High Quality Industry Rail AREMA Standard Steel Rail

AREMA standard steel rail are key components in railway transportation for load-bearing capacity and safety. They have multiple functions of supporting, guiding, transmitting and fixing trains. Its application covers all fields of railway transportation systems and is also one of the important technical supports for railway transportation.

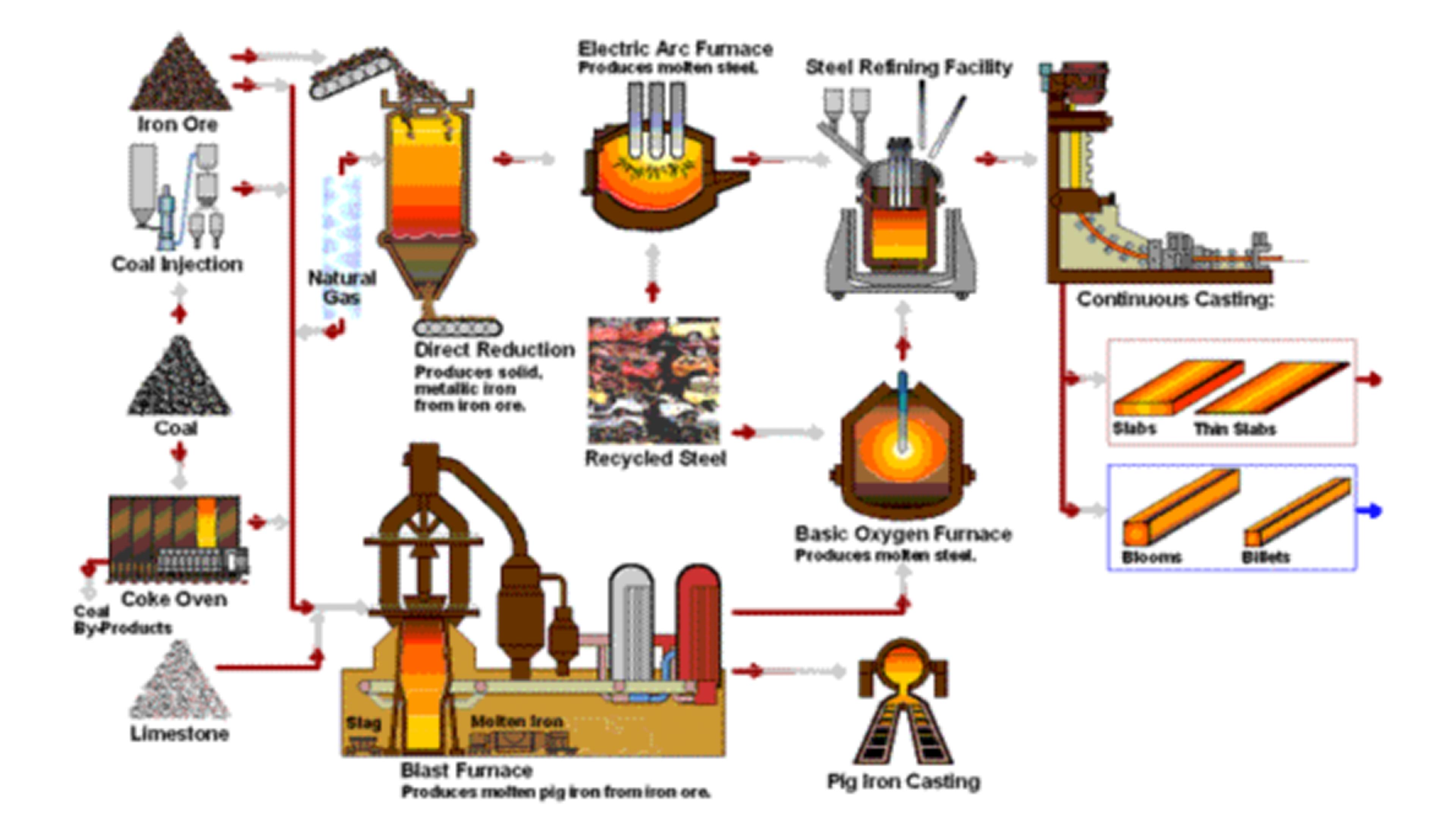

PRODUCT PRODUCTION PROCESS

Technology and Construction Process

The process of constructing rail of train tracks involves precision engineering and careful consideration of various factors. It begins with designing the track layout, taking into account the intended usage, train speeds, and terrain. Once the design is finalized, the construction process commences with the following key steps:

1. Excavation and Foundation: The construction crew prepares the ground by excavating the area and creating a sturdy foundation to support the weight and stress imposed by trains.

2. Ballast Installation: A layer of crushed stone, known as ballast, is laid on the prepared surface. This serves as a shock-absorbing layer, providing stability, and helping to distribute the load evenly.

3. Ties and Fastening: Wooden or concrete ties are then installed on top of the ballast, imitating a frame-like structure. These ties offer a secure base for the steel railroad tracks. They are fastened using specific spikes or clips, ensuring they remain firmly in place.

4. Rail Installation: The steel railroad rails 10m, often referred to as standard rails, are meticulously laid on top of the ties. Being made of high-quality steel, these tracks possess remarkable strength and durability.

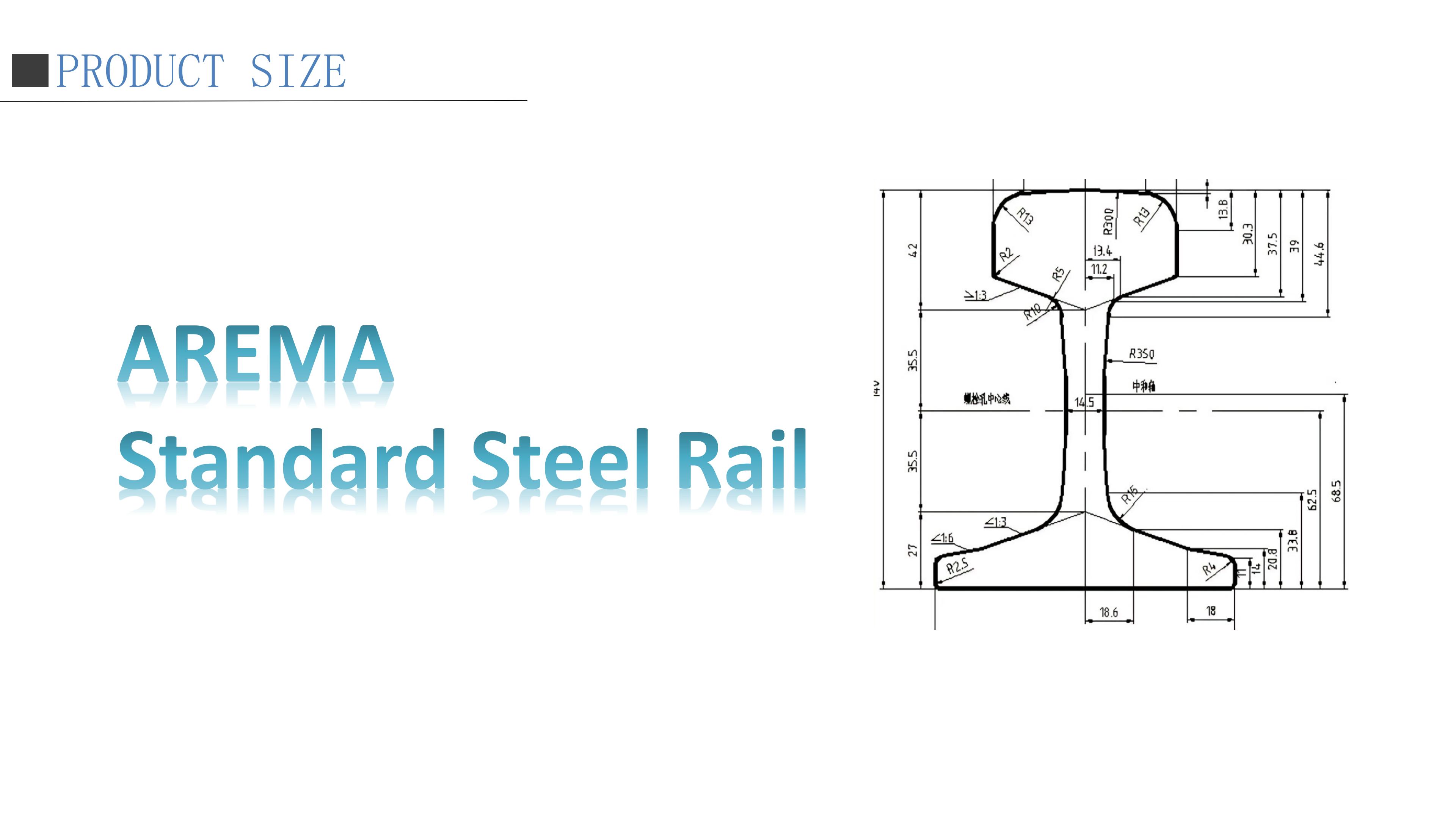

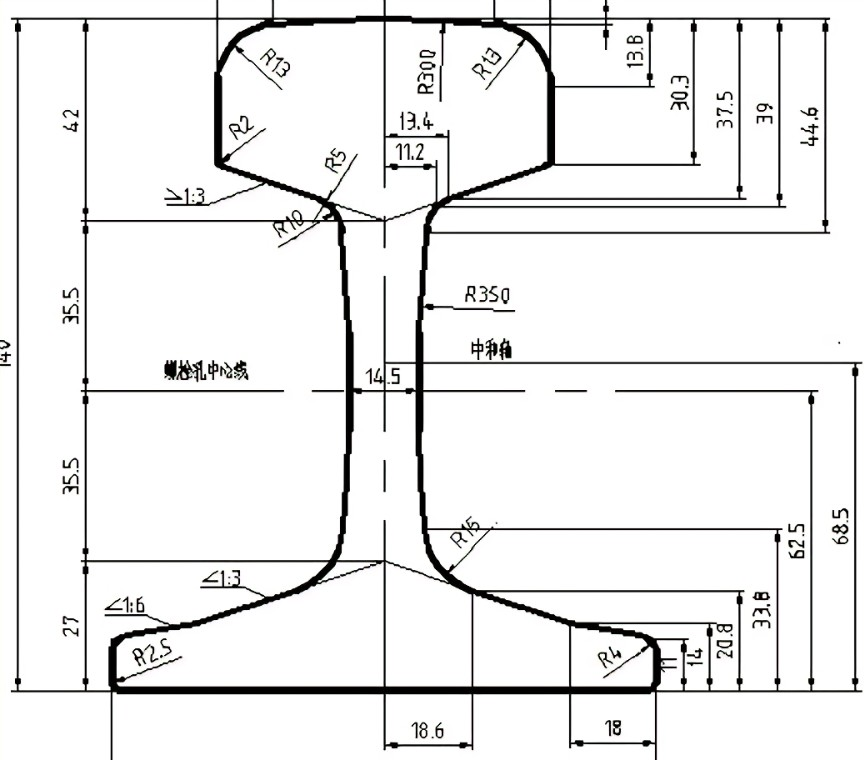

PRODUCT SIZE

| United States standard steel rail | |||||||

| model | size (mm) | substance | material quality | length | |||

| head breadth | altitude | baseboard | waist depth | (kg/m) | (m) | ||

| A(mm) | B(mm) | C(mm) | D(mm) | ||||

| ASCE 25 | 38.1 | 69.85 | 69.85 | 7.54 | 12.4 | 700 | 6-12 |

| ASCE 30 | 42.86 | 79.38 | 79.38 | 8.33 | 14.88 | 700 | 6-12 |

| ASCE 40 | 47.62 | 88.9 | 88.9 | 9.92 | 19.84 | 700 | 6-12 |

| ASCE 60 | 60.32 | 107.95 | 107.95 | 12.3 | 29.76 | 700 | 6-12 |

| ASCE 75 | 62.71 | 122.24 | 22.24 | 13.49 | 37.2 | 900A/110 | 12-25 |

| ASCE 83 | 65.09 | 131.76 | 131.76 | 14.29 | 42.17 | 900A/110 | 12-25 |

| 90RA | 65.09 | 142.88 | 130.18 | 14.29 | 44.65 | 900A/110 | 12-25 |

| 115RE | 69.06 | 168.28 | 139.7 | 15.88 | 56.9 | Q00A/110 | 12-25 |

| 136RE | 74.61 | 185.74 | 152.4 | 17.46 | 67.41 | 900A/110 | 12-25 |

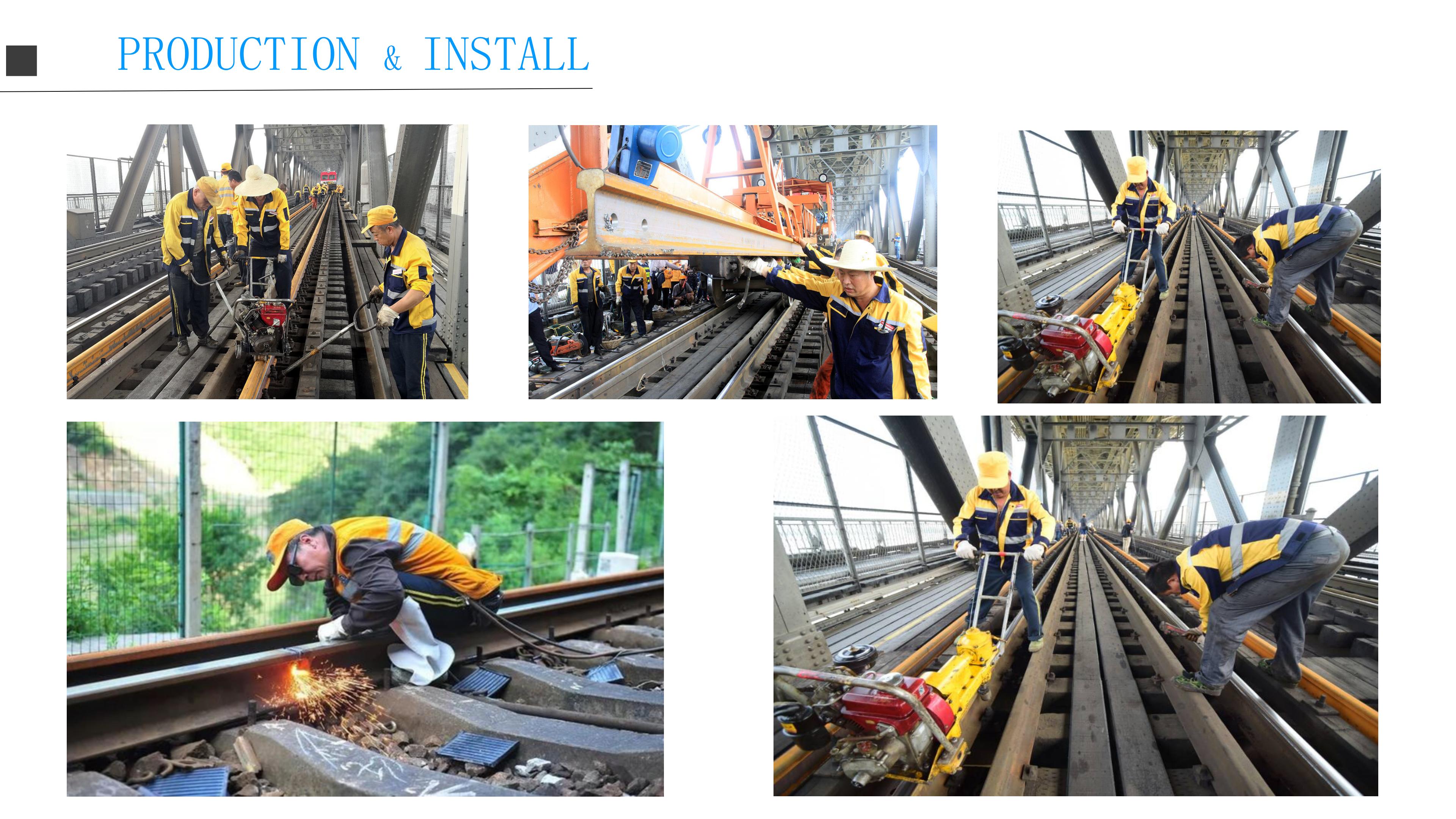

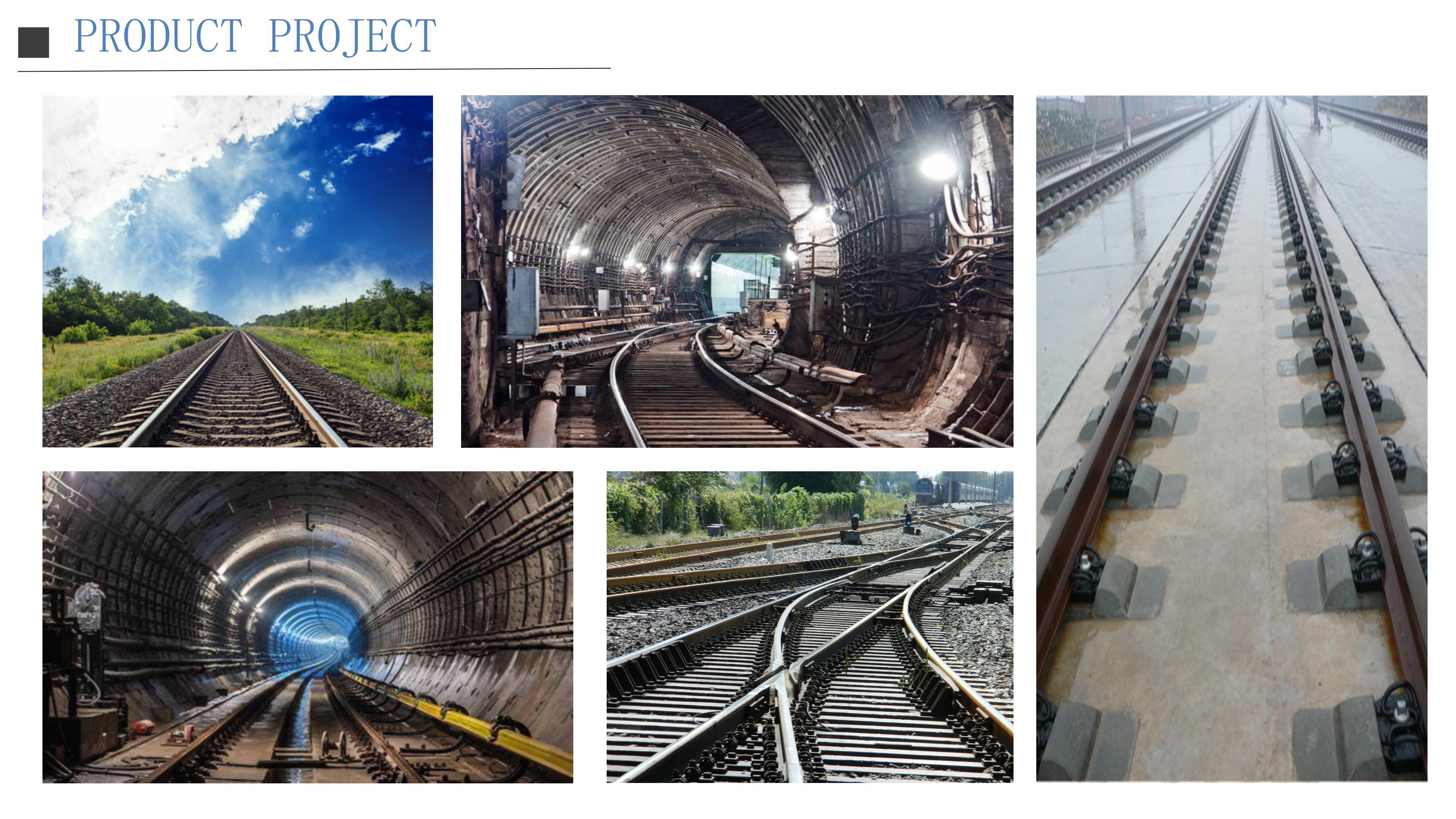

PROJECT

Our company’s 13,800 tons of railroad rail exported to the United States were shipped at Tianjin Port at one time. The construction project was completed with the last rail being steadily laid on the railway line. These rails are all from the universal production line of our rail and steel beam factory, using global Produced to the highest and most rigorous technical standards.

For more information about rail products, please contact us!

WeChat: +86 13652091506

Tel: +86 13652091506

Email: chinaroyalsteel@163.com

AREMA standard steel rail:

Specifications: ASCE25, ASCE30, ASCE40, ASCE60,ASCE75,ASCE85,90RA,115RE,136RE, 175LBs

Standard: ASTM A1,AREMA

Material: 700/900A/1100

Length: 6-12m, 12-25m

ADVANTAGE

1. Characteristics of rail products

1. High strength: After optimized design and special material formula, the rails have high bending strength and compressive strength, and can withstand the heavy load and impact of the train, ensuring the safety and stability of railway transportation.

2. Wear resistance: The rail surface has high hardness and small friction coefficient, which can resist the wear of train wheels and rails and extend the service life.

3. Good stability: The rails have precise geometric dimensions and stable horizontal and vertical dimensions, which can ensure the smooth operation of the train and reduce noise and vibration.

4. Convenient construction: The rails can be connected to any length through joints, making it easier to install and replace the rails.

5. Low maintenance costs: Rails are relatively stable and reliable during transportation, and have low maintenance costs.

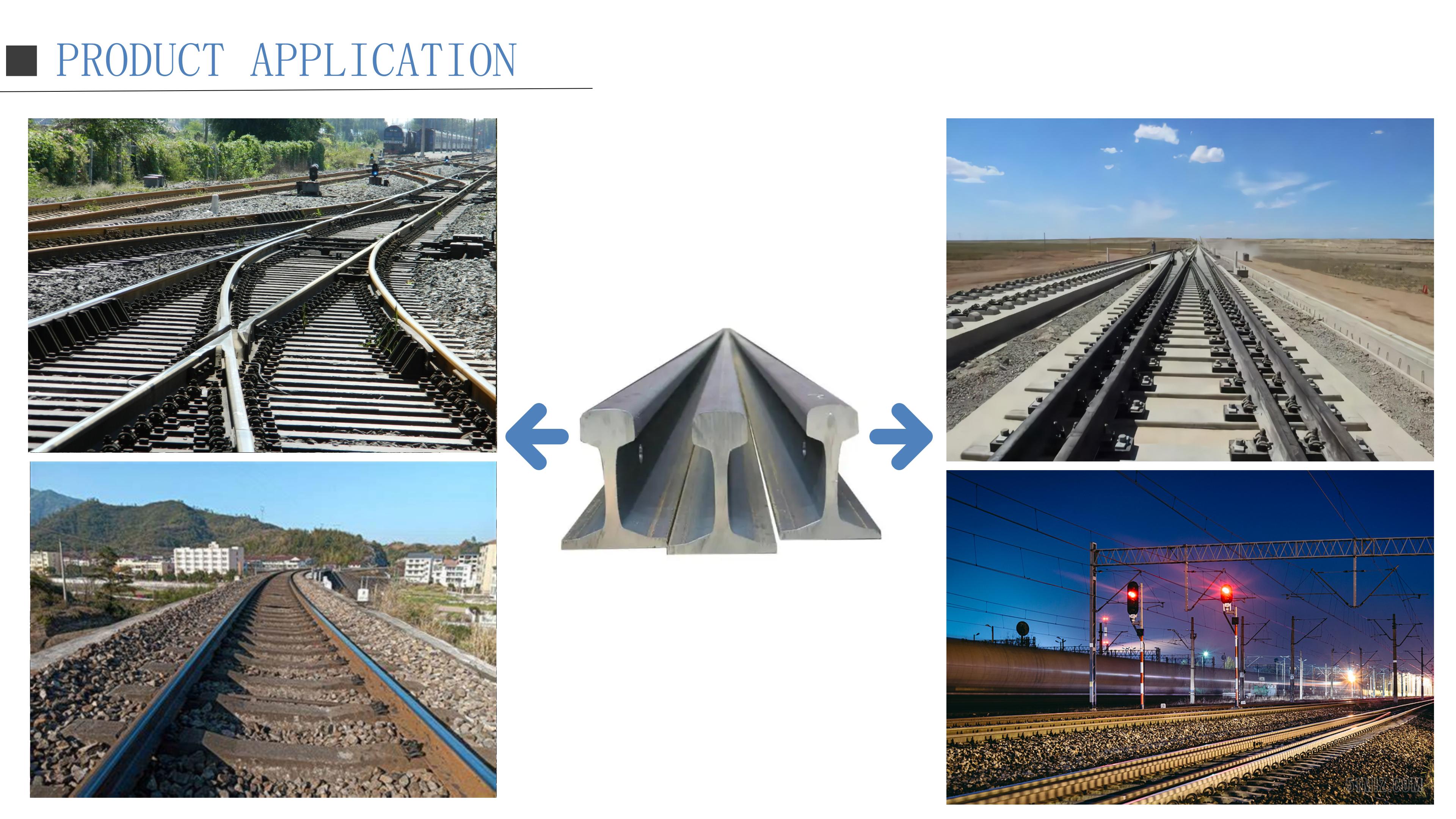

APPLICATION

American standard rails refer to rails that comply with American standards ("AREMA 2012"). American standard rails are divided into four types: 85, 90, 115, and 136, which are mainly used in railway lines in the United States and South America. Among them, models 85 and 90 are suitable for ordinary trucks with transport speeds below 160km/h, and models 115 and 136 are suitable for rigid trucks and buses.The weight of the train is exerted directly on the Track Of Railway, which distribute the weight by transferring it to the railway foundation. Therefore, when the train is running, the rails can bear a large amount of weight and ensure the stability of the track.

PACKAGING AND SHIPPING

1. Railway transportation

Railroad Track Rail are one of the commonly used goods in railway transportation. Railway transportation has the advantages of safety, speed and low cost. During transportation, attention should be paid to protecting the rails from damage, and special railway transportation vehicles are usually used for transportation. During the installation process, pay attention to the laying direction and connection methods to avoid errors caused by human factors.

2. Road transportation

Road transportation is another common method of transporting long rails and is also one of the common methods when building or repairing railways. During transportation, certain measures must be taken to ensure that the goods do not slide or swing, thereby avoiding accidents. At the same time, a detailed transportation plan should also be formulated and operated according to the plan.

3. Water transportation

For the transportation of long rails over long distances, water transportation is generally used. In water transportation, a variety of ships can be selected for transportation, such as cargo ships, barges, etc. Before loading goods, the length and weight of the rails, as well as the load-bearing capacity and safety performance of the ship need to be considered to determine the appropriate loading method and quantity. In addition, protective measures need to be taken to avoid accidental damage to the rails during water transportation.

The transportation of long rails is a very important engineering matter, and a series of operating specifications and protection details need to be paid attention to to avoid adverse consequences such as losses and casualties due to negligence.

COMPANY STRENGTH

Made in China, first-class service, cutting-edge quality, world-renowned

1. Scale effect: Our company has a large supply chain and a large steel factory, achieving scale effects in transportation and procurement, and becoming a steel company that integrates production and services

2. Product diversity: Product diversity, any steel you want can be purchased from us, mainly engaged in steel structures, steel rails, steel sheet piles, photovoltaic brackets, channel steel, silicon steel coils and other products, which makes it more flexible Choose the desired product type to meet different needs.

3. Stable supply: Having a more stable production line and supply chain can provide more reliable supply. This is especially important for buyers who require large quantities of steel.

4. Brand influence: Have higher brand influence and larger market

5. Service: A large steel company that integrates customization, transportation and production

6. Price competitiveness: reasonable price

*Send the email to chinaroyalsteel@163.com to get a quotation for your projects

CUSTOMERS VISIT

FAQ

1.How can I get a quotation from you ?

You can leave us message, and we will reply every message in time.

2.Will you delivery the goods on time?

Yes,we promise to provide best quality products and delivery on time. Honesty is our company's tenet.

3.Can I get samples before order ?

Yes, of course. Usually our samples are free,we can produce by your samples or technical drawings.

4.What is your payment terms?

Our usual payment term is 30% deposit, and rest against B/L. EXW, FOB,CFR, CIF.

5.Do you accept the third party inspection?

Yes absolutely we accept.

6.How do we trust your company?

We specialise in steel business for years as golden supplier, headquarter locates in Tianjin province, welcome to investigate in any ways, by all means.