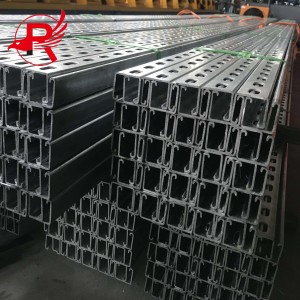

Hot Dip Galvanized Steel Slotted Strut Channel With Ce( C Purlin Unistrut, Uni Strut Channel)

C Channel Structural Steel is a highly sought-after steel product known for its exceptional load-bearing capabilities. Its name originates from its distinctive "C" shape, which provides excellent structural support while minimizing unnecessary weight and material usage. This efficiency allows for cost-effectiveness without compromising strength.

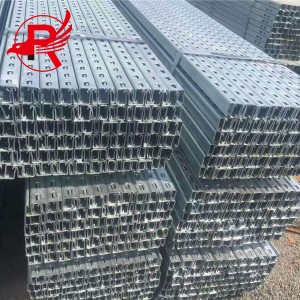

PRODUCT PRODUCTION PROCESS

PRODUCT SIZE

|

Product Size

|

41*21,/41*41 /41*62/41*82mm with slotted or plain1-5/8'' x 1-5/8'' 1-5/8'' x 13/16''/or customized size

length is cut according to customer's requirements U or C shape with standard AISI, ASTM, GB,BS,EN,JIS,DIN or customer's drawings |

|

Product Material and Surface

|

· Material: carbon steel

· Surface coating: o Galvanized o Hot Dipped Galvanizing o Electrolytic Galvanizing o Powder coating o Neomagnal |

|

Corrosion Rating of Hot Dipped Galvanized

|

For example

Indoor:Production premises with high humidity levels and some impurities in the air, such as food industry facilities.

Outdoor:Urban and industrial atmosphere with medium sulphur dioxide levels. Coastal areas with low salinity levels.

Galvanization wear:0,7 μm - 2,1 μm in a year

Indoor:Chemical industry production plants, coastal shipyards and boatyards.

Outdoor:Industrial areas and coastal areas with medium salinity levels.

Galvanization wear:2,1 μm - 4,2 μm in a year

|

| No. | Size | Thickness | Type | Surface

Treatment |

||

| mm | inch | mm | Gauge | |||

| A | 41x21 | 1-5/8x13/16" | 1.0,1.2,1.5,2.0,2.5 | 20,19,17,14,13 | Slotted, Solid | GI,HDG,PC |

| B | 41x25 | 1-5/8x1" | 1.0,1.2,1.5,2.0,2.5 | 20,19,17,14,13 | Slotted, Solid | GI,HDG,PC |

| C | 41x41 | 1-5/8x1-5/8" | 1.0,1.2,1.5,2.0,2.5 | 20,19,17,14,13 | Slotted, Solid | GI,HDG,PC |

| D | 41x62 | 1-5/8x2-7/16" | 1.0,1.2,1.5,2.0,2.5 | 20,19,17,14,13 | Slotted, Solid | GI,HDG,PC |

| E | 41x82 | 1-5/8x3-1/4" | 1.0,1.2,1.5,2.0,2.5 | 20,19,17,14,13 | Slotted, Solid | GI,HDG,PC |

ADVANTAGE

Construction field: In the construction field of subway, high-speed rail, bridge and so on, channel steel is often used to support and strengthen the structure, which plays an important role.

Manufacturing: The production of channel steel has high precision and good surface finish, which is used for the production of machine tools, automation equipment and other parts.

Home furnishing field: channel steel structure is simple, easy to assemble, used to make furniture, shelves, exhibition racks and so on.

PRODUCT INSPECTION

The process of photovoltaic bracket inspection is as follows:

Preparation before testing: Check whether the testing equipment is working properly, check whether there is dirt or damage on the surface of the photovoltaic module, check whether the connecting wire of the photovoltaic module is loose or damaged, and check whether the photovoltaic module bracket is stable.

Communication: Communicate with the party being tested before the test, introduce the project situation, test work arrangements, and determine on-site accompanying personnel.

Test: Perform various tests.

Result reporting: Report the test results to the party being tested. If there are minor non-compliances with the technical specifications, require them to make corrections; if there are serious safety hazards or serious non-compliance with the technical specifications, explain the problem to them and report the results.

PROJECT

Our company has participated in the largest solar energy development project in South America, providing brackets and solution design. We provided 15,000 tons of photovoltaic brackets for this project. The photovoltaic brackets adopted domestic emerging technologies to help the development of the photovoltaic industry in South America and improve local residents. Life. The photovoltaic support project includes a photovoltaic power station with an installed capacity of approximately 6MW and a battery energy storage power station of 5MW/2.5h. It can generate approximately 1,200 kilowatt hours per year. The system has good photoelectric conversion capabilities.

APPLICATION

Applicable scenarios for photovoltaic brackets

1. Roof installation

Photovoltaic brackets can be used on flat roofs, pitched roofs, etc. When selecting photovoltaic brackets, factors such as the size, load-bearing capacity and inclination of the roof need to be considered. For small photovoltaic power stations, small and medium-sized structures that are easy to install and dismantle are generally used.

2. Ground installation

Photovoltaic power stations installed on the ground are generally larger, and photovoltaic supports need to consider the terrain and slope to ensure that the installation structure is firm and meets safety and stability requirements. Ground-mounted photovoltaic power stations allow photovoltaic power stations to meet adjustability and convenience, and to perform repair operations during maintenance.

3. Water surface installation

Surface installation is mainly used in lakes, reservoirs and other water areas. The installation area is large, and the photovoltaic bracket material is required to have strong corrosion resistance and water resistance to cope with the complex water environment.

When it comes to constructing sturdy and reliable structures, the strut C channel has proved to be an invaluable component. Its ingenious design makes it versatile for numerous applications, ensuring the utmost support and durability.

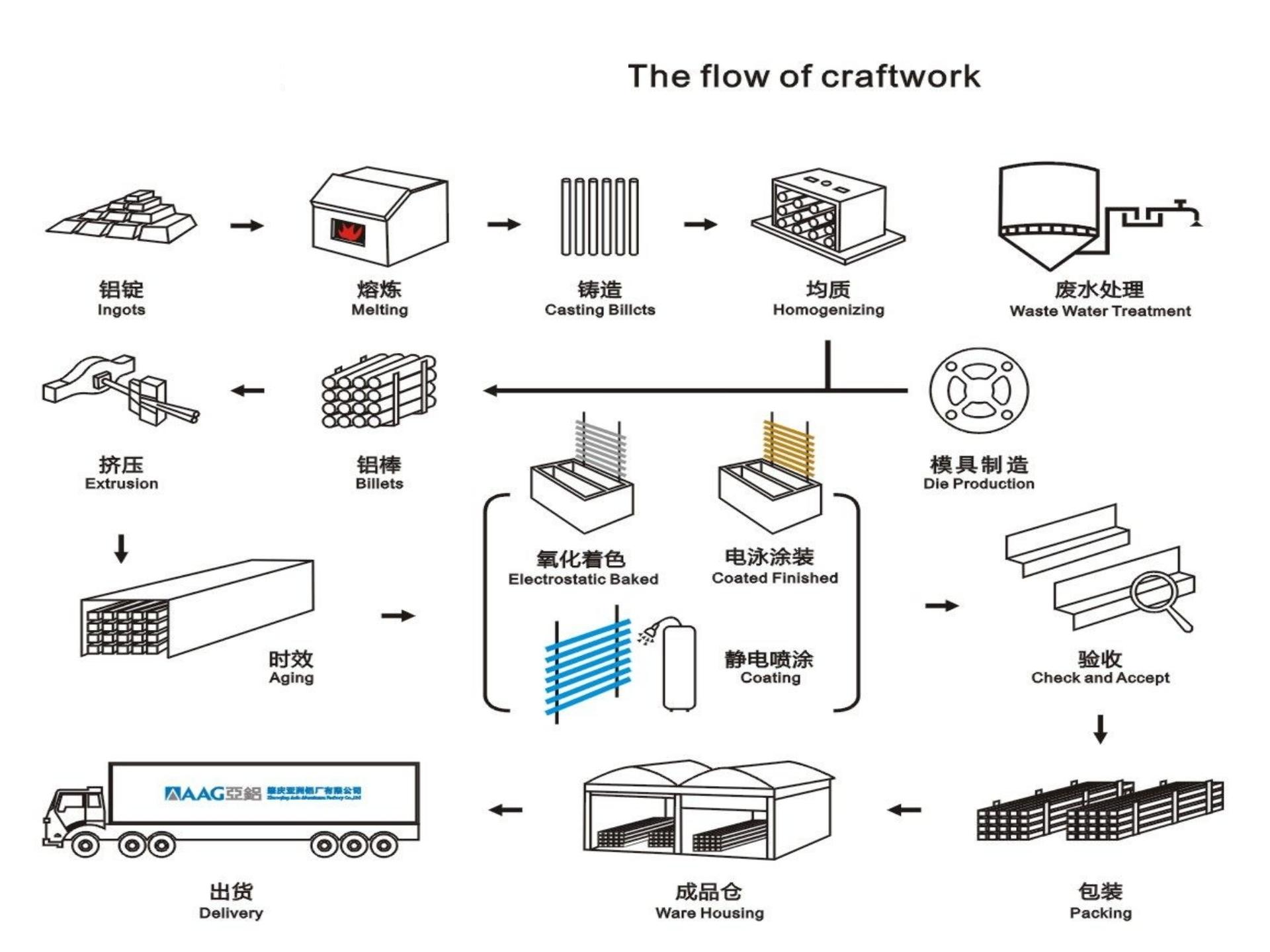

PACKAGING AND SHIPPING

Packaging:

We pack the products in bundles. A bundle of 500-600kg. A small cabinet weighs 19 tons.The outer layer will be wrapped with plastic film.

Shipping:

Choose a suitable mode of transportation: Depending on the quantity and weight of the Strut Channel, select the appropriate mode of transportation, such as flatbed trucks, containers, or ships. Consider factors like distance, time, cost, and any regulatory requirements for transportation.

Use appropriate lifting equipment: To load and unload the Strut Channel, use suitable lifting equipment such as cranes, forklifts, or loaders. Ensure that the equipment used has sufficient capacity to handle the weight of the sheet piles safely.

Secure the load: Properly secure the packaged stack of Strut Channel on the transportation vehicle using strapping, bracing, or other suitable means to prevent shifting, sliding, or falling during transit.

|

Package

|

Standard export seaworthy package,suit for all kinds of transport, or as required.

Water-proof Paper + Edge protection + Wooden Pallets

|

|

Loading Port

|

Tianjin, Xingang Port, Qingdao,Shanghai, Ningbo, or any China Seaport

|

|

Container

|

1*20ft container load Max. 25 Ton, Max. length 5.8m

1*40ft container load Max. 25 Ton, Max. Length 11.8m

|

|

Delivery Time

|

7-15 days or according to the order's quantity

|

COMPANY STRENGTH

Made in China, first-class service, cutting-edge quality, world-renowned

1. Scale effect: Our company has a large supply chain and a large steel factory, achieving scale effects in transportation and procurement, and becoming a steel company that integrates production and services

2. Product diversity: Product diversity, any steel you want can be purchased from us, mainly engaged in steel structures, steel rails, steel sheet piles, photovoltaic brackets, channel steel, silicon steel coils and other products, which makes it more flexible Choose the desired product type to meet different needs.

3. Stable supply: Having a more stable production line and supply chain can provide more reliable supply. This is especially important for buyers who require large quantities of steel.

4. Brand influence: Have higher brand influence and larger market

5. Service: A large steel company that integrates customization, transportation and production

6. Price competitiveness: reasonable price

*Send the email to chinaroyalsteel@163.com to get a quotation for your projects

CUSTOMERS VISIT

FAQ

1. Why choose your company?

Because we are factory directly, So the price is lower. Delivery time can be ensured.

2.Where is your factory located? How can I visit there?

Our factory is located in the center of Tianjin, China, About 1 hours bus ride from Tianjin port. So it's really convenient for you to come to our company. We are here warmly welcome you.

3.What type of payment do you have available?

TT and L/C, As to sample order West union will be also acceptable.

4.How can I get some samples?

We are honored to offer you samples.

5.How does your factory do regarding quality control?

Each products need be inspected before into the wherehouse. Our boss and all SAIYANG staff had pay highly attention of the quality.

6. How can I get a quotation?

Because all our products are OEM products. This means customized products. In order to send you an accurate quotation, the following information will be needed: Materials and thickness, Size, Surface treatment, order quantity, Drawings will be highly appreciated. Then I will send you an accurate quotation.