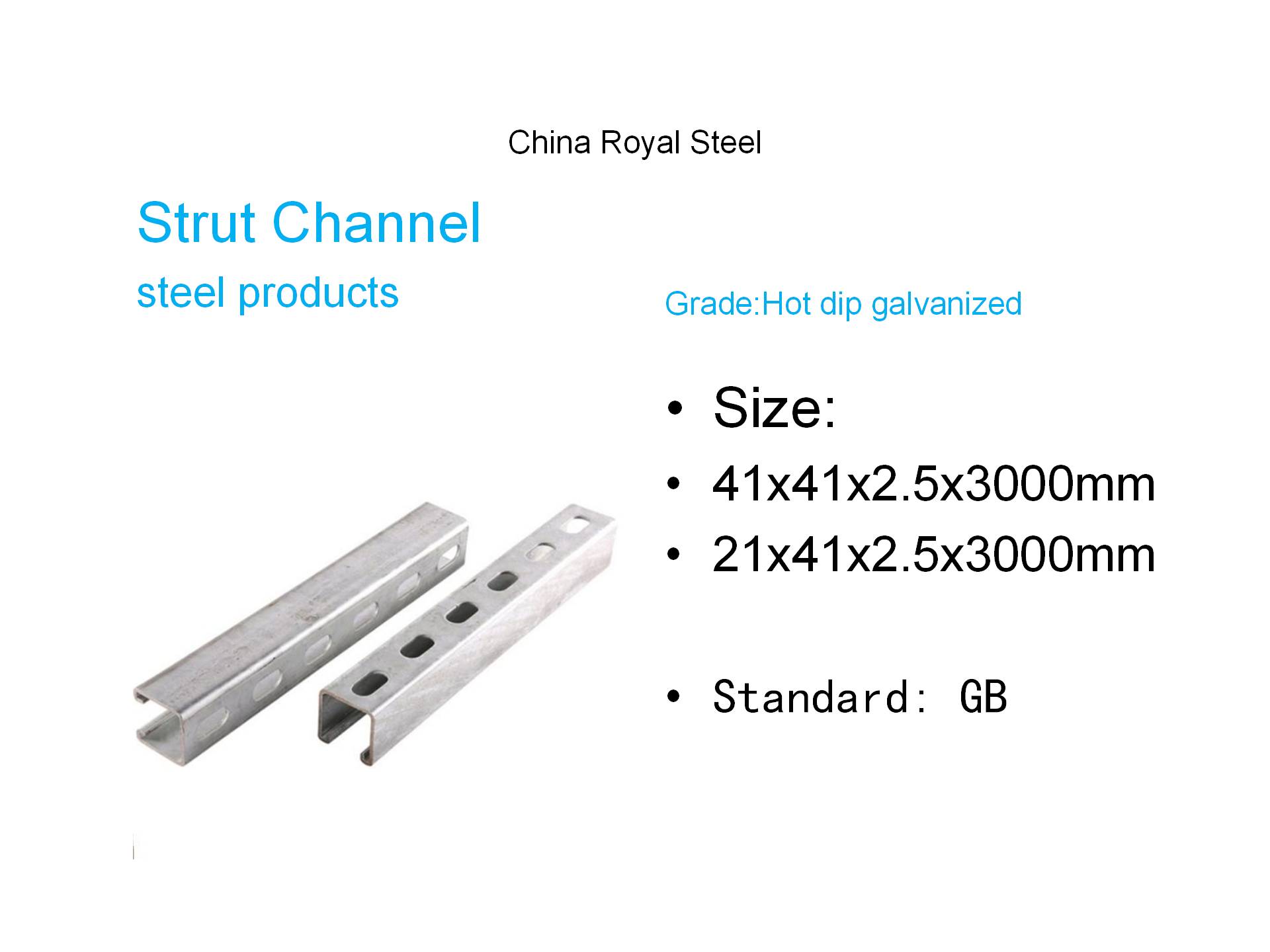

Hot Rolled Steel Profile Unistrut C Channel Steel Price

Product Detail

In addition to zinc, aluminum and magnesium, brackets are usually made of stainless steel. Solar zinc-aluminum-magnesium photovoltaic brackets can be divided into ground brackets, flat roof brackets, adjustable angle roof brackets, inclined roof brackets and column brackets, etc.

| Material | Carbon steel / SS304 /SS316 / Aluminum |

| Surface Treatment | GI,HDG(Hot Dipped Dalvanized ),powder coating (Black,Green,White,Grey,Blue)etc. |

| Lengths | Either 10FT or 20FT

or cut into the length according to Customer's Requirements |

| Thickness | 1.0mm,,1.2mm1.5mm, 1.8mm,2.0mm, 2.3mm,2.5mm |

| Holes | 12*30mm/41*28mm or according to Customer's Requirements |

| Style | Plain or Slotted or back to back |

| Type | (1)Tapered Flange Channel (2)Parallel Flange Channel |

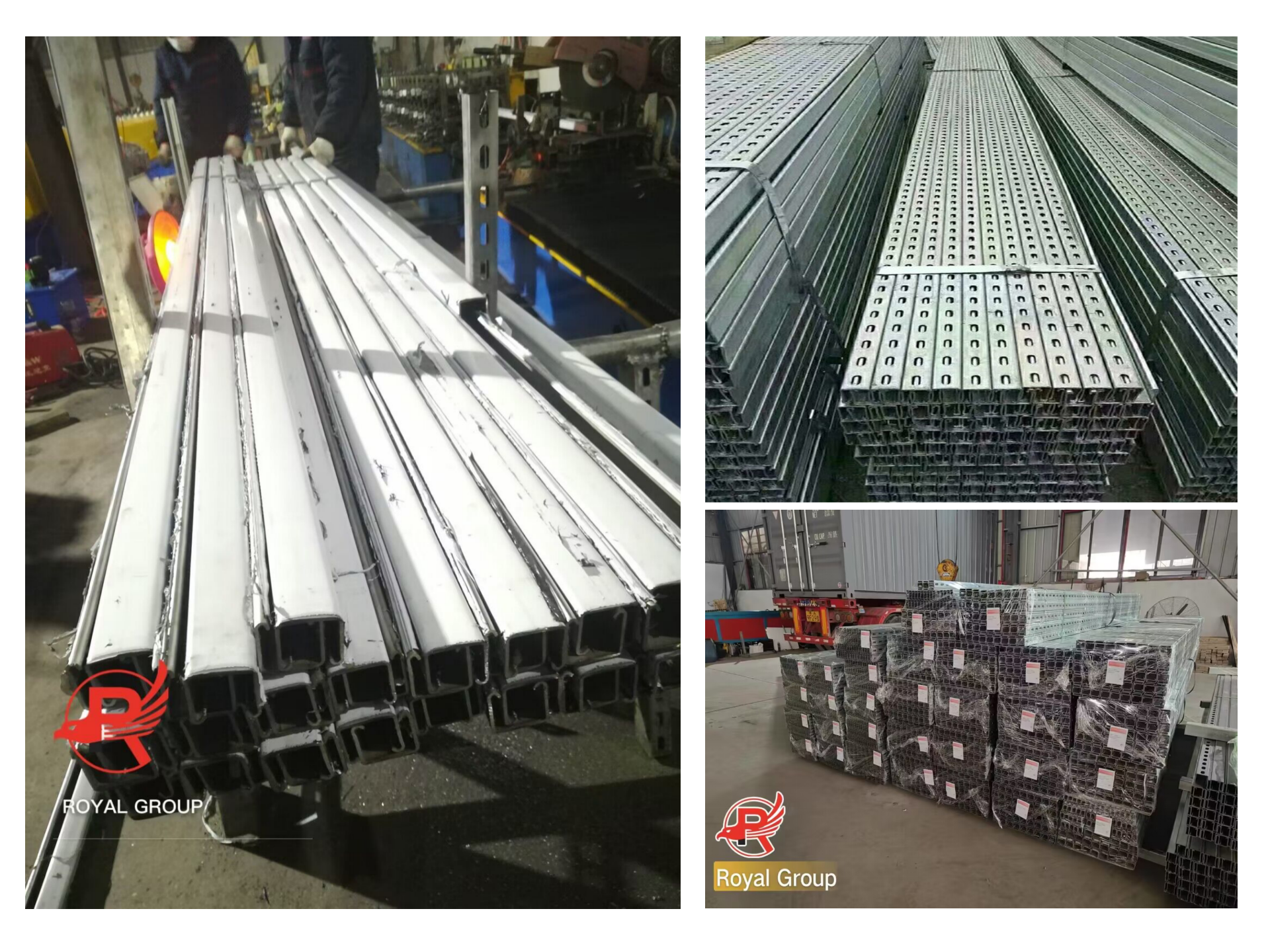

| Packaging | Standard Seaworthy Package:In Bundles and fasten with steel strips

or packed with braided tape outside |

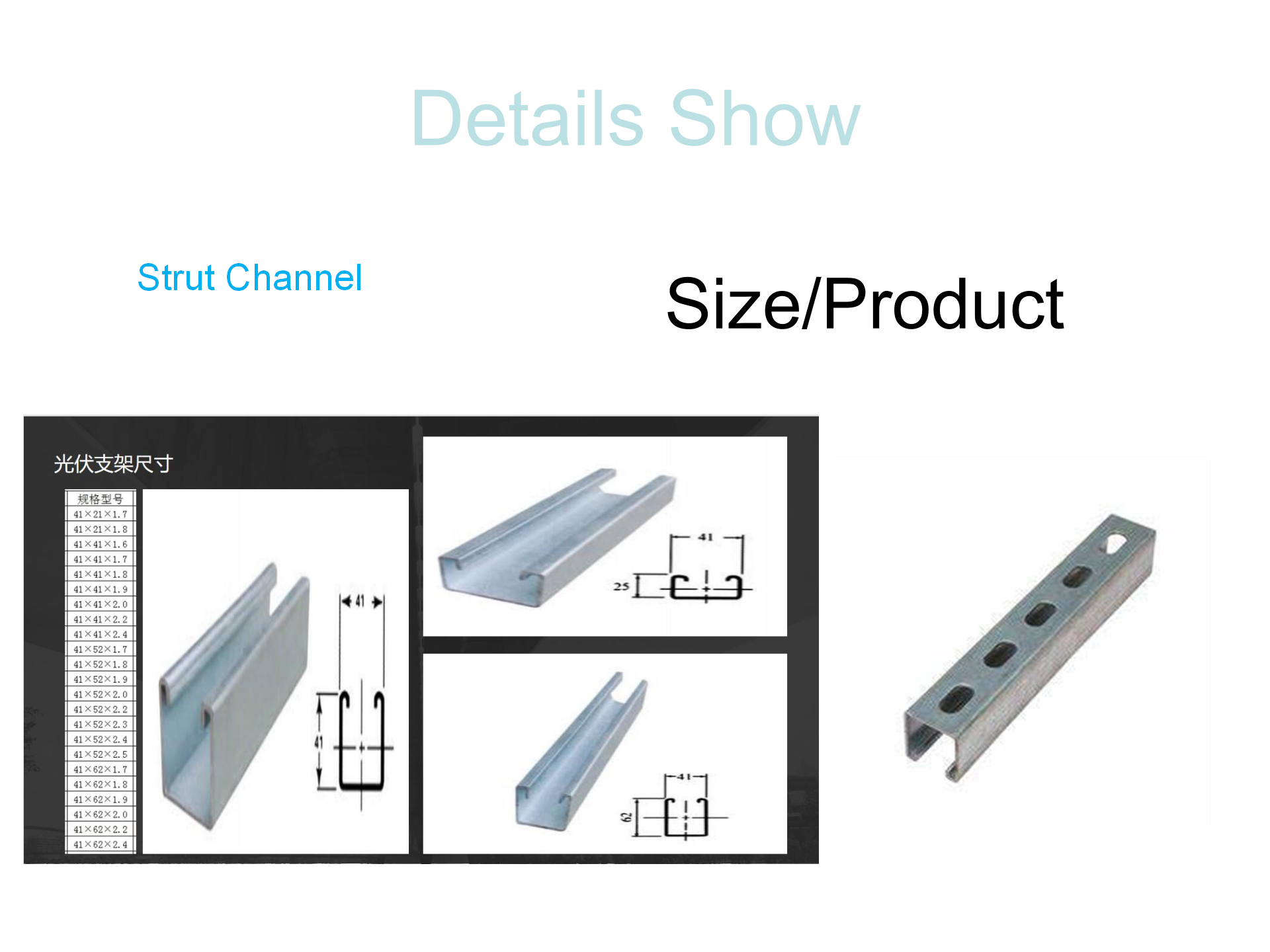

| No. | Size | Thickness | Type | Surface

Treatment |

||

| mm | inch | mm | Gauge | |||

| A | 41x21 | 1-5/8x13/16" | 1.0,1.2,1.5,2.0,2.5 | 20,19,17,14,13 | Slotted, Solid | GI,HDG,PC |

| B | 41x25 | 1-5/8x1" | 1.0,1.2,1.5,2.0,2.5 | 20,19,17,14,13 | Slotted, Solid | GI,HDG,PC |

| C | 41x41 | 1-5/8x1-5/8" | 1.0,1.2,1.5,2.0,2.5 | 20,19,17,14,13 | Slotted, Solid | GI,HDG,PC |

| D | 41x62 | 1-5/8x2-7/16" | 1.0,1.2,1.5,2.0,2.5 | 20,19,17,14,13 | Slotted, Solid | GI,HDG,PC |

| E | 41x82 | 1-5/8x3-1/4" | 1.0,1.2,1.5,2.0,2.5 | 20,19,17,14,13 | Slotted, Solid | GI,HDG,PC |

Features

1. Resist natural corrosion: Aluminum placed in the air can form a dense aluminum oxide protective layer on the surface. This protective layer can prevent further oxidation of aluminum materials.

2. Anti-galvanic corrosion: When the steel bracket is in contact with the aluminum photovoltaic panel frame, the aluminum photovoltaic panel frame is prone to galvanic corrosion, but the aluminum bracket avoids this phenomenon.

Application

3. Balanced voltage: Aluminum has excellent electrical conductivity, so it can better conduct weak currents generated by various reasons in the photovoltaic bracket system.

4. Easy to form: Aluminum profile products with different cross-sectional shapes can be easily obtained through extrusion process using different molds.

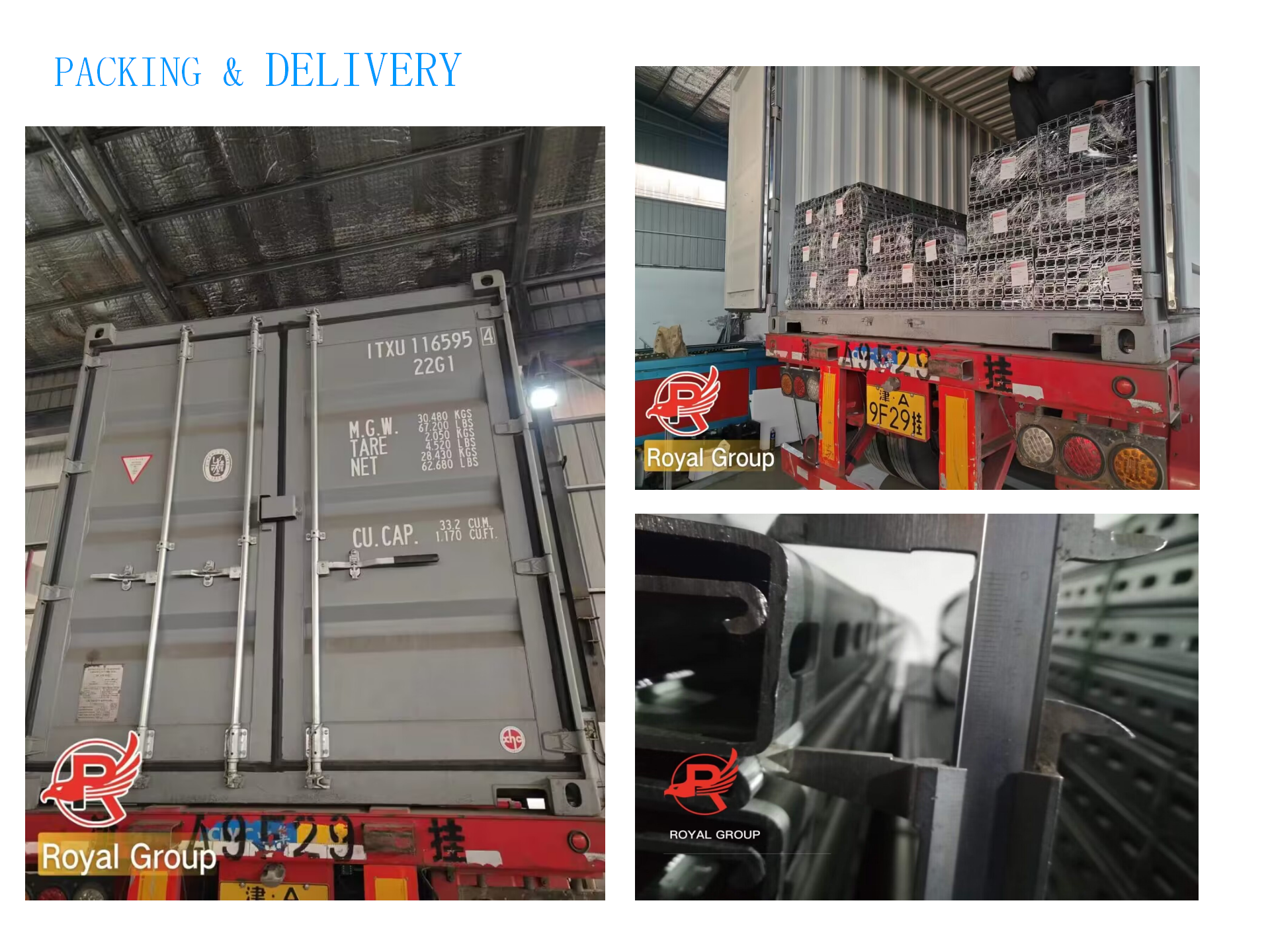

Packaging & Shipping

1. Photovoltaic module packaging

The packaging of photovoltaic modules is mainly to protect their glass surfaces and bracket systems and to prevent collision and damage during transportation. Therefore, in the packaging of photovoltaic modules, the following packaging materials are commonly used:

1. Foam box: Use rigid foam box for packaging. The box is made of high-strength cardboard or wooden box, which can effectively protect the photovoltaic modules and is more convenient for transportation and handling operations.

2. Wooden boxes: Fully consider that heavy objects may be collided, squeezed, etc. during transportation, so using ordinary wooden boxes will be stronger. However, this packaging method takes up a certain amount of space and is not conducive to environmental protection.

3. Pallet: It is packaged in a special pallet and placed on corrugated cardboard, which can hold up the photovoltaic panels stably and is firm and easy to transport.

4. Plywood: Plywood is used to fix the photovoltaic modules to ensure that they are not subject to collision and extrusion to avoid damage or deformation during transportation.

2. Transportation of photovoltaic modules

There are three main modes of transportation for photovoltaic modules: land transportation, sea transportation, and air transportation. Each method has its own characteristics.

1. Land transportation: Applicable to transportation within the same city or province, with a single transportation distance not exceeding 1,000 kilometers. General transportation companies and logistics companies can transport photovoltaic modules to their destinations via land transportation. During transportation, pay attention to avoid collisions and extrusions, and choose a professional transportation company to cooperate as much as possible.

2. Sea transportation: suitable for inter-provincial, cross-border and long-distance transportation. Pay attention to packaging, protection and moisture-proof treatment, and try to choose a large logistics company or a professional shipping company as a partner.

3. Air transportation: suitable for cross-border or long-distance transportation, which can greatly shorten transportation time. However, air freight costs are relatively high and appropriate protection measures are required.

FAQ

1.How can I get a quotation from you ?

You can leave us message, and we will reply every message in time.

2.Will you delivery the goods on time?

Yes,we promise to provide best quality products and delivery on time. Honesty is our company's tenet.

3.Can I get samples before order ?

Yes, of course. Usually our samples are free,we can produce by your samples or technical drawings.

4.What is your payment terms?

Our usual payment term is 30% deposit, and rest against B/L. EXW, FOB,CFR, CIF.

5.Do you accept the third party inspection?

Yes absolutely we accept.

6.How do we trust your company?

We specialise in steel business for years as golden supplier, headquarter locates in Tianjin province, welcome to investigate in any ways, by all means.