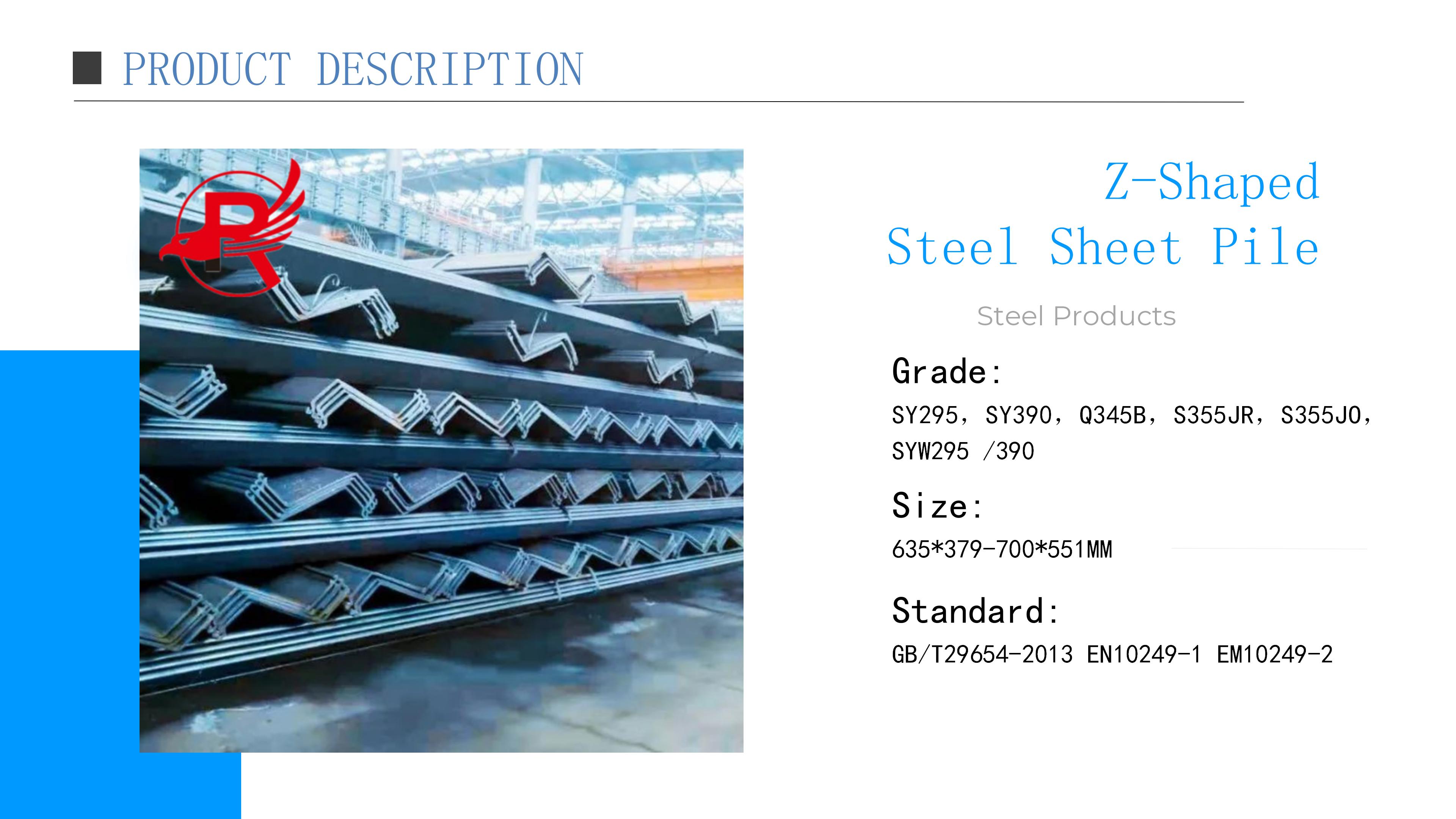

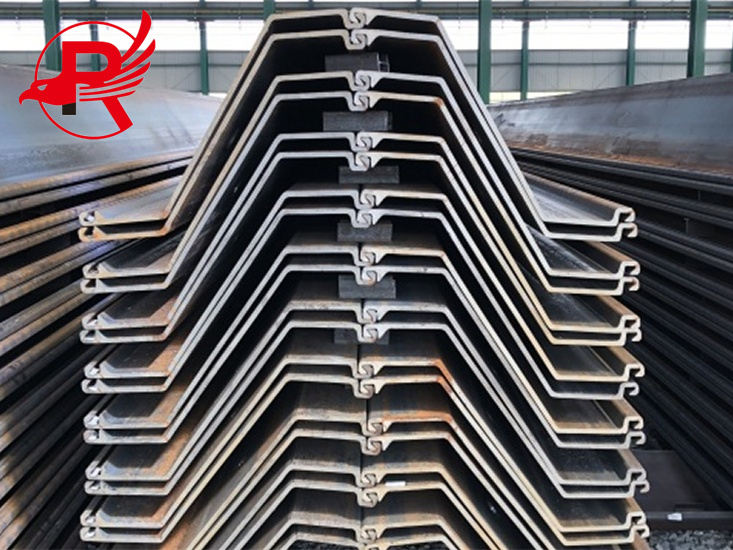

Hot Rolled Larsen Steel Sheet P Z type Steel Piles Factory Wholesale Price

The production process of hot-rolled Z-shaped steel sheet piles usually includes the following steps:

Raw material preparation: First, raw materials need to be prepared, usually using high-quality steel as raw materials. These steels need to be inspected and classified to ensure they meet production requirements.

Heating and rolling: The raw materials are heated to bring them to the appropriate temperature and then rolled through the rolling mill. In this process, the steel is processed into a Z-shaped shape and rolled through multiple passes through different rollers to ensure that the shape and size of the final product meet standard requirements.

Cooling and shaping: After rolling, the steel needs to be cooled to stabilize its structure and properties. At the same time, shaping and trimming are also required to ensure that the product has a smooth surface and accurate dimensions.

Inspection and packaging: The completed steel sheet piles need to undergo strict quality inspection, including inspection of appearance quality, dimensional deviation, chemical composition, etc. Qualified products will be packed and ready to be shipped.

Factory and transportation: The final product will be loaded onto the truck and shipped out of the factory, ready to be shipped to the customer site for use. Care must be taken to protect the product during transportation to avoid damage.

The above is the general production process of Z-shaped steel sheet piles. The specific production process may vary depending on the manufacturer and equipment.

*Send the email to chinaroyalsteel@163.com to get a quotation for your projects

|

Steel Grade

|

S275,S355,S390,S430,SY295,SY390,ASTM A690

|

|

standard

|

EN10248,EN10249,JIS5528,JIS5523,ASTM,GB/T 20933-2014

|

|

Delivery time

|

10~20 Days

|

|

Certificates

|

ISO9001,ISO14001,ISO18001,CE FPC

|

|

Length

|

6m-24m,9m,12m,15m,18m are common export length

|

|

Type

|

|

|

Processing Service

|

Punching, Cutting

|

|

Technique

|

Hot Rolled,Cold Rolled

|

|

Dimensions

|

PU400x100 PU400x125 PU400x150 PU400x170 PU500x200 PU500x225 PU600x130 PU600x180 PU600x210

|

|

Interlock types

|

Larssen locks,cold rolled interlock,hot rolled interlock

|

|

Length

|

1-12 meter or customized length

|

|

Application |

river bank,harbour pier,municipal facilities,urban tube corridor,seismic reinforcement,bridge pier,bearing foundation,underground

garage,foundation pit cofferdam,road widening retaining wall and temporary works. |

*Send the email to chinaroyalsteel@163.com to get a quotation for your projects

The height (H) of z sheet pile usually ranges from 200mm to 600mm.

The width (B) of Q235b Z-shaped steel sheet piles usually ranges from 60mm to 210mm.

The thickness (t) of Z-shaped steel sheet piles usually ranges from 6mm to 20mm.

| Section | Width | Height | Thickness | Cross Sectional Area | Weight | Elastic Section Modulus | Moment of Inertia | Coating Area (both sides per pile) | ||

|---|---|---|---|---|---|---|---|---|---|---|

| (w) | (h) | Flange (tf) | Web (tw) | Per Pile | Per Wall | |||||

| mm | mm | mm | mm | cm2/m | kg/m | kg/m2 | cm3/m | cm4/m | m2/m | |

| Type II | 400 | 200 | 10.5 | - | 152.9 | 48 | 120 | 874 | 8,740 | 1.33 |

| Type III | 400 | 250 | 13 | - | 191.1 | 60 | 150 | 1,340 | 16,800 | 1.44 |

| Type IIIA | 400 | 300 | 13.1 | - | 186 | 58.4 | 146 | 1,520 | 22,800 | 1.44 |

| Type IV | 400 | 340 | 15.5 | - | 242 | 76.1 | 190 | 2,270 | 38,600 | 1.61 |

| Type VL | 500 | 400 | 24.3 | - | 267.5 | 105 | 210 | 3,150 | 63,000 | 1.75 |

| Type IIw | 600 | 260 | 10.3 | - | 131.2 | 61.8 | 103 | 1,000 | 13,000 | 1.77 |

| Type IIIw | 600 | 360 | 13.4 | - | 173.2 | 81.6 | 136 | 1,800 | 32,400 | 1.9 |

| Type IVw | 600 | 420 | 18 | - | 225.5 | 106 | 177 | 2,700 | 56,700 | 1.99 |

| Type VIL | 500 | 450 | 27.6 | - | 305.7 | 120 | 240 | 3,820 | 86,000 | 1.82 |

Section Modulus Range

1100-5000cm3/m

Width Range (single)

580-800mm

Thickness Range

5-16mm

Production Standards

BS EN 10249 Part 1 & 2

Steel Grades

SY295, SY390 & S355GP for Type II to Type VIL

S240GP, S275GP, S355GP & S390 for VL506A to VL606K

Length

27.0m maximum

Standard Stock Lengths of 6m, 9m, 12m, 15m

Delivery Options

Single or Pairs

Pairs either loose, welded or crimped

Lifting Hole

By container (11.8m or less) or Break Bulk

Corrosion Protection Coatings

FEATURES

Steel sheet pile is widely used in civil engineering, mainly used in the following aspects:

1. Tunnel and subway construction: In tunnel and subway construction, steel sheet piles are needed to support and strengthen soil and building structures.

2. Retaining wall construction: steel sheet piles can be used for the construction of retaining walls to support and strengthen the soil.

3. River and canal treatment: In the process of river and canal treatment, steel sheet piles are needed to strengthen the river bed and prevent cement penetration.

4. Marine engineering: Steel sheet piles can be used in Marine engineering, such as the support and reinforcement of submarine pipelines.

5. Wharf construction: In wharf construction, steel sheet piles are needed to build port infrastructure and support wharf buildings.

APPLICATION

Sheet piles are infrastructure materials that embed large steel sheets into the soil to form a structural system. The common steel sheet pile types include hoop steel sheet pile, locking steel sheet pile, assembled steel sheet pile and so on. By embedding in soil, steel sheet pile can play the role of lateral support, interlayer division, peripheral closure, suspension locking and so on

PACKAGING AND SHIPPING

Container transportation is a common way to transport steel sheet piles, which is suitable for smaller steel sheet piling. At present, many enterprises use the way of shipping containers for international trade of steel sheet piles, which is economical and efficient, and is not affected by weather, road conditions and other factors.

COMPANY STRENGTH

Made in China, first-class service, cutting-edge quality, world-renowned

1. Scale effect: Our company has a large supply chain and a large steel factory, achieving scale effects in transportation and procurement, and becoming a steel company that integrates production and services

2. Product diversity: Product diversity, any steel you want can be purchased from us, mainly engaged in steel structures, steel rails, steel sheet piles, photovoltaic brackets, channel steel, silicon steel coils and other products, which makes it more flexible Choose the desired product type to meet different needs.

3. Stable supply: Having a more stable production line and supply chain can provide more reliable supply. This is especially important for buyers who require large quantities of steel.

4. Brand influence: Have higher brand influence and larger market

5. Service: A large steel company that integrates customization, transportation and production

6. Price competitiveness: reasonable price

*Send the email to chinaroyalsteel@163.com to get a quotation for your projects

CUSTOMER VISIT PROCESS

When a customer wishes to visit a product, the following steps can usually be arranged:

Make an appointment to visit: Customers can contact the manufacturer or sales representative in advance to make an appointment for the time and place to visit the product.

Arrange a guided tour: Arrange professionals or sales representatives as tour guides to show customers the production process, technology and quality control process of the product.

Display products: During the visit, show products at different stages to customers so that customers can understand the production process and quality standards of the products.

Answer questions: During the visit, customers may have various questions, and the tour guide or sales representative should answer them patiently and provide relevant technical and quality information.

Provide samples: If possible, product samples can be provided to customers so that customers can more intuitively understand the quality and characteristics of the product.

Follow-up: After the visit, promptly follow up on customer feedback and needs to provide customers with further support and services.

FAQ

1.How can I get a quotation from you ?

You can leave us message, and we will reply every message in time.

2.Will you delivery the goods on time?

Yes,we promise to provide best quality products and delivery on time. Honesty is our company's tenet.

3.Can I get samples before order ?

Yes, of course. Usually our samples are free,we can produce by your samples or technical drawings.

4.What is your payment terms?

Our usual payment term is 30% deposit, and rest against B/L. EXW, FOB,CFR, CIF.

5.Do you accept the third party inspection?

Yes absolutely we accept.

6.How do we trust your company?

We specialise in steel business for years as golden supplier, headquarter locates in Tianjin province, welcome to investigate in any ways, by all means.