Hot Sale Steel Quality Rail Railway Track in Bulk Used Rail

Development History

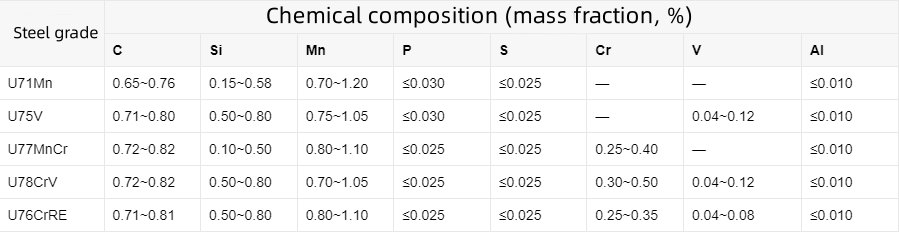

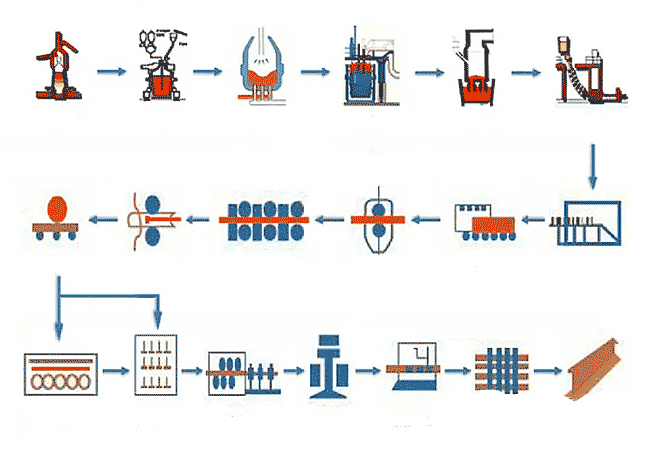

Quality control is crucial throughout the production process. The first is the selection of raw materials, which must ensure that the quality of steel meets national standards and is strictly tested. The second is the temperature control in the heating process, and the temperature parameters must be accurately mastered to ensure that the steel has good plasticity and toughness.

In the rolling process, it is necessary to strictly control the pressure and speed to ensure uniform deformation of the steel. Processes such as cooling, grinding and cutting also need to be carried out in strict accordance with standards to ensure the dimensional accuracy and surface quality of the rail.

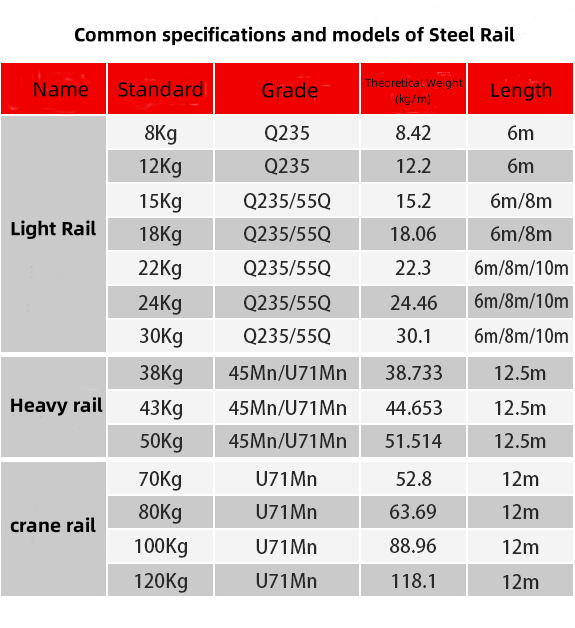

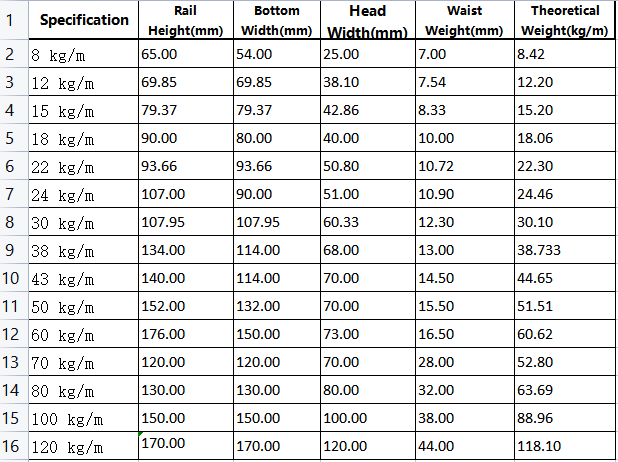

Specifications

In addition to the control in the production process, the quality of the rail also needs to undergo strict testing. The commonly used detection methods include ultrasonic inspection, magnetic particle inspection, hardness testing and so on. These detection methods can effectively detect the surface and internal defects of the rail to ensure its safety and reliability.

Our company supplies the following series of rails

Composite rail is mainly used for railway lines under special conditions, such as high altitude areas, coastal areas and so on. It has the advantage of a variety of materials and can meet the needs of use under special conditions.

Japanese and Korean standard rails

Specifications: 15kg, 22kg, 30kg, 37A, 50N, CR73, CR100

Standard: JIS E1103-91/JIS E1101-93

Material: implement JIS E standard

Length: 9-10m 10-12m 10-25m

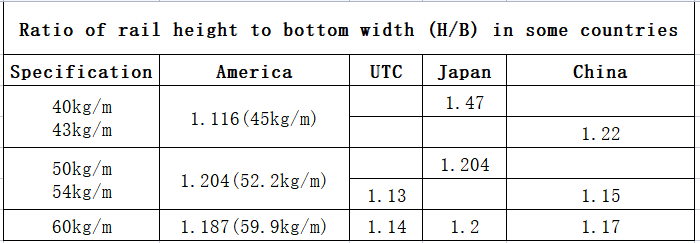

In order to best match the stiffness and stability, countries usually control the ratio of the rail height to the bottom width, is H/B, when designing the rail section. Generally, H/B is controlled between 1.15 and 1.248. The H/B values of rails in some countries are shown in the table.

As an important part of railway transportation, the quality of rail is directly related to the safety and efficiency of railway transportation. Therefore, it is essential to strictly control the quality during the production process to ensure that the rail meets national standards.

Rail production flow chart

Customer Visit

FAQ

1.How can I get a quotation from you ?

You can leave us message, and we will reply every message in time.

2.Will you delivery the goods on time?

Yes,we promise to provide best quality products and delivery on time. Honesty is our company's tenet.

3.Can I get samples before order ?

Yes, of course. Usually our samples are free,we can produce by your samples or technical drawings.

4.What is your payment terms?

Our usual payment term is 30% deposit, and rest against B/L. EXW, FOB,CFR, CIF.

5.Do you accept the third party inspection?

Yes absolutely we accept.

6.How do we trust your company?

We specialise in steel business for years as golden supplier, headquarter locates in Tianjin province, welcome to investigate in any ways, by all means.