Hot Sales U Type-Draw/Steel Sheet Pile /Type3/Type4/Type2 /Hot Rolled/Carbon/Steel Sheet Pile

PRODUCT SIZE

|

Product Name

|

|

|

Steel Grade

|

S275,S355,S390,S430,SY295,SY390,ASTM A690

|

|

Production standard

|

EN10248,EN10249,JIS5528,JIS5523,ASTM

|

|

Delivery time

|

One week,80000 tons in stock

|

|

Certificates

|

ISO9001,ISO14001,ISO18001,CE FPC

|

|

Dimensions

|

Any dimensions,any width x height x thickness

|

|

Interlock types

|

Larssen locks,cold rolled interlock,hot rolled interlock

|

|

Length

|

Single length up to over 80m

|

|

Processing Type

|

Cutting, bending,stamping,welding,cnc machining

|

|

Cutting Type

|

Laser cutting;water-jet cutting;flame cutting

|

|

Protection

|

1. Inter paper available2. PVC protecting film available

|

|

Application

|

Costruction Industry/Kichten Products/Fabrication Industry/Home Decoration

|

|

Export packing

|

Waterproof paper, and steel strip packed.

Standard Export Seaworthy Package.Suit for all kinds of transport,or as required |

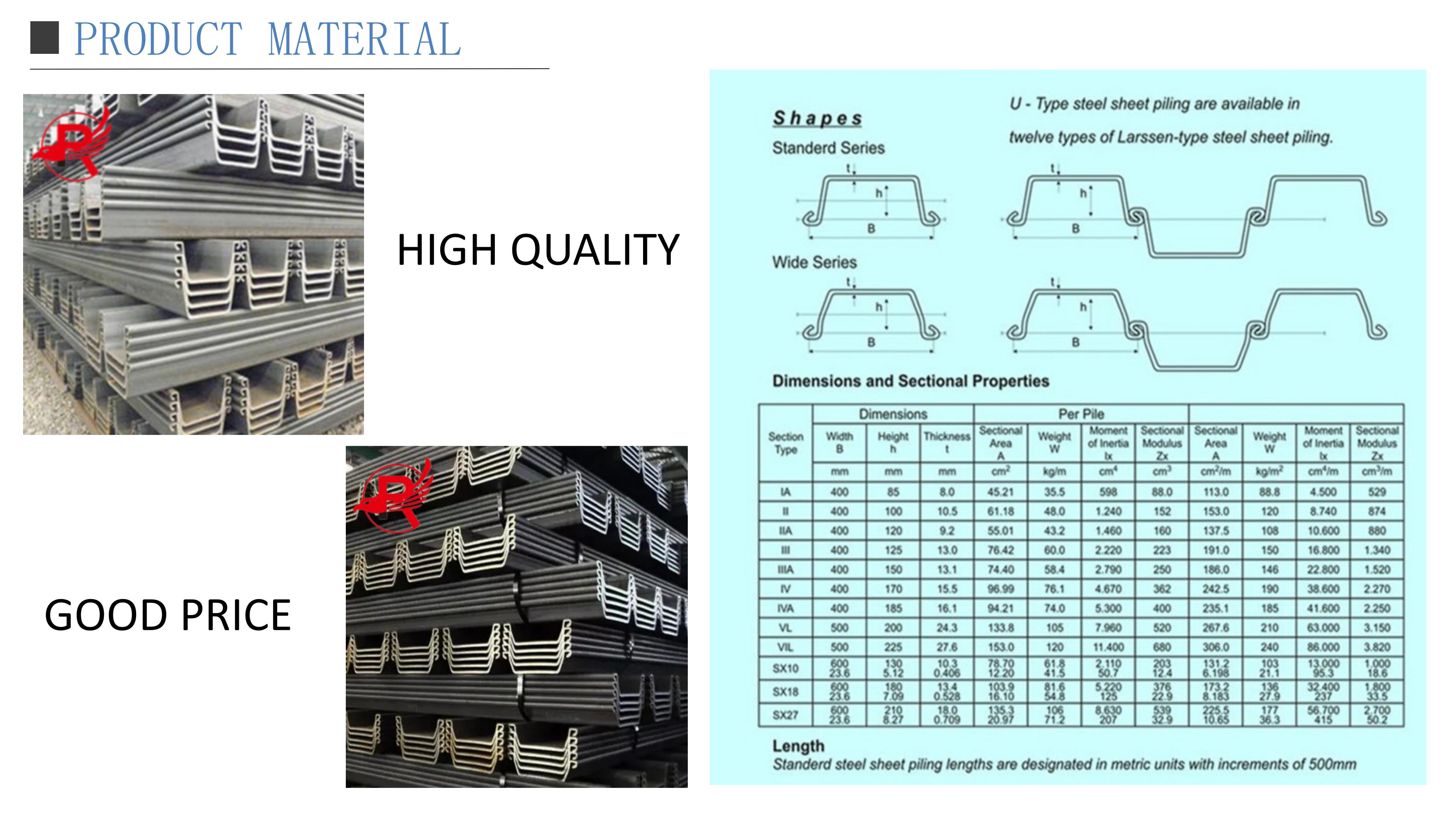

U type steel sheet piles

|

Size

|

Per piece

|

||||

|

Specification

|

Width

(mm) |

High

(mm) |

Thick

(mm) |

Section area

(cm2) |

Weight

(kg/m) |

|

400 x 85

|

400

|

85

|

8.0

|

45.21

|

35.5

|

|

400 x 100

|

400

|

100

|

10.5

|

61.18

|

48.0

|

|

400 x 125

|

400

|

125

|

13.0

|

76.42

|

60.0

|

|

400 x 150

|

400

|

150

|

13.1

|

74.40

|

58.4

|

|

400 x 170

|

400

|

170

|

15.5

|

96.99

|

76.1

|

|

600 x 130

|

600

|

130

|

10.3

|

78.7

|

61.8

|

|

600 x 180

|

600

|

180

|

13.4

|

103.9

|

81.6

|

|

600 x 210

|

600

|

210

|

18.0

|

135.3

|

106.2

|

|

750 x 205

|

750

|

204

|

10.0

|

99.2

|

77.9

|

|

750

|

205.5

|

11.5

|

109.9

|

86.3

|

|

|

750

|

206

|

12.0

|

113.4

|

89.0

|

|

| Section | Width | Height | Thickness | Cross Sectional Area | Weight | Elastic Section Modulus | Moment of Inertia | Coating Area (both sides per pile) | ||

|---|---|---|---|---|---|---|---|---|---|---|

| (w) | (h) | Flange (tf) | Web (tw) | Per Pile | Per Wall | |||||

| mm | mm | mm | mm | cm2/m | kg/m | kg/m2 | cm3/m | cm4/m | m2/m | |

| Type II | 400 | 200 | 10.5 | - | 152.9 | 48 | 120 | 874 | 8,740 | 1.33 |

| Type III | 400 | 250 | 13 | - | 191.1 | 60 | 150 | 1,340 | 16,800 | 1.44 |

| Type IIIA | 400 | 300 | 13.1 | - | 186 | 58.4 | 146 | 1,520 | 22,800 | 1.44 |

| Type IV | 400 | 340 | 15.5 | - | 242 | 76.1 | 190 | 2,270 | 38,600 | 1.61 |

| Type VL | 500 | 400 | 24.3 | - | 267.5 | 105 | 210 | 3,150 | 63,000 | 1.75 |

| Type IIw | 600 | 260 | 10.3 | - | 131.2 | 61.8 | 103 | 1,000 | 13,000 | 1.77 |

| Type IIIw | 600 | 360 | 13.4 | - | 173.2 | 81.6 | 136 | 1,800 | 32,400 | 1.9 |

| Type IVw | 600 | 420 | 18 | - | 225.5 | 106 | 177 | 2,700 | 56,700 | 1.99 |

| Type VIL | 500 | 450 | 27.6 | - | 305.7 | 120 | 240 | 3,820 | 86,000 | 1.82 |

*Send the email to chinaroyalsteel@163.com to get a quotation for your projects

Section Modulus Range

1100-5000cm3/m

Width Range (single)

580-800mm

Thickness Range

5-16mm

Production Standards

BS EN 10249 Part 1 & 2

Steel Grades

SY295, SY390 & S355GP for Type II to Type VIL

S240GP, S275GP, S355GP & S390 for VL506A to VL606K

Length

27.0m maximum

Standard Stock Lengths of 6m, 9m, 12m, 15m

Delivery Options

Single or Pairs

Pairs either loose, welded or crimped

Lifting Hole

By container (11.8m or less) or Break Bulk

Corrosion Protection Coatings

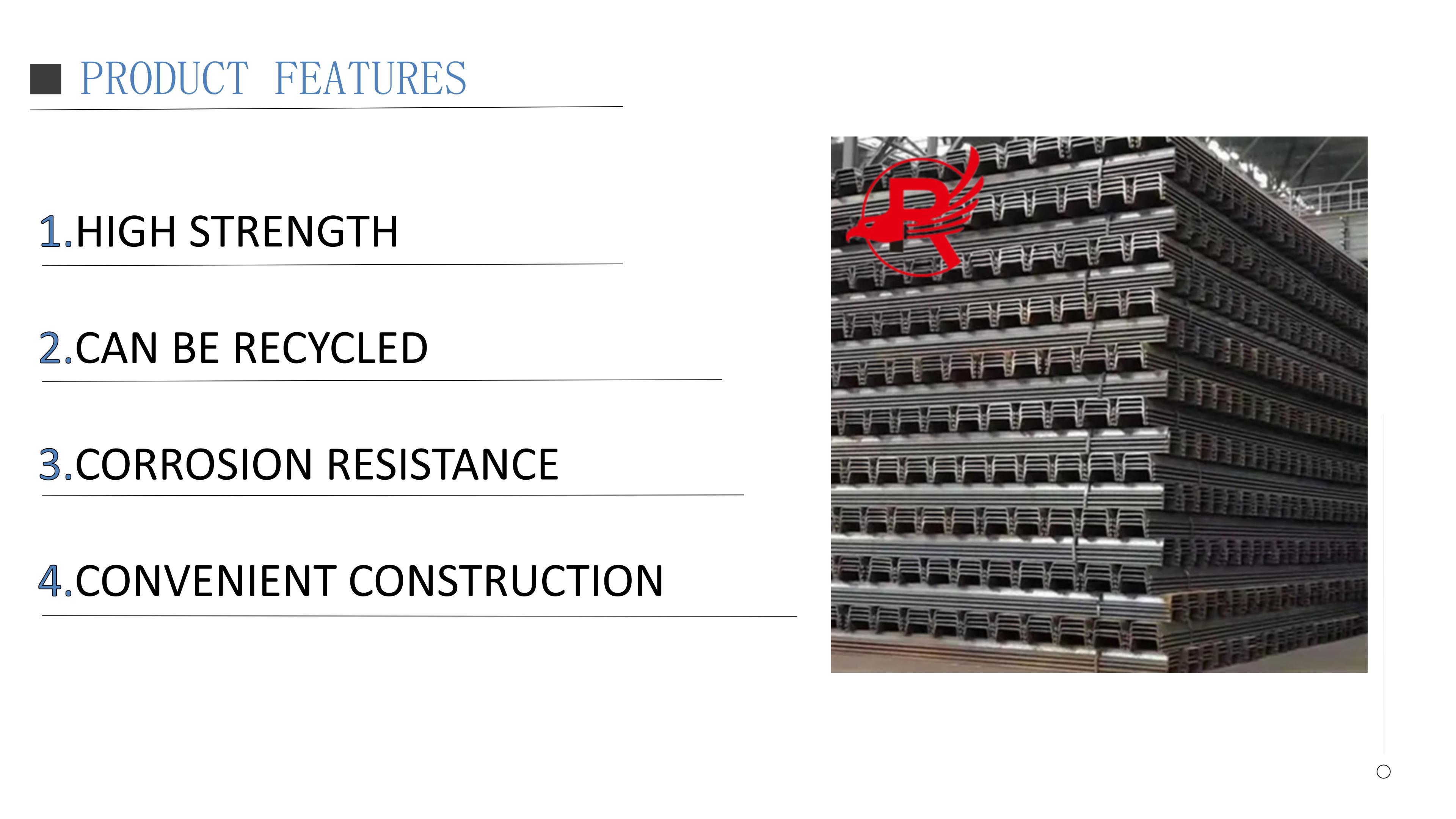

FEATURES

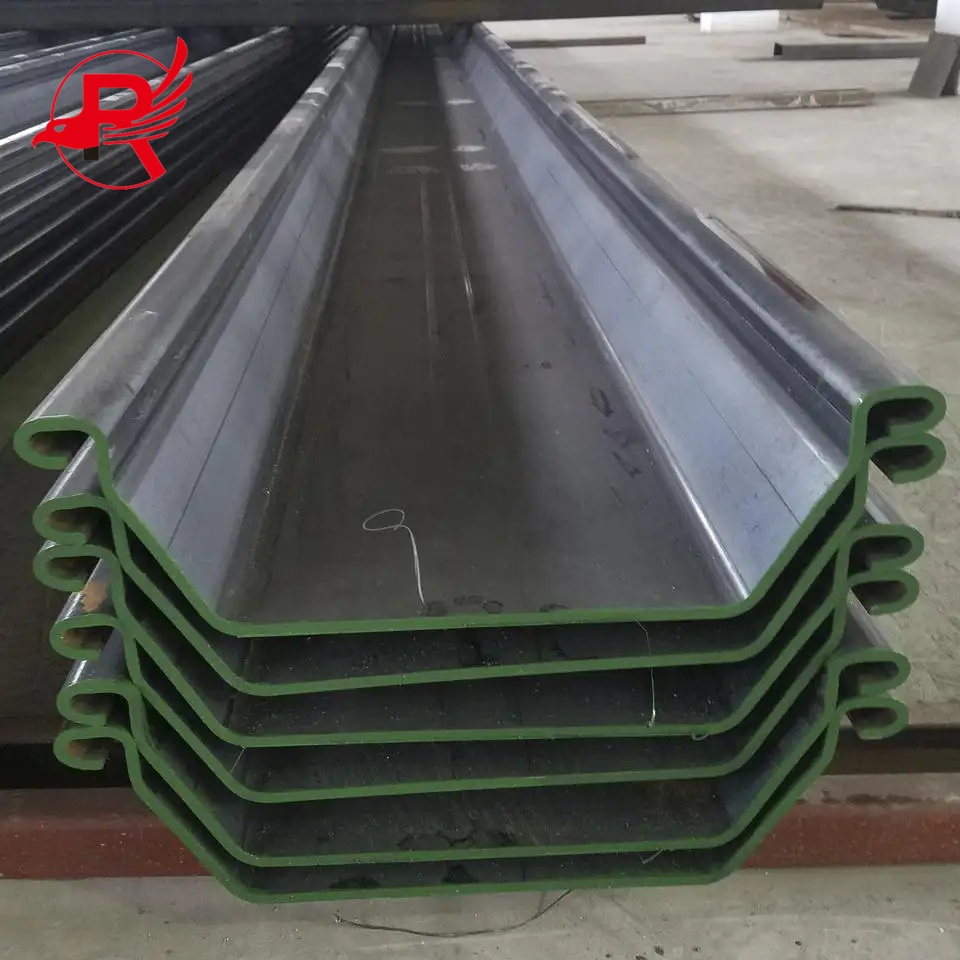

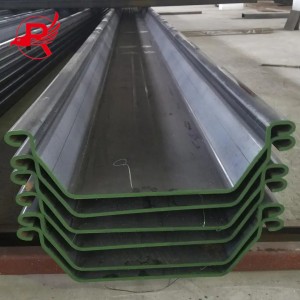

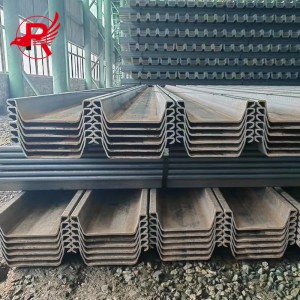

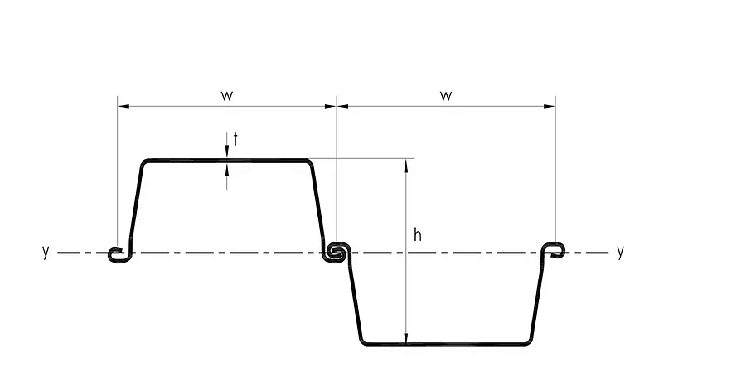

Shape: metal sheet pile have a symmetric U shape with a flange and an interlock on the neutral axis. This design provides strength and stability to the sheet pile wall.

Interlocking Mechanism: sheet pile u type are designed to interlock with adjacent piles to form a continuous wall. The interlocks ensure tight connections between the sheet piles, enhancing the wall's integrity and load-bearing capacity.

Versatility: U type sheet piles are versatile and can be used in both temporary and permanent applications. They are suitable for various soil conditions and can be installed in a variety of configurations, such as straight or curved walls.

Watertightness: foundation piles are often used in waterfront structures where watertightness is crucial. The interlocks are designed to resist water ingress, making U type sheet pile walls effective in marine and coastal applications.

Efficient Installation: 500 x 200 u sheet pile can be installed using different methods, including driving, vibrating, and pressing. This flexibility in installation methods allows for efficient and cost-effective construction.

Strength and Durability: U type sheet piles are typically made from high-strength steel, providing excellent durability and resistance to corrosion, which is essential for long-term performance in various environmental conditions.

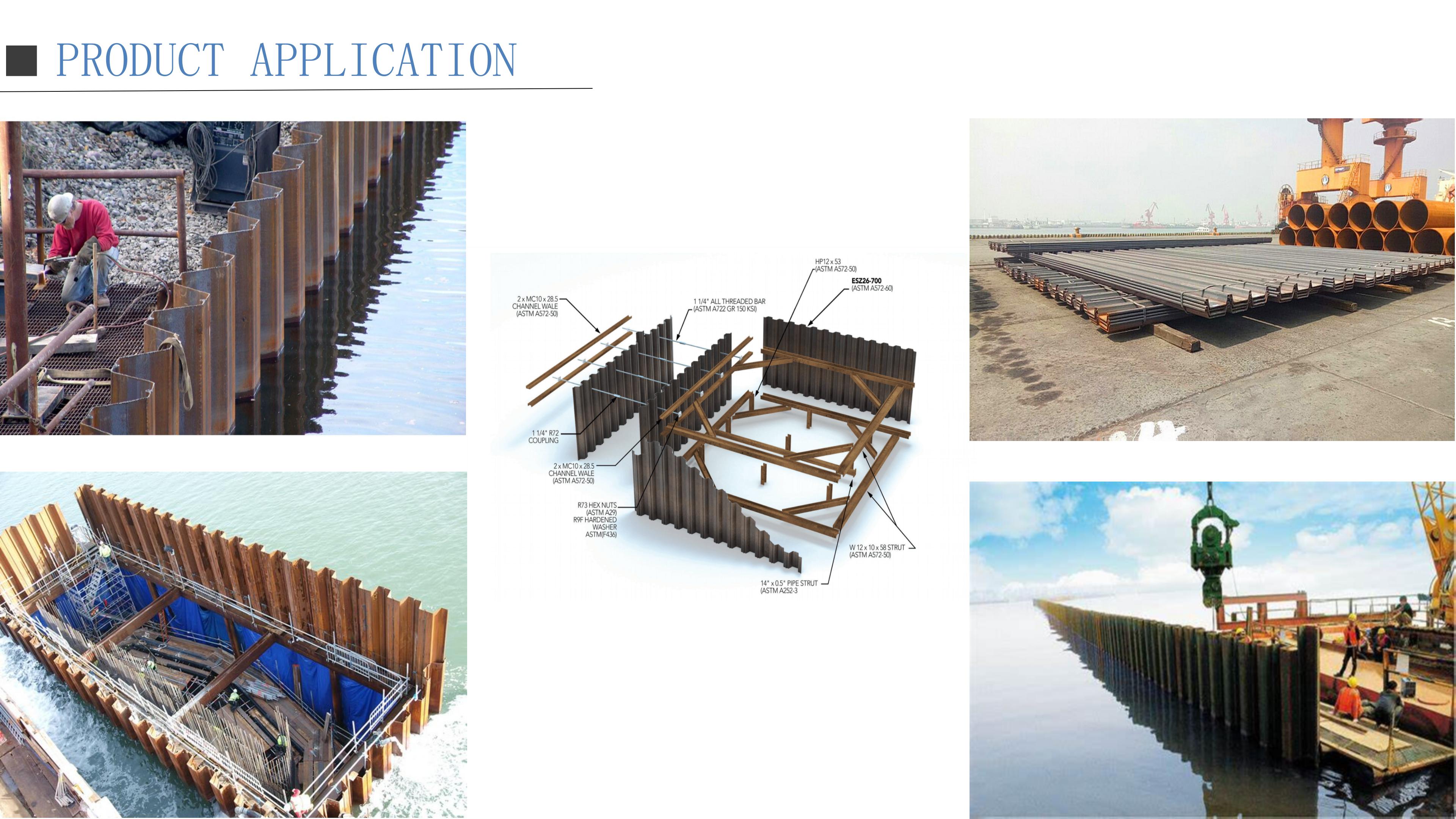

APPLICATION

Steel sheet pile walls have a wide range of applications in civil engineering and construction. Some of the common applications include:

Retaining Walls: Steel sheet pile walls are often used as retaining structures to provide support and containment for earth embankments, excavations, and cut slopes. They are commonly used in waterfront areas, highways, railways, and building foundations.

Flood Protection: Steel sheet pile walls are utilized in flood control and protection systems to create barriers that prevent water from inundating certain areas. They are commonly deployed in areas prone to flooding, such as riverbanks, coastal regions, and levees.

Marine Structures: Steel sheet pile walls are used in the construction of marine structures such as quay walls, bulkheads, and seawalls. These structures provide support for waterfront facilities, docks, ports, and other marine infrastructure.

Cofferdams: Steel sheet pile walls are used to create temporary enclosures, known as cofferdams, to facilitate construction in areas that need to be dewatered temporarily. They are frequently employed for assembling bridge piers and other submerged structures.

Underground Structures: Steel sheet pile walls are used to create underground enclosures for structures such as basements, underground parking garages, and utility vaults.

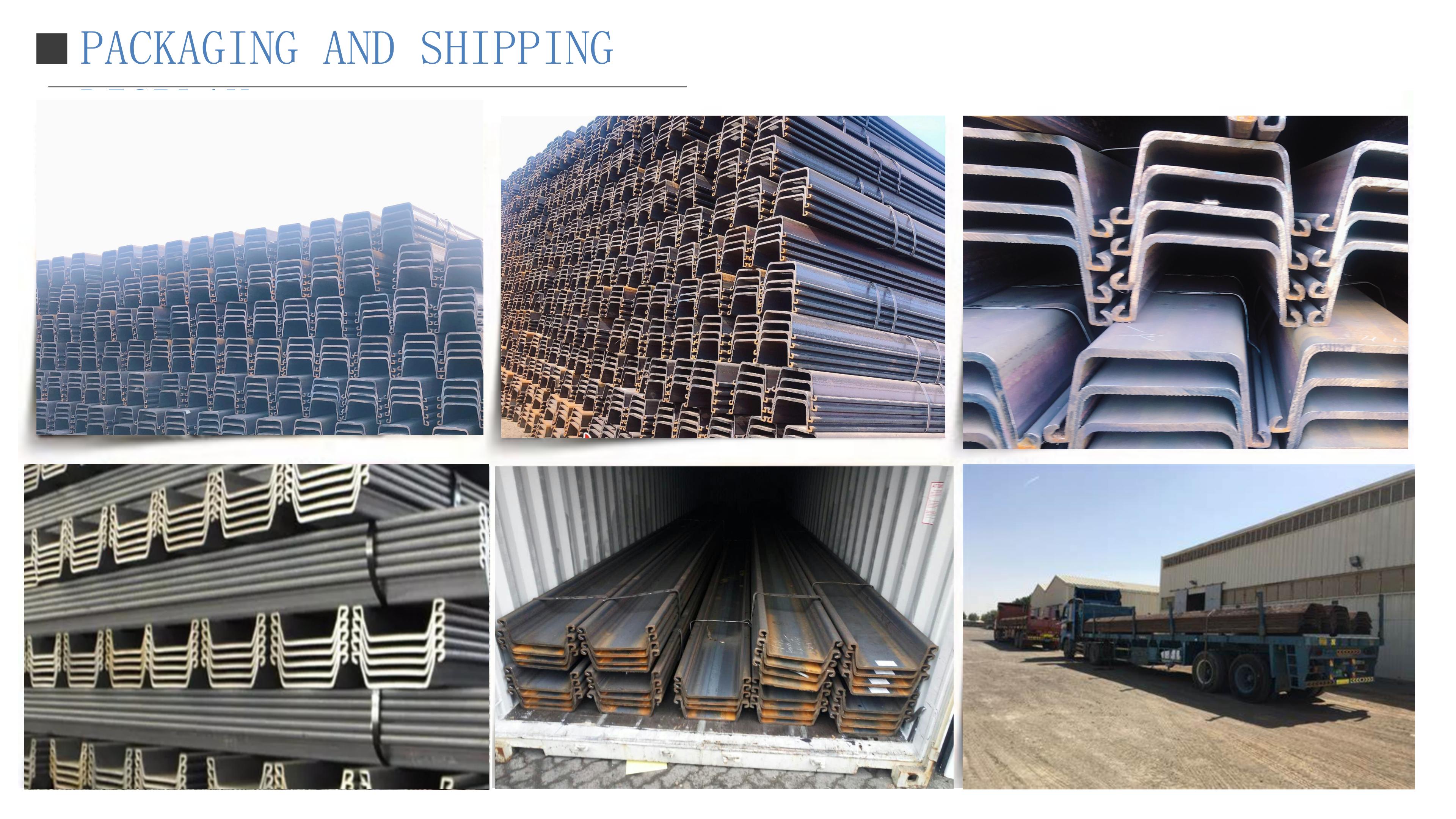

PACKAGING AND SHIPPING

Packaging and shipping for U type sheet pile walls typically involves the following considerations:

Material Handling: U type sheet piles are usually made of steel and require careful handling to prevent damage during transportation. Proper lifting equipment and handling procedures should be used to ensure the safety and integrity of the materials.

Bundling and Securing: Depending on the length and quantity of SY295 400×100 STEEL SHEET PILE, they are often bundled and secured using steel bands or straps to prevent shifting and damage during transit. Proper bundling ensures that the sheet piles arrive at the destination in the same condition as when they were packaged.

Protection: It is essential to protect U type sheet piles from corrosion during shipping. This may involve applying a protective coating, such as paint or galvanizing, to the sheet piles before packaging. Additionally, using suitable covers or wrapping to shield the sheet piles from environmental elements, such as moisture and dirt, is crucial.

Labelling: Clear and accurate labelling of the packaging is important to identify the type, size, quantity, and handling instructions for the U type sheet piles. This helps to ensure proper handling and efficient unloading at the destination.

Transportation: The mode of transportation will depend on the quantity and destination of the sheet piles. Whether by truck, train, or ship, the transportation method should be chosen based on cost, time, and handling requirements.

COMPANY STRENGTH

Made in China, first-class service, cutting-edge quality, world-renowned

1. Scale effect: Our company has a large supply chain and a large steel factory, achieving scale effects in transportation and procurement, and becoming a steel company that integrates production and services

2. Product diversity: Product diversity, any steel you want can be purchased from us, mainly engaged in steel structures, steel rails, steel sheet piles, photovoltaic brackets, channel steel, silicon steel coils and other products, which makes it more flexible Choose the desired product type to meet different needs.

3. Stable supply: Having a more stable production line and supply chain can provide more reliable supply. This is especially important for buyers who require large quantities of steel.

4. Brand influence: Have higher brand influence and larger market

5. Service: A large steel company that integrates customization, transportation and production

6. Price competitiveness: reasonable price

*Send the email to chinaroyalsteel@163.com to get a quotation for your projects

CUSTOMERS VISIT

FAQ

1.How can I get a quotation from you ?

You can leave us message, and we will reply every message in time.

2.Will you delivery the goods on time?

Yes,we promise to provide best quality products and delivery on time. Honesty is our company's tenet.

3.Can I get samples before order ?

Yes, of course. Usually our samples are free,we can produce by your samples or technical drawings.

4.What is your payment terms?

Our usual payment term is 30% deposit, and rest against B/L. EXW, FOB,CFR, CIF.

5.Do you accept the third party inspection?

Yes absolutely we accept.

6.How do we trust your company?

We specialise in steel business for years as golden supplier, headquarter locates in Tianjin province, welcome to investigate in any ways, by all means.