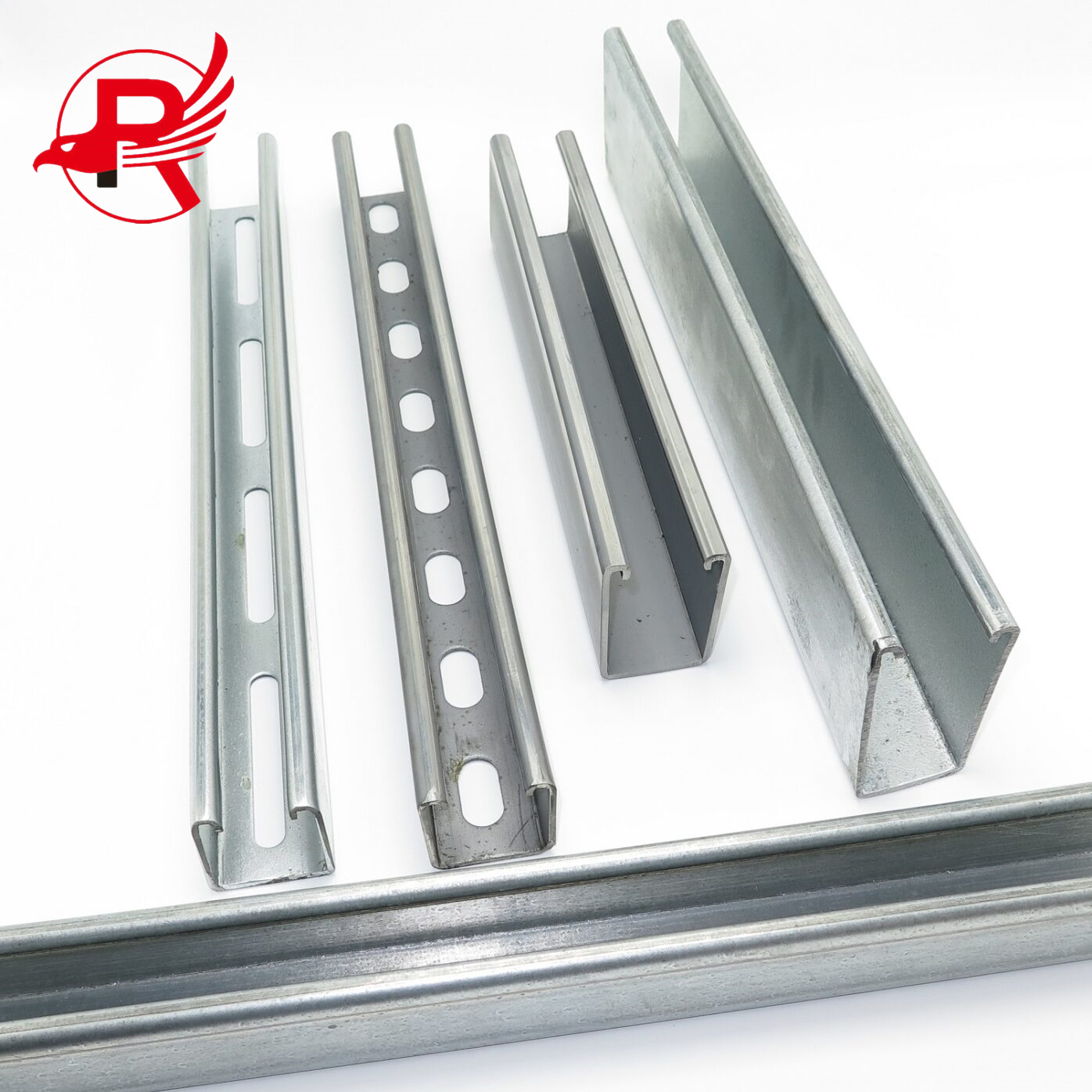

Galvanized Channels Solid And Slotted Channel Black 41×41 Slotted Steel Unistrut Channel

C Channel Structural Steel, specifically Strut C Channel Products, offer an array of advantages in the construction industry. Their strength, cost-effectiveness, and ease of installation make them an ideal choice for various applications. Furthermore, the galvanized coating enhances their durability and safeguards them against corrosion. With such versatile features, galvanized C Purlins have rightfully earned their place as reliable building solutions in modern construction practices.

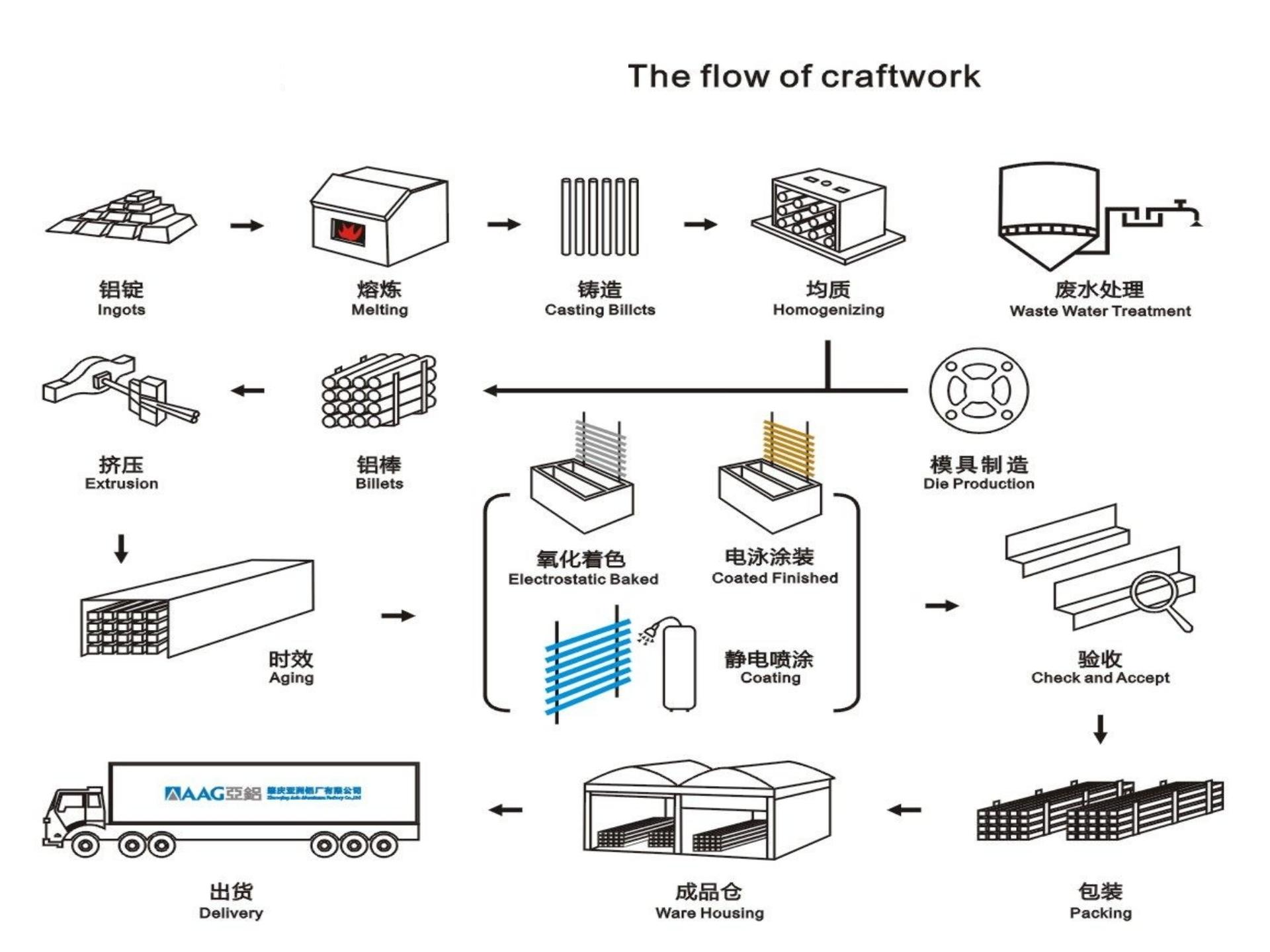

PRODUCT PRODUCTION PROCESS

PRODUCT SIZE

|

Material

|

Q195/Q235/SS304/SS316/

|

|

Thickness

|

1.5mm/1.9mm/2.0mm/2.5mm/2.7mm12GA/14GA/16GA/0.079''/0.098''

|

|

Cross Section

|

41*21,/41*41 /41*62/41*82mm with slotted or plain1-5/8'' x 1-5/8'' 1-5/8'' x 13/16''

|

|

Standard

|

GB/DIN/ANSI/JIS/ISO

|

|

Length

|

2m/3m/6m/customized10ft/19ft/customized

|

|

Packing

|

50~100pcs wapped by plastic bag

|

|

Finished

|

1. Pre-galvanized steel

2. HDG(Hot dip galvanized)

3. Stainless steel SS304 4. Stainless steel SS316 5. Aluminium 6. Powder Coated |

| No. | Size | Thickness | Type | Surface

Treatment |

||

| mm | inch | mm | Gauge | |||

| A | 41x21 | 1-5/8x13/16" | 1.0,1.2,1.5,2.0,2.5 | 20,19,17,14,13 | Slotted, Solid | GI,HDG,PC |

| B | 41x25 | 1-5/8x1" | 1.0,1.2,1.5,2.0,2.5 | 20,19,17,14,13 | Slotted, Solid | GI,HDG,PC |

| C | 41x41 | 1-5/8x1-5/8" | 1.0,1.2,1.5,2.0,2.5 | 20,19,17,14,13 | Slotted, Solid | GI,HDG,PC |

| D | 41x62 | 1-5/8x2-7/16" | 1.0,1.2,1.5,2.0,2.5 | 20,19,17,14,13 | Slotted, Solid | GI,HDG,PC |

| E | 41x82 | 1-5/8x3-1/4" | 1.0,1.2,1.5,2.0,2.5 | 20,19,17,14,13 | Slotted, Solid | GI,HDG,PC |

ADVANTAGE

Advantage

1. Improve photovoltaic power generation efficiency

The absorption efficiency of photovoltaic modules is related to its tilt angle and orientation. Through appropriate bracket design, the tilt angle and orientation of the Slotted C Channel can be optimized, thereby maximizing the absorption of solar energy and improving photovoltaic power generation efficiency.

2. Extend the life of photovoltaic modules

The function of the bracket is to protect the Galvanized Strut Channel to withstand 30 years of damage from sunlight, corrosion, strong winds, etc. Photovoltaic modules are installed on brackets to avoid direct contact with the ground or other unstable foundations, thereby reducing shaking and looseness caused by natural factors such as wind and rain, and ensuring the stability of photovoltaic modules. Photovoltaic brackets can place photovoltaic modules in a position that is easier to maintain, making cleaning, inspection and replacement easier, thus extending the service life of photovoltaic modules. Photovoltaic brackets can also prevent photovoltaic modules from being hit by external forces, reducing mechanical damage, thereby extending the service life of photovoltaic modules.

3. Convenient maintenance and management

Since the photovoltaic bracket can arrange the photovoltaic modules more regularly, it can be more convenient for maintenance and management. If something breaks down or needs to be serviced, technicians can find the problem faster and make removal and replacement easier.

4. Save land space

By combining photovoltaic modules and fishing rafts, the ocean space is utilized to the maximum extent without occupying additional land resources. Setting up photovoltaic modules at sea can avoid problems such as land reclamation and environmental damage caused by land-based photovoltaic power plants, and at the same time reduce the impact of human activities at sea on marine ecology.

5. Environmental protection and energy saving

Photovoltaic brackets are usually made of renewable materials and are environmentally friendly and energy-saving. And photovoltaic modules can directly generate electricity by converting solar energy, without requiring any fuel, producing no pollutants, and having no negative impact on the environment.

PRODUCT INSPECTION

1. Galvanized C Channel inspection: Prepare inspection equipment and tools, formulate inspection plans and inspection standards, and conduct visual inspection of photovoltaic brackets.

2. Inspection of size and geometry: Use professional measuring instruments to measure and inspect the size and shape of the photovoltaic bracket.

3. Inspection of connecting parts and welding quality: Use tensile tester, hardness tester and other testing equipment to inspect the connecting parts and welding quality.

4. Inspection of surface quality and coating: Visually inspect the coating, and test the surface quality using measuring equipment such as a finish meter and thickness meter.

5. Inspection of load-bearing capacity and stability: Use load testing equipment to test the load-bearing capacity and stability of the photovoltaic bracket under various conditions.

PROJECT

Our company Strut C Channel Supplier has participated in the largest solar energy development project in South America, providing brackets and solution design. We provided 15,000 tons of photovoltaic brackets for this project. The photovoltaic brackets adopted domestic emerging technologies to help the development of the photovoltaic industry in South America and improve local residents. Life. The photovoltaic support project includes a photovoltaic power station with an installed capacity of approximately 6MW and a battery energy storage power station of 5MW/2.5h. It can generate approximately 1,200 kilowatt hours per year. The system has good photoelectric conversion capabilities.

APPLICATION

Applicable scenarios for photovoltaic brackets

1. Roof installation

Photovoltaic brackets can be used on flat roofs, pitched roofs, etc. When selecting photovoltaic brackets, factors such as the size, load-bearing capacity and inclination of the roof need to be considered. For small photovoltaic power stations, small and medium-sized structures that are easy to install and dismantle are generally used.

2. Ground installation

Photovoltaic power stations installed on the ground are generally larger, and photovoltaic supports need to consider the terrain and slope to ensure that the installation structure is firm and meets safety and stability requirements. Ground-mounted photovoltaic power stations allow photovoltaic power stations to meet adjustability and convenience, and to perform repair operations during maintenance.

3. Water surface installation

Surface installation is mainly used in lakes, reservoirs and other water areas. The installation area is large, and the photovoltaic bracket material is required to have strong corrosion resistance and water resistance to cope with the complex water environment.

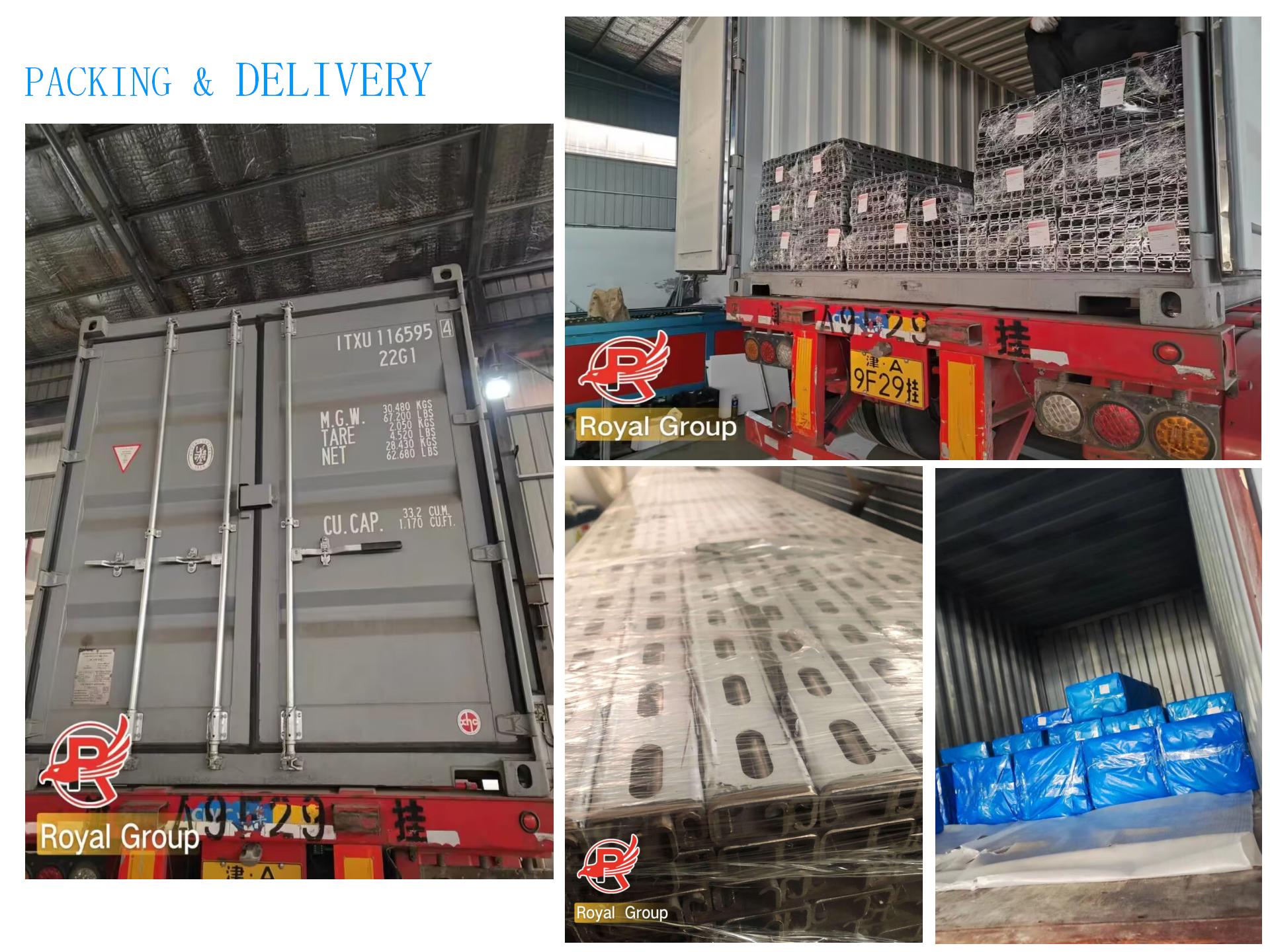

PACKAGING AND SHIPPING

A complete set of photovoltaic brackets includes materials of different specifications and shapes such as keels, columns, diagonal braces, connectors, and hardware accessories. In order to save logistics costs and ensure the safety of material transportation, Jugao New Energy provides customers with a complete and cost-effective photovoltaic bracket packaging solution.

1. Iron frame packaging

For all-steel round pipes and shaped steel materials, such as columns, diagonal braces, U-shaped keels, and polyheight, iron frames are used for packaging. This packaging method has the advantages of stable structure, strong load-bearing capacity, low damage rate, convenient loading and unloading, and long service life. After loading/cabineting, Jugao will also use ropes, straps and other rigging to tie and reinforce the goods to prevent displacement during transportation. Whether it is transported to remote mountainous areas in China, or across the ocean to Japan, the Philippines, Thailand and other Southeast Asian regions, or as far away as South Africa and other places, Jugao's photovoltaic racks are still intact.

2. Wooden frame wooden box packaging

For aluminum profiles, some steel profiles such as aluminum keel round tubes, U-shaped steel, photovoltaic bracket samples, etc., Jugao uses wooden frames and wooden boxes to package them. Wooden packaging materials have low damage rate to materials, good seismic resistance, low transportation costs, and the waste is easier to process. After loading/containing, Jugao will use paper to fill the gaps in the container with aluminum profile goods to prevent the goods from shifting during transportation. All-steel goods are tied and reinforced with ropes, straps and other rigging to prevent the goods from shifting during transportation. Whether it is transported to remote mountainous areas in China, or across the ocean to Japan, the Philippines, Thailand and other Southeast Asian regions, or as far away as South Africa and other places, Jugao's photovoltaic racks are still intact.

3. Carton pallet packaging

The accessories, small components, and hardware in the photovoltaic bracket, such as compression codes, connectors, bolts, etc. are relatively scattered and small. Jugao uses carton packaging for this part of the material and then places it on the pallet. This packaging method has low cost, high protective performance, easy transportation, and easy disposal of waste materials. After loading into the container, Jugao will bundle and reinforce the goods with ropes, straps and other rigging to prevent the goods from shifting during transportation. Whether it is transported to remote mountainous areas in China, or across the ocean to Japan, the Philippines, Thailand and other Southeast Asian regions, or as far away as South Africa and other places, Jugao's photovoltaic racks are still intact.

COMPANY STRENGTH

Made in China, first-class service, cutting-edge quality, world-renowned

1. Scale effect: Our company has a large supply chain and a large steel factory, achieving scale effects in transportation and procurement, and becoming a steel company that integrates production and services

2. Product diversity: Product diversity, any steel you want can be purchased from us, mainly engaged in steel structures, steel rails, steel sheet piles, photovoltaic brackets, channel steel, silicon steel coils and other products, which makes it more flexible Choose the desired product type to meet different needs.

3. Stable supply: Having a more stable production line and supply chain can provide more reliable supply. This is especially important for buyers who require large quantities of steel.

4. Brand influence: Have higher brand influence and larger market

5. Service: A large steel company that integrates customization, transportation and production

6. Price competitiveness: reasonable price

*Send the email to [email protected] to get a quotation for your projects

CUSTOMERS VISIT

FAQ

1. who are we?

We are based in Tianjin, China, start from 2012,sell to Southeast Asia(20.00%),South Asia(20.00%),Southern Europe(10.00%),Western Europe(10.00%),Africa(10.00%),North America(25.00%),South America(5.00%). There are total about 51-100 people in our office.

2. how can we guarantee quality?

Always a pre-production sample before mass production;

Always final Inspection before shipment;

3.what can you buy from us?

Steel Pipes,Iron Angles,Iron Beams,Welded Steel Structures,Perforated Steel Products

4. why should you buy from us not from other suppliers?

High quality; Competitive price; Short delivery time; Satisfied service; Manufactured according to different standards

5. what services can we provide?

Accepted Delivery Terms: FOB,CFR,CIF;

Accepted Payment Currency:USD,CNY;

Accepted Payment Type: T/T;

Language Spoken:English,Chinese