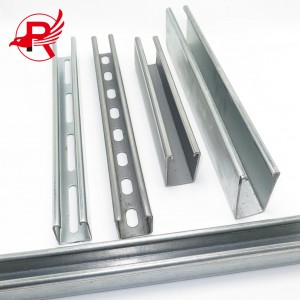

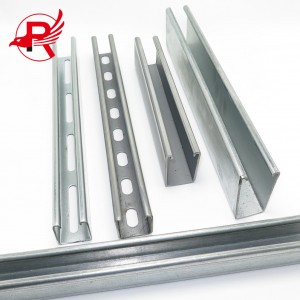

High Quality High Strength Supply Slotted Galvanized Unistrut HDG Gi Strut C Channel Steel

Buy Slotted C Channel Product specifically galvanized C Purlins, bringing a series of advantages to the construction industry.Its high strength, cost-effectiveness, and ease of installation make it an ideal choice for a variety of applications. Furthermore, its galvanized coating enhances its durability and protects against corrosion. With these versatile properties, galvanized C-purlins have earned their place as a reliable building solution in modern construction practices.

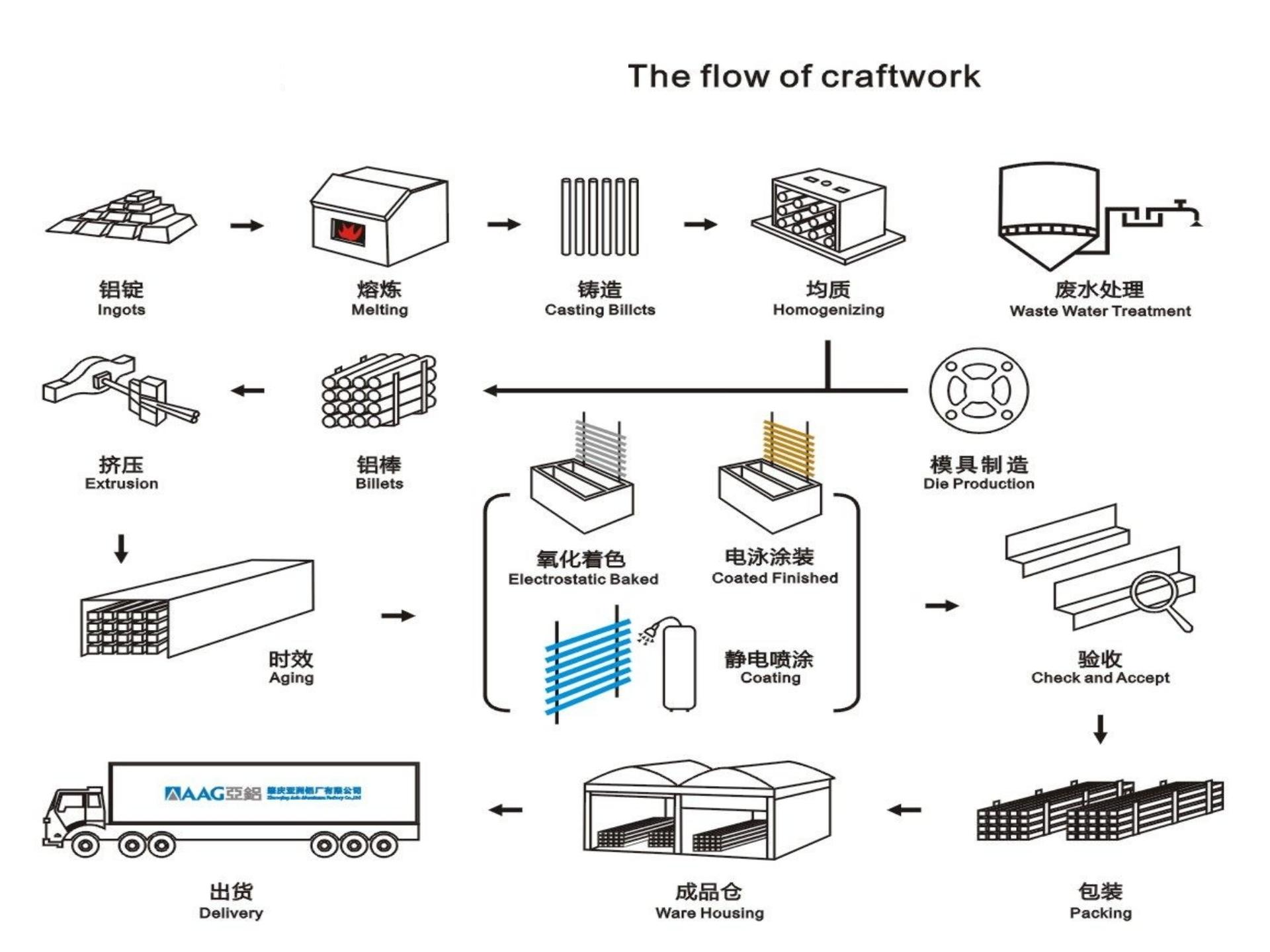

PRODUCT PRODUCTION PROCESS

PRODUCT SIZE

|

Material

|

Q195/Q235/SS304/SS316/

|

|

Thickness

|

1.5mm/1.9mm/2.0mm/2.5mm/2.7mm12GA/14GA/16GA/0.079''/0.098''

|

|

Cross Section

|

41*21,/41*41 /41*62/41*82mm with slotted or plain1-5/8'' x 1-5/8'' 1-5/8'' x 13/16''

|

|

Standard

|

GB/DIN/ANSI/JIS/ISO

|

|

Length

|

2m/3m/6m/customized10ft/19ft/customized

|

|

Packing

|

50~100pcs wapped by plastic bag

|

|

Finished

|

1. Pre-galvanized steel

2. HDG(Hot dip galvanized)

3. Stainless steel SS304 4. Stainless steel SS316 5. Aluminium 6. Powder Coated |

| No. | Size | Thickness | Type | Surface

Treatment |

||

| mm | inch | mm | Gauge | |||

| A | 41x21 | 1-5/8x13/16" | 1.0,1.2,1.5,2.0,2.5 | 20,19,17,14,13 | Slotted, Solid | GI,HDG,PC |

| B | 41x25 | 1-5/8x1" | 1.0,1.2,1.5,2.0,2.5 | 20,19,17,14,13 | Slotted, Solid | GI,HDG,PC |

| C | 41x41 | 1-5/8x1-5/8" | 1.0,1.2,1.5,2.0,2.5 | 20,19,17,14,13 | Slotted, Solid | GI,HDG,PC |

| D | 41x62 | 1-5/8x2-7/16" | 1.0,1.2,1.5,2.0,2.5 | 20,19,17,14,13 | Slotted, Solid | GI,HDG,PC |

| E | 41x82 | 1-5/8x3-1/4" | 1.0,1.2,1.5,2.0,2.5 | 20,19,17,14,13 | Slotted, Solid | GI,HDG,PC |

ADVANTAGE

Advantages of photovoltaic brackets:

1. High Stability: Fixed photovoltaic mounts feature a robust structural design that maintains stability in all weather conditions.

2. Low Maintenance Cost: Fixed photovoltaic mounts have no moving parts, are simple to construct, and are relatively easy to manufacture and install, resulting in relatively low maintenance costs.

3. Wide Applicability: Fixed photovoltaic mounts have low site requirements and are suitable for a variety of locations, including rooftops, ground, and hillsides.

4. Long Service Life

PRODUCT INSPECTION

Photovoltaic mounting systems are the core structural system that supports and secures solar photovoltaic panels. They are primarily composed of connectors, columns, keels, beams, and various auxiliary components, providing the foundation for stable operation. Mounting systems can be categorized by various dimensions: welded and assembled, fixed and truss, and ground-mounted and roof-mounted, adapting to diverse application scenarios.

To ensure the safe and stable operation of photovoltaic power plants, a systematic inspection of photovoltaic mounting systems is required. This includes the following four core inspection areas:

1. Overall Appearance Inspection: This focuses on the integrity of the mounting structure, the quality of welds (e.g., weld bumps, cracks, and cold welds), and the condition of fasteners and anchors. Check for component damage and severe deformation, thereby eliminating potential safety hazards from a visual perspective.

2. Bracket Stability Inspection: Verify the structural stability of the bracket by testing key parameters such as tilt, levelness, and offset. This ensures it maintains a stable operating position even in natural disasters such as heavy rain, strong winds, and heavy snow, or during long-term operation, preventing structural instability from impacting component operation.

3. Load-bearing Capacity Inspection: Compare the actual load borne by the bracket (including component weight, wind and snow loads, etc.) with the designed load-bearing capacity to assess whether the structural load-bearing capacity meets the requirements. This ensures that the load is properly distributed among the bracket components, preventing bracket collapse and safety accidents caused by loads exceeding the designed upper limit.

4. Fastener Condition Inspection: Focus on inspecting fasteners such as plate connection points and bolts to confirm that the connections are free of looseness, burrs, and rust. Loose, damaged, or degraded fasteners should be promptly repaired or replaced to ensure the reliability of the bracket components.

PROJECT

Royal Steel is a China Galvanized Steel C Channel Supplier. As a professional C-channel steel manufacturer, our company is deeply involved in South America's largest solar energy development project. We not only provided 15,000 tons of core photovoltaic racking products, but also provided customized racking solution design services to fully meet the project's construction needs.

The project includes a 6MW photovoltaic power station and a 5MW/2.5h battery energy storage station. Leveraging the emerging domestic technologies used in our photovoltaic racking systems, the system boasts excellent photovoltaic conversion efficiency and is expected to generate approximately 12 million kWh of clean electricity annually. This achievement will not only inject strong momentum into the development of the South American photovoltaic industry but will also improve local residents' electricity access through clean energy supply, contributing to the upgrading of the regional energy structure and improving people's well-being. If you would like to inquire about C-channel steel prices, please send me a WhatsApp or email.

APPLICATION

The main function of the Custom C Channel With Hole is to install photovoltaic modules, which are the core components of the solar power generation system. The bracket can firmly fix the photovoltaic modules so that they will not fall off or be damaged due to vibration or other external forces during operation. In addition, the cables on the photovoltaic modules are also routed through brackets to ensure stable operation of the system.

Another important function of photovoltaic (PV) mounting systems is to adjust the orientation of PV panels for optimal energy collection efficiency. The efficiency of a solar power system is directly related to the angle at which PV panels capture sunlight. Mounting systems ensure that PV panels are always facing the sun, thereby collecting more solar energy.

PV mounting systems must operate in extreme outdoor conditions, such as sunlight, rain, snow, and storms. Mounting systems must be designed with sufficient strength to withstand these natural impacts and ensure reliable operation of the solar power system. Furthermore, PV mounting systems must consider factors such as geological conditions and architectural style. For example, if your location has unstable foundations or you require a more aesthetically pleasing architectural environment, the design and selection of mounting systems require special consideration.

PV mounting systems also protect PV panels from external damage. During major natural disasters such as earthquakes, storms, and floods, mounting systems serve as a critical line of defense for PV panels. Furthermore, mounting systems must protect PV panels from damage by small animals, such as birds, and from contaminants.

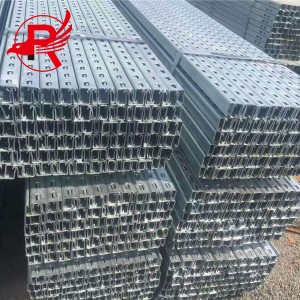

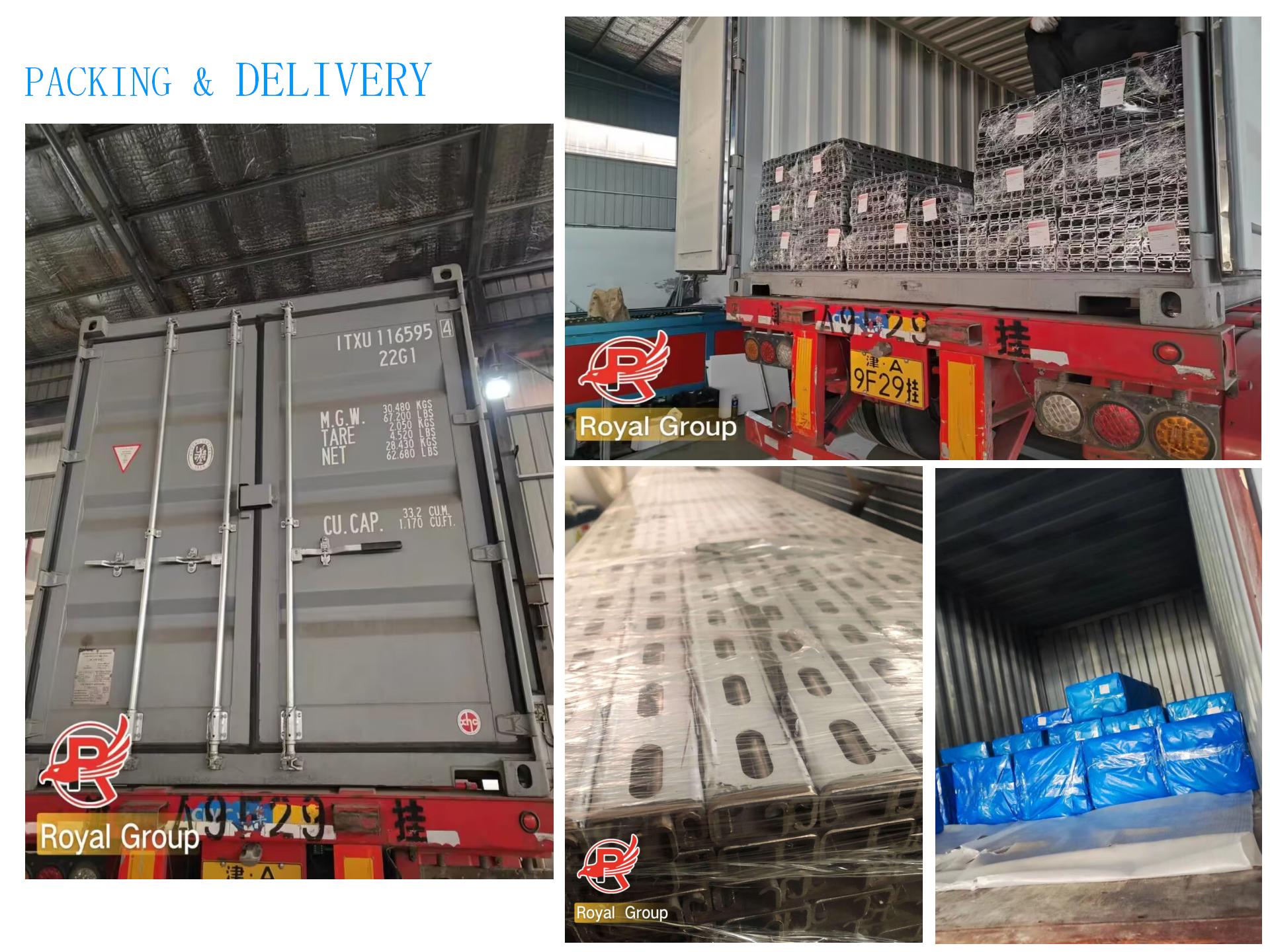

PACKAGING AND SHIPPING

Packaging:

We package our products in bundles. Each bundle weighs 500-600 kg. A small container weighs 19 tons. The bundles are wrapped in plastic film.

Transportation:

Choose the appropriate shipping method: Based on the number and weight of the support trays, we'll select the appropriate method, such as a flatbed truck, container, or ship. Please consider factors such as distance, time, cost, and shipping regulations.

Use appropriate lifting equipment: To load and unload the Strut Channel, use suitable lifting equipment such as cranes, forklifts, or loaders. Ensure that the equipment used has sufficient capacity to handle the weight of the sheet piles safely Custom Galvanized C Channel

Secure the load: Properly secure the packaged stack of Strut Channel on the transportation vehicle using strapping, bracing, or other suitable means to prevent shifting, sliding, or falling during transit.

COMPANY STRENGTH

Made in China, first-class service, cutting-edge quality, world-renowned

1. Scale effect: Our company has a large supply chain and a large steel factory, achieving scale effects in transportation and procurement, and becoming a steel company that integrates production and services

2. Product diversity: Product diversity, any steel you want can be purchased from us, mainly engaged in steel structures, steel rails, steel sheet piles, photovoltaic brackets, channel steel, silicon steel coils and other products, which makes it more flexible Choose the desired product type to meet different needs.

3. Stable supply: Having a more stable production line and supply chain can provide more reliable supply. This is especially important for buyers who require large quantities of steel.

4. Brand influence: Have higher brand influence and larger market

5. Service: A large steel company that integrates customization, transportation and production

6. Price competitiveness: reasonable price

*Send the email to [email protected] to get a quotation for your projects

CUSTOMERS VISIT

FAQ

1. who are we?

We are based in Tianjin, China, start from 2012,sell to Southeast Asia(20.00%),South Asia(20.00%),Southern Europe(10.00%),Western Europe(10.00%),Africa(10.00%),North America(25.00%),South America(5.00%). There are total about 51-100 people in our office.

2. how can we guarantee quality?

Always a pre-production sample before mass production;

Always final Inspection before shipment;

3.what can you buy from us?

Steel Pipes,Iron Angles,Iron Beams,Welded Steel Structures,Perforated Steel Products

4. why should you buy from us not from other suppliers?

High quality; Competitive price; Short delivery time; Satisfied service; Manufactured according to different standards

5. what services can we provide?

Accepted Delivery Terms: FOB,CFR,CIF;

Accepted Payment Currency:USD,CNY;

Accepted Payment Type: T/T,L/C;

Language Spoken:English,Chinese