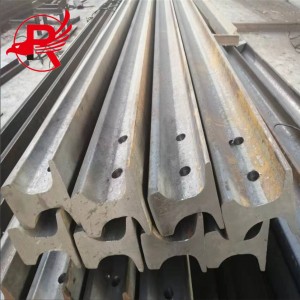

High Quality Industry EN Standard Rail/UIC Standard Steel Rail Mining Rail Railroad Steel Rail

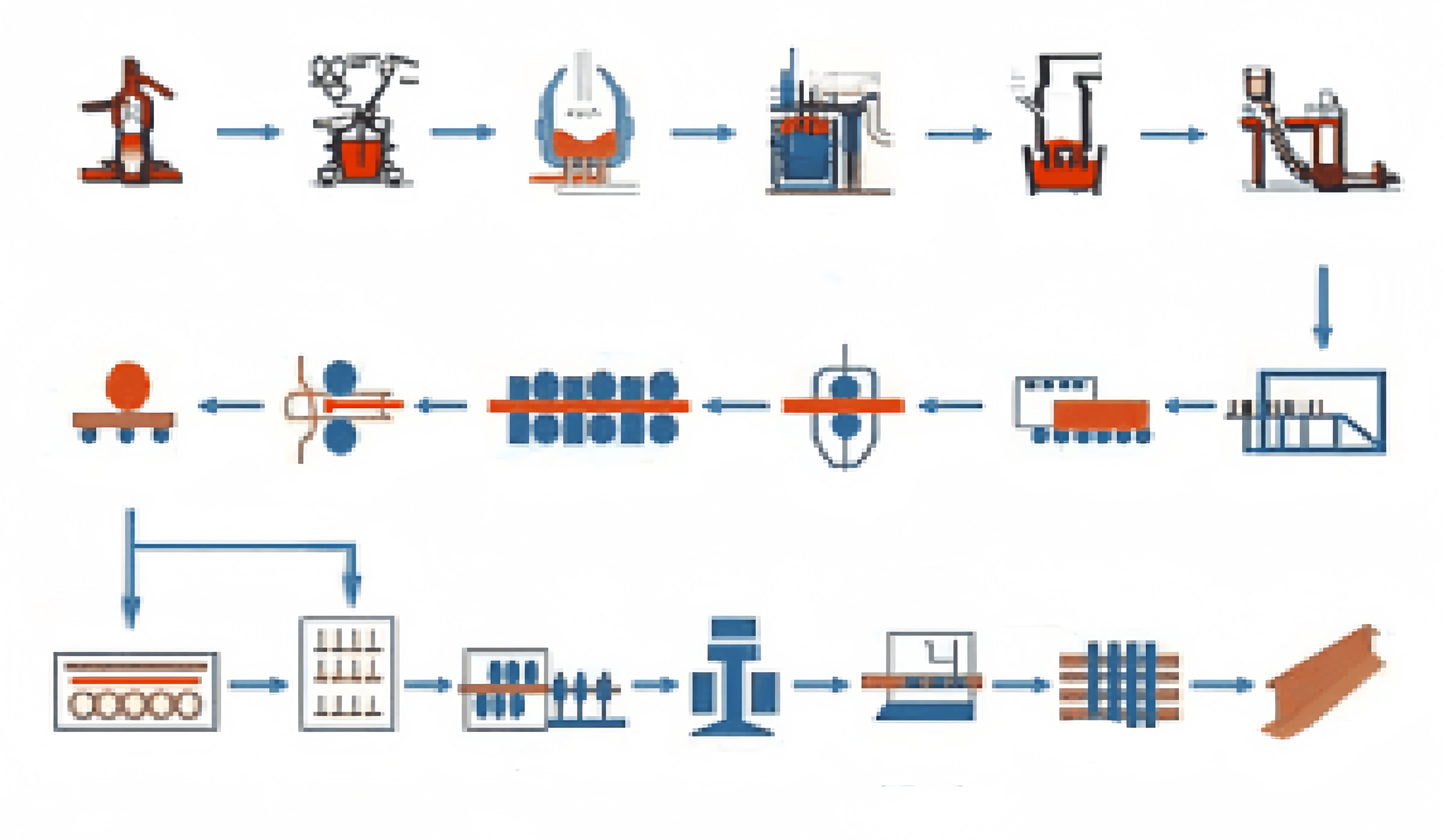

PRODUCT PRODUCTION PROCESS

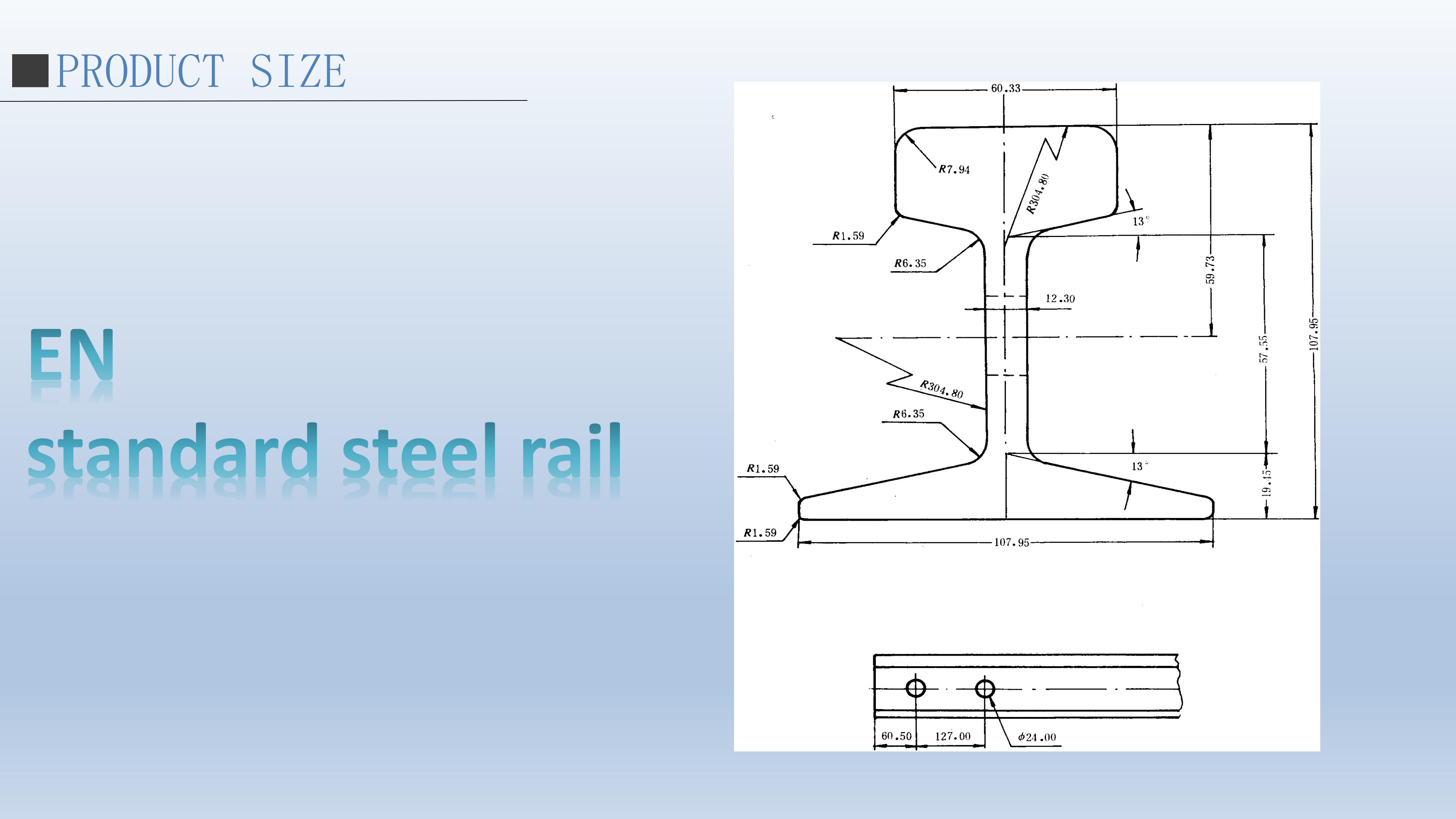

European standard rails refer to railway track rails that comply with European standards and are used in railway systems. These rails generally comply with the European standard EN 13674 "Specification for railway track materials". These standards specify the materials, dimensions, strength, geometric requirements, etc. of rails.

| EN standard steel rail | Section size(m) | Theoretical weight | Remark | |||

| Specification | head width | Bottom width | rail height | Thick waist | ||

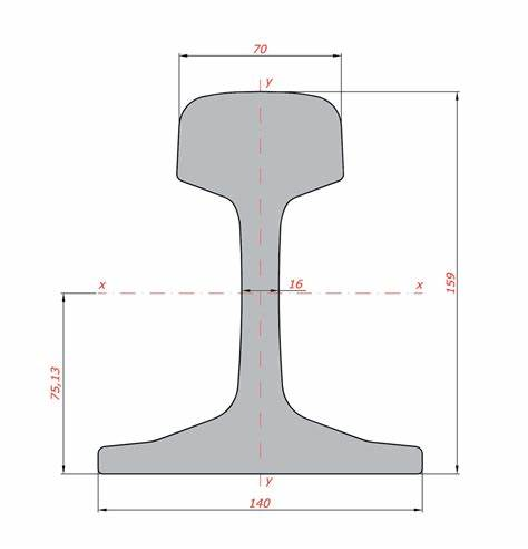

| UIC54 | 70 | 140 | 159 | 16.0 | 54. 43 | UIC860 |

| UIC60 | 72 | 150 | 172 | 16.5 | 60.34 | UIC860 |

| 54E1 | 70 | 140 | 159 | 16.0 | 54.77 | EN13674-1 |

| 6OE1 | 72 | 150 | 172 | 16.5 | 60.21 | EN13674-1 |

| 60E2 | 72 | 150 | 172 | 16.5 | 60.03 | EN13674-1 |

European standard steel rails are commonly used in railway systems to carry the weight of trains, provide a stable driving route, and ensure that trains can operate safely and efficiently. These rails are usually made of high-strength steel and are able to withstand heavy stress and continuous use, so they play a vital role in rail transportation in Europe.

UIC rail:

Specifications: UIC50/UIC54/UIC60

Standard: UIC860

Material: 900A/1100

Length: 12-25m

FEATURES

European standard rails usually have the following characteristics:

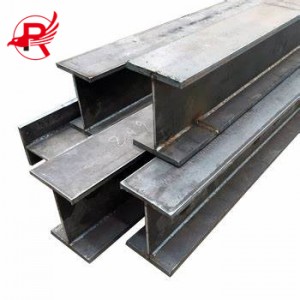

High strength: European standard rails are made of high-quality carbon structural steel or alloy steel, which have high strength and load-bearing capacity and can withstand the weight and operating pressure of the train.

Wear resistance: The rail surface has been specially treated to improve its wear resistance, extend its service life and reduce maintenance costs.

Anti-corrosion: The surface of the rail may be treated with anti-corrosion to enhance its corrosion resistance and adapt to different environmental conditions, especially for better durability in humid or corrosive environments.

Standardization: Compliance with the European standard EN 13674 ensures the quality and safety of the track, making it suitable for railway systems within Europe.

Reliability: European standard rails undergo strict quality control, have stable performance and reliable quality, and can ensure the safe and stable operation of the railway system.

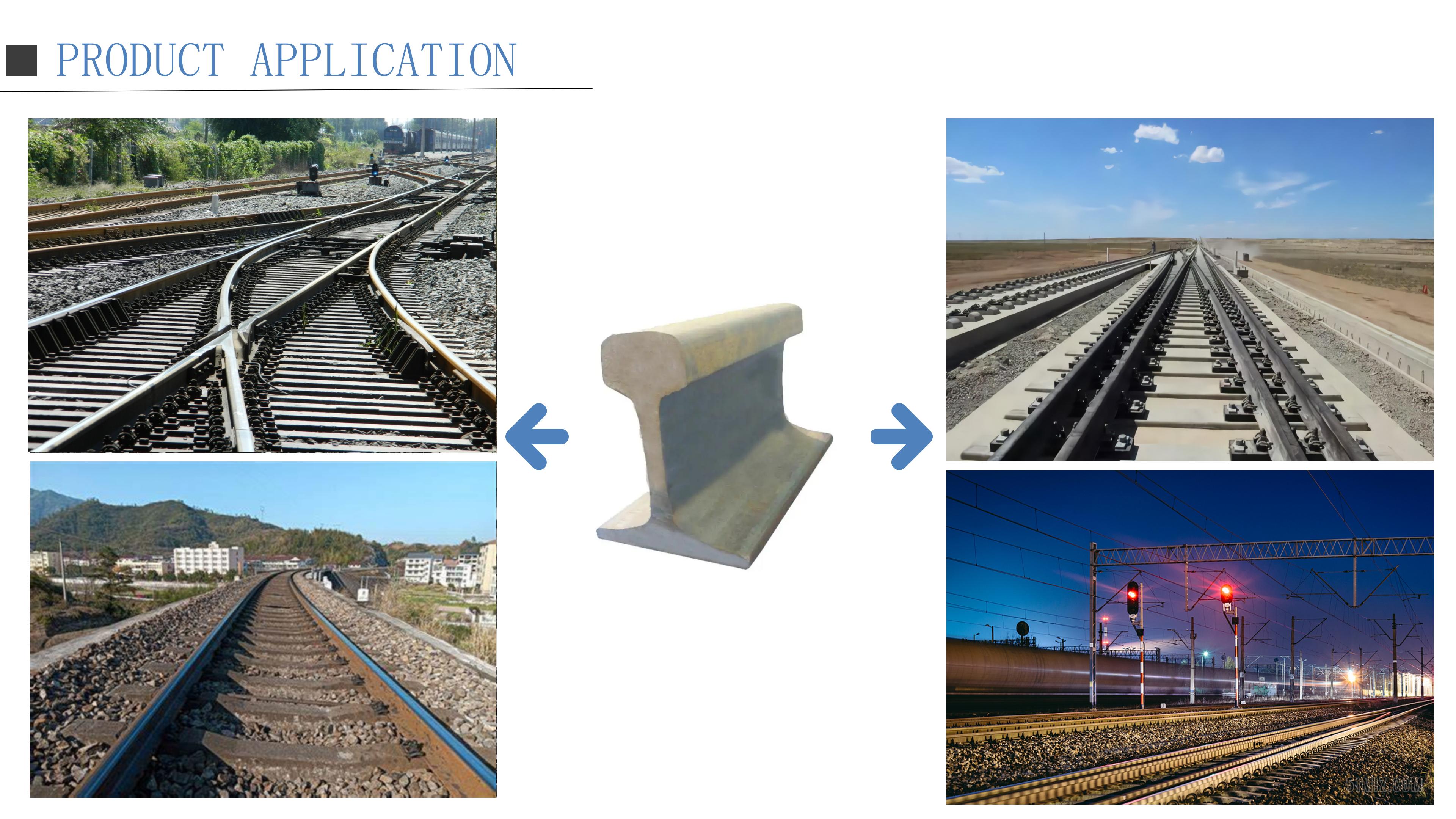

APPLICATION

European standard rails are mainly used in railway systems as tracks for trains to travel. They carry the weight of the train, provide a stable route, and ensure that the train can operate safely and efficiently. European standard rails are usually made of high-strength steel and are able to withstand heavy pressure and continuous use, so they play a vital role in railway transportation.

PACKAGING AND SHIPPING

European standard rails usually require some special measures during packaging and transportation to ensure their safety and integrity. Specific packaging methods may include:

Bundling: Rails are typically bundled with steel straps or wire rope to ensure they do not move or get damaged during transportation. This helps maintain the shape and integrity of the rails.

Timber braces: Timber braces are often added to the ends of the rails to prevent bundling from damaging the track and to provide additional support and protection.

Identification: The specifications, model, production date and other information of the rail are usually marked on the package to facilitate identification and management.

In addition, the packaging and transportation of rails also need to comply with relevant international transportation standards and safety regulations to ensure that they are not damaged during transportation and can be safely transported to the destination.

SITE CONSTRUCTION

Site preparation: including cleaning the construction area, determining track laying lines, preparing construction equipment and materials, etc.

Laying the track base: The base is laid on the determined track line, usually using gravel or concrete as the track base.

Install the track support: Install the track support on the track base to ensure that the support is flat and stable.

Laying the track: Place the national standard steel rail on the track support, adjust and fix it, and ensure that the track is straight and level.

Welding and connection: Weld and connect the rails to ensure the continuity and stability of the rails.

Adjustment and inspection: Adjust and inspect the laid rails to ensure that the rails meet national standards and safety requirements.

Fixing and installation of fixtures: Fix the rails and install rail fixtures to ensure the stability and safety of the rails.

Laying track slabs and switches: Laying and installing track slabs and switches on the track as needed.

Acceptance and testing: Acceptance and testing of the laid track to ensure the quality and safety of the track.

FAQ

1.How can I get a quotation from you ?

You can leave us message, and we will reply every message in time.

2.Will you delivery the goods on time?

Yes,we promise to provide best quality products and delivery on time. Honesty is our company's tenet.

3.Can I get samples before order ?

Yes, of course. Usually our samples are free,we can produce by your samples or technical drawings.

4.What is your payment terms?

Our usual payment term is 30% deposit, and rest against B/L. EXW, FOB,CFR, CIF.

5.Do you accept the third party inspection?

Yes absolutely we accept.

6.How do we trust your company?

We specialise in steel business for years as golden supplier, headquarter locates in Tianjin province, welcome to investigate in any ways, by all means.