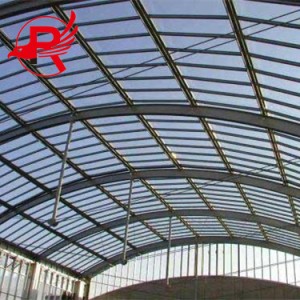

Top Quality Customized Pre-Engineerd Prefabricated Light/Heavy Steel Structure Building for Industrial Construction

Steel structures are designed individually according to the client's architectural and structural requirements, then assembled in a rational sequence. Due to the material's advantages and flexibility, steel structures are widely used in medium-sized and large-scale projects (e.g., prefabricated steel structures).

Steel structures also include secondary structures and other steel components of buildings. Each steel structure has a characteristic shape and chemical composition to meet the requirements of the project.

Steel is primarily composed of iron and carbon. Manganese, alloys, and other chemical components are also added to enhance strength and durability.

Depending on the specific requirements of each project, steel components can be formed by hot or cold rolling or welded from thin or bent plates.

When the temperature is between 300℃ and 400℃, the bolt strength and elastic abrasive tools are significantly reduced. When the temperature is around 600℃, the tensile strength of the stainless steel plate tends to zero. In construction projects with special fire safety regulations, the steel structure should be maintained with fire-resistant insulation materials in all aspects to improve the flame retardancy level.

Steel structures have poor corrosion resistance, especially in humid and corrosive material environments, and are prone to rust. Generally, steel structures need to be rust-proofed, hot-dip galvanized or industrially painted, and must be repaired and maintained. For the submarine integrated service platform structure located at sea level, unique preventive measures such as "zinc block anode protection" need to be adopted to resist corrosion.

If you want to buy steel structure, Steel Structure China Factory is a good choice

*Send the email to [email protected] to get a quotation for your projects

|

Material List

|

|

|

Project

|

|

|

Size

|

According to Customer Need

|

|

Main Steel Structure Frame

|

|

| Main structural types | Truss structure,Frame structure,Grid structure,Arch structure,Prestressed structure,Girder bridge,Truss bridge,Arch bridge,Cable bridge,Suspension bridge |

|

Beam

|

I-beam,H-beam,Z-beam,C-beam,Tube,Angle,Channel,T-beam,Track section,Bar,Rod,Plate,Hollow beam |

|

Secondary Steel Structure Frame

|

|

|

Purlin

|

Q235B C and Z Type Steel

|

|

Knee Brace

|

Q235B C and Z Type Steel

|

|

Tie Tube

|

Q235B Circular Steel Pipe

|

|

Brace

|

Q235B Round Bar

|

|

Vertical and Horizontal Support

|

Q235B Angle Steel, Round Bar or Steel Pipe

|

|

Application :

|

All kinds of industrial workshop ,warehouse ,high-rise building,Light Steel Structure House,Steel Structure School Building,Steel Structure Warehouse,Prefab Steel Structure House,Steel Structure Shed,Steel Structure Car Garage,Steel Structure For Workshop

|

PRODUCT PRODUCTION PROCESS

ADVANTAGE

Advantages:

1. Cost Reduction

Steel structures require lower production and maintenance costs than traditional building structures. Furthermore, 98% of steel components can be reused in new structures without compromising mechanical properties.

2. Fast Installation

Precise machining of steel components speeds up installation and allows for monitoring using management software, accelerating construction progress.

3. Health and Safety

Steel components are factory-produced and safely installed on-site by a professional installation team. Field investigations have proven that steel structures are the safest solution.

Because all components are prefabricated in the factory, construction generates minimal dust and noise.

4. Flexibility

Steel structures can be modified to meet future needs, loads, longitudinal expansion requirements, and meet client requirements that are unattainable with other structures.

Mezzanines can be added to steel structures even years after the original structure is completed.

Bearing Capacity:

Practice has shown that the greater the load, the greater the deformation of a steel structural member. However, when the load is excessive, the steel structural member may fracture or undergo severe and significant plastic deformation, thus affecting the proper functioning of the structural member. To ensure that engineering materials and structures function properly under load, each steel structural member must possess sufficient bearing capacity, also known as bearing capacity. Bearing capacity is primarily measured by the steel structural member's sufficient strength, stiffness, and stability.

Sufficient Strength

Strength refers to the ability of a steel structural member to resist damage (fracture or permanent deformation). This means that it must withstand load without yielding or fracture, ensuring safe and reliable operation. Strength is a fundamental requirement for all load-bearing structural members and, therefore, a key learning point.

Sufficient Stiffness

Stiffness refers to the ability of a steel structural member to resist deformation. If a steel component deforms excessively under load, even if it doesn't break down, it will not function properly. Therefore, steel components must possess sufficient rigidity—in other words, rigidity failure is not permitted. Different types of components have different rigidity requirements, so relevant standards and specifications should be consulted when applying these requirements.

Stability

Stability refers to the ability of a steel component to maintain its original equilibrium state under external forces.

Instability occurs when a steel component suddenly changes its equilibrium state when pressure increases to a certain level. This phenomenon is called buckling. Some thin-walled components under pressure may also suddenly change their equilibrium state, becoming unstable. Therefore, these steel components must be able to maintain their original equilibrium state—that is, have sufficient stability—to ensure they do not buckle and fail under specified operating conditions.

DEPOSIT

Steel Structure Design generally include frames, plan trusses, spherical grids (shells), cable membranes, light steel structures, tower masts and other structural forms.

PROJECT

Our company often exports steel structure products to the Americas and Southeast Asian countries. We participated in one of the projects in the Americas with a total area of approximately 543,000 square meters and a total use of approximately 20,000 tons of steel. After the project is completed, it will become a steel structure complex integrating production, living, office, education and tourism.

Whether you are looking for a contractor, a partner, or want to learn more about steel structures, please feel free to contact us to discuss further. We undertake a variety of light and heavy steel structure buildings, and we accept custom steel building designs.We can also provide the steel structure materials you need.We will help you quickly resolve your project issues.

*Send the email to [email protected] to get a quotation for your projects

PRODUCT INSPECTION

Non-destructive testing refers to the use of sound waves, radiation, electromagnetic and other means to detect steel structure factory building without affecting the performance of the steel structure. Non-destructive testing can effectively detect defects such as cracks, pores, inclusions and other defects inside the steel structure, thereby improving the safety and reliability of the steel structure. Commonly used non-destructive testing methods include ultrasonic testing, radiographic testing, magnetic particle testing, etc.

Structural performance testing is conducted after the steel structure is installed, primarily involving load and vibration testing. This testing determines the strength, stiffness, and stability of the steel structure under load, ensuring its safety and reliability during operation. In summary, steel structure testing encompasses material testing, component testing, connection testing, coating testing, nondestructive testing, and structural performance testing. These tests effectively ensure the quality and safety of the steel structure, thereby providing strong assurance for the safety and longevity of the building.

APPLICATION

The automated machinery for Steel Structure House processing and installation has high technology, and steel structure components are conducive to production, processing and assembly at the construction site. The automated machinery of the manufacturing plant produces and processes steel structure components with high precision and high production efficiency. The assembly speed at the construction site is very fast and can meet the construction period requirements. The steel structure is the most intelligent structure.

PACKAGING AND SHIPPING

The Steel Structure System construction project has a relatively light weight, high tensile strength, good overall rigidity and strong deformation ability. The weight of the building itself is only one-fifth of the brick-concrete structure, and it can withstand hurricanes of 70 meters per second, so that life and property can be effectively maintained on a daily basis.

COMPANY STRENGTH

Made in China, first-class service, cutting-edge quality, world-renowned

1. Scale effect: Our company has a large supply chain and a large steel factory, achieving scale effects in transportation and procurement, and becoming a steel company that integrates production and services

2. Product diversity: Product diversity, any steel you want can be purchased from us, mainly engaged in steel structures, steel rails, steel sheet piles, photovoltaic brackets, channel steel, silicon steel coils and other products, which makes it more flexible Choose the desired product type to meet different needs.

3. Stable supply: Having a more stable production line and supply chain can provide more reliable supply. This is especially important for buyers who require large quantities of steel.

4. Brand influence: Have higher brand influence and larger market

5. Service: A large steel company that integrates customization, transportation and production

6. Price competitiveness: reasonable price

*Send the email to [email protected] to get a quotation for your projects

CUSTOMERS VISIT