the visit, promptly follow up on customer feedback and needs to provide customers with further support and services.

FAQ

Q1: Are you a trading company or a manufacturer?

A: We are a professional steel manufacturer, and our company is also a very professional steel trading company. We can also provide various steel products.

Q2: Can you send samples?

A: Of course, we can provide customers with free samples and express delivery services to all over the world.

Q3: Can OEM/ODM service be provided?

Answer: Yes. Please feel free to contact us for more details.

Q4: What certifications do your products have?

A: We have ISO 9001, MTC, third-party inspection such as SGS, COC, BV, BIS, ABSect.

Q5: Can I visit your factory?

A: Of course, we welcome customers from all over the world to visit our factory, and you can also watch the factory live broadcast.

Q6: How to ensure quality?

A: The factory test certificate is provided with the shipment. Can be inspected by a third party if needed

Q7: How many countries have you exported to?

A: We have exported to more than 150 countries and regions. We have rich export experience and we are familiar with different market needs and can help customers avoid a lot of trouble.

Q8: Why choose our company?

A: We have been specialized in this industry for more than 10 years and welcome you to investigate in any way and by all means.