Factory Direct Price Finely Processed High Efficiency Hot-Rolling Steel Sheet Pile For Industry

PRODUCT SIZE

|

Product Name

|

|

|

Steel Grade

|

S275,S355,S390,S430,SY295,SY390,ASTM A690

|

|

Production standard

|

EN10248,EN10249,JIS5528,JIS5523,ASTM

|

|

Delivery time

|

One week,80000 tons in stock

|

|

Certificates

|

ISO9001,ISO14001,ISO18001,CE FPC

|

|

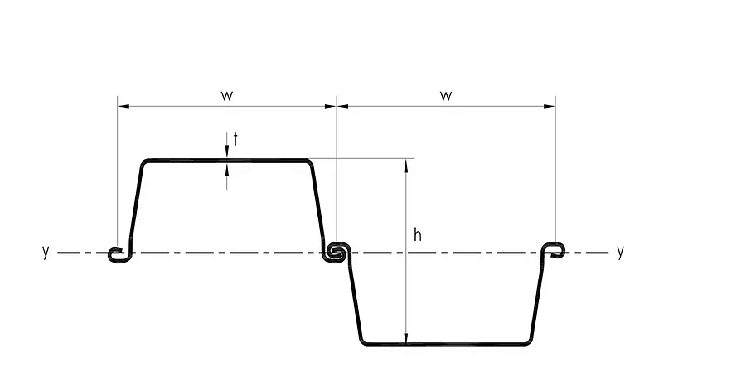

Dimensions

|

Any dimensions,any width x height x thickness

|

|

Length

|

Single length up to over 80m

|

1. We can produce all types of sheet piles,pipe piles and accessories,we can adjust our machines to produce in any width x height x thickness .

2. We can produce single length up to over 100m,and we can do all painting,cutting,welding etc fabrications in factory .

3. Fully internationally certified:ISO9001,ISO14001,ISO18001,CE,SGS,BV etc..

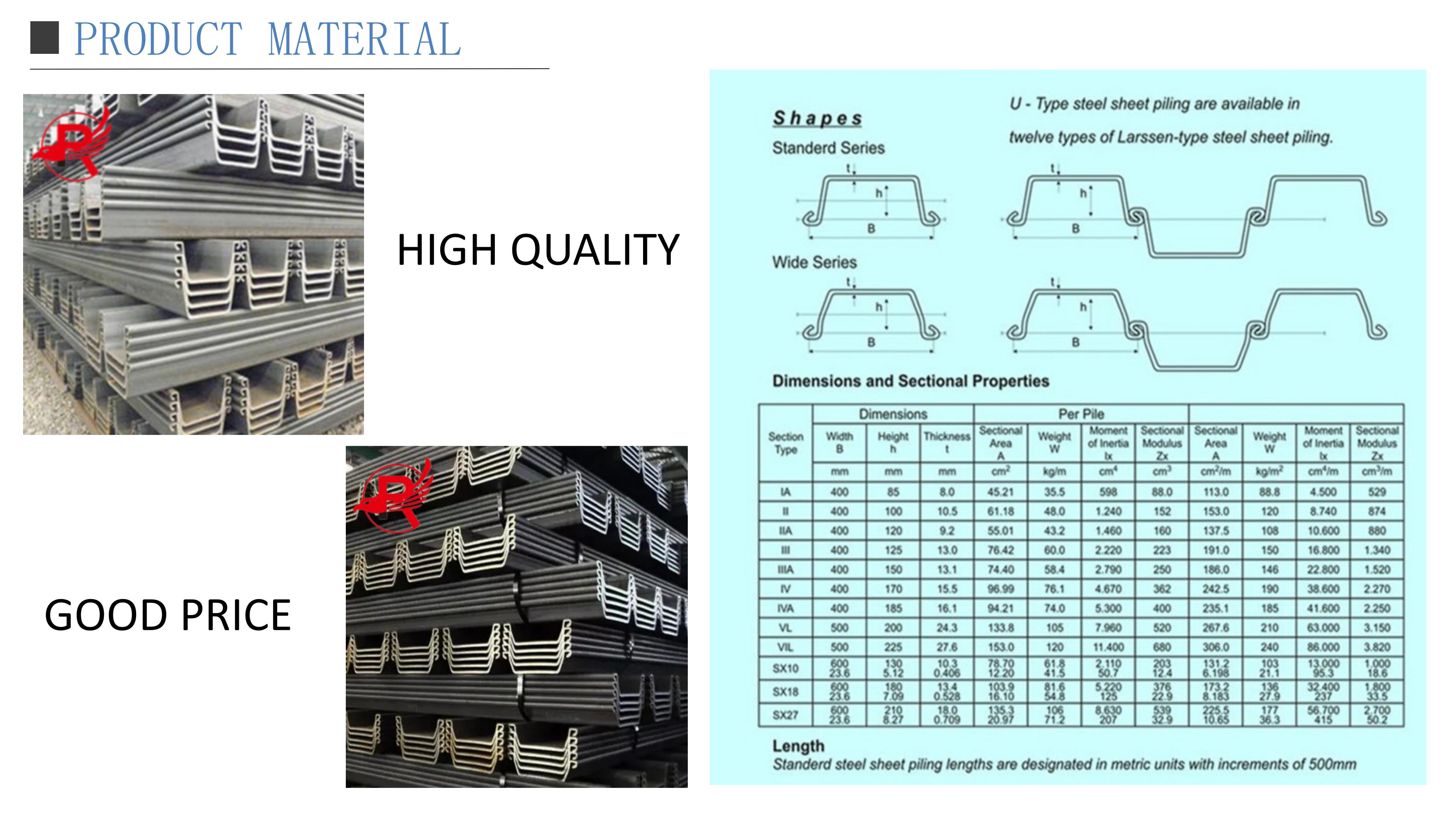

| Section | Width | Height | Thickness | Cross Sectional Area | Weight | Elastic Section Modulus | Moment of Inertia | Coating Area (both sides per pile) | ||

|---|---|---|---|---|---|---|---|---|---|---|

| (w) | (h) | Flange (tf) | Web (tw) | Per Pile | Per Wall | |||||

| mm | mm | mm | mm | cm2/m | kg/m | kg/m2 | cm3/m | cm4/m | m2/m | |

| Type II | 400 | 200 | 10.5 | - | 152.9 | 48 | 120 | 874 | 8,740 | 1.33 |

| Type III | 400 | 250 | 13 | - | 191.1 | 60 | 150 | 1,340 | 16,800 | 1.44 |

| Type IIIA | 400 | 300 | 13.1 | - | 186 | 58.4 | 146 | 1,520 | 22,800 | 1.44 |

| Type IV | 400 | 340 | 15.5 | - | 242 | 76.1 | 190 | 2,270 | 38,600 | 1.61 |

| Type VL | 500 | 400 | 24.3 | - | 267.5 | 105 | 210 | 3,150 | 63,000 | 1.75 |

| Type IIw | 600 | 260 | 10.3 | - | 131.2 | 61.8 | 103 | 1,000 | 13,000 | 1.77 |

| Type IIIw | 600 | 360 | 13.4 | - | 173.2 | 81.6 | 136 | 1,800 | 32,400 | 1.9 |

| Type IVw | 600 | 420 | 18 | - | 225.5 | 106 | 177 | 2,700 | 56,700 | 1.99 |

| Type VIL | 500 | 450 | 27.6 | - | 305.7 | 120 | 240 | 3,820 | 86,000 | 1.82 |

*Send the email to [email protected] to get a quotation for your projects

Section Modulus Range

1100-5000cm3/m

Width Range (single)

580-800mm

Thickness Range

5-16mm

Production Standards

BS EN 10249 Part 1 & 2

Steel Grades

SY295, SY390 & S355GP for Type II to Type VIL

S240GP, S275GP, S355GP & S390 for VL506A to VL606K

Length

27.0m maximum

Standard Stock Lengths of 6m, 9m, 12m, 15m

Delivery Options

Single or Pairs

Pairs either loose, welded or crimped

Lifting Hole

By container (11.8m or less) or Break Bulk

Corrosion Protection Coatings

FEATURES

Understanding Hot Rolled Steel Sheet Pile

Steel sheet piles are long, interlocking sections of steel that are driven into the ground to form a continuous wall. They are typically used in projects that involve retaining soil or water, such as foundation construction, underground parking lots, waterfront structures, and marine bulkheads. Two common types of steel sheet piles are cold-formed and hot-rolled, each offering unique advantages for different applications.

1. Q235 Steel Sheet Pile: Versatility and Cost-Effectiveness

Cold-formed sheet piles are made by bending thin steel plates into the desired shape. They are considered cost-effective and versatile, making them suitable for various construction scenarios. Due to their lightweight nature, they are easier to handle and transport, reducing both time and costs associated with the construction process. Cold-formed sheet piles are ideal for projects with moderate load requirements, such as small-scale retaining walls, temporary excavations, and landscape enhancements.

2. Sheet Pile Construction: Unmatched Strength and Durability

Hot-rolled sheet piles, on the other hand, are manufactured by heating steel to a high temperature and then rolling it into the desired shape. This process enhances the strength and durability of the steel, making hot-rolled sheet piles ideal for heavy-duty applications. Their interlocking design ensures stability and can withstand greater pressure and load capacities. Consequently, hot-rolled sheet piles are commonly used in large-scale construction projects, such as deep excavations, port infrastructure, flood protection systems, and foundations for tall buildings.

Benefits of Steel Sheet Pile Walls

Steel sheet pile walls offer numerous benefits that make them an attractive choice for construction projects:

a. Strength and Stability: Steel sheet piles provide unmatched strength and stability, ensuring the safety and longevity of the structure. They can withstand high pressure from soil, water, and other external forces, making them suitable for a wide range of applications.

b. Versatility: With various types and sizes available, steel sheet piles can adapt to different site conditions and construction requirements. They can be easily modified to accommodate irregular shapes or inclined surfaces.

c. Environmental Sustainability: Steel is a recyclable material, and many steel sheet piles are made from recycled steel. This reduces the carbon footprint and promotes eco-friendly construction practices.

d. Cost-Effectiveness: Steel sheet piles offer long-term cost savings due to their durability and low maintenance requirements. Their ease of installation also helps reduce labor costs and project timelines.

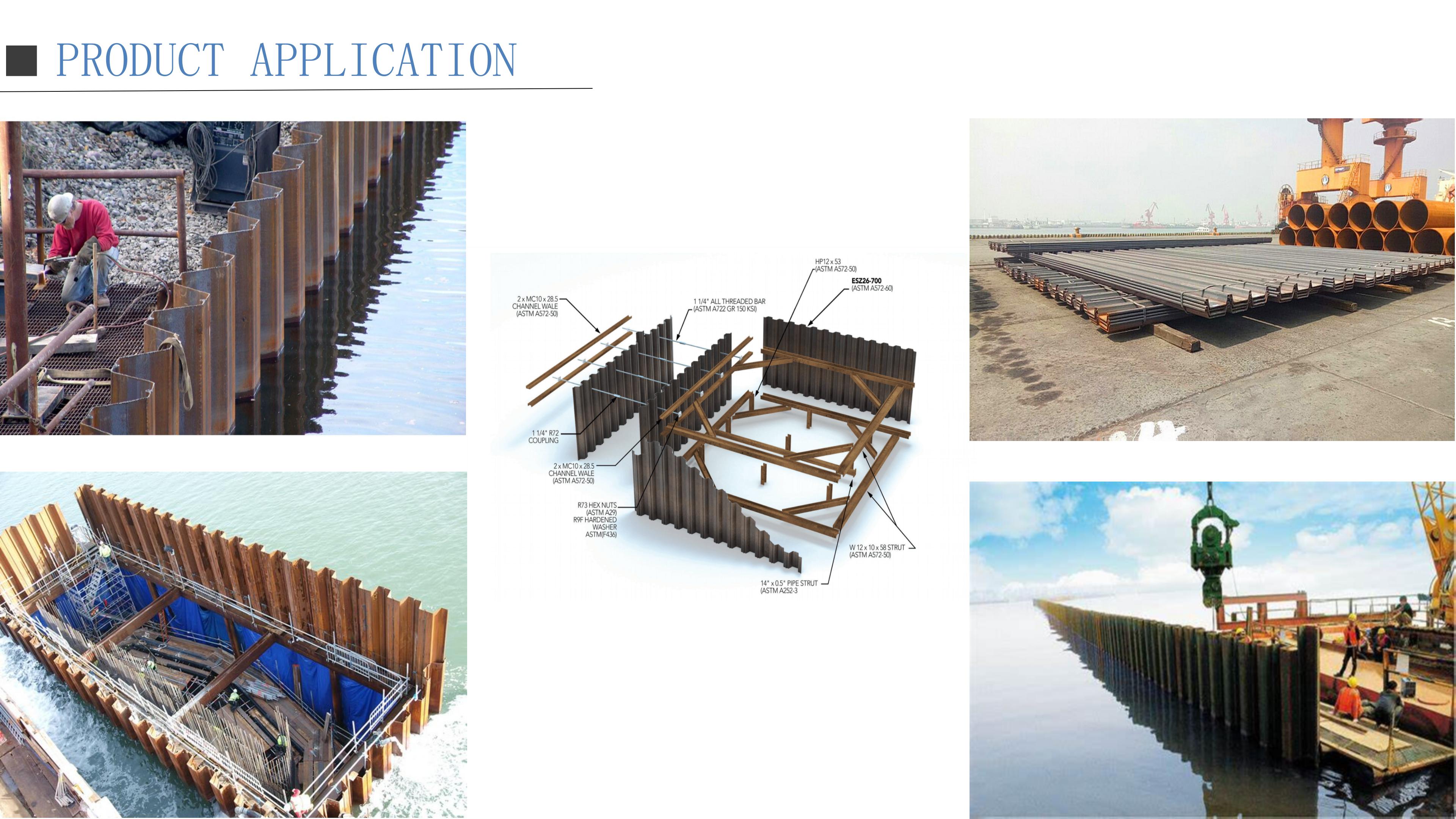

APPLICATION

Hot rolled steel sheet piles are commonly used in various applications, including:

Retaining walls: They are often used as retaining structures to prevent soil erosion, stabilize slopes, and provide structural support for structures near excavations or bodies of water.

Harbor and port projects: Steel sheet piles are widely used in the construction of harbors, docks, quays, and breakwaters. They provide structural support against water pressure and help protect the coastline from erosion.

Flood protection: Steel sheet piles are used to create flood barriers and protect areas from being inundated during heavy rain or flood events. They are installed along riverbanks and waterways to create a containment system for floodwaters.

Construction of underground structures: Steel sheet piles are commonly used in the construction of underground car parks, basements, and tunnels. They provide effective earth retention and prevent the ingress of water and soil.

Cofferdams: Steel sheet piles are used to construct temporary cofferdams, which isolate a construction area from water or soil during construction activities. This allows for excavation and construction work to take place in a dry environment.

Bridge abutments: Steel sheet piles are used in the construction of bridge abutments to provide lateral support and stabilize the foundation. They help to distribute the load from the bridge to the ground, preventing soil movement.

Overall, hot rolled steel sheet piles are versatile and can be used in a wide range of applications where earth retention, water containment, and structural support are required.

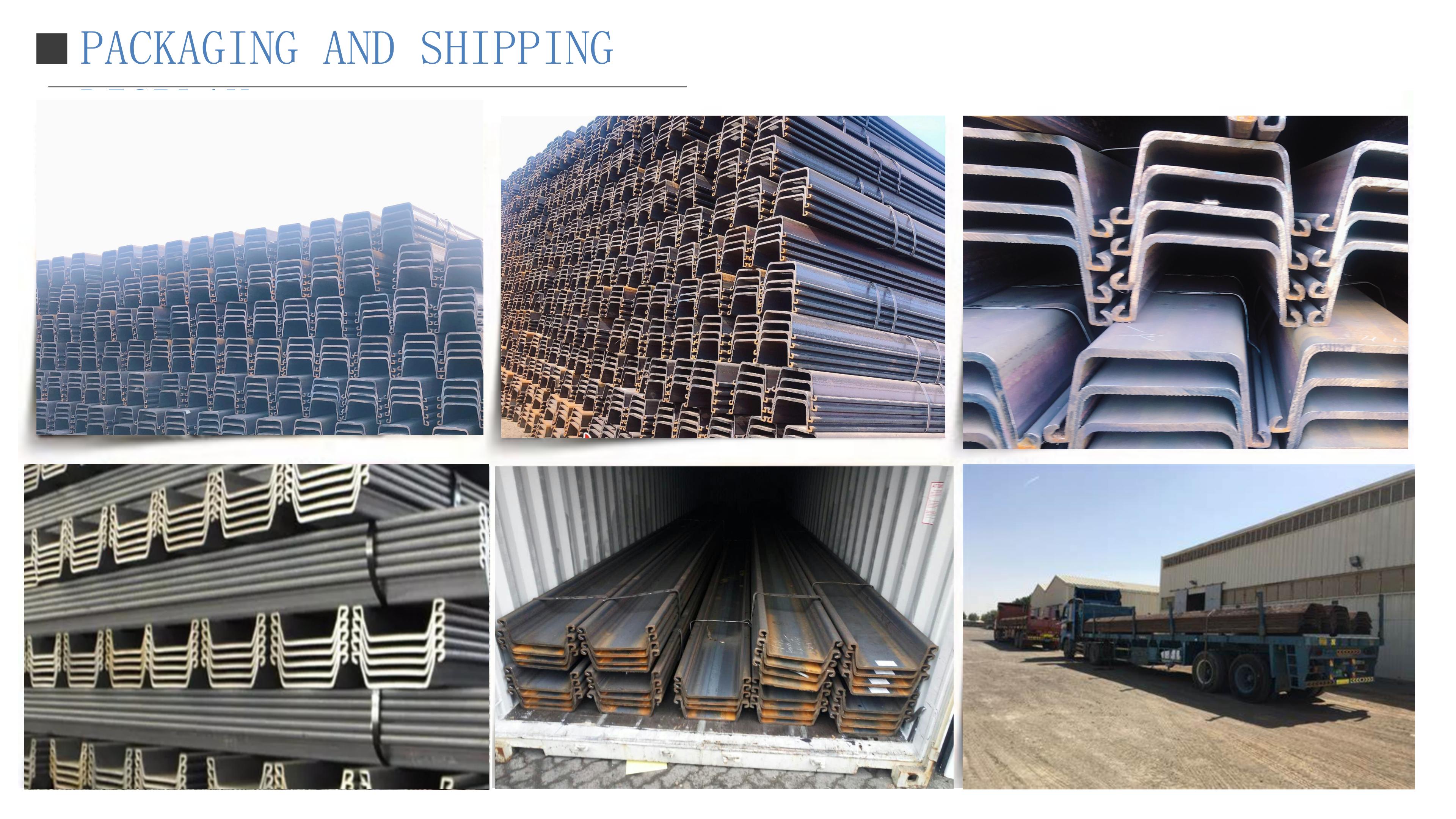

PACKAGING AND SHIPPING

Packaging:

Stack the sheet piles securely: Arrange the sheet steel pile n a neat and stable stack, ensuring that they are aligned properly to prevent any instability. Use strapping or banding to secure the stack and prevent shifting during transportation.

Use protective packaging materials: Wrap the stack of sheet piles with a moisture-resistant material, such as plastic or waterproof paper, to protect them from exposure to water, humidity, and other environmental elements. This will help prevent rust and corrosion.

Shipping:

Choose a suitable mode of transportation: Depending on the quantity and weight of the sheet piles, select the appropriate mode of transportation, such as flatbed trucks, containers, or ships. Consider factors like distance, time, cost, and any regulatory requirements for transportation.

Use appropriate lifting equipment: To load and unload the U-shaped steel sheet piles, use suitable lifting equipment such as cranes, forklifts, or loaders. Ensure that the equipment used has sufficient capacity to handle the weight of the sheet piles safely.

Secure the load: Properly secure the packaged stack of sheet piles on the transportation vehicle using strapping, bracing, or other suitable means to prevent shifting, sliding, or falling during transit.

COMPANY STRENGTH

Made in China, first-class service, cutting-edge quality, world-renowned

1. Scale effect: Our company has a large supply chain and a large steel factory, achieving scale effects in transportation and procurement, and becoming a steel company that integrates production and services

2. Product diversity: Product diversity, any steel you want can be purchased from us, mainly engaged in steel structures, steel rails, steel sheet piles, photovoltaic brackets, channel steel, silicon steel coils and other products, which makes it more flexible Choose the desired product type to meet different needs.

3. Stable supply: Having a more stable production line and supply chain can provide more reliable supply. This is especially important for buyers who require large quantities of steel.

4. Brand influence: Have higher brand influence and larger market

5. Service: A large steel company that integrates customization, transportation and production

6. Price competitiveness: reasonable price

*Send the email to [email protected] to get a quotation for your projects

CUSTOMERS VISIT

When a customer wishes to visit a product, the following steps can usually be arranged:

Make an appointment to visit: Customers can contact the manufacturer or sales representative in advance to make an appointment for the time and place to visit the product.

Arrange a guided tour: Arrange professionals or sales representatives as tour guides to show customers the production process, technology and quality control process of the product.

Display products: During the visit, show products at different stages to customers so that customers can understand the production process and quality standards of the products.

Answer questions: During the visit, customers may have various questions, and the tour guide or sales representative should answer them patiently and provide relevant technical and quality information.

Provide samples: If possible, product samples can be provided to customers so that customers can more intuitively understand the quality and characteristics of the product.

Follow-up: After the visit, promptly follow up on customer feedback and needs to provide customers with further support and services.

FAQ

1. How can I get a quotation from you ?

You can leave us message, and we will reply every message in time . Or we may talk on line by WhatsApp . And you can also find our contact information on contact page .

2. Can I get samples before order ?

Yes, of course. Usually our samples are free . we can produce by your samples or technical drawings . We can build the molds and fixtures .

3. What is your delivery time ?

A. The time of delivery is usually around 1 month(1*40FT as usual) ;

B. We can send out in 2 days , if it has stock .

4. What is your payment terms ?

Our usual payment term is 30% deposite, and rest against B/L. L/C is also acceptatble .

5. How can you garantee what I got will be good ?

We are factory with 100% pre-delivery inspection which garantee the quality .

And as golden supplier on Alibaba , Alibaba assurance will make garanteewhich means alibaba will pay your money back in advance , if there is any problem with the products .

6. How do you make our business long-term and good relationship ?

A. We keep good quality and competitive price to ensure our customers benefit ;

B. We respect every customer as our friend and we sincerely do business and make friends with them no matter where they come from