China factory high quality industrial standard railway track steel rail

Galvanised Rails is a major component of railway tracks. 1. South African track steel implements the standard ISCOR, 2. South African track steel material is 700 and 900A. 3. The specifications of South African track steel are 15KG, 22KG, 30KG, 40KG, 48KG, 57KG.

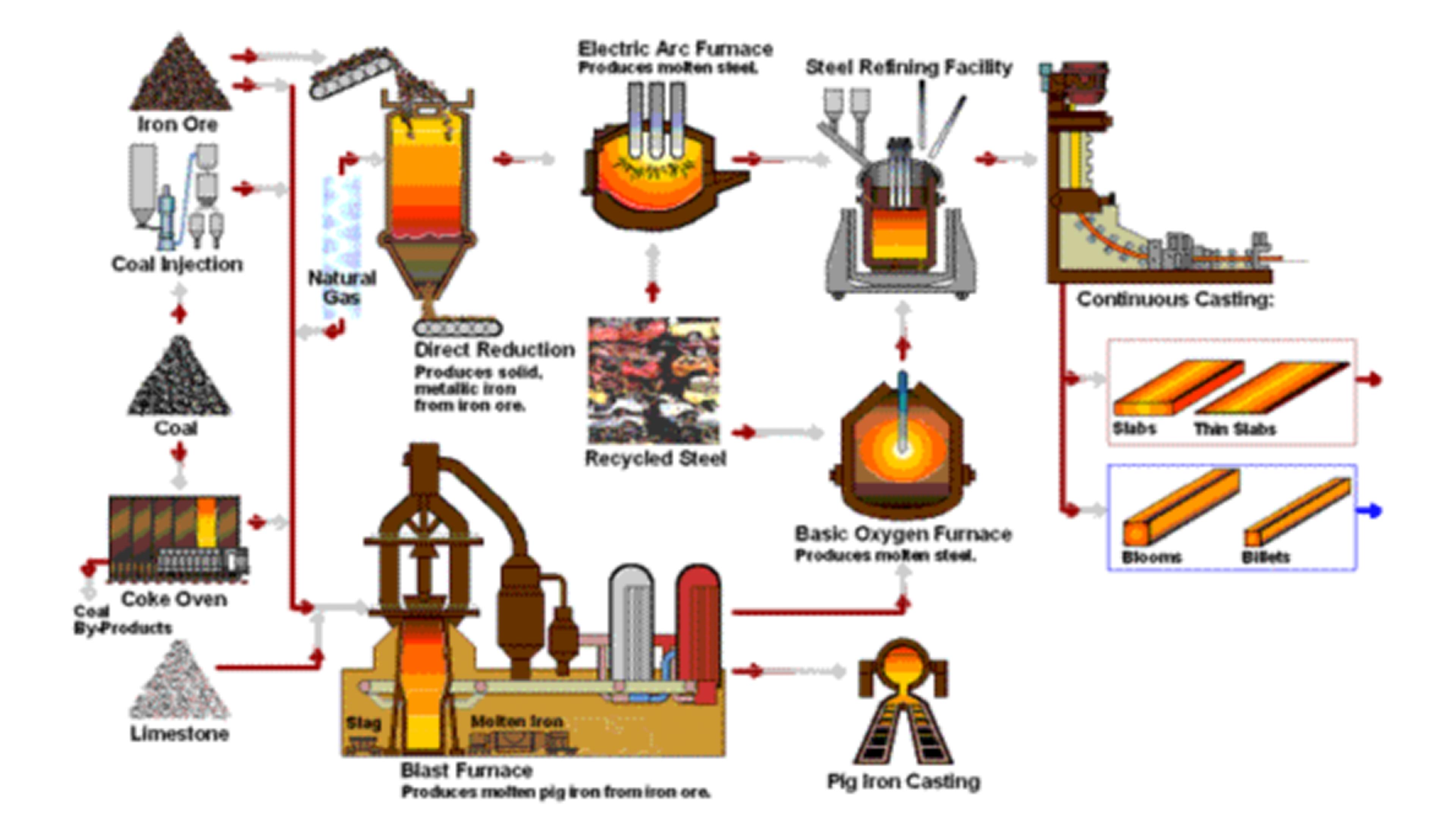

PRODUCT PRODUCTION PROCESS

The production process of ISCOR steel rail usually includes the following steps:

Raw material preparation: Prepare raw materials for steel, usually high-quality carbon structural steel or low alloy steel.

Smelting and casting: The raw materials are smelted, and then the molten steel is cast into preliminary steel billets through continuous casting or pouring.

Refining and rolling: Refining the preliminary steel billet, including removing impurities and adjusting the composition, and then rolling the steel billet through rolling equipment into track billets that meet national standards.

Pretreatment: Pretreatment of track billets, including forging, heat treatment and surface treatment, etc., to improve the strength and durability of the rails.

Rolling and forming: The pre-treated track billet is rolled and formed through a rolling machine to make it into a rail profile that meets the national standard requirements.

Inspection and quality control: Strict inspection and quality control are carried out on the produced rails to ensure that they meet national standards and customer requirements.

Packaging and leaving the factory: Qualified rails are packaged and marked, and then delivered to the customer or stored in the warehouse waiting for shipment.

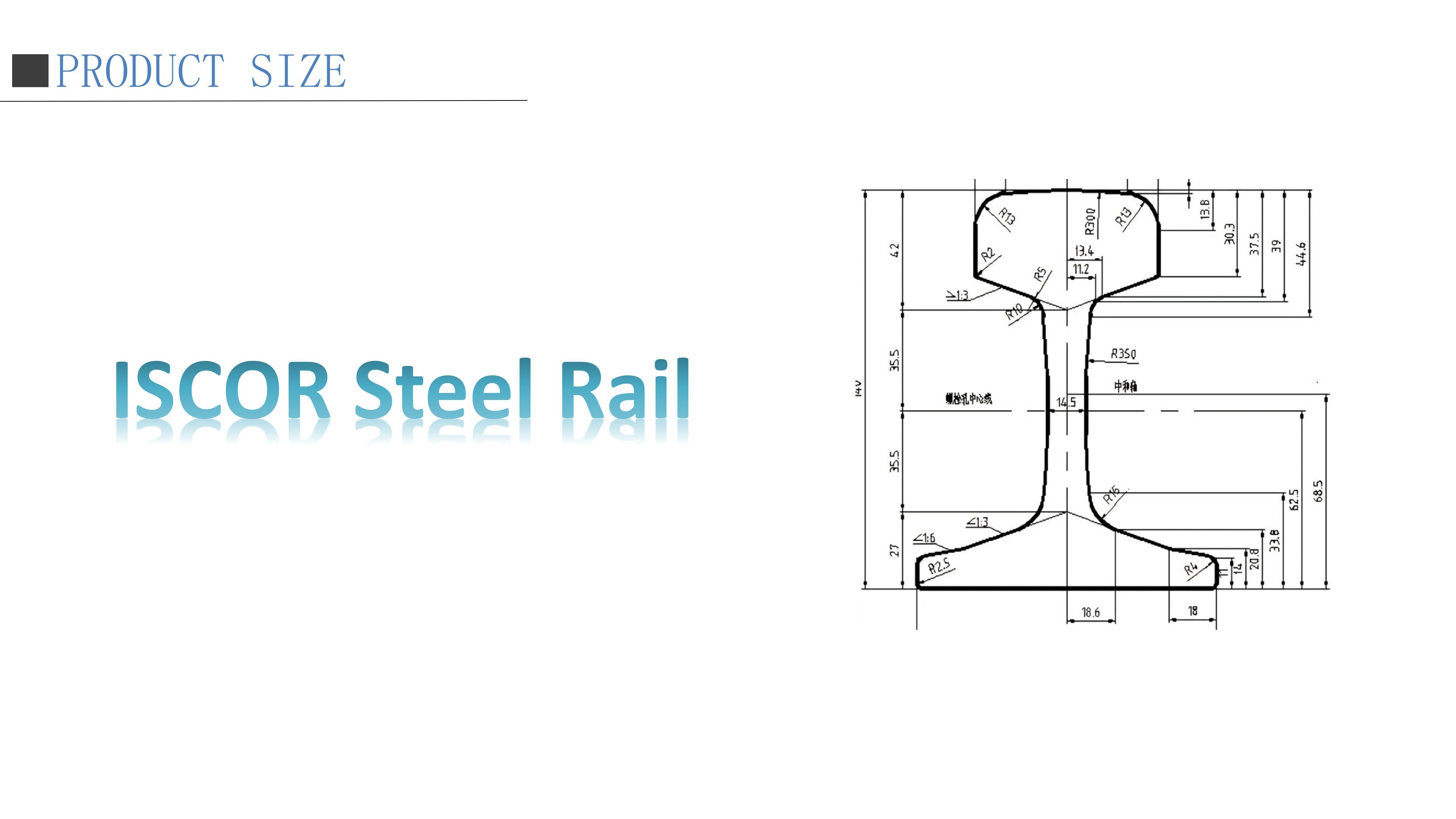

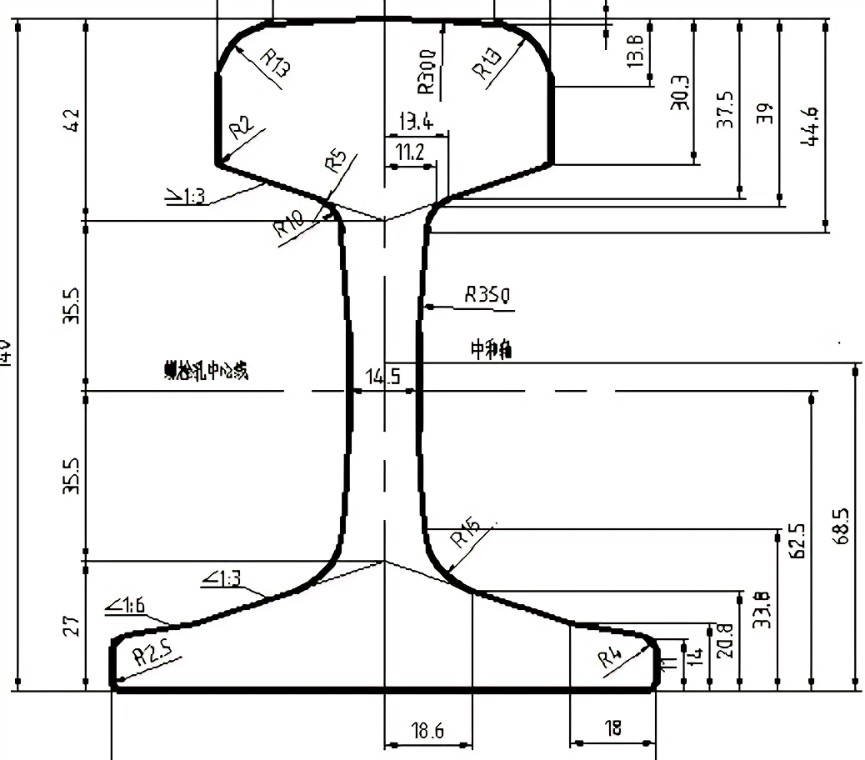

PRODUCT SIZE

| The ISCOR standard steel rail | |||||||

|

model |

size (mm) | substance |

material quality |

length | |||

| head breadth | altitude | baseboard | waist depth | (kg/m) | (m) | ||

| A(mm | B(mm) | C(mm) | D(mm) | ||||

| 15KG | 41.28 | 76.2 | 76.2 | 7.54 | 14.905 | 700 | 9 |

| 22KG | 50.01 | 95.25 | 95.25 | 9.92 | 22.542 | 700 | 9 |

| 30KG | 57.15 | 109.54 | 109.54 | 11.5 | 30.25 | 900A | 9 |

| 40KG | 63.5 | 127 | 127 | 14 | 40.31 | 900A | 9-25 |

| 48KG | 68 | 150 | 127 | 14 | 47.6 | 900A | 9-25 |

| 57KG | 71.2 | 165 | 140 | 16 | 57.4 | 900A | 9-25 |

The origins of china steel rail are Angang and Panzhihua Iron and Steel. 5. The length of South Africa track steel is about 12 meters. 6. The main functions of South Africa track steel It guides the wheels of rolling stock forward, withstands the huge pressure of the wheels, and transmits it to the sleepers.

ISCOR steel rail:

Specifications: 15kg, 22kg, 30kg, 40kg, 48kg, 57kg

Standard: ISCOR

Length: 9-25m

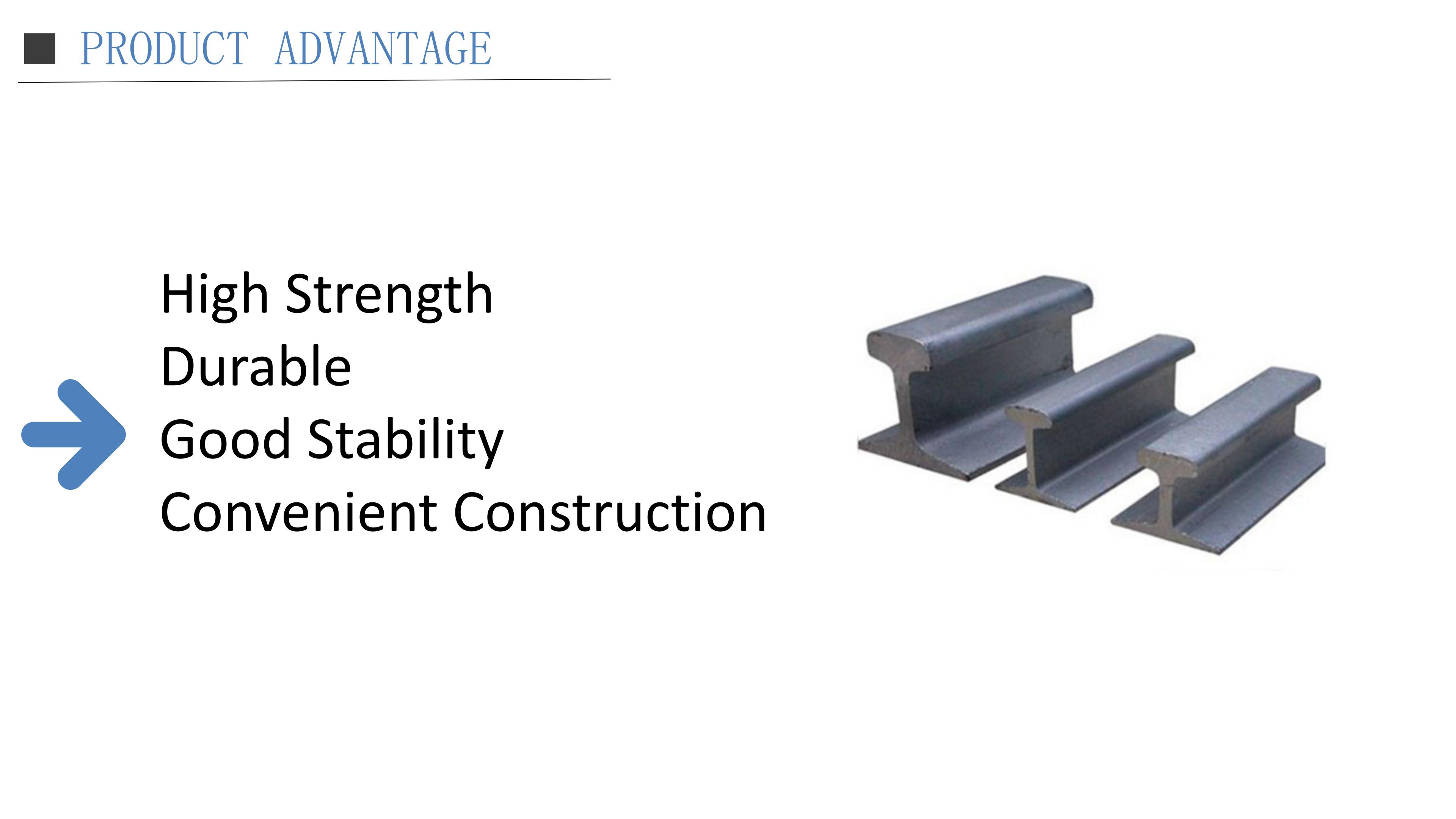

ADVANTAGE

1. Characteristics of rails

1. High strength: After optimized design and special material formula, the rails have high bending strength and compressive strength, and can withstand the heavy load and impact of the train, ensuring the safety and stability of railway transportation.

2. Wear resistance: The rail surface has high hardness and small friction coefficient, which can resist the wear of train wheels and rails and extend the service life.

3. Good stability: The rails have precise geometric dimensions and stable horizontal and vertical dimensions, which can ensure the smooth operation of the train and reduce noise and vibration.

4. Convenient construction: The rails can be connected to any length through joints, making it easier to install and replace the rails.

5. Low maintenance costs: Rails are relatively stable and reliable during transportation, and have low maintenance costs.

PROJECT

Our company’s Railroad Track for sale 13,800 tons of steel rails exported to the United States were shipped at Tianjin Port at one time. The construction project was completed with the last rail being steadily laid on the railway line. These rails are all from the universal production line of our rail and steel beam factory, using global Produced to the highest and most rigorous technical standards.

For more information about rail products, please contact us!

WeChat: +86 13652091506

Tel: +86 13652091506

Email: chinaroyalsteel@163.com

APPLICATION

steel rail are an indispensable infrastructure in the railway transportation system. They provide safe and stable driving routes for trains and are an important part of the railway transportation field.The surface of the wholesale rail products should be clean and smooth, without defects such as cracks, scars, scratches, etc. The end surface should be free of shrinkage marks and interlayers. The allowable defects on the overall surface of light and heavy rails and the extent of their geometric quantities shall not exceed the provisions of the standard.

PACKAGING AND SHIPPING

railway steel are often very long and heavy, so they require special care and professional handling during packaging and shipping. Generally speaking, the packaging of rails may include the following steps and measures:

Bundling: Rails are typically bundled with steel straps or wire rope to ensure they do not move or get damaged during transportation. This helps maintain the shape and integrity of the rails.

Timber braces: Timber braces are often added to the ends of the rails to prevent bundling from damaging the track and to provide additional support and protection.

Identification: The specifications, model, production date and other information of the rail are usually marked on the package to facilitate identification and management.

Transportation: Steel rails usually need to be transported long or short distances by specialized transportation vehicles, such as railway freight trains or professional transportation vehicles.

COMPANY STRENGTH

Made in China, first-class service, cutting-edge quality, world-renowned

1. Scale effect: Our company has a large supply chain and a large steel factory, achieving scale effects in transportation and procurement, and becoming a steel company that integrates production and services

2. Product diversity: Product diversity, any steel you want can be purchased from us, mainly engaged in steel structures, steel rails, steel sheet piles, photovoltaic brackets, channel steel, silicon steel coils and other products, which makes it more flexible Choose the desired product type to meet different needs.

3. Stable supply: Having a more stable production line and supply chain can provide more reliable supply. This is especially important for buyers who require large quantities of steel.

4. Brand influence: Have higher brand influence and larger market

5. Service: A large steel company that integrates customization, transportation and production

6. Price competitiveness: reasonable price

*Send the email to chinaroyalsteel@163.com to get a quotation for your projects

CUSTOMERS VISIT

FAQ

1.How can I get a quotation from you ?

You can leave us message, and we will reply every message in time.

2.Will you delivery the goods on time?

Yes,we promise to provide best quality products and delivery on time. Honesty is our company's tenet.

3.Can I get samples before order ?

Yes, of course. Usually our samples are free,we can produce by your samples or technical drawings.

4.What is your payment terms?

Our usual payment term is 30% deposit, and rest against B/L. EXW, FOB,CFR, CIF.

5.Do you accept the third party inspection?

Yes absolutely we accept.

6.How do we trust your company?

We specialise in steel business for years as golden supplier, headquarter locates in Tianjin province, welcome to investigate in any ways, by all means.