Hot Selling Sheet Pile Hot Rolled Type 2 SY295 SY390 Steel Sheet Pile

Hot Rolled Sheet Piles are an essential component in various construction projects, providing reliable and cost-effective solutions for stabilizing soil and preventing erosion. Among different types of sheet steel piles, the U-type sheet pile stands out for its versatility, strength, and ease of installation.

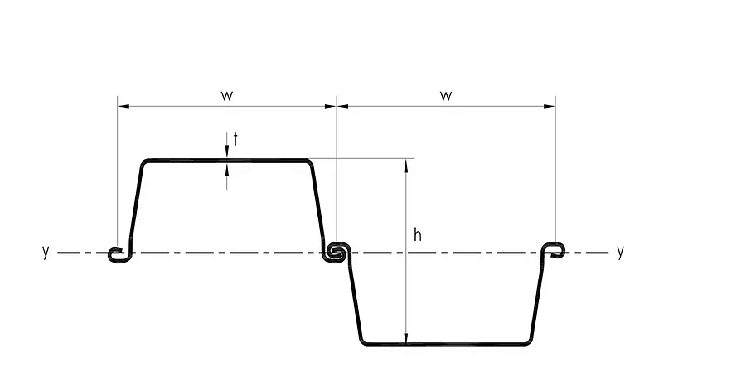

PRODUCT SIZE

|

Product name

|

|||||

|

U Type, Z Type

|

|||||

|

Technique

|

Hot Rolled, Cold Rolled

|

||||

|

Further Processing

|

Cutting, Punching

|

||||

|

Steel Grade

|

S275, S355, S390, S430, Sy295, Sy390

|

||||

|

Length

|

6m~24m

|

||||

|

Surface Treatment

|

Bared Steel, Galvanized, Color Painting

|

||||

|

Payment Term

|

T/T, L/C at Sight

|

||||

|

Supplier

|

Factory

|

||||

|

Usages

|

River Bank, Harbour Pier, Bridge Pier etc

|

||||

|

Specification

|

PU400, PU500, PU600.etc

|

||||

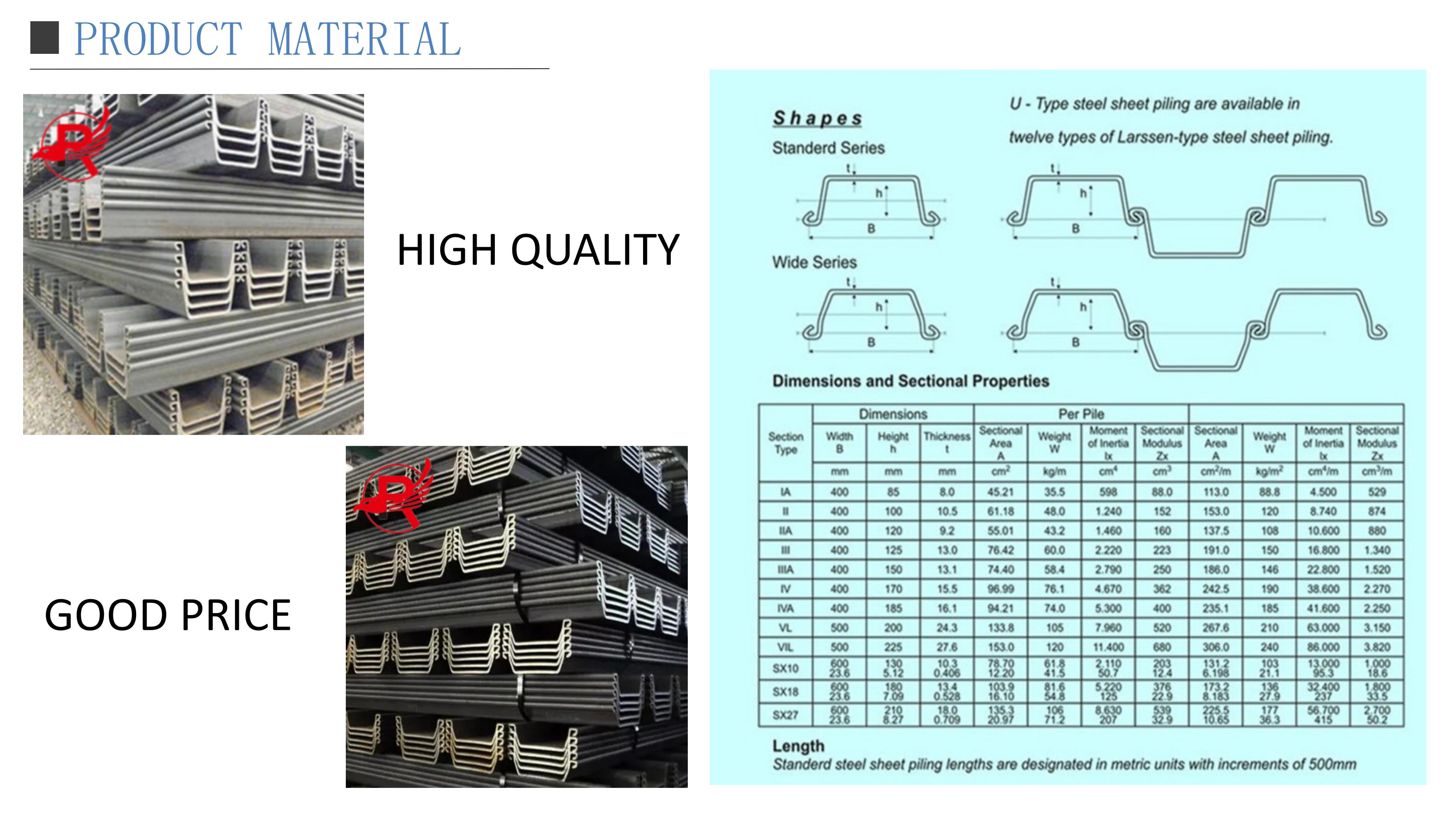

| Section | Width | Height | Thickness | Cross Sectional Area | Weight | Elastic Section Modulus | Moment of Inertia | Coating Area (both sides per pile) | ||

|---|---|---|---|---|---|---|---|---|---|---|

| (w) | (h) | Flange (tf) | Web (tw) | Per Pile | Per Wall | |||||

| mm | mm | mm | mm | cm2/m | kg/m | kg/m2 | cm3/m | cm4/m | m2/m | |

| Type II | 400 | 200 | 10.5 | - | 152.9 | 48 | 120 | 874 | 8,740 | 1.33 |

| Type III | 400 | 250 | 13 | - | 191.1 | 60 | 150 | 1,340 | 16,800 | 1.44 |

| Type IIIA | 400 | 300 | 13.1 | - | 186 | 58.4 | 146 | 1,520 | 22,800 | 1.44 |

| Type IV | 400 | 340 | 15.5 | - | 242 | 76.1 | 190 | 2,270 | 38,600 | 1.61 |

| Type VL | 500 | 400 | 24.3 | - | 267.5 | 105 | 210 | 3,150 | 63,000 | 1.75 |

| Type IIw | 600 | 260 | 10.3 | - | 131.2 | 61.8 | 103 | 1,000 | 13,000 | 1.77 |

| Type IIIw | 600 | 360 | 13.4 | - | 173.2 | 81.6 | 136 | 1,800 | 32,400 | 1.9 |

| Type IVw | 600 | 420 | 18 | - | 225.5 | 106 | 177 | 2,700 | 56,700 | 1.99 |

| Type VIL | 500 | 450 | 27.6 | - | 305.7 | 120 | 240 | 3,820 | 86,000 | 1.82 |

*Send the email to chinaroyalsteel@163.com to get a quotation for your projects

Section Modulus Range

1100-5000cm3/m

Width Range (single)

580-800mm

Thickness Range

5-16mm

Production Standards

BS EN 10249 Part 1 & 2

Steel Grades

SY295, SY390 & S355GP for Type II to Type VIL

S240GP, S275GP, S355GP & S390 for VL506A to VL606K

Length

27.0m maximum

Standard Stock Lengths of 6m, 9m, 12m, 15m

Delivery Options

Single or Pairs

Pairs either loose, welded or crimped

Lifting Hole

By container (11.8m or less) or Break Bulk

Corrosion Protection Coatings

FEATURES

Benefits and Applications of U-Type Sheet Steel Piles

1. Exceptional Strength: U-type sheet steel piles are engineered to withstand substantial vertical and horizontal loads, making them ideal for heavy-duty applications in civil engineering projects such as retaining walls, cofferdams, and deep foundation systems. The design of the U-shaped profile efficiently distributes the forces, maximizing its load-bearing capacity.

2. Versatility: One of the key advantages of U-type sheet steel piles is their adaptability to different soil and site conditions. The U-shaped profile offers improved driving characteristics, allowing easy installation even in challenging terrains. Furthermore, these piles are reusable, making them an environmentally-friendly and cost-effective solution for temporary structures.

3. Water Resistance: Q355 Steel Sheet Pile are widely used in waterfront developments due to their excellent water resistance properties. The tight interlock connections between piles provide a watertight seal, preventing seepage and soil erosion, and ensuring the stability and safety of structures even in areas prone to flooding and wave actions.

4. Enhanced Durability: sheet pile u type are hot-rolled sheets that exhibit exceptional resistance against corrosion, abrasion, and impact. With a higher yield strength compared to traditional steel sheet piles, Q355 U-type sheet piles offer enhanced durability, longevity, and lower maintenance costs. This makes them an ideal choice for harsh marine environments or long-term applications.

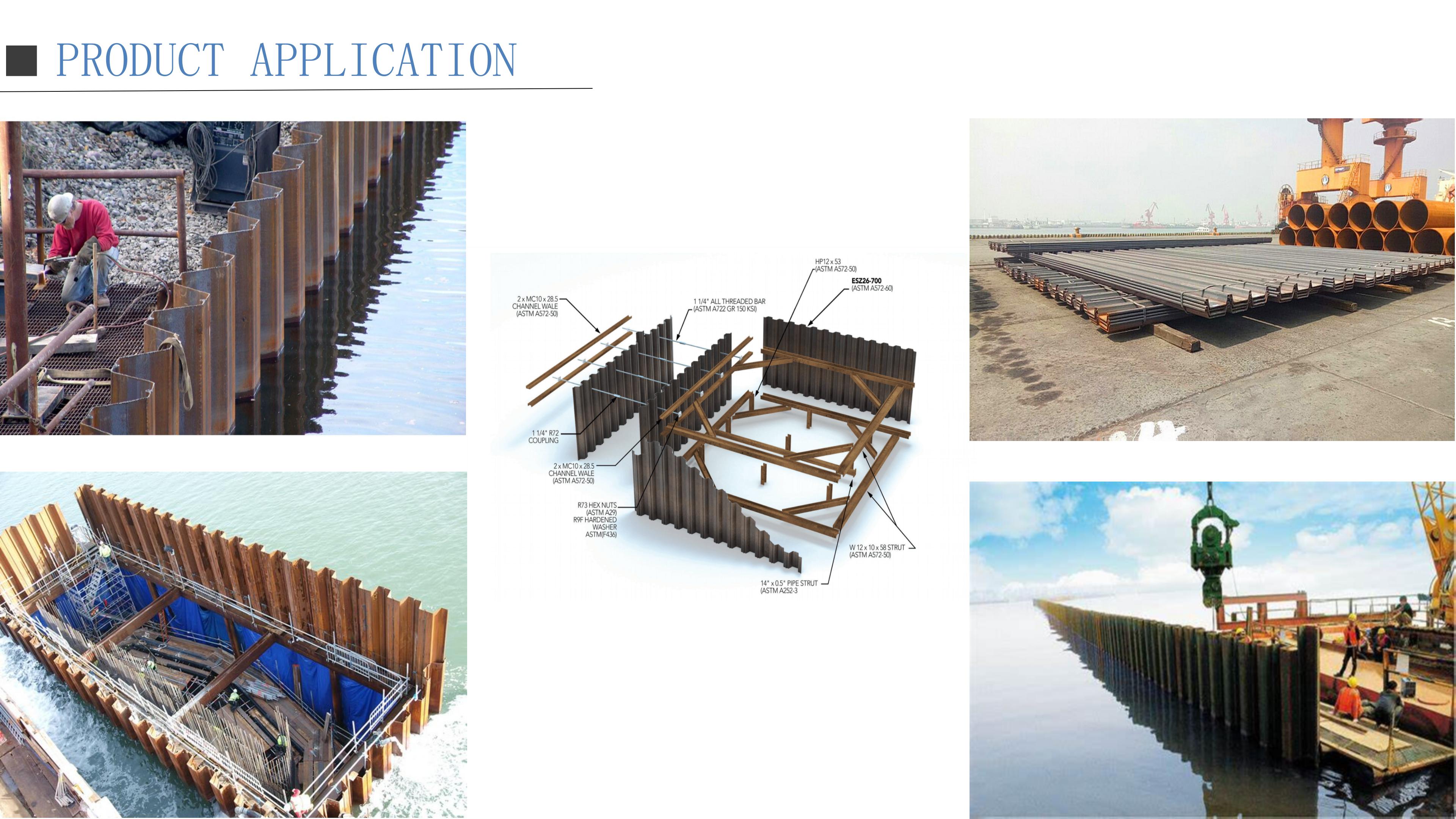

APPLICATION

1. Retaining Walls and Flood Protection

sheet pile wall are widely used for creating retaining walls, especially in areas with uneven terrain. As they are driven vertically into the ground, sheet piles provide excellent support to prevent soil erosion and maintain slope stability. Additionally, they are ideal for flood protection, as their interlocking design effectively hinders water penetration and reduces the risk of flooding, safeguarding infrastructure and human lives.

2. Deep Excavation and Basement Construction

During deep excavation and basement construction, sheet steel pile serve as a temporary or permanent solution. Their high-strength steel material and interlocking profiles enable them to withstand immense pressure from surrounding soil and water. These sheet piles act as a protective barrier, ensuring the safety and stability of excavation sites while minimizing the risk of unexpected collapses.

3. Cofferdams and Trench Shoring

Another essential application of hot rolled sheet piles is in the creation of cofferdams and trench shoring systems. When working on waterfront projects or pipelines, constructing a dry working area is crucial. Sheet piles are meticulously installed to form a watertight enclosure, also known as a cofferdam, allowing contractors to create a safe zone free from water intrusion during construction or repair. Furthermore, sheet piles prove invaluable in trench shoring applications, providing a shield against soil collapse during the installation of underground utilities.

4. Bridge Abutments and Marine Structures

Hot rolled sheet piles find extensive usage in the construction of bridge abutments and marine structures. They give vital support to bridge abutments, preventing soil movement and erosion that could compromise the structural integrity of bridges. Similarly, in coastal areas, sheet piles are employed for marine structures, such as quay walls and breakwaters, due to their exceptional resistance to water and strong impact resistance.

5. Noise and Vibrations Control

In densely populated urban areas, noise and vibrations caused by construction activities can disrupt the peace and tranquility of the surroundings. Hot rolled sheet piles act as effective noise barriers and vibration absorbers, reducing the nuisance caused to nearby residents during the construction process. Their use in noise and vibration control demonstrates their adaptability in projects with stringent environmental and community regulations.

6. Environmental Remediation

Remediating contaminated sites involves intricate engineering techniques, and hot rolled sheet piles offer an instrumental solution. By creating impermeable barriers, sheet piles prevent the spread of pollutants, ensuring the safe and effective isolation of contaminated soil or groundwater. Additionally, sheet piles facilitate groundwater extraction by providing a physical barrier between the contaminated and unpolluted areas.

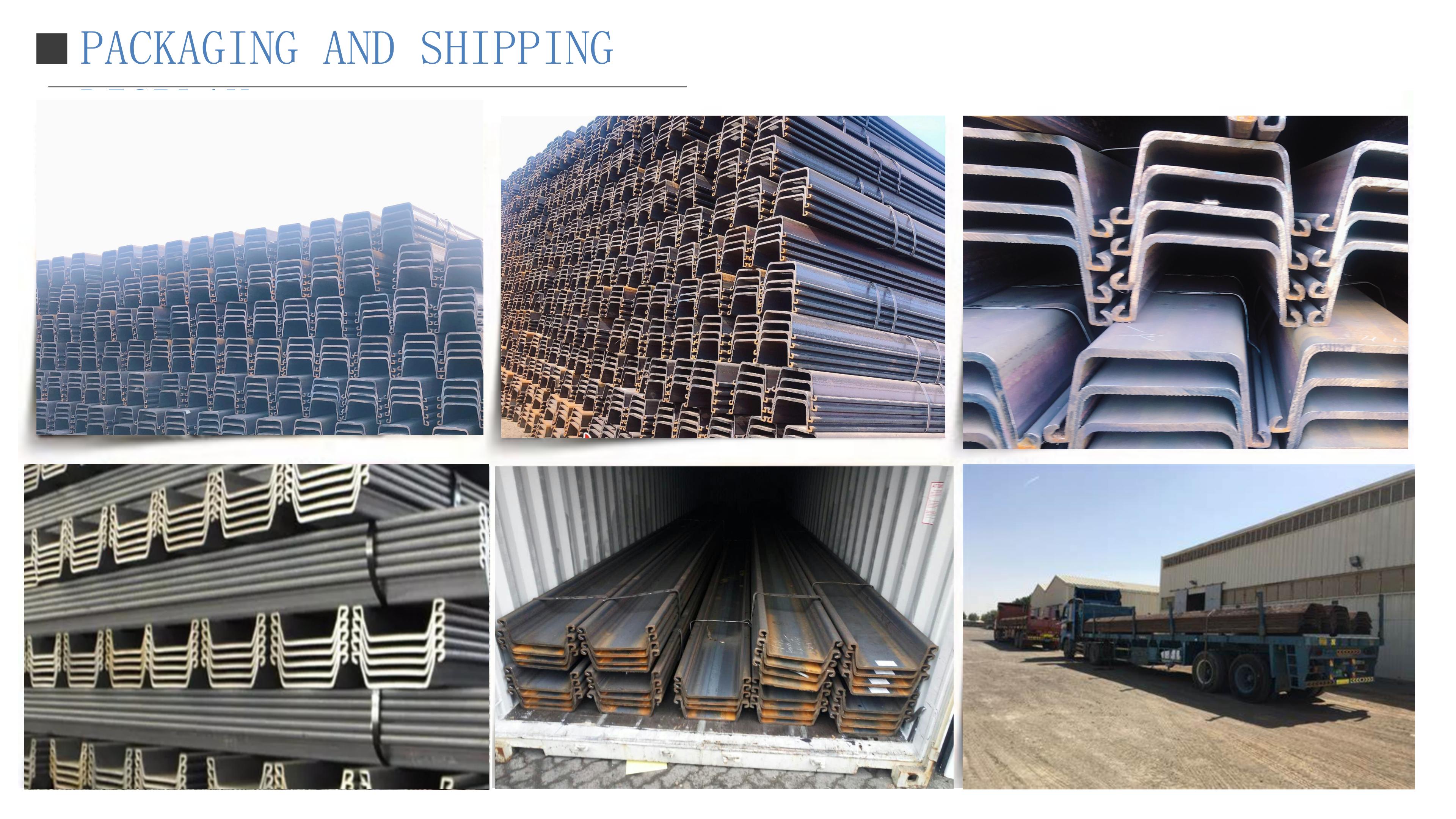

PACKAGING AND SHIPPING

The packaging and shipping method for hot rolled U type steel sheet piles will typically depend on the quantity and destination of the product. Here is a general outline of the process:

Packaging: The steel sheet piles are usually bundled together and secured with steel straps or wire ropes to prevent movement and damage during transportation. Depending on the length and weight of the piles, they may be packaged in various sizes and quantities to ensure safe handling.

Loading: The packaged sheet piles are loaded onto trucks or containers using cranes or forklifts. It is important to distribute the weight evenly and secure the bundles to prevent shifting or tilting during transportation.

Transportation: The steel sheet piles can be transported by truck, rail, or sea, depending on the destination. Trucks are commonly used for shorter distances, while rail and sea transportation are preferred for longer hauls. The appropriate transportation method will also depend on the size and weight of the shipments.

Shipping Documentation: Proper shipping documentation, including packing lists, invoices, bills of lading, and any required customs clearance documents, need to be prepared accurately to comply with international trade regulations.

Handling and Unloading: Upon arrival at the destination, the sheet piles should be handled carefully to prevent damage. Depending on the transportation method, unloading can be done with cranes or forklifts. It's important to follow proper unloading procedures to ensure worker safety and protect the integrity of the product.

It is worth noting that specific packaging and shipping requirements may vary based on the supplier, customer preferences, and local regulations. It's always recommended to consult with the supplier or shipping experts for detailed instructions based on your specific requirements.

COMPANY STRENGTH

Made in China, first-class service, cutting-edge quality, world-renowned

1. Scale effect: Our company has a large supply chain and a large steel factory, achieving scale effects in transportation and procurement, and becoming a steel company that integrates production and services

2. Product diversity: Product diversity, any steel you want can be purchased from us, mainly engaged in steel structures, steel rails, steel sheet piles, photovoltaic brackets, channel steel, silicon steel coils and other products, which makes it more flexible Choose the desired product type to meet different needs.

3. Stable supply: Having a more stable production line and supply chain can provide more reliable supply. This is especially important for buyers who require large quantities of steel.

4. Brand influence: Have higher brand influence and larger market

5. Service: A large steel company that integrates customization, transportation and production

6. Price competitiveness: reasonable price

*Send the email to chinaroyalsteel@163.com to get a quotation for your projects

CUSTOMERS VISIT

When a customer wishes to visit a product, the following steps can usually be arranged:

Make an appointment to visit: Customers can contact the manufacturer or sales representative in advance to make an appointment for the time and place to visit the product.

Arrange a guided tour: Arrange professionals or sales representatives as tour guides to show customers the production process, technology and quality control process of the product.

Display products: During the visit, show products at different stages to customers so that customers can understand the production process and quality standards of the products.

Answer questions: During the visit, customers may have various questions, and the tour guide or sales representative should answer them patiently and provide relevant technical and quality information.

Provide samples: If possible, product samples can be provided to customers so that customers can more intuitively understand the quality and characteristics of the product.

Follow-up: After the visit, promptly follow up on customer feedback and needs to provide customers with further support and services.

FAQ

1. How can I get a quotation from you ?

You can leave us message, and we will reply every message in time. And you can also find our contact information on contact page .

2. Can I get samples before order ?

Yes, of course. Usually our samples are free . we can produce by your samples or technical drawings . We can build the molds and fixtures

3. What is your delivery time ?

A. The time of delivery is usually around 15 working days.

B. We can send out in 3 days , if it has stock .

4. What is your payment terms ?

Our usual payment term is 30% deposit, 70% before shipment.

We can also accept other payment methods.

5. How do you make our business long-term and good relationship ?

A. We keep good quality and competitive price to ensure our customers benefit ;

B. We respect every customer as our friend and we sincerely do business and make friends with them no matter where they come from.