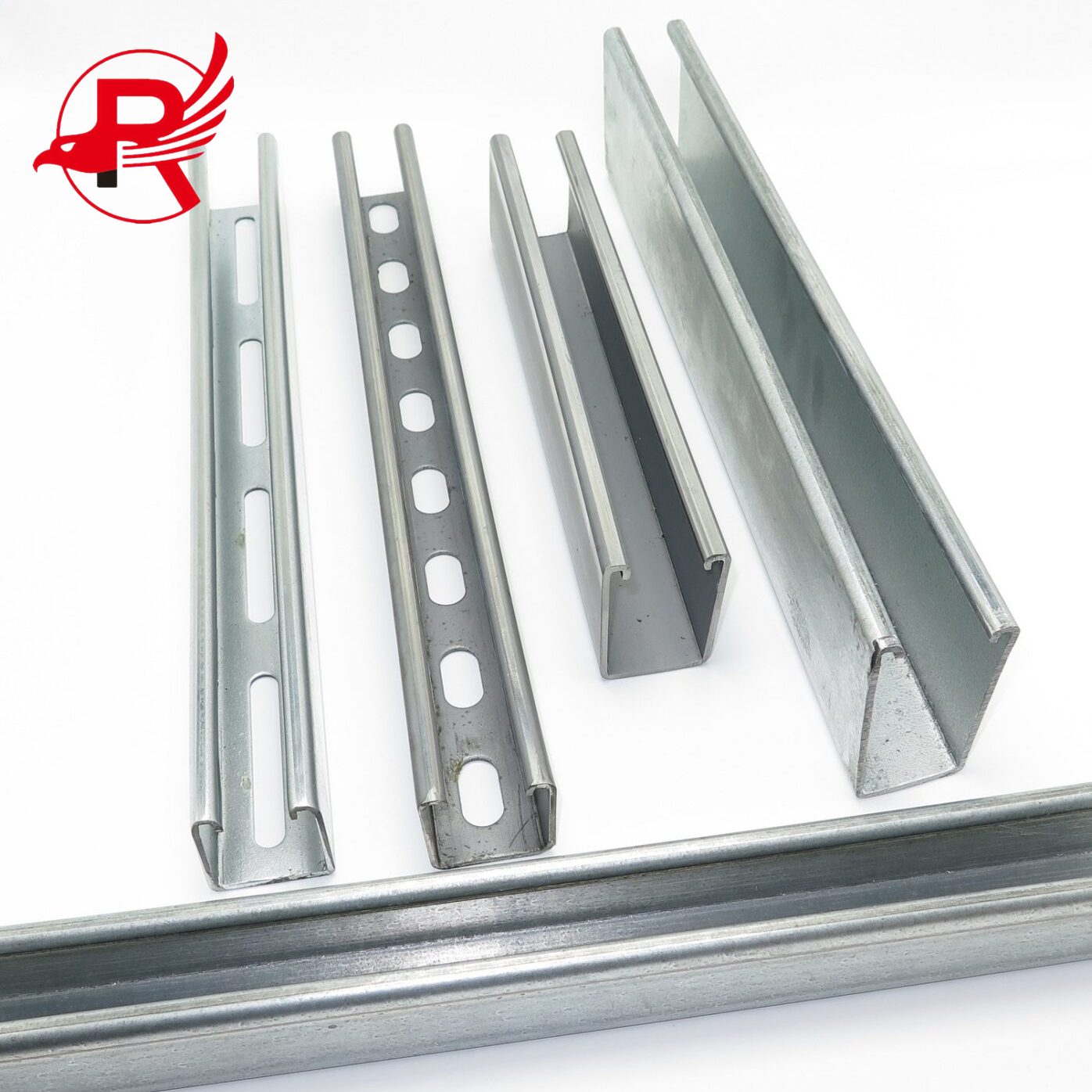

41 X 21mm Lightweight Trough Single Frame Construction

C Channel Structural Steel can be divided into fixed, adjustable and automatic tracking. The fixed bracket is fixed on the foundation by means of embedded parts, etc., which is suitable for installation needs of different angles; The adjustable bracket can adapt to different installation environments by adjusting the Angle and position of the bracket; The automatic tracking bracket can automatically adjust the Angle according to the position of the sun to improve power generation efficiency.

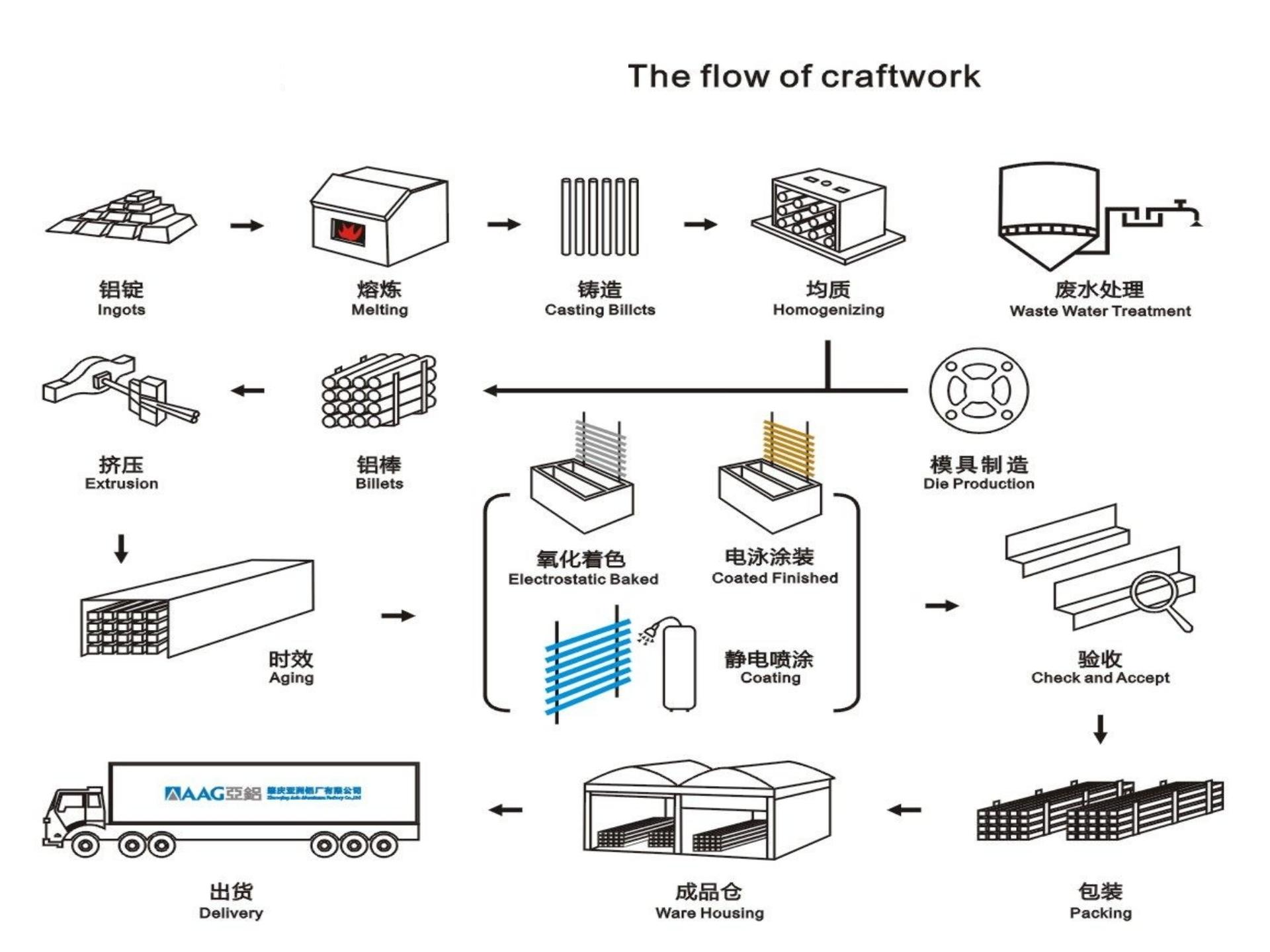

PRODUCT PRODUCTION PROCESS

PRODUCT SIZE

|

Material

|

Q195/Q235/SS304/SS316/Aluminum

|

|

Thickness

|

1.5mm/1.9mm/2.0mm/2.5mm/2.7mm12GA/14GA/16GA/0.079''/0.098''

|

|

Cross Section

|

41*21,/41*41 /41*62/41*82mm with slotted or plain1-5/8'' x 1-5/8'' 1-5/8'' x 13/16''

|

|

Standard

|

DIN/ANSI/JIS/ISO

|

|

Length

|

2m/3m/6m/customized10ft/19ft/customized

|

|

Packing

|

50~100pcs wapped by plastic bag

|

|

Finished

|

1. Pre-galvanized steel

2. HDG(Hot dip galvanized)

3. Stainless steel SS304 4. Stainless steel SS316 5. Aluminium 6. Powder Coated |

| No. | Size | Thickness | Type | Surface

Treatment |

||

| mm | inch | mm | Gauge | |||

| A | 41x21 | 1-5/8x13/16" | 1.0,1.2,1.5,2.0,2.5 | 20,19,17,14,13 | Slotted, Solid | GI,HDG,PC |

| B | 41x25 | 1-5/8x1" | 1.0,1.2,1.5,2.0,2.5 | 20,19,17,14,13 | Slotted, Solid | GI,HDG,PC |

| C | 41x41 | 1-5/8x1-5/8" | 1.0,1.2,1.5,2.0,2.5 | 20,19,17,14,13 | Slotted, Solid | GI,HDG,PC |

| D | 41x62 | 1-5/8x2-7/16" | 1.0,1.2,1.5,2.0,2.5 | 20,19,17,14,13 | Slotted, Solid | GI,HDG,PC |

| E | 41x82 | 1-5/8x3-1/4" | 1.0,1.2,1.5,2.0,2.5 | 20,19,17,14,13 | Slotted, Solid | GI,HDG,PC |

ADVANTAGE

Strut channel play an important role in the field of solar power generation. It can not only ensure the normal operation of solar photovoltaic panels, but also improve the power generation efficiency and reliability of photovoltaic systems. With the rapid development of the solar industry, the demand for photovoltaic brackets is also increasing. In order to meet market demand, various types and specifications of photovoltaic bracket products have also emerged. At the same time, the combination of some emerging technologies and photovoltaic brackets is also being explored and developed, such as intelligent tracking systems and multi-axis brackets, which can automatically adjust and optimize according to the sun's position and light intensity to further improve the power generation efficiency of photovoltaic systems.

PRODUCT INSPECTION

Outdoor C-Shaped Steel Purlins safety testing and appraisal include structural bearing capacity testing, connection quality testing, wind resistance testing, earthquake resistance testing, material quality testing, anti-corrosion performance testing and electrical safety testing to ensure the safety of photovoltaic equipment during use. and stability. For equipment with potential safety hazards, timely measures need to be taken to repair or replace them.

PROJECT

Our company has participated in the largest solar energy development project in South America, providing brackets and solution design. We provided 15,000 tons of photovoltaic brackets for this project. The photovoltaic brackets adopted domestic emerging technologies to help the development of the photovoltaic industry in South America and improve local residents. Life. The photovoltaic support project includes a photovoltaic power station with an installed capacity of approximately 6MW and a battery energy storage power station of 5MW/2.5h. It can generate approximately 1,200 kilowatt hours per year. The system has good photoelectric conversion capabilities.

APPLICATION

C-Shaped Steel Purlins is a vital equipment in the solar photovoltaic system, it not only plays the role of supporting and fixing solar photovoltaic panels, but also improves the power generation efficiency and reliability of the photovoltaic system. The proper design and selection of photovoltaic brackets is crucial to the successful implementation of photovoltaic power generation projects. In the future, with the further development of the solar industry and technological innovation, photovoltaic brackets will continue to play an important role, and continue to pursue higher efficiency, stability and sustainability.

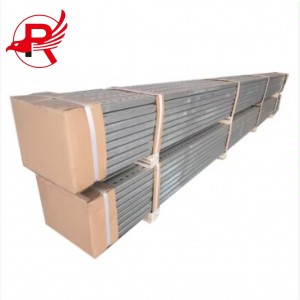

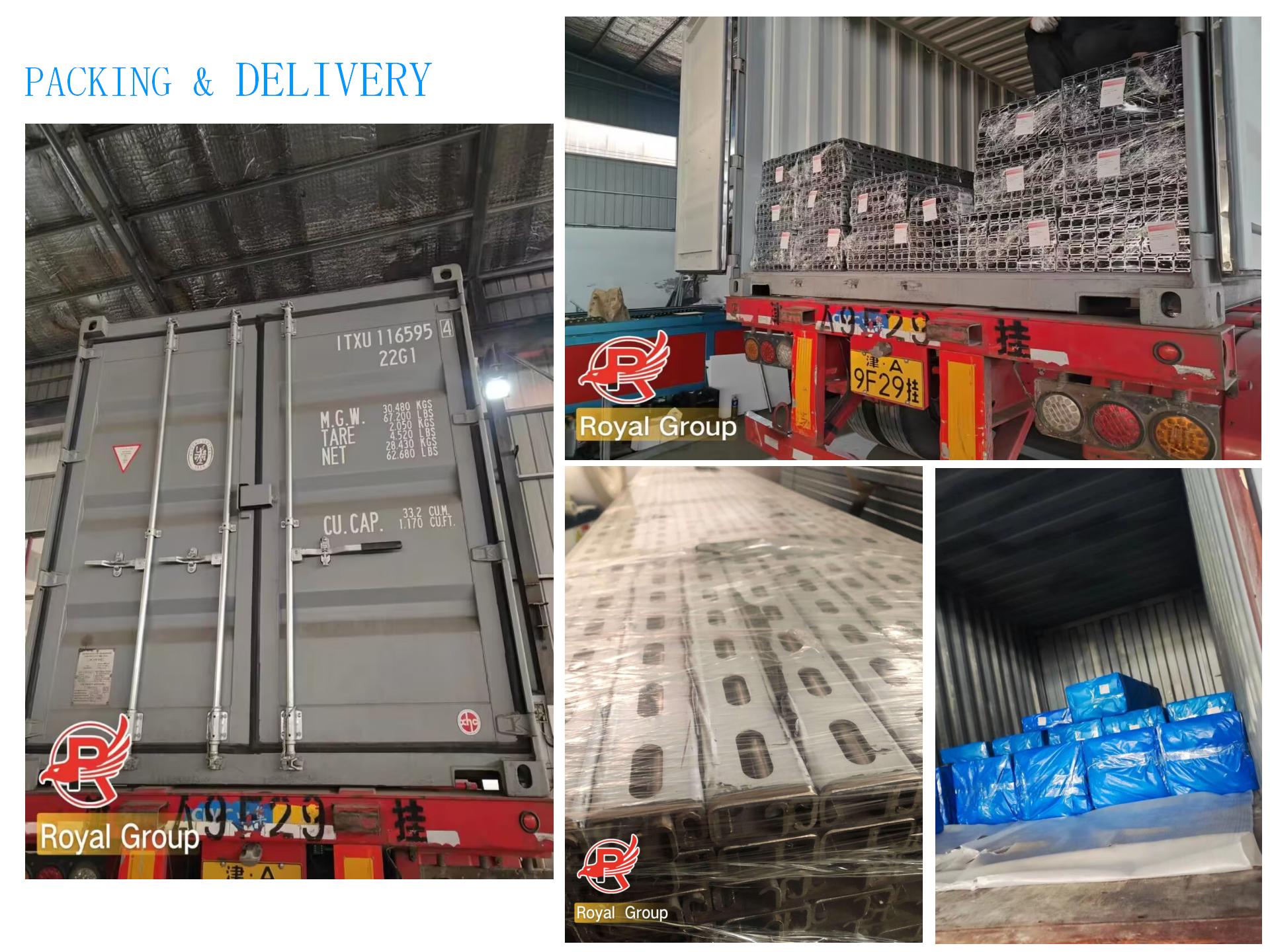

PACKAGING AND SHIPPING

The Galvanized Strut Channel can be packed in a box, exposed, and there are three packaging methods:

1. Box: When the transport conditions are poor or the environmental impact is large, the photovoltaic bracket should be packed, and if there are bulk accessories in the box, the accessories and the box should be packed to avoid collision damage;

2. Exposed: In the process of transportation or storage protection requirements are not high, and does not affect the quality of the photovoltaic bracket, can be used in the open;

3. Because the customer's requirements are not high, it can be wrapped with cloth or other materials on the photovoltaic bracket. After the local photovoltaic bracket is damaged, it can be packaged.

It should be noted that the photovoltaic bracket, no matter what kind of packaging is used, must be packaged in accordance with the customer's specific design, relevant technical documents and relevant requirements.

COMPANY STRENGTH

Made in China, first-class service, cutting-edge quality, world-renowned

1. Scale effect: Our company has a large supply chain and a large steel factory, achieving scale effects in transportation and procurement, and becoming a steel company that integrates production and services

2. Product diversity: Product diversity, any steel you want can be purchased from us, mainly engaged in steel structures, steel rails, steel sheet piles, photovoltaic brackets, channel steel, silicon steel coils and other products, which makes it more flexible Choose the desired product type to meet different needs.

3. Stable supply: Having a more stable production line and supply chain can provide more reliable supply. This is especially important for buyers who require large quantities of steel.

4. Brand influence: Have higher brand influence and larger market

5. Service: A large steel company that integrates customization, transportation and production

6. Price competitiveness: reasonable price

*Send the email to chinaroyalsteel@163.com to get a quotation for your projects

CUSTOMERS VISIT

FAQ

1. who are we?

We are based in Tianjin, China, start from 2012,sell to Southeast Asia(20.00%),South Asia(20.00%),Southern Europe(10.00%),Western Europe(10.00%),Africa(10.00%),North America(25.00%),South America(5.00%). There are total about 51-100 people in our office.

2. how can we guarantee quality?

Always a pre-production sample before mass production;

Always final Inspection before shipment;

3.what can you buy from us?

Steel Pipes,Iron Angles,Iron Beams,Welded Steel Structures,Perforated Steel Products

4. why should you buy from us not from other suppliers?

High quality; Competitive price; Short delivery time; Satisfied service; Manufactured according to different standards

5. what services can we provide?

Accepted Delivery Terms: FOB,CFR,CIF;

Accepted Payment Currency:USD,CNY;

Accepted Payment Type: T/T,L/C;

Language Spoken:English,Chinese