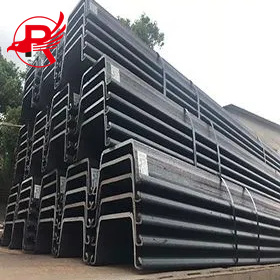

China Factory Steel Sheet Pile/Sheet Piling/Sheet Pile

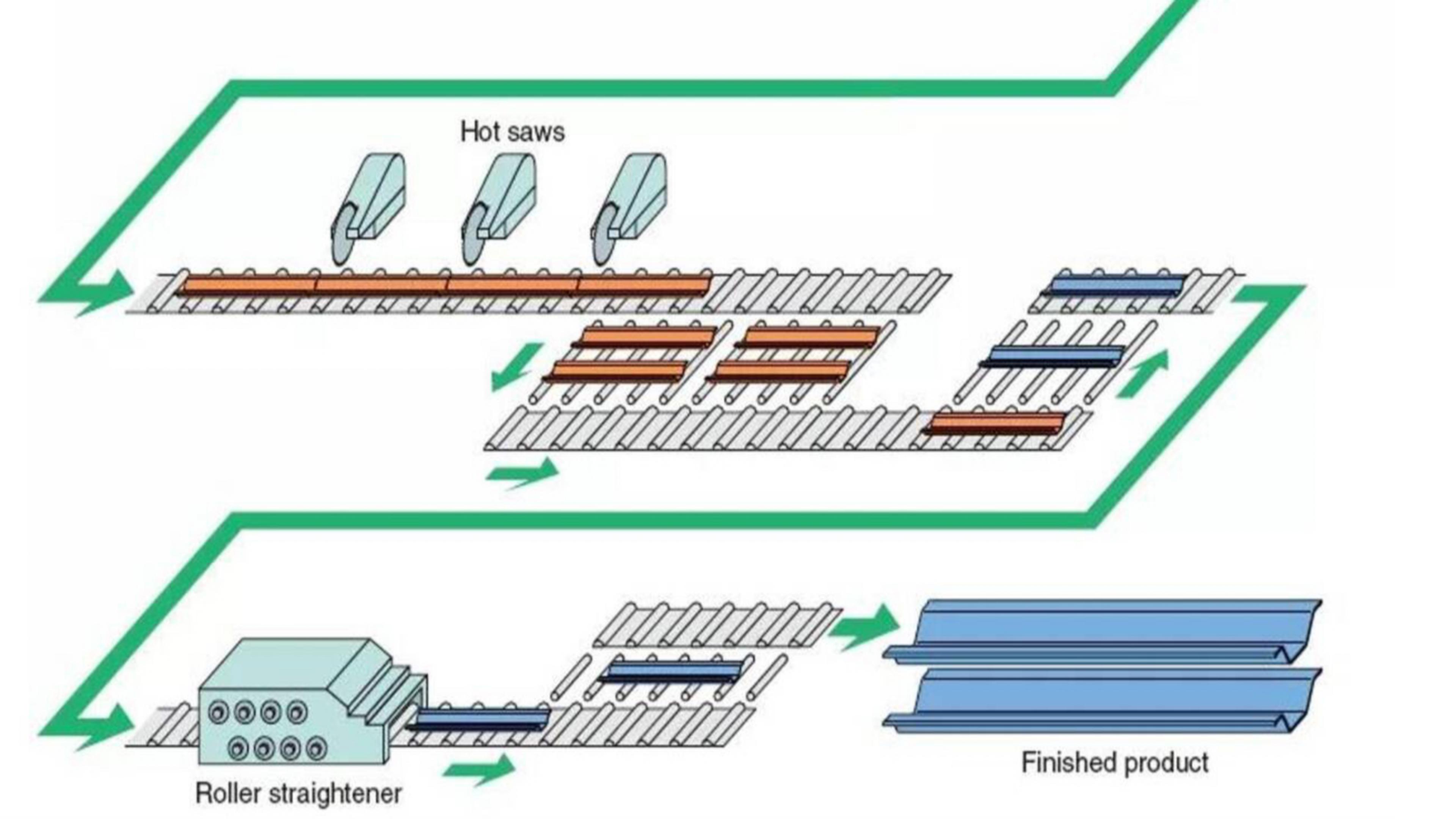

U-shaped steel sheet pile is a supporting structure commonly used in foundation engineering and civil engineering. Its construction process usually includes the following steps:

Early preparation: Determine the construction site, clean up the construction area, ensure the construction site is flat, and conduct necessary geological survey and design plan confirmation.

Positioning and wiring: According to the design requirements and construction drawings, carry out the positioning and wiring of U-shaped steel sheet piles to determine the pile position and pile spacing.

Installation of steel sheet piles: Use equipment such as excavators or pile drivers to install U-shaped steel sheet piles one by one to the depth required by the design to ensure that the verticality and position of the piles are accurate.

Connection and fixation: After installing the U-shaped steel sheet piles, connect and fix the pile parts, usually by bolting or welding, to ensure the overall stability of the pile body.

Pile top treatment: According to the design requirements, necessary treatment, such as cutting, trimming, etc., is carried out on the pile top of the U-shaped steel sheet pile to facilitate subsequent connection and support work.

Auxiliary works: Depending on the specific situation, auxiliary works for U-shaped steel sheet piles are carried out, such as reinforcement support, waterproofing treatment, etc.

Follow-up processes: According to project needs, follow-up processes for U-shaped steel sheet piles are carried out, such as concrete pouring, earthwork backfilling, etc.

During the construction process, it is necessary to strictly follow the design requirements and relevant specifications to ensure the installation quality and project safety of U-shaped steel sheet piles.

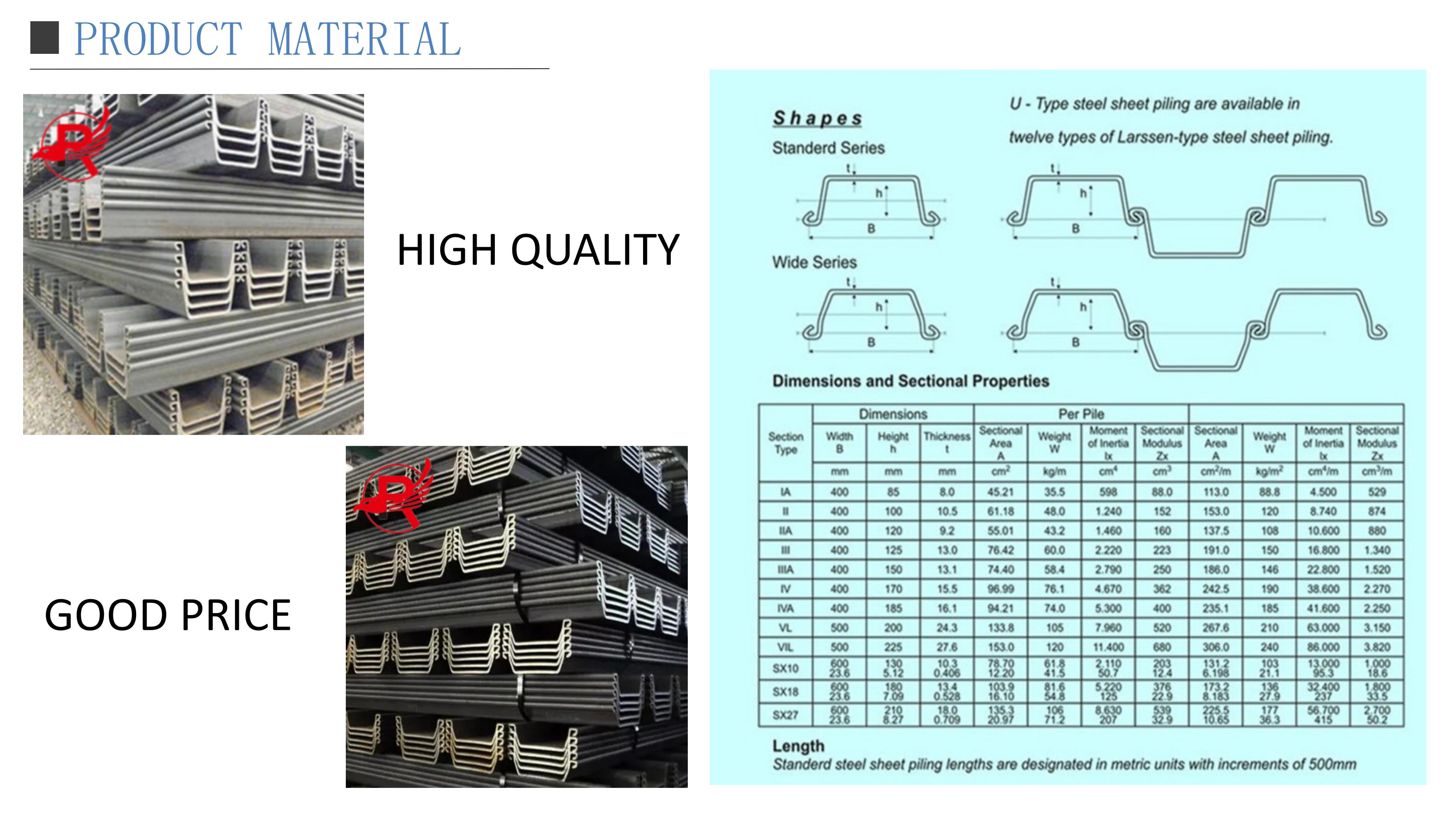

The following is a description of the steel sheet pile material:

|

Product Name

|

|

|

Steel Grade

|

S275,S355,S390,S430,SY295,SY390,ASTM A690

|

|

Production standard

|

EN10248,EN10249,JIS5528,JIS5523,ASTM

|

|

Delivery time

|

One week,80000 tons in stock

|

|

Certificates

|

ISO9001,ISO14001,ISO18001,CE FPC

|

|

Dimensions

|

Any dimensions,any width x height x thickness

|

|

Length

|

Single length up to over 80m

|

1. We can produce all types of sheet piles,pipe piles and accessories,we can adjust our machines to produce in any width x height x thickness .

2. We can produce single length up to over 100m,and we can do all painting,cutting,welding etc fabrications in factory .

3. Fully internationally certified:ISO9001,ISO14001,ISO18001,CE,SGS,BV etc..

*Send the email to chinaroyalsteel@163.com to get a quotation for your projects

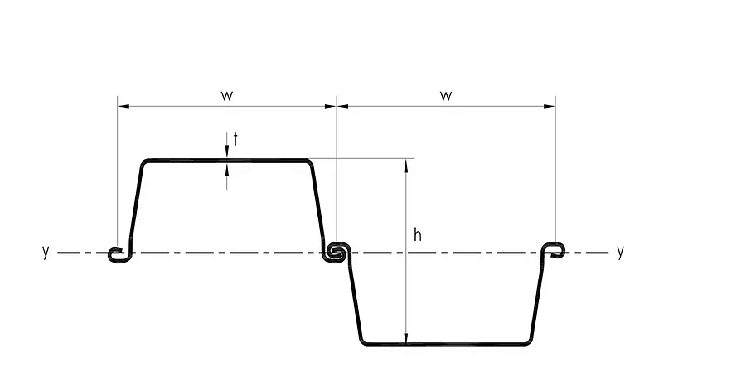

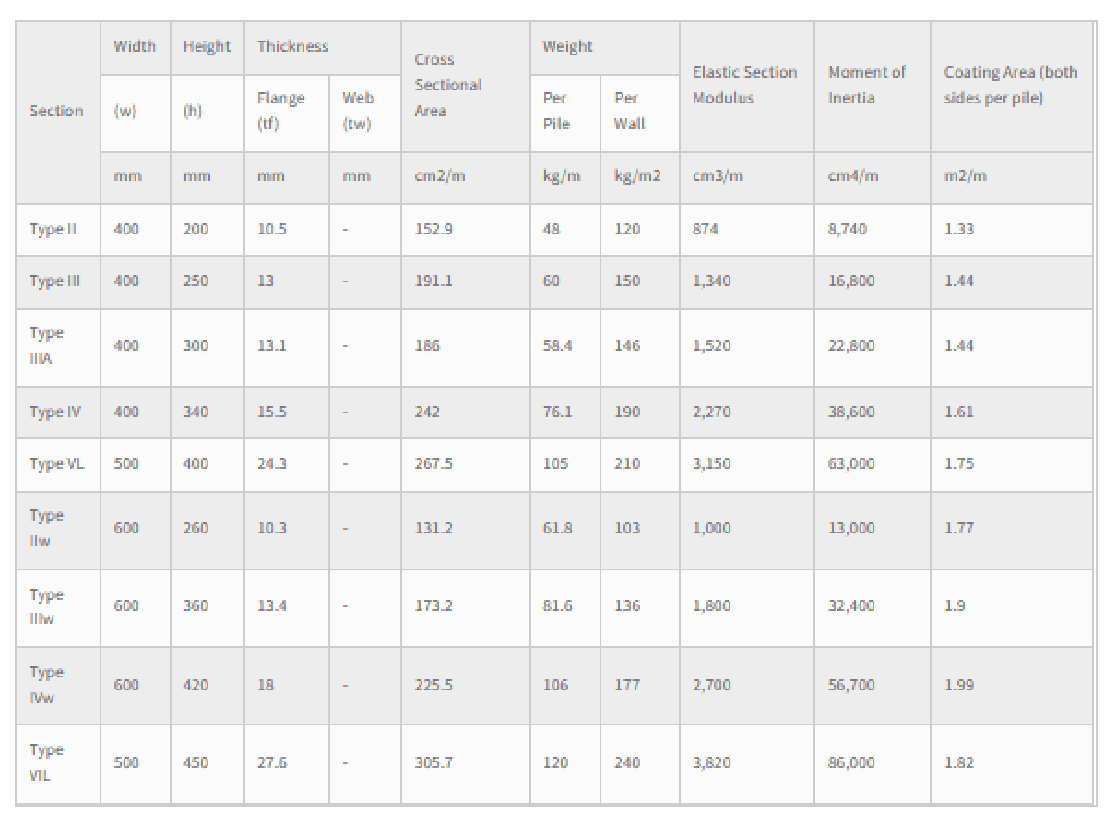

Product Size

Section Modulus Range

1100-5000cm3/m

Width Range (single)

580-800mm

Thickness Range

5-16mm

Production Standards

BS EN 10249 Part 1 & 2

Steel Grades

SY295, SY390 & S355GP for Type II to Type VIL

S240GP, S275GP, S355GP & S390 for VL506A to VL606K

Length

27.0m maximum

Standard Stock Lengths of 6m, 9m, 12m, 15m

Delivery Options

Single or Pairs

Pairs either loose, welded or crimped

Lifting Hole

By container (11.8m or less) or Break Bulk

Corrosion Protection Coatings

Product features

U-shaped steel sheet pile is a commonly used foundation support structure material with the following characteristics:

High strength: U-shaped steel sheet piles are made of high-quality carbon structural steel or low alloy steel. They have high bending strength and compressive strength and can withstand larger loads.

Saving space: The U-shaped steel sheet pile has a compact cross-sectional shape, which can effectively save construction space and is suitable for construction sites with small space.

Flexibility: U-shaped steel sheet piles can be cut and connected as needed to adapt to foundation pits and supporting structures of different shapes and sizes, and have strong flexibility and applicability.

Corrosion resistance: U-shaped steel sheet piles with anti-corrosion treatment have good corrosion resistance and are suitable for construction in humid and corrosive environments.

Convenient construction: The installation and connection of U-shaped steel sheet piles are relatively simple, and construction can be carried out quickly, saving construction time and labor costs.

Environmental protection: U-shaped steel sheet piles can be recycled and reused, reducing the impact on the environment and meeting the requirements of sustainable development.

In general, U-shaped steel sheet piles have the characteristics of high strength, space saving, flexibility, corrosion resistance, convenient construction and environmental protection, and are suitable for support and enclosure structures in various foundation projects and civil engineering.

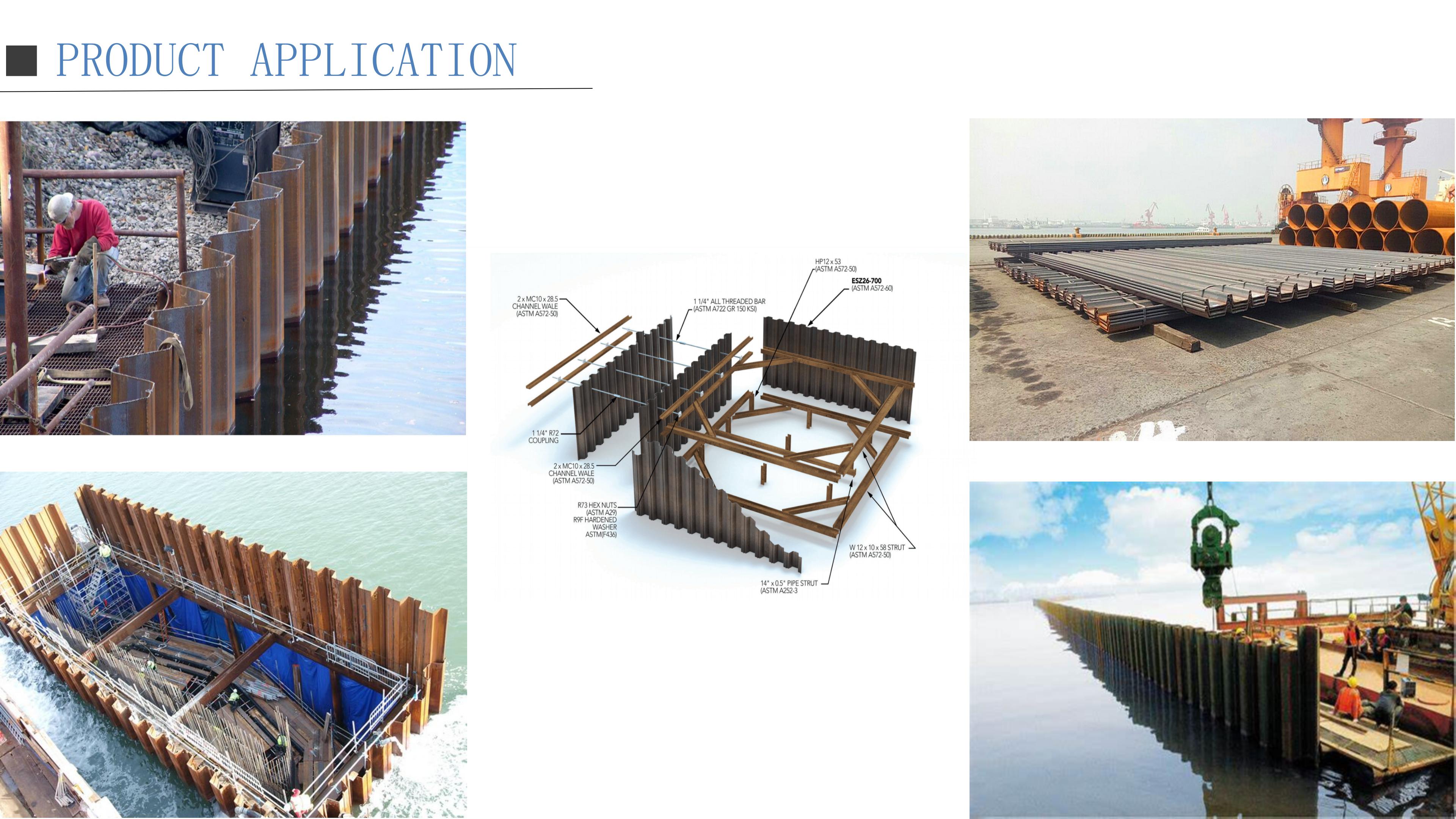

Product Construction Use

U-shaped steel sheet pile is a common foundation support structure material, usually used in the following fields and projects:

River embankment and sea embankment engineering: used for embankment support and breakwater construction in rivers, lakes, oceans and other waters.

Port and dock engineering: used for slope support and cofferdam structures in ports, docks and other water projects.

Foundation engineering: used for foundation pit support and enclosure structures in foundation projects such as buildings, bridges, tunnels, etc.

Water conservancy projects: used for slope support and enclosure structures in water conservancy projects such as reservoirs, channels, and hydropower stations.

Railway and highway engineering: used for slope support and enclosure structures in railway, highway and other transportation projects.

Mining engineering: used for mining, mine support and retaining structures.

Civil Engineering: Used for foundation pit support, slope support and retaining structures in various civil engineering projects.

Generally speaking, U-shaped steel sheet piles are widely used in basic engineering and civil engineering in water conservancy, transportation, construction, mining and other fields.

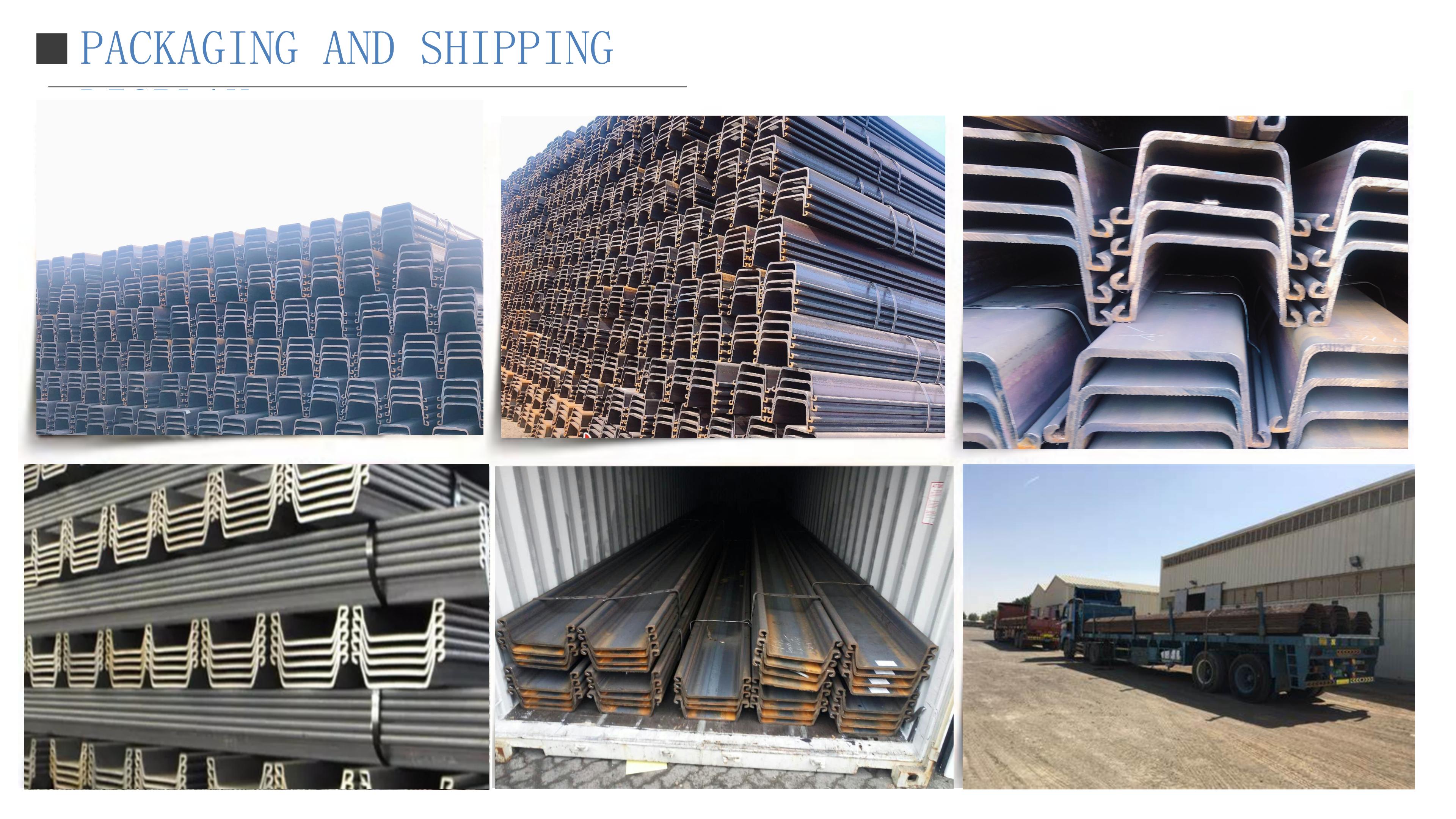

Packaging and Shipping

The packing method of U-shaped steel sheet piles usually depends on the size, weight and transportation method of the product. Generally speaking, U-shaped steel sheet piles can be packed in the following ways:

Pallet packaging: U-shaped steel sheet piles of smaller size and weight can be packed on wooden or metal pallets to facilitate handling and loading by forklifts or cranes.

Winding packaging: For longer U-shaped steel sheet piles, winding packaging can be used. The steel sheet piles are packaged with plastic film or wrapping tape to protect the product surface and facilitate transportation.

Container packing: For large quantities of U-shaped steel sheet piles, container packing can be used for transportation, and the steel sheet piles are neatly stacked in the container to facilitate sea or land transportation.

Naked installation: For some U-shaped steel sheet piles of special size or heavy weight, they can also be transported naked and transported directly by vehicle or ship.

When packing, attention needs to be paid to protecting the surface of the product to avoid scratches and damage, and to ensure the safety and integrity of the product during transportation. At the same time, necessary protection and fixation must be carried out according to the requirements of the transportation method and destination to ensure the safe transportation of the product.

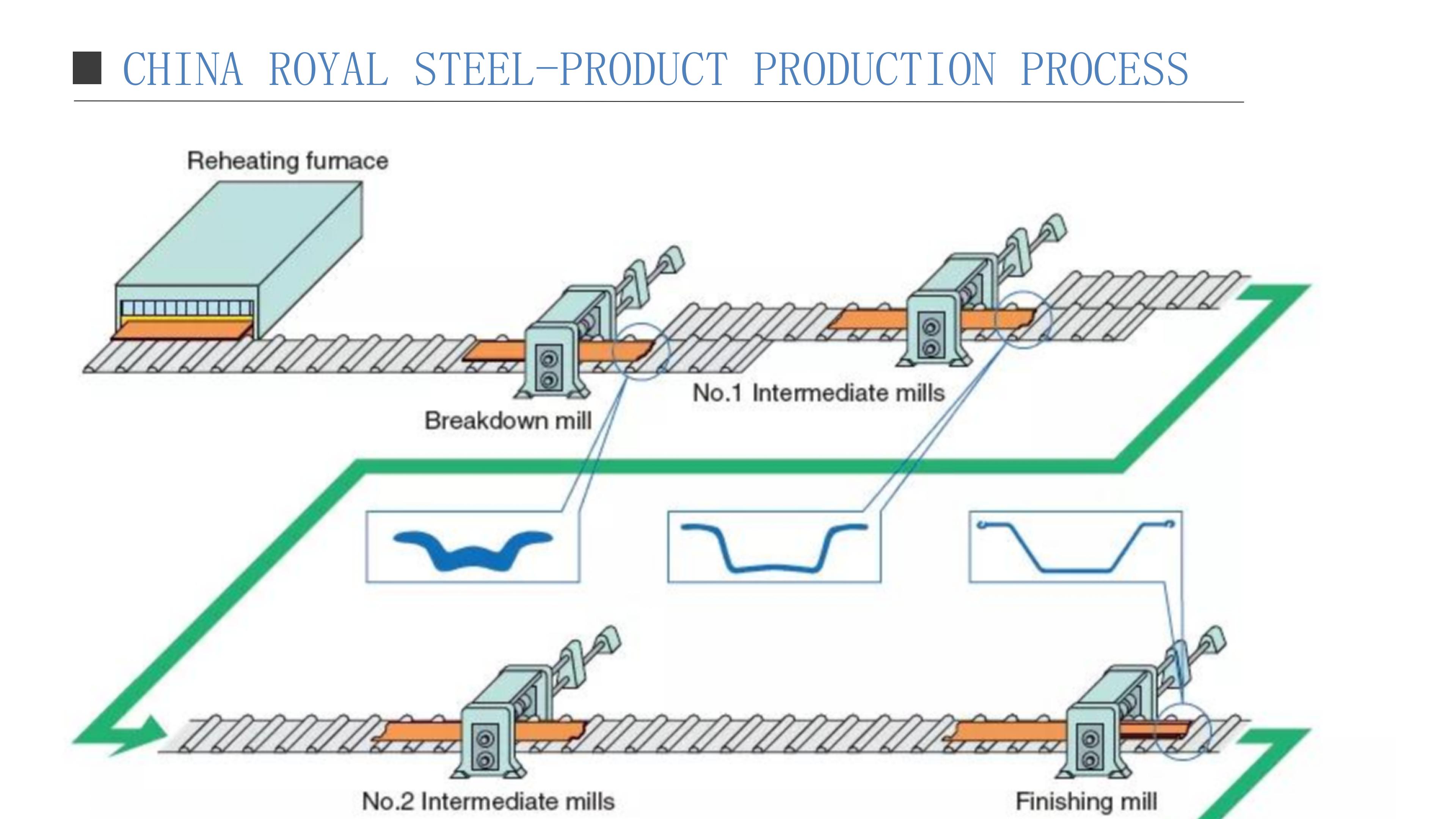

COMPANY STRENGTH

Made in China, first-class service, cutting-edge quality, world-renowned

1. Scale effect: Our company has a large supply chain and a large steel factory, achieving scale effects in transportation and procurement, and becoming a steel company that integrates production and services

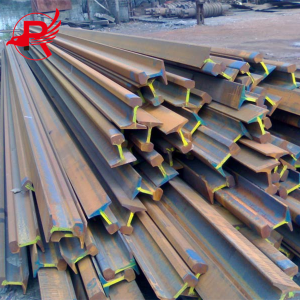

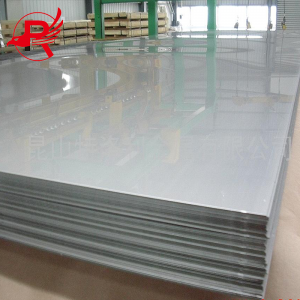

2. Product diversity: Product diversity, any steel you want can be purchased from us, mainly engaged in steel structures, steel rails, steel sheet piles, photovoltaic brackets, channel steel, silicon steel coils and other products, which makes it more flexible Choose the desired product type to meet different needs.

3. Stable supply: Having a more stable production line and supply chain can provide more reliable supply. This is especially important for buyers who require large quantities of steel.

4. Brand influence: Have higher brand influence and larger market

5. Service: A large steel company that integrates customization, transportation and production

6. Price competitiveness: reasonable price

*Send the email to chinaroyalsteel@163.com to get a quotation for your projects

CUSTOMERS VISIT

FAQ

1. How can I get a quotation from you ?

You can leave us message, and we will reply every message in time . Or we may talk on line by WhatsApp . And you can also find our contact information on contact page .

2. Can I get samples before order ?

Yes, of course. Usually our samples are free . we can produce by your samples or technical drawings . We can build the molds and fixtures .

3. What is your delivery time ?

A. The time of delivery is usually around 1 month(1*40FT as usual) ;

B. We can send out in 2 days , if it has stock .

4. What is your payment terms ?

Our usual payment term is 30% deposite, and rest against B/L. L/C is also acceptatble .

5. How can you garantee what I got will be good ?

We are factory with 100% pre-delivery inspection which garantee the quality .

And as golden supplier on Alibaba , Alibaba assurance will make garanteewhich means alibaba will pay your money back in advance , if there is any problem with the products .

6. How do you make our business long-term and good relationship ?

A. We keep good quality and competitive price to ensure our customers benefit ;

B. We respect every customer as our friend and we sincerely do business and make friends with them no matter where they come from