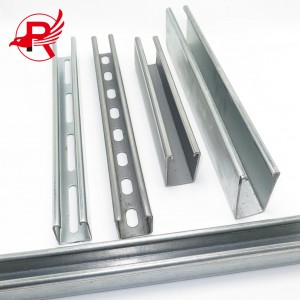

Galvanized Steel Zam310 S350GD Unistrut 41 X 21mm Light Duty Slotted Channel

C Channel Structural Steel, specifically Custom Mild Steel C Channel, offer an array of advantages in the construction industry. Their strength, cost-effectiveness, and ease of installation make them an ideal choice for various applications. Furthermore, the galvanized coating enhances their durability and safeguards them against corrosion. With such versatile features, galvanized C Purlins have rightfully earned their place as reliable building solutions in modern construction practices.

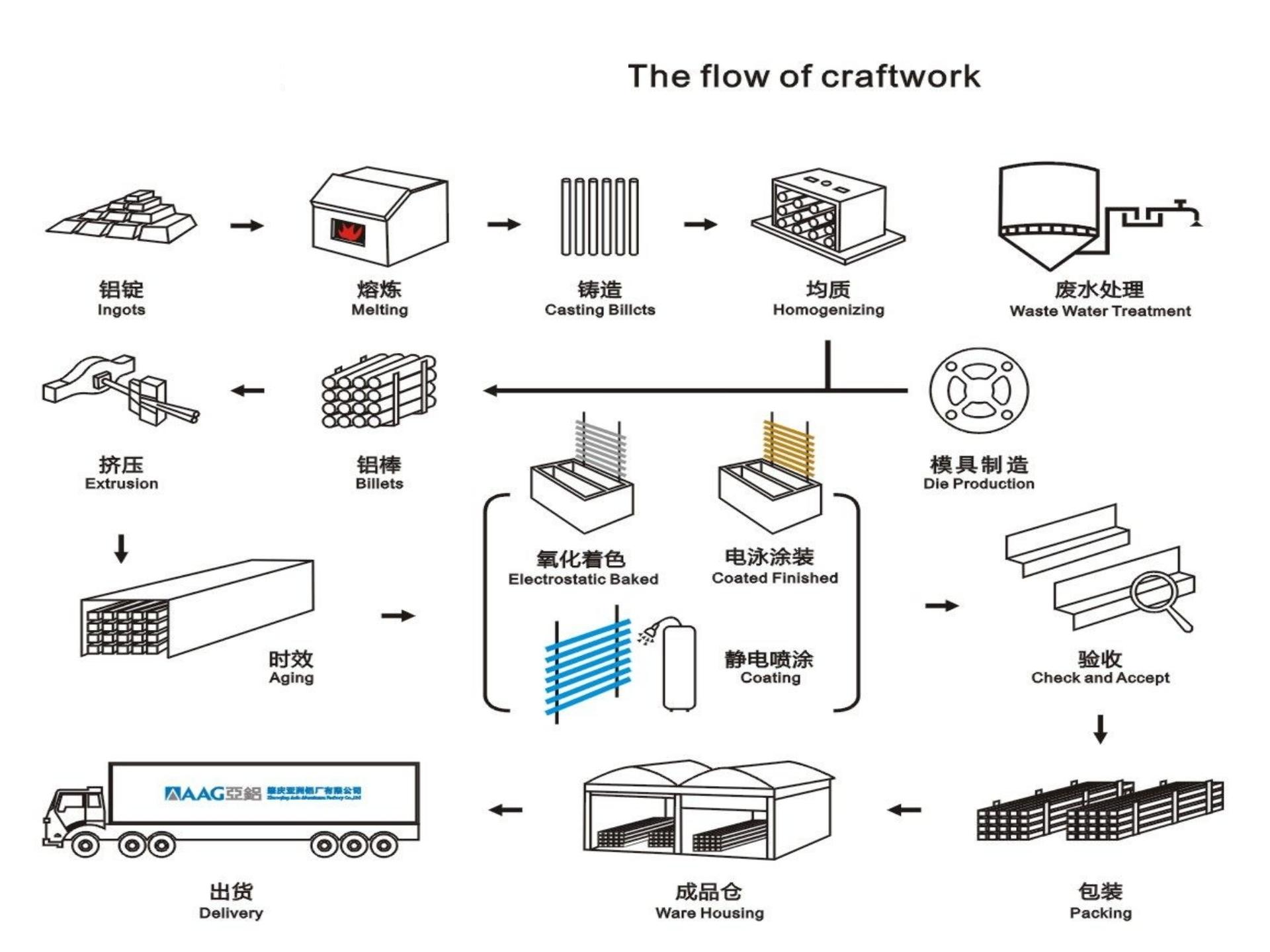

PRODUCT PRODUCTION PROCESS

PRODUCT SIZE

|

Material

|

Q195/Q235/SS304/SS316/

|

|

Thickness

|

1.5mm/1.9mm/2.0mm/2.5mm/2.7mm12GA/14GA/16GA/0.079''/0.098''

|

|

Cross Section

|

41*21,/41*41 /41*62/41*82mm with slotted or plain1-5/8'' x 1-5/8'' 1-5/8'' x 13/16''

|

|

Standard

|

GB/DIN/ANSI/JIS/ISO

|

|

Length

|

2m/3m/6m/customized10ft/19ft/customized

|

|

Packing

|

50~100pcs wapped by plastic bag

|

|

Finished

|

1. Pre-galvanized steel

2. HDG(Hot dip galvanized)

3. Stainless steel SS304 4. Stainless steel SS316 5. Aluminium 6. Powder Coated |

| No. | Size | Thickness | Type | Surface

Treatment |

||

| mm | inch | mm | Gauge | |||

| A | 41x21 | 1-5/8x13/16" | 1.0,1.2,1.5,2.0,2.5 | 20,19,17,14,13 | Slotted, Solid | GI,HDG,PC |

| B | 41x25 | 1-5/8x1" | 1.0,1.2,1.5,2.0,2.5 | 20,19,17,14,13 | Slotted, Solid | GI,HDG,PC |

| C | 41x41 | 1-5/8x1-5/8" | 1.0,1.2,1.5,2.0,2.5 | 20,19,17,14,13 | Slotted, Solid | GI,HDG,PC |

| D | 41x62 | 1-5/8x2-7/16" | 1.0,1.2,1.5,2.0,2.5 | 20,19,17,14,13 | Slotted, Solid | GI,HDG,PC |

| E | 41x82 | 1-5/8x3-1/4" | 1.0,1.2,1.5,2.0,2.5 | 20,19,17,14,13 | Slotted, Solid | GI,HDG,PC |

ADVANTAGE

Advantages of Custom Roof C Channel Product

1. Strong adaptability

Due to different climate conditions and terrain in different regions, photovoltaic brackets need to have strong adaptability, and installation methods and materials can be selected according to different situations.

2. High economy

The use of photovoltaic brackets effectively improves the power generation efficiency of the photovoltaic system, speeds up electricity bill recovery, and helps companies reduce costs and improve efficiency.

3. Strong reliability

Through scientific design, photovoltaic brackets can withstand the test of natural disasters such as harsh weather environments and strong winds and rains, and have high reliability and stability.

PRODUCT INSPECTION

The testing standards are based on the following six aspects:

1. Material testing items for photovoltaic brackets mainly include steel and hardware materials, aluminum alloy materials, lightning protection grounding equipment, exotic metal materials, etc.

2. Galvanized C Channel Product appearance inspection items mainly include steel surface, aluminum alloy material appearance and other items.

3. Photovoltaic support dimensional deviation detection items mainly include components such as columns, beams, and frames.

4. Photovoltaic bracket wall thickness detection items mainly include steel plate wall thickness, aluminum alloy wall thickness and other items.

5. The photovoltaic bracket mechanical performance testing items mainly include the slenderness ratio limit of the tensile and compressive components of the bracket, the deflection and column top displacement of the components under constant load, wind load, snow load and earthquake load.

6. Photovoltaic bracket corrosion performance testing items mainly include anti-corrosion measures for carbon structural steel and low-alloy high-strength structural steel, surface treatment of aluminum alloy profiles, etc.

PROJECT

Our company Slotted C Channel Supplier has participated in the largest solar energy development project in South America, providing brackets and solution design. We provided 15,000 tons of photovoltaic brackets for this project. The photovoltaic brackets adopted domestic emerging technologies to help the development of the photovoltaic industry in South America and improve local residents. Life. The photovoltaic support project includes a photovoltaic power station with an installed capacity of approximately 6MW and a battery energy storage power station of 5MW/2.5h. It can generate approximately 1,200 kilowatt hours per year. The system has good photoelectric conversion capabilities.

APPLICATION

Applications of Galvanized C Purlins:

1. Industrial Buildings: Galvanized C Purlins are extensively used in the construction of industrial buildings, such as factories, warehouses, and manufacturing units. Their robustness and dimensional stability ensure the structural integrity required in such demanding environments.

2. Agricultural Structures: The agricultural sector also benefits from the use of Slotted C Channel Suppliers They provide ample support for roofing systems in barns, storage sheds, and livestock shelters. The corrosion resistance of the galvanized coating ensures that these structures can withstand harsh weather conditions.

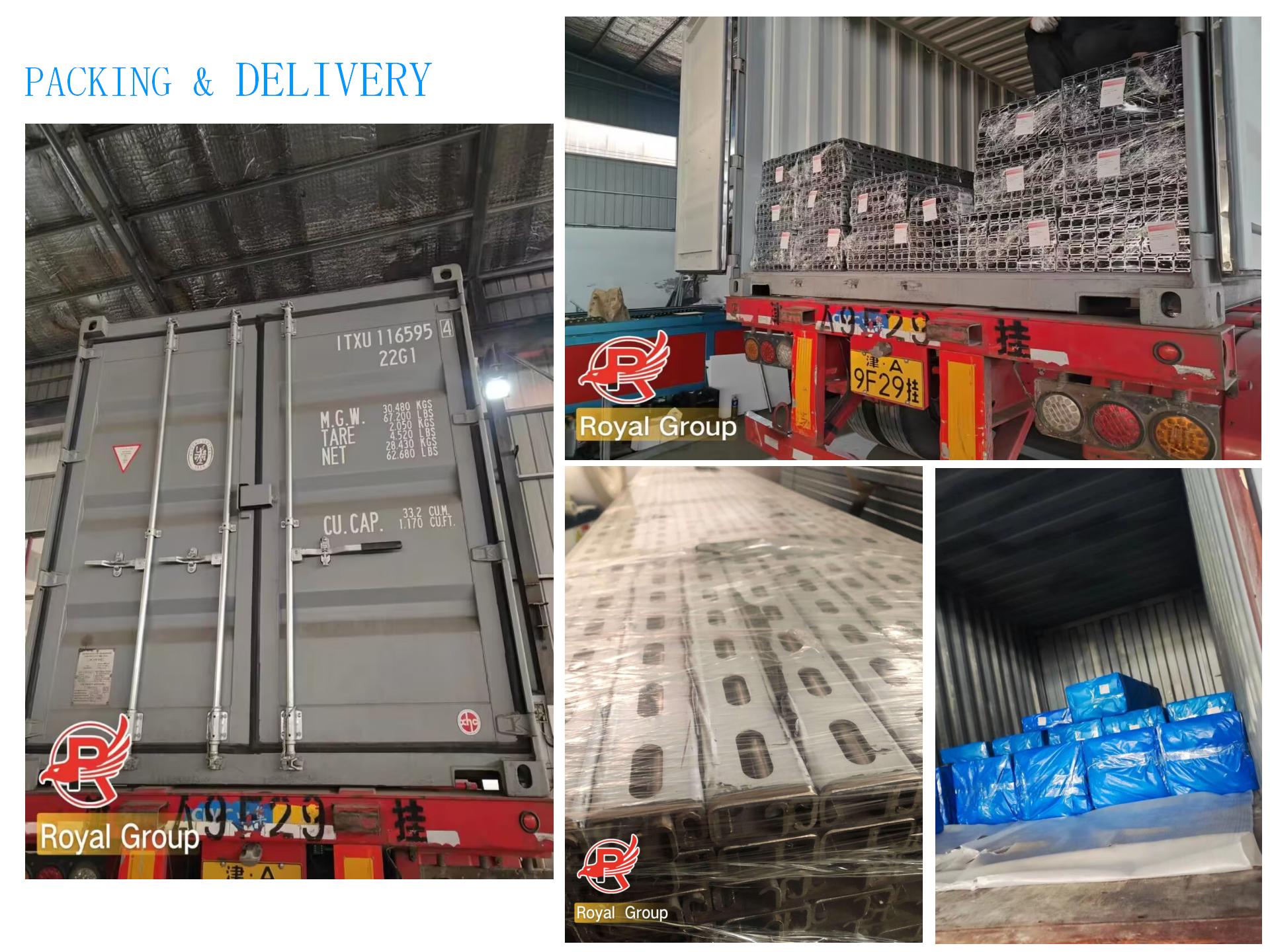

PACKAGING AND SHIPPING

Packaging:

We pack the products in bundles. A bundle of 500-600kg. A small cabinet weighs 19 tons.The outer layer will be wrapped with plastic film.

Shipping:

Choose a suitable mode of transportation: Depending on the quantity and weight of the Strut Channel, select the appropriate mode of transportation, such as flatbed trucks, containers, or ships. Consider factors like distance, time, cost, and any regulatory requirements for transportation.

Use appropriate lifting equipment: To load and unload the Strut Channel, use suitable lifting equipment such as cranes, forklifts, or loaders. Ensure that the equipment used has sufficient capacity to handle the weight of the sheet piles safely.

Secure the load: Properly secure the packaged stack of Strut Channel on the transportation vehicle using strapping, bracing, or other suitable means to prevent shifting, sliding, or falling during transit.

COMPANY STRENGTH

Made in China, first-class service, cutting-edge quality, world-renowned

1. Scale effect: Our company has a large supply chain and a large steel factory, achieving scale effects in transportation and procurement, and becoming a steel company that integrates production and services

2. Product diversity: Product diversity, any steel you want can be purchased from us, mainly engaged in steel structures, steel rails, steel sheet piles, photovoltaic brackets, channel steel, silicon steel coils and other products, which makes it more flexible Choose the desired product type to meet different needs.

3. Stable supply: Having a more stable production line and supply chain can provide more reliable supply. This is especially important for buyers who require large quantities of steel.

4. Brand influence: Have higher brand influence and larger market

5. Service: A large steel company that integrates customization, transportation and production

6. Price competitiveness: reasonable price

*Send the email to chinaroyalsteel@163.com to get a quotation for your projects

CUSTOMERS VISIT

FAQ

1. who are we?

We are based in Tianjin, China, start from 2012,sell to Southeast Asia(20.00%),South Asia(20.00%),Southern Europe(10.00%),Western Europe(10.00%),Africa(10.00%),North America(25.00%),South America(5.00%). There are total about 51-100 people in our office.

2. how can we guarantee quality?

Always a pre-production sample before mass production;

Always final Inspection before shipment;

3.what can you buy from us?

Steel Pipes,Iron Angles,Iron Beams,Welded Steel Structures,Perforated Steel Products

4. why should you buy from us not from other suppliers?

High quality; Competitive price; Short delivery time; Satisfied service; Manufactured according to different standards

5. what services can we provide?

Accepted Delivery Terms: FOB,CFR,CIF;

Accepted Payment Currency:USD,CNY;

Accepted Payment Type: T/T,L/C;

Language Spoken:English,Chinese