China Prefabricated Steel Structure for Workshop Office Building

Steel has toughness, good plasticity, uniform material, high structural reliability, is suitable for withstanding impact and dynamic loads, and has good seismic resistance. The internal structure of steel is uniform and close to isotropic homogeneous body. The actual working performance of the steel structure is consistent with the calculation theory. Therefore, steel structures have high reliability.

The material is strong and lightweight. Steel has high strength and high modulus of elasticity. Its density to yield strength ratio is relatively low compared to concrete and wood. Therefore, under the same stress conditions, the steel structure members have small cross-sections and are light in weight. The mb lightweight steel concrete green residence is easy to transport and install, and is suitable for large spans, high heights, and heavy loads. structure.

*Send the email to chinaroyalsteel@163.com to get a quotation for your projects

PRODUCT PRODUCTION PROCESS

| Product name: | Steel Building Metal Structure |

| Material : | Q235B ,Q345B |

| Main frame : | H-shape steel beam |

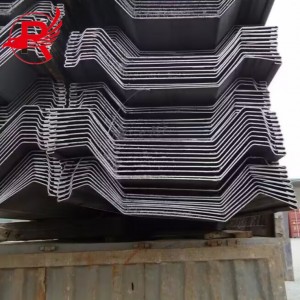

| Purlin : | C,Z - shape steel purlin |

| Roof and wall : | 1.corrugated steel sheet ;

2.rock wool sandwich panels ;

3.EPS sandwich panels ; 4.glass wool sandwich panels |

| Door: | 1.Rolling gate

2.Sliding door

|

| Window: | PVC steel or aluminum alloy |

| Down spout : | Round pvc pipe |

| Application : | All kinds of industrial workshop ,warehouse ,high-rise building |

ADVANTAGE

prefabricated steel structure have the advantages of light weight, high structural reliability, high degree of mechanization of manufacturing and installation, good sealing performance, heat and fire resistance, low carbon, energy saving, green and environmental protection.

Steel structure is a structure composed of steel materials and is one of the main types of building structures. The structure is mainly composed of steel beams, steel columns, steel trusses and other components made of shaped steel and steel plates, and adopts rust removal and anti-rust processes such as silanization, pure manganese phosphating, washing and drying, and galvanizing. Each component or component is usually connected by welds, bolts or rivets. Because of its light weight and easy construction, it is widely used in large factories, venues, super high-rises and other fields. Steel structures are prone to rust. Generally, steel structures need to be derusted, galvanized or painted, and must be maintained regularly.

High strength and light weight. Compared with concrete and wood, the density and yield strength are lower. Therefore, under the same stress conditions, steel structure members have small cross-sections, light weight, easy transportation and installation, and are suitable for large-span, high-height, heavy-load structures. Steel tools have good toughness and plasticity, uniform materials, high structural reliability, are suitable for withstanding impact and dynamic loads, and have good seismic resistance. The internal structure of the steel is uniform and close to isotropic homogeneous body. The workability of the steel structure fully complies with the calculation theory, so it has high safety and reliability.

High strength and light weight. Compared with concrete and wood, the density and yield strength are lower. Therefore, under the same stress conditions, steel structure members have small cross-sections, light weight, easy transportation and installation, and are suitable for large-span, high-height, heavy-load structures. 2. Steel tools have good toughness and plasticity, uniform materials, high structural reliability, are suitable for withstanding impact and dynamic loads, and have good seismic resistance. The internal structure of the steel is uniform and close to isotropic homogeneous body. The workability of the steel structure fully complies with the calculation theory, so it has high safety and reliability.

DEPOSIT

In the construction of construction projects, the use of Steel structure building case engineering for design not only allows the construction project to have a larger span space, but also has the advantages of convenient installation and low cost, which makes its application in construction projects Getting wider. With the further development of my country's urbanization process, the number of high-rise buildings will increase dramatically, which puts forward higher requirements for the design of steel structure projects.

In recent years, Steel Structure Design have been used more and more widely in construction projects, and have achieved very good application results. However, in the actual application process, there are also problems with insufficient stability of steel structure buildings due to inadequate design of steel structure projects, which seriously affects the safety of users' lives and property. In order to ensure that the construction of building steel structure projects has higher quality, it is necessary to strictly follow the corresponding specifications and standards when designing steel structure projects, and do the corresponding design key work, so as to provide users with more Safe and reliable steel structure buildings.

PRODUCT INSPECTION

1. Detection of component size and flatness. Each dimension is measured at 3 parts of the component, and the average value of the 3 locations is taken as the representative value of the dimension. The dimensional deviation of steel components should be calculated based on the dimensions specified in the design drawings; the allowable value of the deviation should comply with the requirements of its product standards. The deformation of beams and truss members includes vertical deformation in the plane and lateral deformation out of the plane, so the straightness in both directions must be detected. The deformation of the column mainly includes the tilt and deflection of the column body.

When inspecting, visual inspection can be performed first. If any abnormalities or doubts are found, a wire or thin wire can be tightened between the fulcrums of the beams and trusses, and then the sag and deviation of each point can be measured; the inclination of the column can be measured with a theodolite or lead. vertical measurement. Column deflection can be measured by stretching a wire or thin wire between the fulcrum points of the member.

2. Detection of steel corrosion

Steel structures are prone to rust in humid, water-containing and acid-alkali-salt corrosive environments. Rust causes the steel section to weaken and the bearing capacity to decrease. The degree of corrosion of steel can be reflected by changes in its cross-sectional thickness. Instruments used to detect steel thickness (rust must be removed first) include ultrasonic thickness gauges (sound speed setting, coupling agent) and vernier calipers. The ultrasonic thickness gauge adopts the pulse reflection wave method. When an ultrasonic wave propagates from one uniform medium to another, it will be reflected at the interface. The thickness gauge can measure the time from when the probe emits the ultrasonic wave to when it receives the interface reflection echo. The propagation speed of ultrasonic waves in various steel materials is known, or determined through actual measurements. The thickness of the steel is calculated from the wave speed and propagation time. For digital ultrasonic thickness gauges, the thickness value will be directly displayed on the display.

3. Detection of surface defects of components-magnetic particle inspection

The basic principle of magnetic particle inspection: When there are defects inside the steel structure, such as cracks, inclusions, pores and other non-ferromagnetic substances, the magnetic resistance is very large and the magnetic permeability is low, which will inevitably cause the distribution of magnetic lines of force to change. The magnetic field lines at the defect cannot pass through and will bend to a certain extent. When defects are located on or close to the surface of the steel structure, they will leak through the surface of the steel structure into the air to form a fine leakage magnetic field.

The intensity of the leakage magnetic field mainly depends on the intensity of the magnetizing field and the influence of defects on the vertical cross-section of the magnetizing field. Magnetic powder can be used to display or measure the leakage magnetic field, so as to analyze and determine the existence, location and size of defects.

PROJECT

Our steel structure company often exports steel structure products to the Americas and Southeast Asian countries. We participated in one of the projects in the Americas with a total area of approximately 543,000 square meters and a total use of approximately 20,000 tons of steel. After the project is completed, it will become a steel structure complex integrating production, living, office, education and tourism.

APPLICATION

Petrochemical industry: Steel structures are widely used in the petrochemical industry, including various chemical equipment, pipelines, storage tanks, reactors, etc. Steel structures have the advantages of good corrosion resistance, high strength, and high temperature resistance, and can meet the requirements of the petrochemical industry for equipment stability and safety.

Vehicle manufacturing field: Steel structures have been widely used in the vehicle manufacturing field, including cars, trains, subways, light rails and other means of transportation. Steel structures have the advantages of light weight, high strength, easy processing, and good durability, and can meet the requirements of vehicle safety and economy in the field of vehicle manufacturing.

Shipbuilding field: Steel structures have been widely used in the shipbuilding field, including various civilian ships and military ships. Steel structures have the advantages of light weight, high strength, easy processing, and good corrosion resistance, and can meet the requirements for ship safety and stability in the shipbuilding field.

In short, steel structure is a widely used structural form, suitable for projects in various fields, environmentally friendly, energy-saving, and reusable, and is one of the important directions for future construction development. If you want to know more about the applicable industries of steel structures, please follow us and leave a message!

PACKAGING AND SHIPPING

Steel structures are heat-resistant but not fire-resistant. When the temperature is below 150°C, the properties of steel change very little. Therefore, steel structures are suitable for high-temperature workshops, but when the surface of the structure is subject to thermal radiation of about 150°C, it must be protected by heat insulation panels. When the temperature is between 300°C and 400°C, the strength and elastic modulus of steel decrease significantly.

COMPANY STRENGTH

Made in China, first-class service, cutting-edge quality, world-renowned

1. Scale effect: Our company has a large supply chain and a large steel factory, achieving scale effects in transportation and procurement, and becoming a steel company that integrates production and services

2. Product diversity: Product diversity, any steel you want can be purchased from us, mainly engaged in steel structures, steel rails, steel sheet piles, photovoltaic brackets, channel steel, silicon steel coils and other products, which makes it more flexible Choose the desired product type to meet different needs.

3. Stable supply: Having a more stable production line and supply chain can provide more reliable supply. This is especially important for buyers who require large quantities of steel.

4. Brand influence: Have higher brand influence and larger market

5. Service: A large steel company that integrates customization, transportation and production

6. Price competitiveness: reasonable price

*Send the email to chinaroyalsteel@163.com to get a quotation for your projects

CUSTOMERS VISIT