Factory direct GB Standard Round Bar are cost-effective

Steel rod is a kind of metal material with high strength and corrosion resistance.

Usually used in construction, machinery, ships and other industries. In the construction industry, steel rods can be used to reinforce concrete structures such as stairs, Bridges, floors, etc. Steel rods can also be used to make mechanical parts, such as bearings, gears, bolts, etc. In addition, steel rods can also be used in foundation engineering, tunnel engineering, water conservancy engineering and so on.

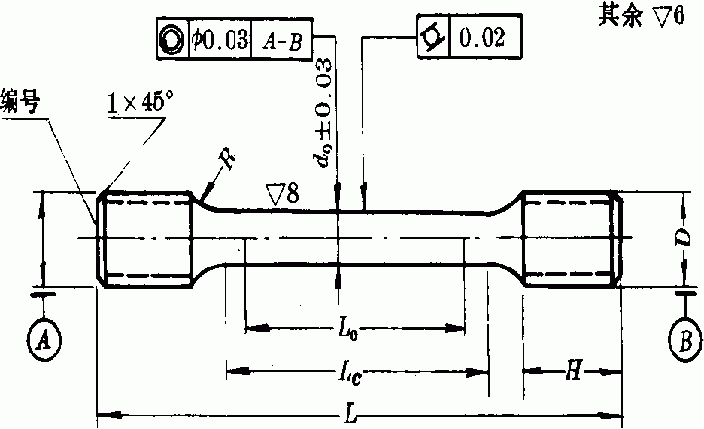

The details of the steel rod usually include the following specifications: diameter, side length, length, etc. specified according to the engineering requirements.

PRODUCT PRODUCTION PROCESS

1. Preparation of raw materials

1. Material selection: Choose high-quality steel with good quality, no oxide scale, no cracks or cracks, and few impurities as raw materials.

2. Cutting: Cut the raw materials into appropriate lengths and diameters, ensuring that the cutting surface is bright and crack-free.

2. Refining

1. Impurity removal: Use magnetic separator or manual sorting to remove impurities in raw materials.

2. Preheating: heating the raw materials to a certain temperature in the furnace for subsequent operations.

3. Refining: Put the preheated raw materials into a refining furnace for high-temperature treatment to remove harmful substances such as carbon, sulfur, and phosphorus in the raw materials, and adjust the carbon content.

3. Processing and forming

1. Preforming: Processing the refined raw materials into bars of a certain shape.

2. Heat treatment: Heat the preformed rod to a certain temperature and keep it for a period of time to adjust the mechanical properties of the rod.

3. Cooling: Place the heated rod in the air to cool naturally.

4. Finishing: The steel round bar is further subjected to fine processing such as wire cutting and polishing to achieve higher precision and surface quality.

PRODUCT SIZE

|

SPECIFICATIONS FOR STEEL BAR |

|

| 1. Size | 1)6-12M or customer's requirement |

| 2)Diameter: customized | |

| 3) Steel Bar,Square / Rectangular Bar,Deformed steel bar | |

| 2. Standard: | ASTM, DIN, GB, JIS, EN |

| 3.Material | Q235,Q355,20,45,40Cr,HRB400,HRB500 |

| 4. Location of our factory | Tianjin,China |

| 5. Usage: | 1)Solid building structure |

| 2) Processing and manufacturing mechanical parts | |

| 3) Making bearings | |

| 6. Coating: | 1) Bared

2) Black Painted (varnish coating) 3) galvanized |

| 7. Technique: | hot rolled |

| 8. Type: | Carbon Steel Bar |

| 9. Section Shape: | round |

| 10. Inspection: | Client inspection or inspection by 3rd party. |

| 11. Delivery: | Container, Bulk Vessel. |

| 12. About Our Quality: | 1) No damage, no bent

2) Free for oiled&marking 3) All goods can be checked by third party inspection before shipment |

| Round steel rod properties table | |||||

| diameter mm |

Section cm² |

unit mass kg/m |

diameter mm |

Section cm² |

unit mass kg/m |

| 6 | 0.283 | 0.222 | (45) | 15.9 | 12.5 |

| 7 | 0.385 | 0.302 | 46 | 16.6 | 13.0 |

| 8 | 0.503 | 0.395 | 48 | 18.1 | 14.2 |

| 9 | 0.636 | 0.499 | 50 | 19.6 | 15.4 |

| 10 | 0.785 | 0.617 | (52) | 21.2 | 16.7 |

| 11 | 0.950 | 0.746 | 55 | 23.8 | 18.7 |

| 12 | 1.13 | 0.888 | 56 | 24.6 | 19.3 |

| 13 | 1.33 | 1.04 | 60 | 28.3 | 22.2 |

| (14) | 1.54 | 1.21 | 64 | 32.2 | 25.3 |

| 16 | 2.01 | 1.58 | 65 | 33.2 | 26.0 |

| (18) | 2.55 | 2.00 | (68) | 36.3 | 28.5 |

| 19 | 2.84 | 2.23 | 70 | 38.5 | 30.2 |

| 20 | 3.14 | 2.47 | 75 | 44.2 | 34.7 |

| 22 | 3.80 | 2.98 | 80 | 50.3 | 39.5 |

| 24 | 4.52 | 3.55 | 85 | 56.8 | 44.6 |

| 25 | 4.91 | 3.85 | 90 | 63.6 | 49.9 |

| (27) | 5.73 | 4.50 | 95 | 70.9 | 55.6 |

| 28 | 6.16 | 4.83 | 100 | 78.5 | 61.7 |

| 30 | 7.07 | 5.55 | 110 | 95.0 | 74.6 |

| 32 | 8.04 | 6.31 | 120 | 113 | 88.7 |

| (33) | 8.55 | 6.71 | 130 | 133 | 104 |

| 36 | 10.2 | 7.99 | 140 | 154 | 121 |

| 38 | 11.3 | 8.90 | 150 | 177 | 139 |

| (39) | 11.9 | 9.38 | 160 | 201 | 158 |

| 42 | 13.9 | 10.9 | 180 | 255 | 200 |

| 200 | 314 | 247 | |||

GB Standard Round Bar

Specifications: Q235,Q355,20,45,40Gr

Standard: GB/T 1499.2-2007

GB/T 1499.3-2010

Size:6-12M or customer's requirement

| Diameter Sizes (mm) | Mass per meter (kg/m | Pieces per bundle | Nonimal weight per bundle of 12 meter (metric ton) |

| 5.5 | 0.187 | 450 | 1.010 |

| 6.0 | 0.222 | 375 | 0.999 |

| 6.5 | 0.260 | 320 | 0.998 |

| 7.0 | 0.302 | 276 | 1.000 |

| 8.0 | 0.395 | 200 | 0.948 |

| 9.0 | 0.499 | 168 | 1.006 |

| 10.0 | 0.617 | 138 | 1.022 |

| 12.0 | 0.888 | 96 | 1.023 |

FEATURES

GB Standard Round Bar have high strength and hardness. Compared to other materials, steel rods are stronger and can withstand greater forces and pressures. This allows steel rods to play a better role in various projects, providing more stable and reliable support.

Steel rods have good corrosion resistance. Steel rods can withstand long-term exposure to harsh environments such as humidity, acid and alkali without damage. This allows the steel rod to maintain its performance and stability in a variety of environments, extending its service life.

The steel rod also has good machinability. Steel rods can be processed and shaped by heat treatment, cold processing, etc., to meet different engineering and manufacturing needs. This allows steel rods to be flexibly applied in various projects, improving work efficiency and quality.

Steel rods have a wide range of uses and advantages. In the fields of construction, machinery manufacturing and transportation, steel rods play an important role. Its high strength, corrosion resistance and machinability make steel rods an ideal material choice to provide stable, reliable and durable support. Steel rods have broad application prospects in various fields and will continue to play an important role.

APPLICATION

Buildings and building structures: carbon steel round bar can be used for strengthening and supporting buildings and building structures, such as for strengthening concrete beams, columns and foundations.

roads and Bridges: Steel rods can be used for the construction of roads and Bridges, such as for the support and reinforcement of piers, bridge arches, tunnels and railway tracks.

Automobiles and vehicles: Steel rods can be used in the manufacture of automobiles and other vehicles such as for the reinforcement of wheels, chassis and body structures.

Manufacturing: Steel rods are widely used in the manufacturing industry and can be used to make machinery, equipment and tools such as factory equipment, agricultural machinery and cutting tools.

Aerospace: Steel rods can be used in the aerospace industry, for example in the manufacture of structures and components for aircraft, rockets and satellites.

Furniture and decoration: Steel rods can be used for furniture and decoration, such as for making tables, chairs, bed frames and lamps.

Sports equipment: Steel rods can be used to make sports equipment, such as golf clubs, tennis rackets and bicycle frames.

All in all, steel rods play a very important role in various industries and fields, and their high strength, corrosion resistance and plasticity make them a very valuable material.

PACKAGING AND SHIPPING

Packaging:

Steel rod stack firmly: hot rolled steel round bar stack neatly, stable, to ensure that steel rod alignment, to prevent steel rod instability. Use straps or bindings to secure the stack and prevent movement during transportation.

Use protective packaging: Wrap steel rods in a moisture-proof material, such as plastic or waterproof paper, to protect them from water, humidity and other environmental factors. This will help prevent rust and corrosion.

Shipping:

Choose the right mode of transport: According to the number and weight of steel rods, choose the right mode of transport, such as flatbed trucks, containers, ships, etc. Consider factors such as distance, time, cost, and traffic regulations.

Use appropriate lifting equipment: When loading and unloading steel rods, appropriate lifting equipment should be used, such as cranes, forklifts, loaders, etc. Ensure that the equipment used has sufficient capacity to safely handle the weight of the steel rod.

Fixed load: Use straps, braces or other suitable methods to properly secure the packaged steel rods to the transport vehicle to prevent movement, sliding or falling during transport.

COMPANY STRENGTH

Made in China, first-class service, cutting-edge quality, world-renowned

1. Scale effect: Our company has a large supply chain and a large steel factory, achieving scale effects in transportation and procurement, and becoming a steel company that integrates production and services

2. Product diversity: Product diversity, any steel you want can be purchased from us, mainly engaged in steel structures, steel rails, steel sheet piles, photovoltaic brackets, channel steel, silicon steel coils and other products, which makes it more flexible Choose the desired product type to meet different needs.

3. Stable supply: Having a more stable production line and supply chain can provide more reliable supply. This is especially important for buyers who require large quantities of steel.

4. Brand influence: Have higher brand influence and larger market

5. Service: A large steel company that integrates customization, transportation and production

6. Price competitiveness: reasonable price

*Send the email to [email protected] to get a quotation for your projects

CUSTOMERS VISIT

FAQ

1.How can I get a quotation from you ?

You can leave us message, and we will reply every message in time.

2.Will you delivery the goods on time?

Yes,we promise to provide best quality products and delivery on time. Honesty is our company's tenet.

3.Can I get samples before order ?

Yes, of course. Usually our samples are free,we can produce by your samples or technical drawings.

4.What is your payment terms?

Our usual payment term is 30% deposit, and rest against B/L. EXW, FOB,CFR, CIF.

5.Do you accept the third party inspection?

Yes absolutely we accept.

6.How do we trust your company?

We specialise in steel business for years as golden supplier, headquarter locates in Tianjin province, welcome to investigate in any ways, by all means.