High Frequency Welding Q235H Steel Steel Structure Construction Works Galvanized Section Steel

The steel structure 40x60 Steel Building is characterized by high tensile strength, light net weight, good overall rigidity, and strong deformation ability, so it is particularly suitable for the construction of large-span and very tall and super-heavy buildings.

*Depending on your application, we can design the most economical and durable steel frame system to help you create maximum value for your project.

| Product name: | Steel Building Metal Structure |

| Material : | Q235B ,Q345B |

| Main frame : | H-shape steel beam |

| Purlin : | C,Z - shape steel purlin |

| Roof and wall : | 1.corrugated steel sheet ;

2.rock wool sandwich panels ;

3.EPS sandwich panels ; 4.glass wool sandwich panels |

| Door: | 1.Rolling gate

2.Sliding door

|

| Window: | PVC steel or aluminum alloy |

| Down spout : | Round pvc pipe |

| Application : | All kinds of industrial workshop ,warehouse ,high-rise building |

These characteristics of the steel structure make the steel structure have efficient and economical advantages in the manufacturing and installation process.

*Send the email to [email protected] to get a quotation for your projects

PRODUCT PRODUCTION PROCESS

ADVANTAGE

What are the advantages and disadvantages of Custom Metal Buildings engineering?

1. The material has high strength and light weight

Steel has high strength and high elastic modulus. Compared with concrete and wood, the ratio of its density to yield strength is relatively low. Therefore, under the same stress conditions, the steel structure has a small component section, light weight, easy transportation and installation, and is suitable for large spans, high heights, and heavy loads. Structure.

2. Steel has toughness, good plasticity, uniform material, and high structural reliability.

Suitable to withstand impact and dynamic loads, and has good seismic resistance. The internal structure of steel is uniform and close to isotropic homogeneous body. The actual working performance of the steel structure is relatively consistent with the calculation theory. Therefore, the steel structure has high reliability.

3. Steel structure manufacturing and installation are highly mechanized

Steel structural components are easy to manufacture in factories and assemble on construction sites. The factory's mechanized manufacturing of steel structure components has high precision, high production efficiency, fast construction site assembly, and short construction period. Steel structure is the most industrialized structure.

4. The steel structure has good sealing performance

Since the welded structure can be completely sealed, it can be made into high-pressure vessels, large oil pools, pressure pipelines, etc. with good air tightness and water tightness.

5. Steel structure is heat-resistant but not fire-resistant

When the temperature is below 150°C, the properties of steel change very little. Therefore, the steel structure is suitable for hot workshops

DEPOSIT

Custom Steel Building factory building is a common structural form in modern industrial buildings. Its main feature is that it has high load-bearing capacity and stability, and can meet different building requirements. The components of the steel structure factory building include the following parts:

1.Steel column

Steel columns are the main load-bearing components of steel structure factory buildings, and their role is to bear the weight of the factory building and external loads. Steel columns are generally made of H-shaped steel or I-beam steel, which have high strength, high stiffness and good seismic resistance.

2.Steel beam

Steel beams are the main components connecting steel columns, and their role is to bear the horizontal load and transfer load of the factory building. Steel beams are generally made of H-shaped steel or I-beam, which has good stiffness and stability.

3. Steel column and steel beam connectors

The connection between steel columns and steel beams is a very important part of the steel structure factory building. Its function is to ensure the overall stability and load-bearing capacity of the factory building. Connectors generally use bolted or welded connections, which have good seismic resistance and reliability.

4. Walls and roofs

Walls and roofs are the external coverings of steel structure factories, and their role is to protect the equipment and personnel inside the factory from the external environment. Walls and roofs are generally made of sandwich panels, color steel plates and other materials, which have good thermal insulation and waterproof properties.

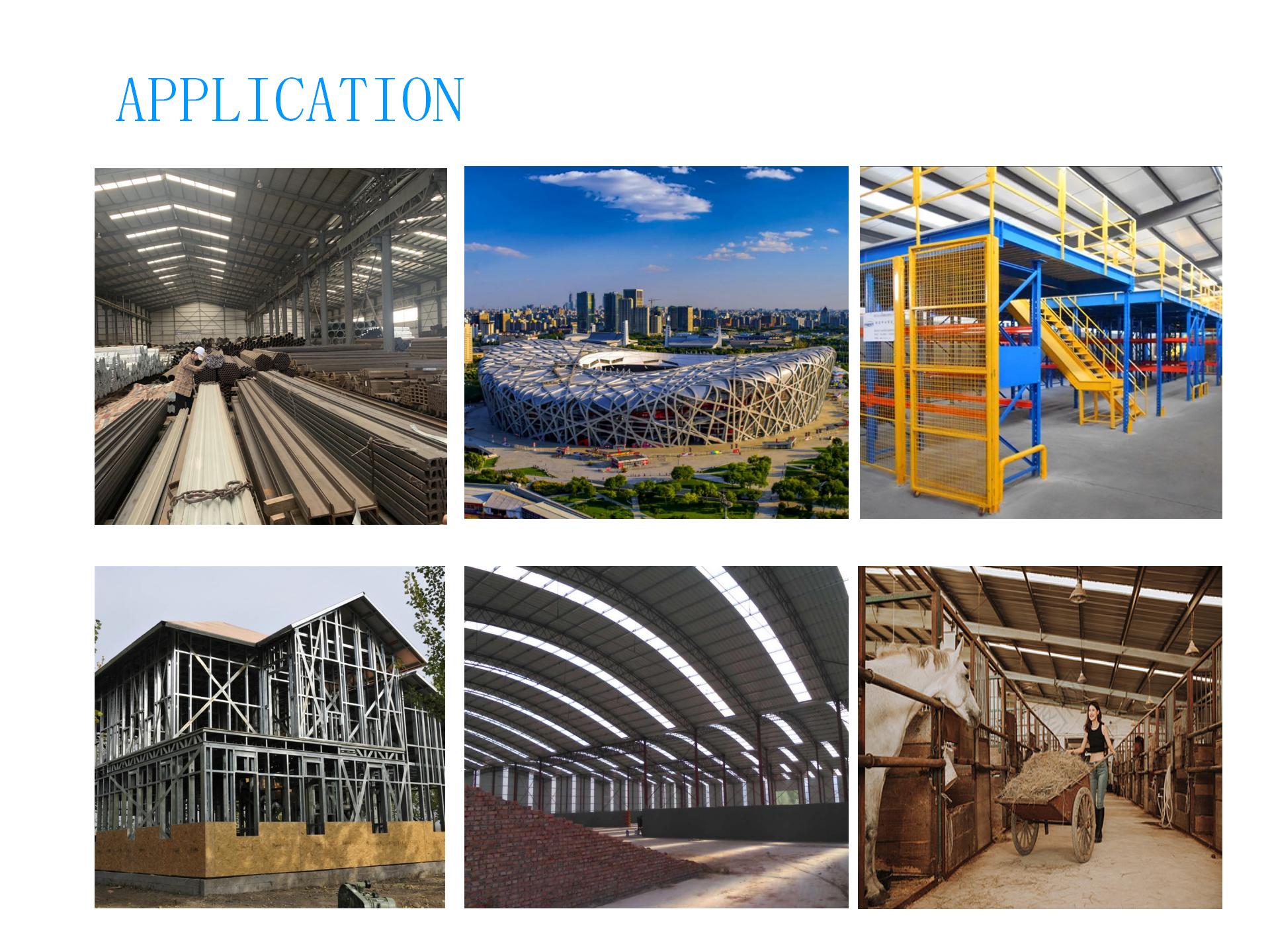

APPLICATION

The Metal Structure Building has good plasticity, good plastic deformation, uniform raw materials, high structural reliability, suitable for bearing destructive driving loads, and has good seismic grade characteristics of buildings. The internal structure of the stainless steel plate is uniform and tends to a variety of homogenized protoplasm.

PROJECT

Our company often exports Steel Building Manufacturers products to the Americas and Southeast Asian countries. We participated in one of the projects in the Americas with a total area of approximately 543,000 square meters and a total use of approximately 20,000 tons of steel. After the project is completed, it will become a steel structure complex integrating production, living, office, education and tourism.

PRODUCT INSPECTION

Steel structure is made of steel beams, steel columns, steel tube trusses and other components made of steel grains and carbon steel plates. The structure of each component or component is welded by electric welding, anchor screws or rivets in the middle.Non-destructive testing refers to the use of sound waves, radiation, electromagnetic and other means to detect steel structures without affecting the performance of the steel structure. Non-destructive testing can effectively detect defects such as cracks, pores, inclusions and other defects inside the steel structure, thereby improving the safety and reliability of the steel structure. Commonly used non-destructive testing methods include ultrasonic testing, radiographic testing, magnetic particle testing, etc.

PACKAGING AND SHIPPING

Steel structures need to be packed during shipping to protect the safety and integrity of the goods and prevent the goods from being damaged and lost during transportation. The following are the basic requirements for steel structure shipping packaging:

1. Packaging materials: Qualified packaging materials must be used for packaging. Including wood, wood boards, steel plates, steel boxes, wooden boxes, wooden pallets, etc., ensure that the packaging materials have sufficient strength and toughness.

2. Packaging fastening: The packaging of steel structures should be fastened and strong, especially large items. They must be installed and fixed on pallets or supports to prevent displacement or shaking during transportation.

3. Smoothness: The appearance of the steel structure must be smooth, and there must be no sharp corners or edges to avoid damaging other goods or endangering the personal safety of workers.

4. Moisture-proof, shock-proof, and wear-resistant: Packaging materials should comply with shipping regulations and be moisture-proof, shock-proof, and wear-resistant. Especially during maritime transportation, attention should be paid to moisture-proof, dehumidification, moisture-proof paper and other treatments to prevent the steel structure from being eroded, rusted, and corroded by seawater.

COMPANY STRENGTH

Made in China, first-class service, cutting-edge quality, world-renowned

1. Scale effect: Our company has a large supply chain and a large steel factory, achieving scale effects in transportation and procurement, and becoming a steel company that integrates production and services

2. Product diversity: Product diversity, any steel you want can be purchased from us, mainly engaged in steel structures, steel rails, steel sheet piles, photovoltaic brackets, channel steel, silicon steel coils and other products, which makes it more flexible Choose the desired product type to meet different needs.

3. Stable supply: Having a more stable production line and supply chain can provide more reliable supply. This is especially important for buyers who require large quantities of steel.

4. Brand influence: Have higher brand influence and larger market

5. Service: A large steel company that integrates customization, transportation and production

6. Price competitiveness: reasonable price

*Send the email to [email protected] to get a quotation for your projects

CUSTOMERS VISIT