Custom Steel Metal Fabrication Welding And Laser Cutting Service Stamping Parts Sheet Metal Processing

Product Detail

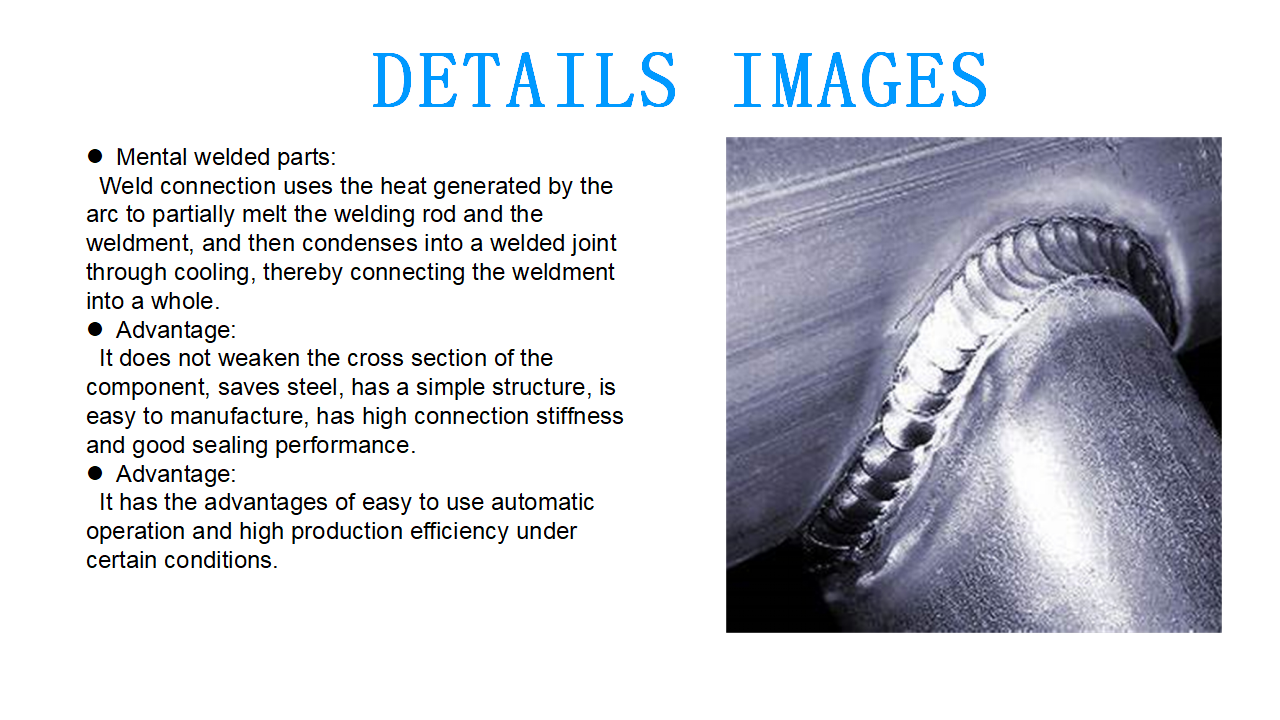

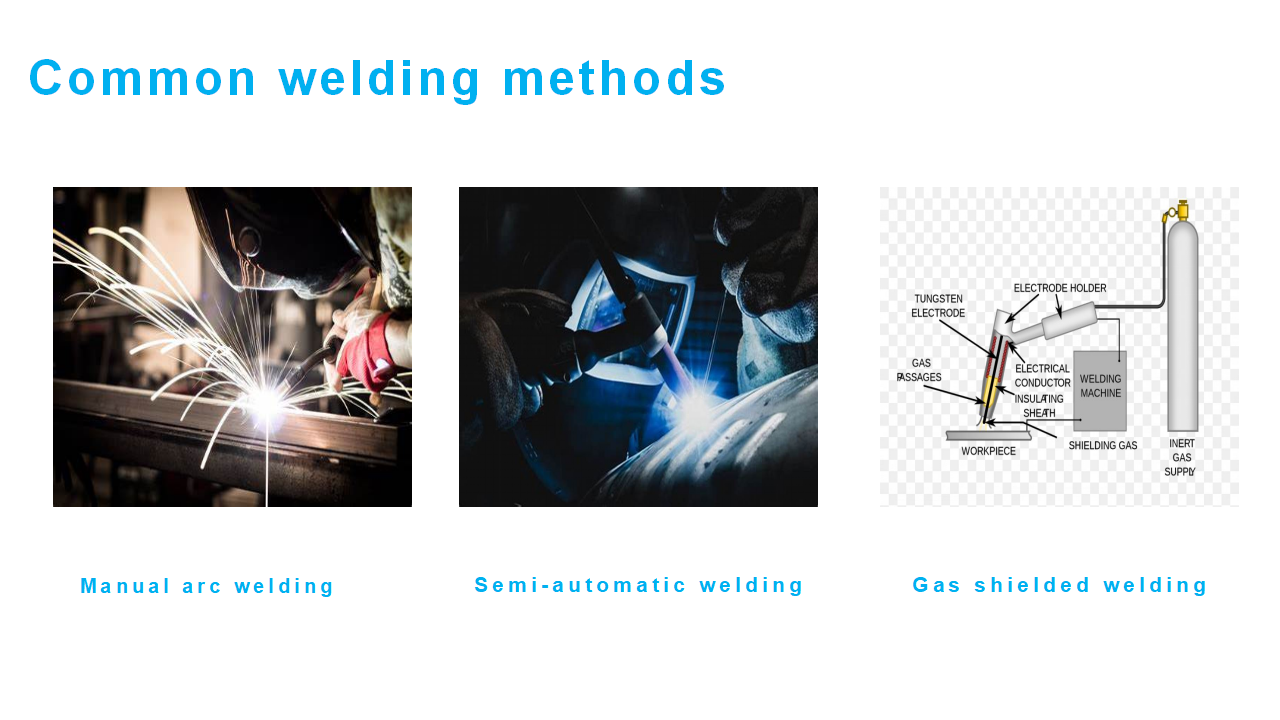

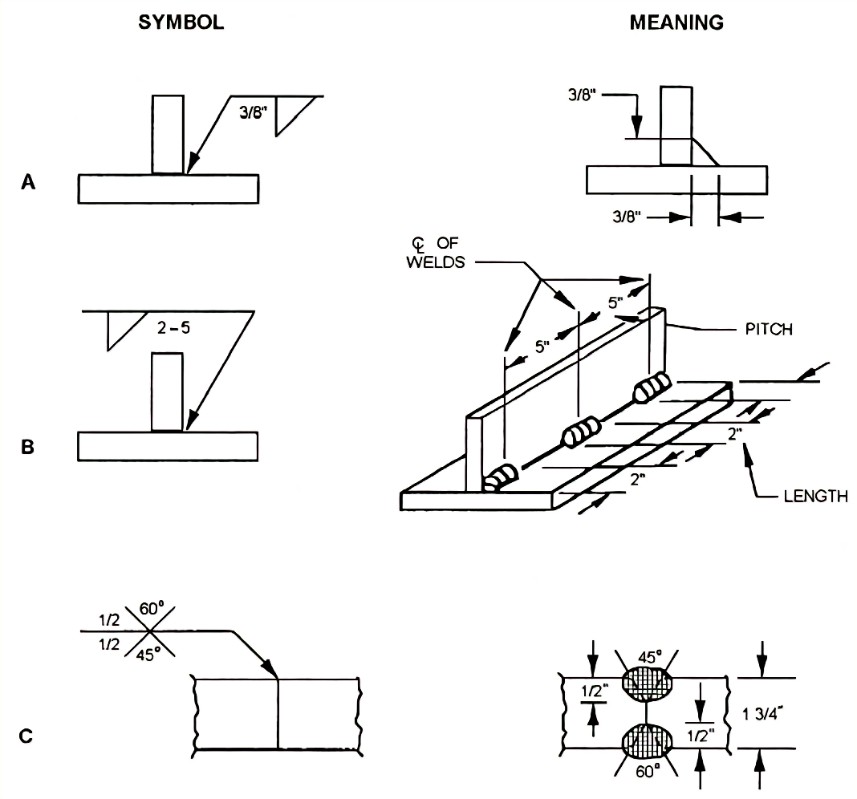

Common welding methods include arc welding, gas shielded welding, laser welding, etc. Arc welding is one of the most commonly used welding methods. The arc generates high temperature to melt the welding materials. It is commonly used in steel structures, shipbuilding and other fields. Gas shielded welding uses inert gas or active gas to protect the welding area to prevent oxidation and other pollution. It is suitable for welding aluminum alloy, stainless steel and other materials. Laser welding uses high-energy laser beams to melt and join welding materials. It has the advantages of high precision and small heat-affected zone, and is suitable for precision welding and automated production.

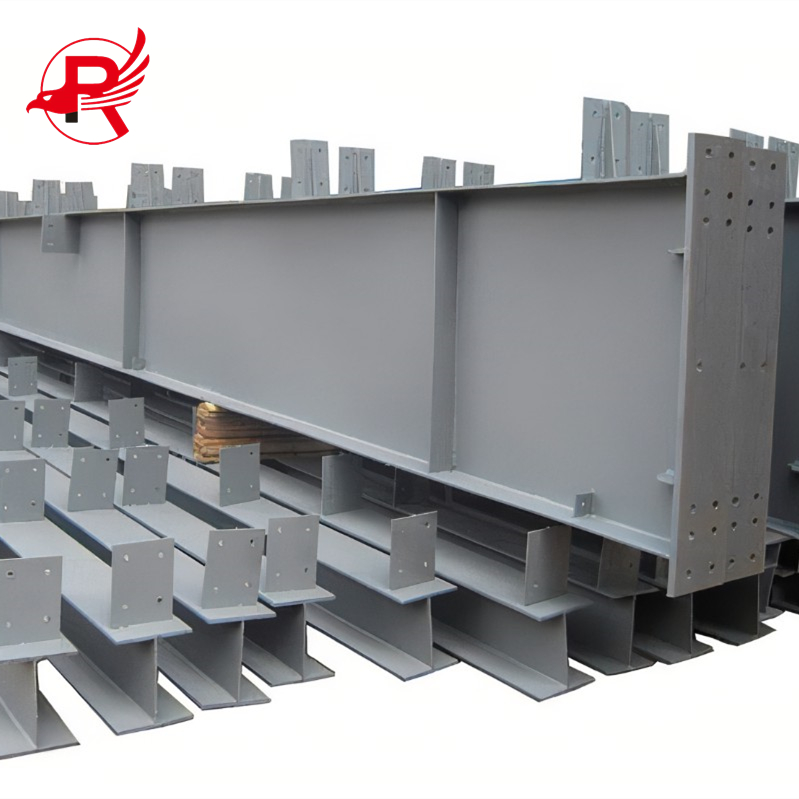

Welding processing plays an important role in the manufacturing industry, enabling the connection and repair of materials, and is widely used in aerospace, automobile manufacturing, construction engineering and other fields. With the continuous development of technology, welding processing is also constantly innovating. The application of high-tech technologies such as laser welding and plasma arc welding provides more choices and possibilities for the manufacturing industry.

In the world of metalworking, welding fabrication is an essential skill that requires precision, expertise, and a keen eye for detail. Whether it’s creating intricate designs or constructing sturdy structures, welding fabricators play a crucial role in bringing metal to life. From fab welding to laser welding sheet metal, the art of welding fabrication encompasses a wide range of techniques and processes that are vital to various industries.

Quality welding is the cornerstone of any successful welding business. It involves not only the technical aspects of welding but also the commitment to delivering durable and flawless results. A skilled welding fabricator understands the importance of using the right materials, equipment, and techniques to ensure the highest quality in their work. This dedication to excellence sets reputable welding businesses apart and earns them the trust and loyalty of their clients.

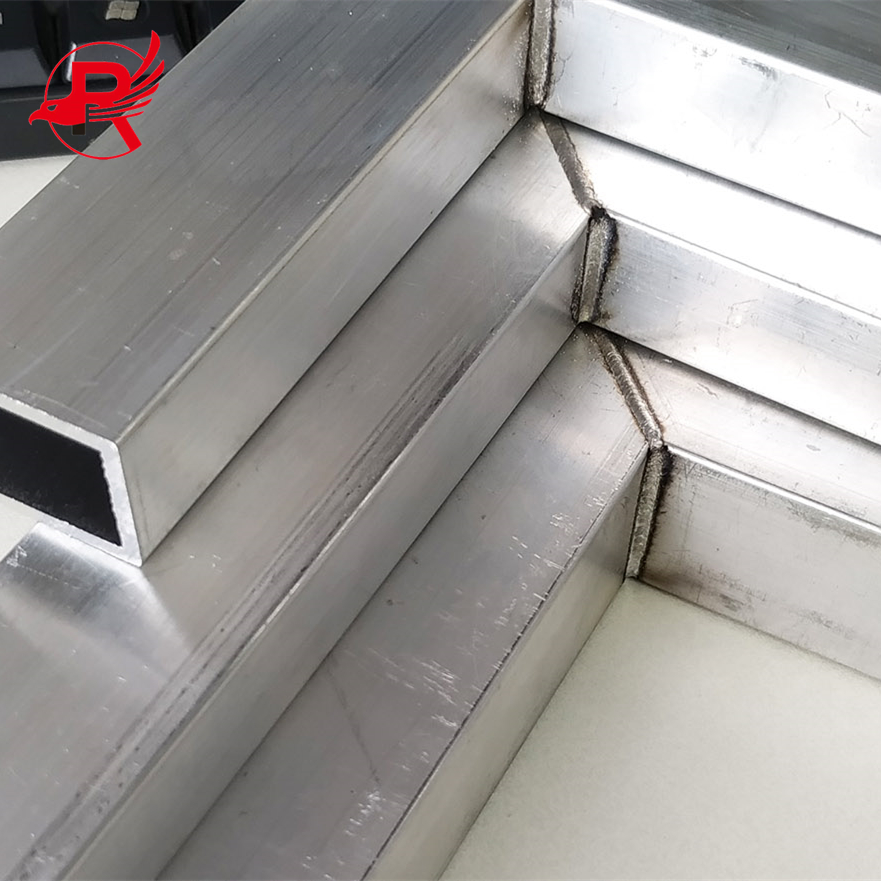

When it comes to welding sheet metal, precision is key. The ability to fuse metal sheets together seamlessly requires a combination of expertise and the right tools. Laser welding sheet metal, in particular, has become increasingly popular due to its ability to produce clean, precise welds with minimal heat-affected zones. This advanced technique has revolutionized the sheet metal welding process, allowing for greater accuracy and efficiency.

In the world of welding fabrication, attention to detail is paramount. Every weld must be meticulously executed to ensure structural integrity and longevity. Whether it’s creating custom metal artwork or fabricating industrial components, the skill and craftsmanship of a welding fabricator can make all the difference.

As technology continues to advance, the future of welding fabrication looks promising. Innovations in materials and techniques are constantly pushing the boundaries of what is possible in the world of metalworking. However, one thing remains constant: the importance of quality and precision in welding fabrication.

In conclusion, welding fabrication is a blend of art and science, where skill and creativity come together to create exceptional metalwork. From fab welding to laser welding sheet metal, the dedication to quality and precision sets the standard for welding fabricators and businesses alike. As the industry continues to evolve, the art of welding fabrication will continue to play a vital role in shaping the world around us.

|

Material

|

Carton steel/aluminum/brass/stainless steel/spcc

|

|

Color

|

Customized

|

|

Processing

|

Laser cutting/CNC Punching/CNC Bending/Welding/Painting/Assembly

|

|

Surface treatment

|

Power coating,zinc plated,Polishing, Plating, Brush, Skill-screen etc.

|

|

Drawing Format

|

CAD, PDF, SOLIDworks etc.

|

|

Certification

|

ISO9001:2008 CE SGS

|

|

Quality Inspection

|

pin gauge,caliper gauge, drop off test, vibration test, product lifecycle test, salt spray test, projector, coordinate measuring

machine calipers, micro caliper, thread miro caliper, pass meter, pass meter etc. |

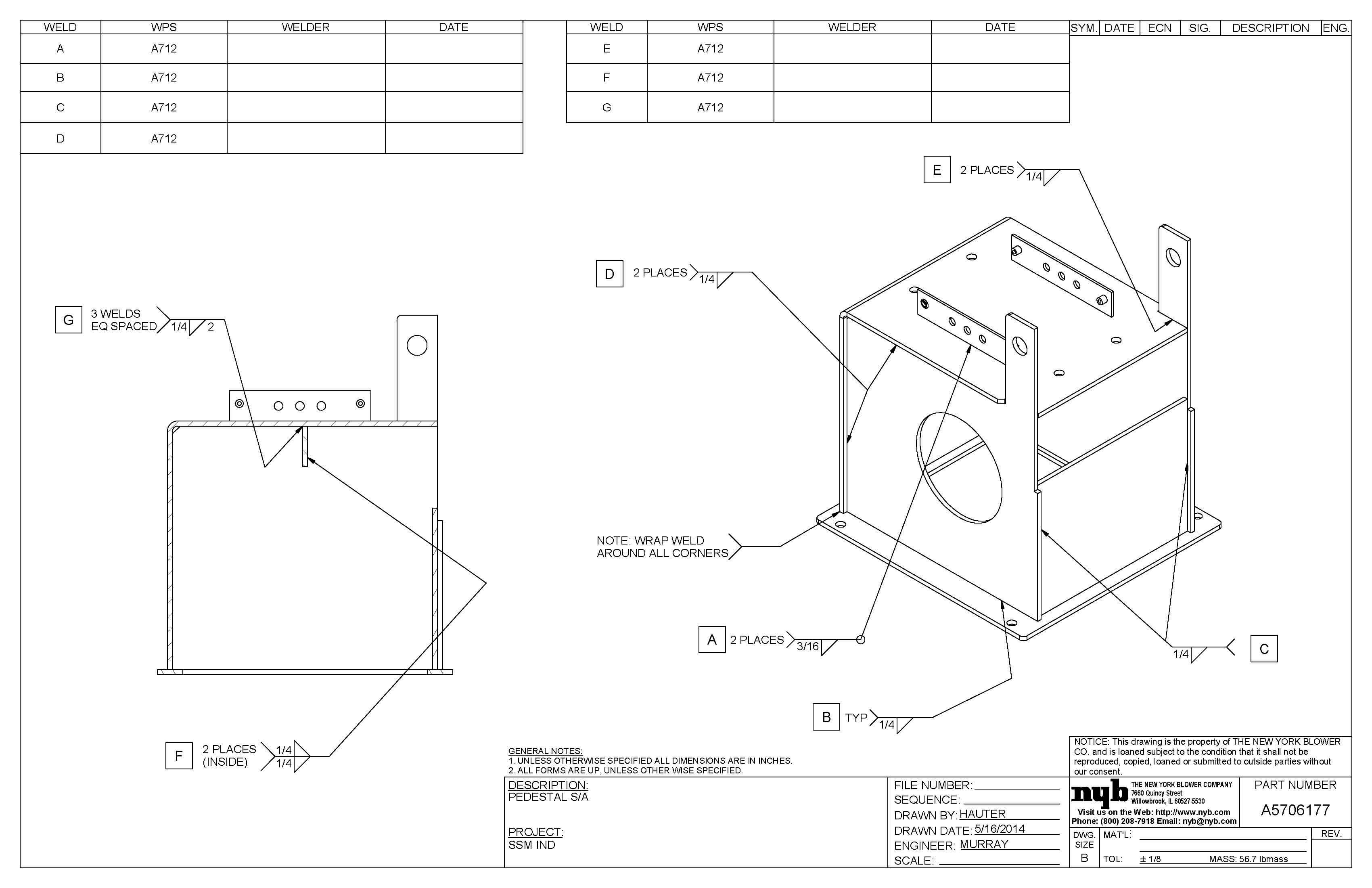

Exemplify

This is the order we received for processing parts.

We will produce accurately according to the drawings.

|

Customized Machined Parts |

|

| 1. Size | Customized |

| 2. Standard: | Customized or GB |

| 3.Material | Customized |

| 4. Location of our factory | Tianjin,China |

| 5. Usage: | Meet customers' own needs |

| 6. Coating: | Customized |

| 7. Technique: | Customized |

| 8. Type: | Customized |

| 9. Section Shape: | Customized |

| 10. Inspection: | Client inspection or inspection by 3rd party. |

| 11. Delivery: | Container, Bulk Vessel. |

| 12. About Our Quality: | 1) No damage, no bent2) Accurate dimensions3) All goods can be checked by third party inspection before shipment |

As long as you have personalized steel product processing needs, we can accurately produce them according to the drawings. If there are no drawings, our designers will also make personalized designs for you based on your product description needs.

Finished product display

Packaging & Shipping

Package:

We will package the products according to customer needs, using wooden boxes or containers, and the larger profiles will be directly packed naked, and the products will be packaged according to customer needs.

Shipping:

Choose the appropriate transportation method: According to the quantity and weight of the customized products, choose the appropriate transportation method, such as flatbed truck, container or ship. Consider factors such as distance, time, cost and any regulatory requirements for transportation.

Use appropriate lifting equipment: To load and unload strut channels, use appropriate lifting equipment such as a crane, forklift, or loader. Make sure the equipment used has sufficient capacity to safely handle the weight of the sheet piles.

Securing Loads: Properly secure stacks of packaged custom products to shipping vehicles using strapping, bracing, or other suitable methods to prevent bumping or damage during transportation.

FAQ

1.How can I get a quotation from you ?

You can leave us message, and we will reply every message in time.

2.Will you delivery the goods on time?

Yes,we promise to provide best quality products and delivery on time. Honesty is our company's tenet.

3.Can I get samples before order ?

Yes, of course. Usually our samples are free,we can produce by your samples or technical drawings.

4.What is your payment terms?

Our usual payment term is 30% deposit, and rest against B/L. EXW, FOB,CFR, CIF.

5.Do you accept the third party inspection?

Yes absolutely we accept.

6.How do we trust your company?

We specialise in steel business for years as golden supplier, headquarter locates in Tianjin province, welcome to investigate in any ways, by all means.