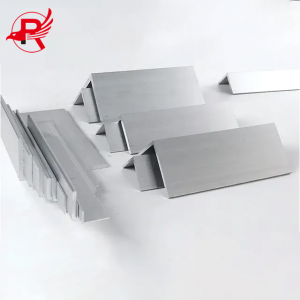

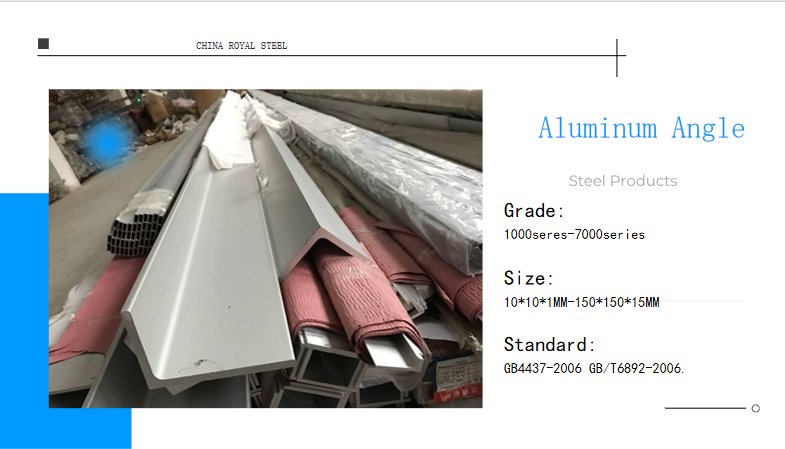

Hot Rolled Aluminum Angle Polished Angle for Sealing

Product Detail

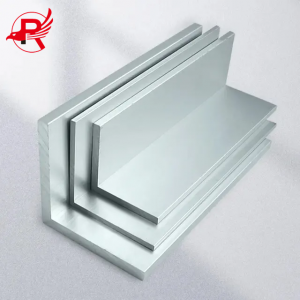

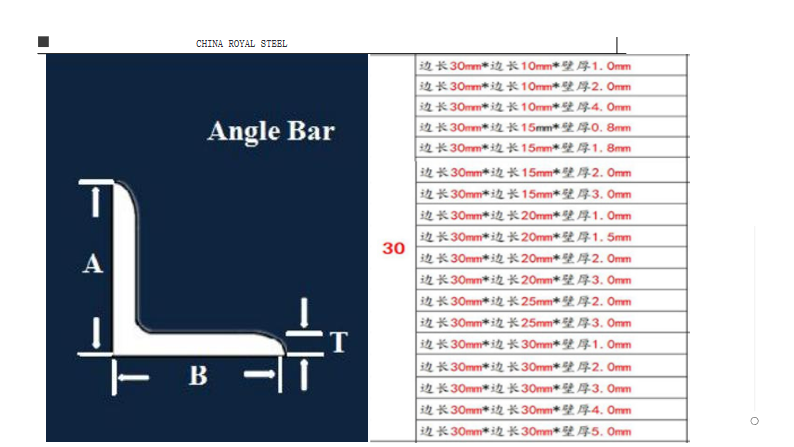

Aluminum angle is an industrial aluminum profile with an angle of 90°vertically. According to the ratio of side length, it can be divided into equilateral aluminum and equilateral aluminum. The two sides of equilateral aluminum are equal in width. Its specifications are expressed in millimeters of side width x side width x side thickness. For example, "∠30×30×3" means an equilateral aluminum with a side width of 30 mm and a side thickness of 3 mm.

The detail of a aluminum angle typically includes the following specifications:

Dimensions: The size and dimensions of the aluminum angle, such as the length, width, and thickness, are specified according to the project requirements.

Usages:In the field of decoration, it is common to seal the edge of the ceiling, and the corner aluminum used for sealing is generally thin, because it only plays a decorative role, so of course, the thinner the cost savings. Decorative corner aluminum generally needs to be sprayed or electrophoretic treatment, generally fixed with cement nails. Industrial aluminum profile Angle aluminum is mainly used for connecting parts.

|

SPECIFICATIONS FOR ALUMINUM AHGEL |

|

| 1. Size: | 10*10*1MM-150*150*15MM |

| 2. Standard: | GB4437-2006,GB/T6892-2006,ASTM,AISI,JIS,GB, DIN,EN |

| 3.Material: | Aluminum alloy |

| 4. Location of our factory: | Tianjin,China |

| 5. Usage: | 1)seal the edge of the ceiling |

| 2)connecting parts | |

| 6. Surface: | mill,bright,polished,hair line,brush,sand Blast,checkered,embossed,etching,etc |

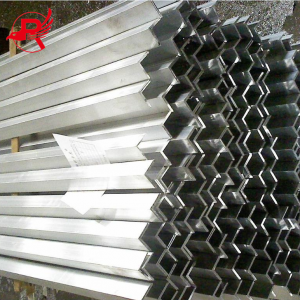

| 7. Technique: | hot rolled |

| 8. Type: | Aluminum Angle |

| 9. Section Shape: | Angle |

| 10. Inspection: | Client inspection or inspection by 3rd party. |

| 11. Delivery: | Container, Bulk Vessel. |

| 12. About Our Quality: | 1) No damage, no bent

2) Free for oiled&marking 3) All goods can be checked by third party inspection before shipment |

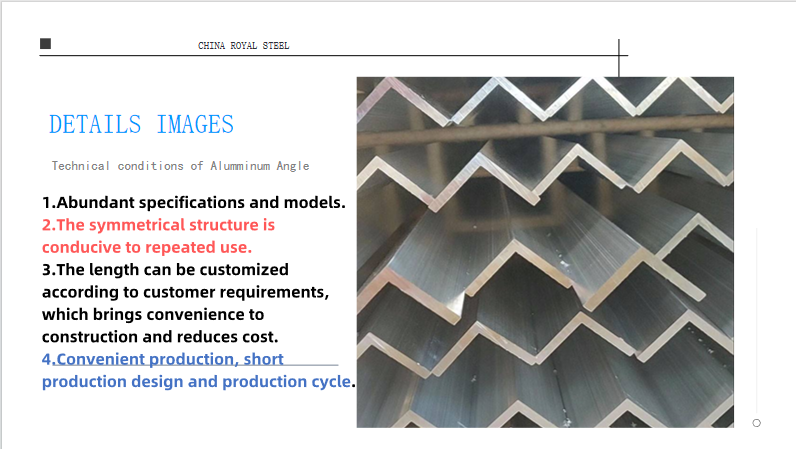

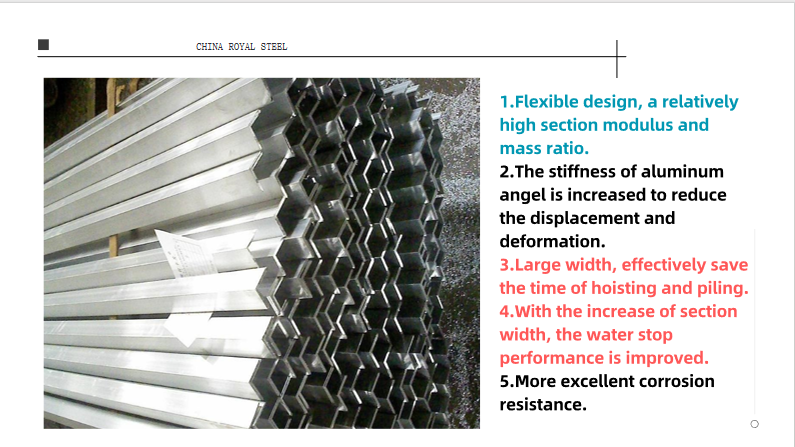

Features

1.High strength: Aluminum Angles are made from high-quality aluminum, which provides excellent strength and stiffness. This allows them to withstand heavy loads, soil pressures, and water pressures.

2.Versatility: Aluminum Angles can be used in a wide range of applications. With good thermoplasticity, it can be extruded into a variety of complex structures and thin-walled hollow profiles at high speed, or forged into forgings with complex structures.

3.Excellent durability: Aluminum angles are highly resistant to corrosion and can withstand extreme weather conditions, making them suitable for long-term use in various environments. They can also be coated or treated for enhanced durability and corrosion protection.

4.Easy maintenance: Maintenance for Aluminum angles is typically minimal. Any necessary repairs or maintenance can often be performed without the need for extensive excavation or disruption to surrounding structures.

5.Cost-effective: Aluminum angles offer a cost-effective solution for many construction projects. They provide a long service life, require minimal maintenance, and their installation can be efficient, allowing for potential cost savings.

Application

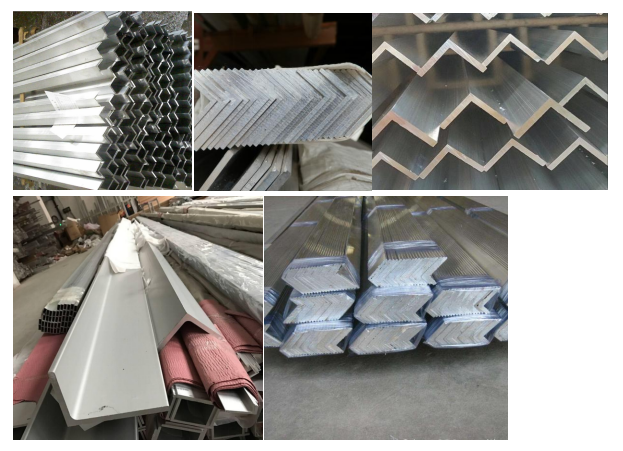

Decoration Field:

It is common to seal the edge of the ceiling, and the aluminum angle used for sealing is generally thin, because it only plays a decorative role. So of course, the thinner the cost savings. Decorative aluminum angle generally needs to be sprayed or electrophoretic treatment and fixed with cement nails.

Industrial Field:

Angle aluminum is mainly used for connecting parts. Itis not only 90 degree angle, but also 45 degree and 135 degree aluminum angel. Through sawing, drilling and other deep pin processing processes, this aluminum angle can be made into a finch digging finished products. Generally would be used as a connection between the two profiles fixed. Industrial aluminum angle is relatively thick, which requires a certain strength to play a fixed role.

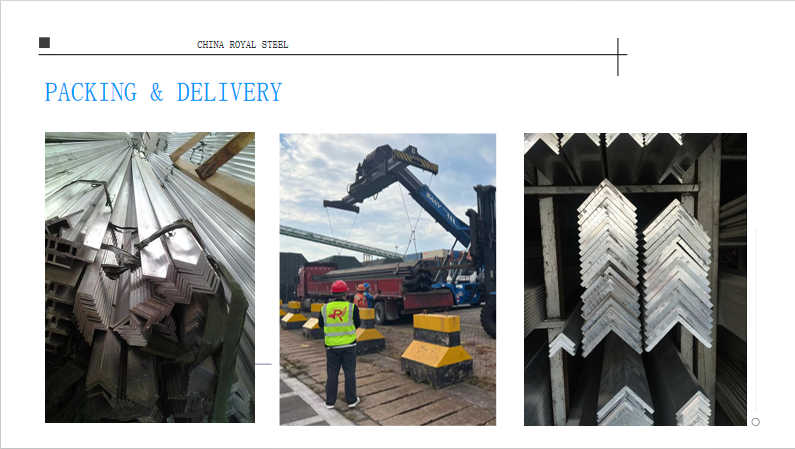

Packaging & Shipping

Packaging:

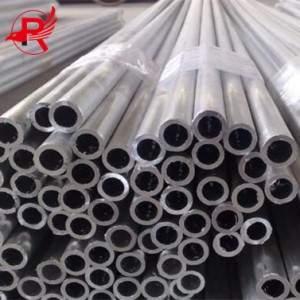

Stack the aluminum angles securely: Arrange the aluminum angles in a neat and stable stack, ensuring that they are aligned properly to prevent any instability. Use strapping or banding to secure the stack and prevent shifting during transportation. Use protective packaging materials: Wrap the stack of aluminum angles with a moisture-resistant material, such as plastic or waterproof paper, to protect them from exposure to water, humidity, and other environmental elements. This will help prevent rust and corrosion.

Shipping:

Choose a suitable mode of transportation: Depending on the quantity and weight of the aluminum angles, select the appropriate mode of transportation, such as flatbed trucks, containers, or ships. Consider factors like distance, time, cost, and any regulatory requirements for transportation.

Use appropriate lifting equipment: To load and unload the aluminum angles, use suitable lifting equipment such as cranes, forklifts, or loaders. Ensure that the equipment used has sufficient capacity to handle the weight of the sheet piles safely.

Secure the load: Properly secure the packaged stack of aluminum angles on the transportation vehicle using strapping, bracing, or other suitable means to prevent shifting, sliding, or falling during transit.

FAQ

1.How can I get a quotation from you ?

You can leave us message, and we will reply every message in time.

2.Will you delivery the goods on time?

Yes,we promise to provide best quality products and delivery on time. Honesty is our company's tenet.

3.Can I get samples before order ?

Yes, of course. Usually our samples are free,we can produce by your samples or technical drawings.

4.What is your payment terms?

Our usual payment term is 30% deposit, and rest against B/L. EXW, FOB,CFR, CIF.

5.Do you accept the third party inspection?

Yes absolutely we accept.

6.How do we trust your company?

We specialise in steel business for years as golden supplier, headquarter locates in Tianjin province, welcome to investigate in any ways, by all means.