High Grade FRP Cold U Sheet Piling Prices for Retaining Wall

PRODUCT PRODUCTION PROCESS

The production process of cold-formed U-shaped steel sheet piles usually includes the following steps:

Raw material preparation: Prepare the raw materials for U-shaped steel sheet piles, usually hot-rolled steel plates or cold-rolled steel plates.

Plate rolling: The raw steel plate is fed into the plate rolling machine for plate rolling processing to shape it into a U-shaped cross section.

Cold bending: The rolled steel plate is cold-bent, and the steel plate is formed by a cold bending machine or bending machine to make it a U-shaped cross-section.

Cutting: Use cutting equipment to cut the sheet piles to the appropriate size based on the required length.

Welding (if necessary): Perform the necessary welding process on cold-formed U-shaped steel sheet piles to ensure that the connection is firm and meets relevant standards.

Surface treatment: Surface treatment is performed on the finished product, such as rust removal, painting, etc., to improve the anti-corrosion performance of the product.

Inspection and Quality Control: Inspection of finished products to ensure they meet the requirements of relevant standards and specifications.

Packaging and Shipping: Pack the finished product and arrange for shipping to the customer or job site.

These steps may vary according to different production processes and equipment, but are usually the basic steps of the production process of cold-formed U-shaped steel sheet piles.

|

Product Name

|

|

|

Steel Grade

|

S275,S355,S390,S430,SY295,SY390,ASTM A690

|

|

Production standard

|

EN10248,EN10249,JIS5528,JIS5523,ASTM

|

|

Delivery time

|

One week,80000 tons in stock

|

|

Certificates

|

ISO9001,ISO14001,ISO18001,CE FPC

|

|

Dimensions

|

Any dimensions,any width x height x thickness

|

|

Length

|

Single length up to over 80m

|

1. We can produce all types of sheet piles,pipe piles and accessories,we can adjust our machines to produce in any width x height x thickness .

2. We can produce single length up to over 100m,and we can do all painting,cutting,welding etc fabrications in factory .

3. Fully internationally certified:ISO9001,ISO14001,ISO18001,CE,SGS,BV etc..

*Send the email to chinaroyalsteel@163.com to get a quotation for your projects

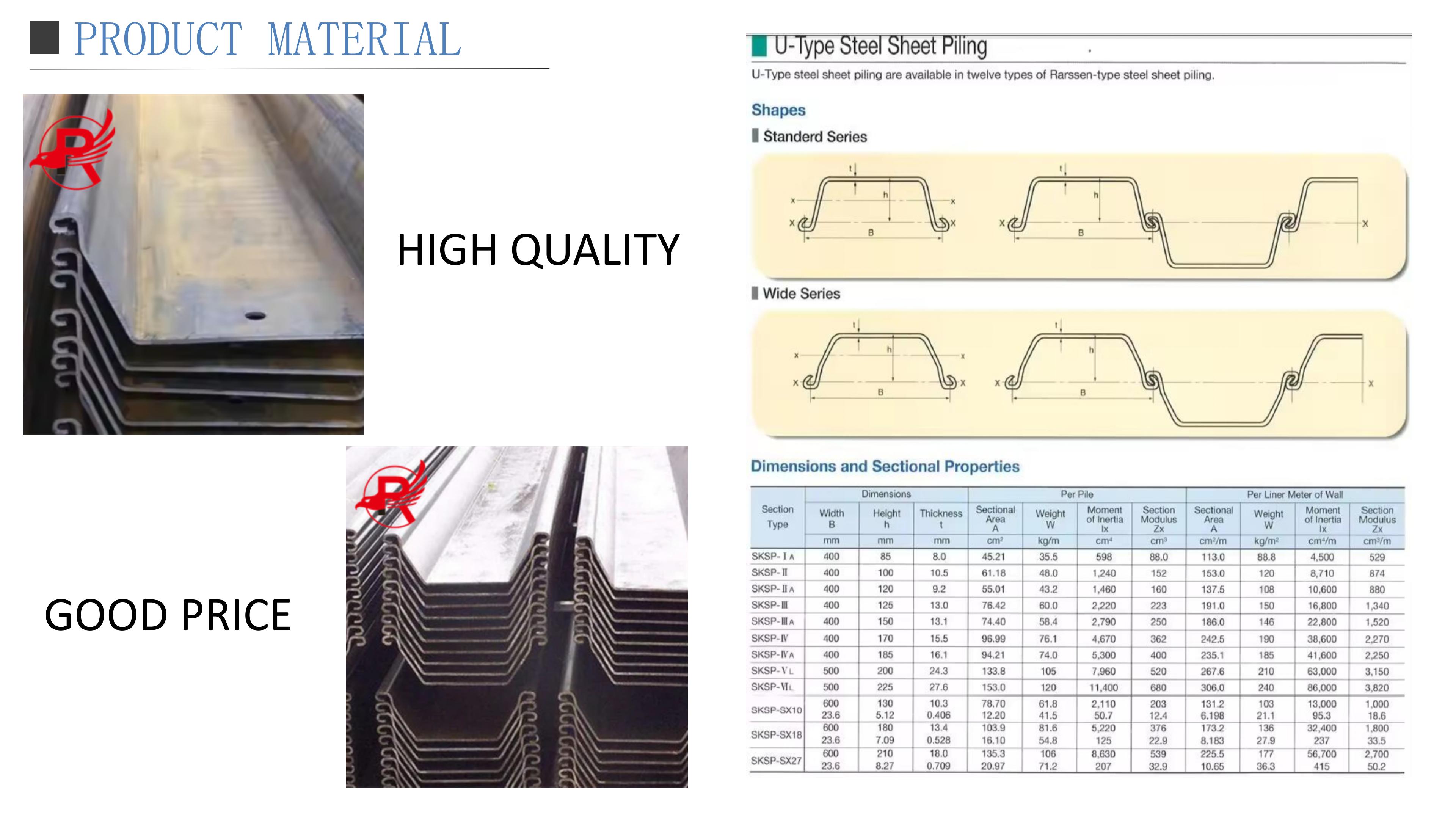

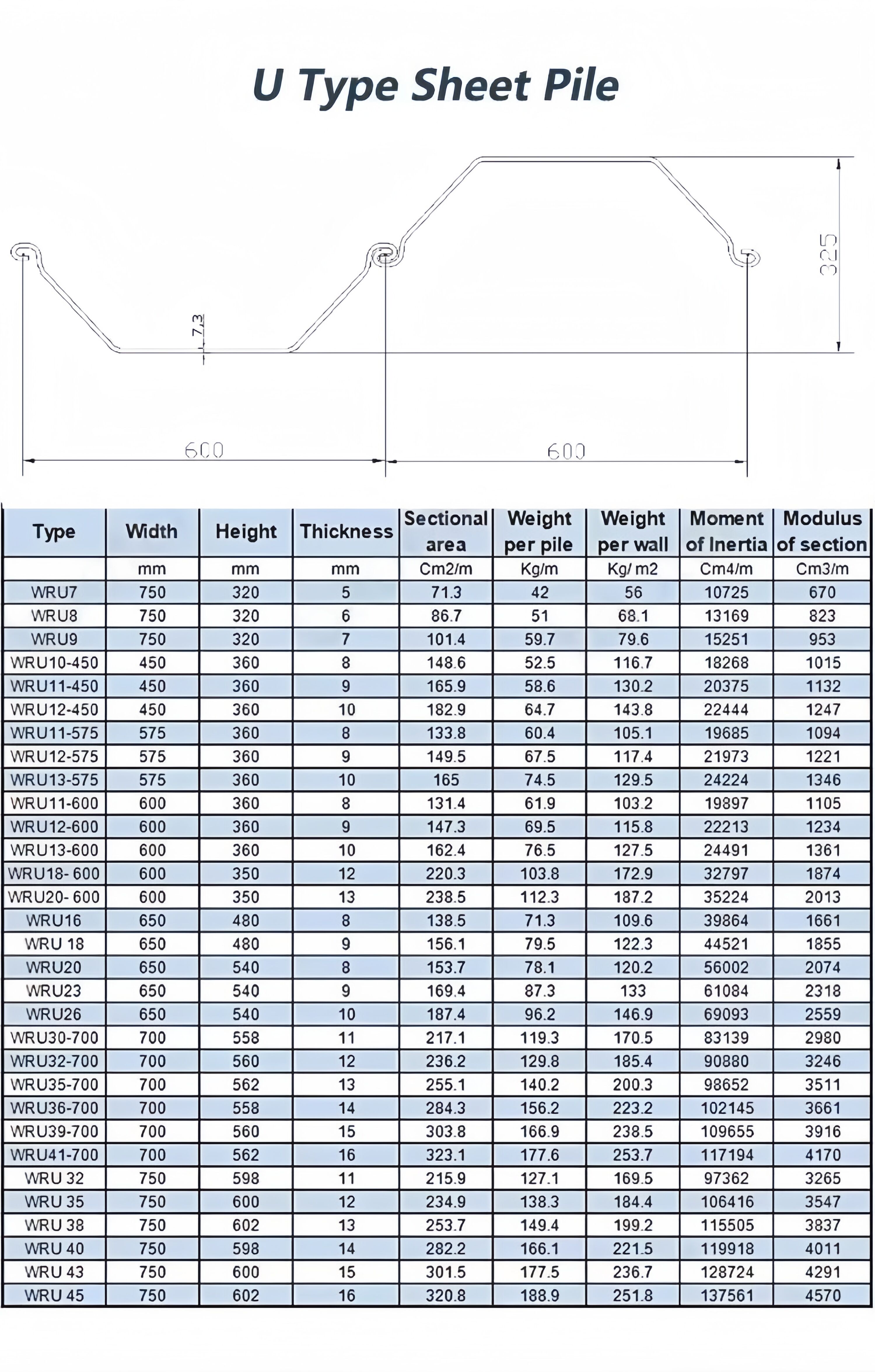

Section Modulus Range

1100-5000cm3/m

Width Range (single)

580-800mm

Thickness Range

5-16mm

Production Standards

BS EN 10249 Part 1 & 2

Steel Grades

SY295, SY390 & S355GP for Type II to Type VIL

S240GP, S275GP, S355GP & S390 for VL506A to VL606K

Length

27.0m maximum

Standard Stock Lengths of 6m, 9m, 12m, 15m

Delivery Options

Single or Pairs

Pairs either loose, welded or crimped

Lifting Hole

By container (11.8m or less) or Break Bulk

Corrosion Protection Coatings

FEATURES

Steel sheet piles are made of thinner sheets and processed by cold-forming forming units. Its production cost is lower, the price is cheaper, and the fixed-length control is more flexible. However, due to the crude processing method, the thickness of each part of the pile body is the same, and the cross-sectional size cannot be optimized, resulting in an increase in the amount of steel used; the shape of the locking part is difficult to control, and the joints are not fastened tightly and cannot stop water;

APPLICATION

Restricted by the capacity of cold bending processing equipment, it can only produce products with low steel strength and thin thickness. Moreover, the stress generated during the cold bending process is large, and the pile body is prone to tearing during use, and its application has great limitations. sex. In engineering construction, the application range of Steel sheet piling is relatively narrow, and most of them are only used as supplementary materials.

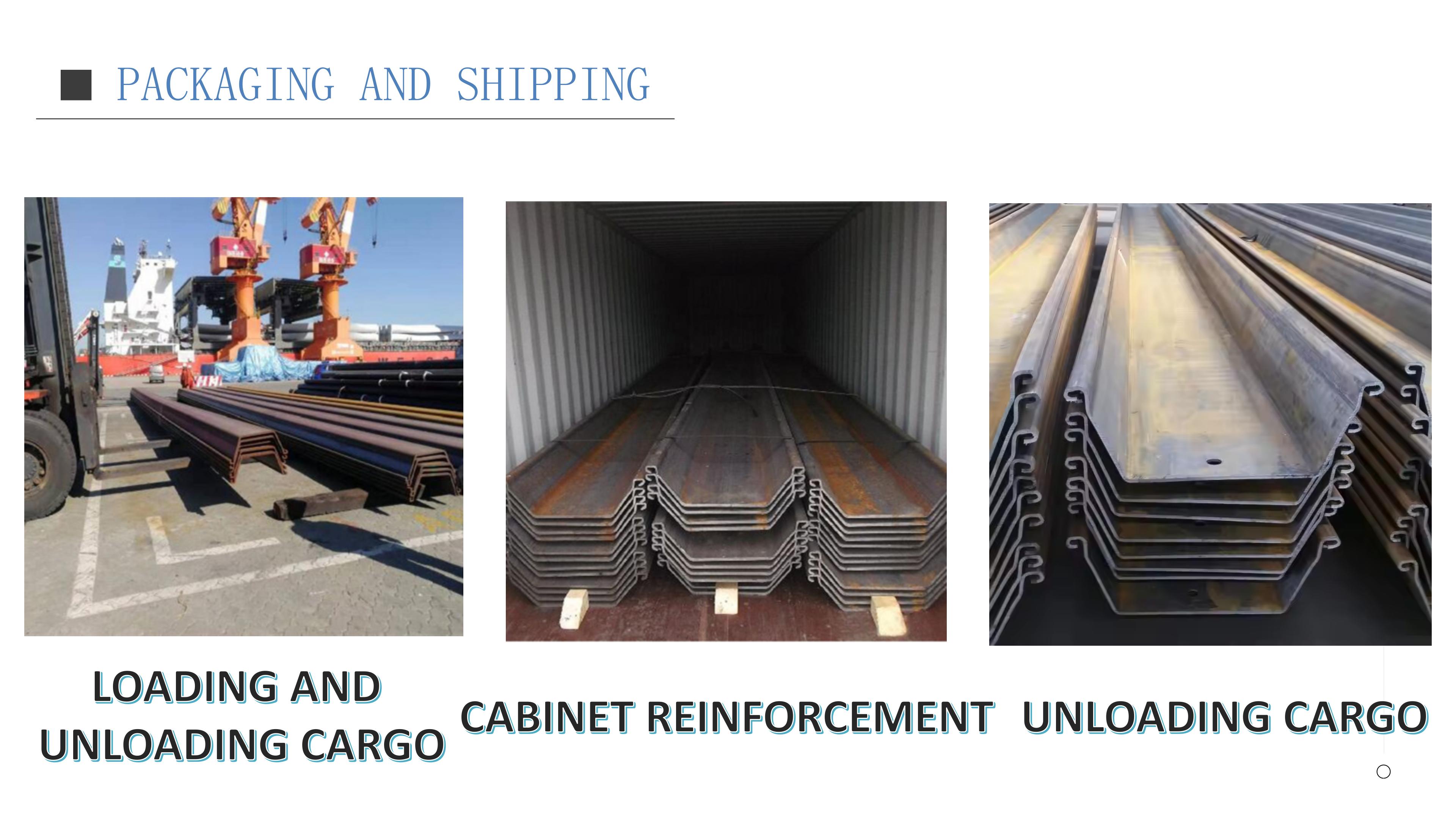

PACKAGING AND SHIPPING

Q235 steel sheet piles transportation, steel sheet pile freight, Larsen steel sheet pile logistics and transportation, steel sheet pile transportation plan, steel sheet pile shipping, Larsen steel sheet pile shipping, Larsen steel sheet pile transportation costs, how to transport Hainan Larsen steel sheet pile, long steel sheet pile transportation , section steel shipping, H-shaped steel shipping, steel sheet pile transportation precautions, Larsen steel sheet pile shipping, transporting steel sheet piles, Larsen steel sheet pile shipping

COMPANY STRENGTH

Made in China, first-class service, cutting-edge quality, world-renowned

1. Scale effect: Our company has a large supply chain and a large steel factory, achieving scale effects in transportation and procurement, and becoming a steel company that integrates production and services

2. Product diversity: Product diversity, any steel you want can be purchased from us, mainly engaged in steel structures, steel rails, steel sheet piles, photovoltaic brackets, channel steel, silicon steel coils and other products, which makes it more flexible Choose the desired product type to meet different needs.

3. Stable supply: Having a more stable production line and supply chain can provide more reliable supply. This is especially important for buyers who require large quantities of steel.

4. Brand influence: Have higher brand influence and larger market

5. Service: A large steel company that integrates customization, transportation and production

6. Price competitiveness: reasonable price

*Send the email to chinaroyalsteel@163.com to get a quotation for your projects

CUSTOMERS VISIT

FAQ

1. How can I get a quotation from you ?

You can leave us message, and we will reply every message in time . Or we may talk on line by WhatsApp . And you can also find our contact information on contact page .

2. Can I get samples before order ?

Yes, of course. Usually our samples are free . we can produce by your samples or technical drawings . We can build the molds and fixtures .

3. What is your delivery time ?

A. The time of delivery is usually around 1 month(1*40FT as usual) ;

B. We can send out in 2 days , if it has stock .

4. What is your payment terms ?

Our usual payment term is 30% deposite, and rest against B/L. L/C is also acceptatble .

5. How can you garantee what I got will be good ?

We are factory with 100% pre-delivery inspection which garantee the quality .

And as golden supplier on Alibaba , Alibaba assurance will make garanteewhich means alibaba will pay your money back in advance , if there is any problem with the products .

6. How do you make our business long-term and good relationship ?

A. We keep good quality and competitive price to ensure our customers benefit ;

B. We respect every customer as our friend and we sincerely do business and make friends with them no matter where they come from